10 Doc.-no.: DS200_01_EN Issue: 05/2017

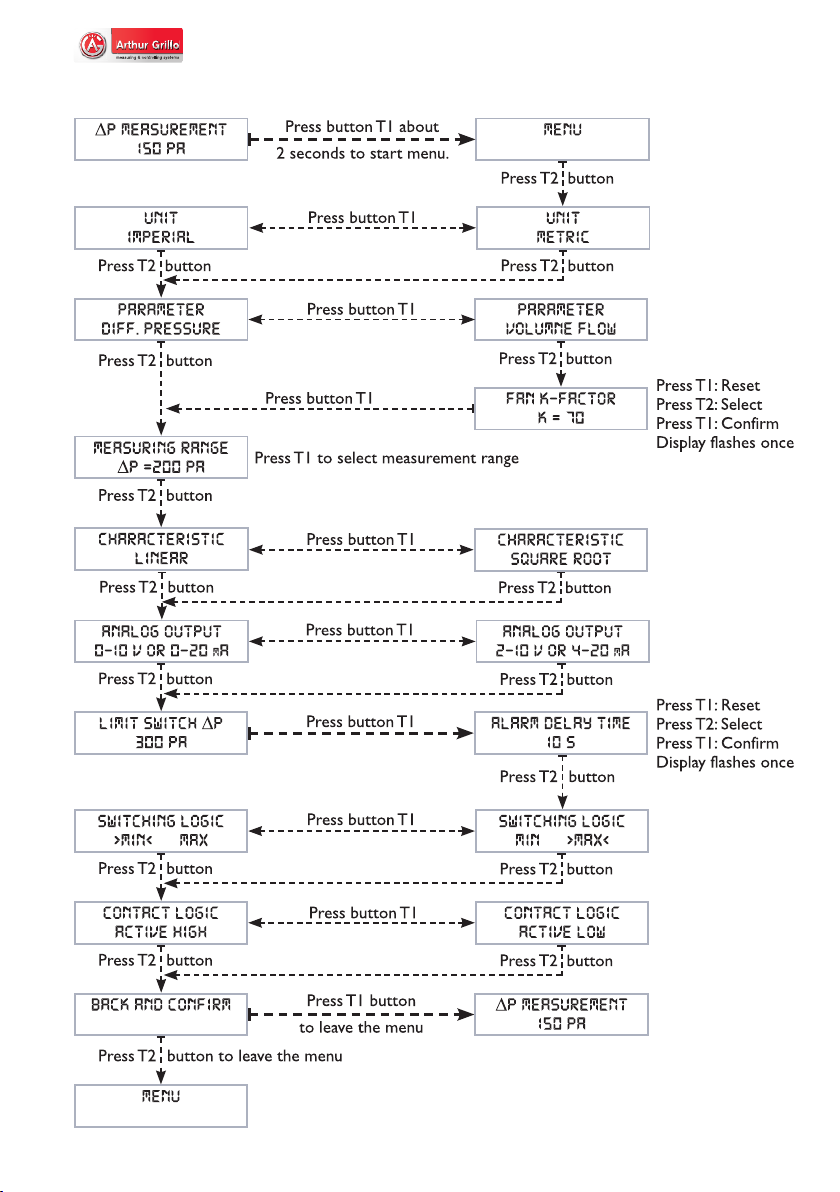

OPERATION

Parameters Selection or parameter range Default

Unit metric or imperial metric

Parameter Differential pressure ΔP [Pa or InH2O]

Volume flow V [m3/h or cfm]

differential

pressure

ΔP [Pa]

K-factor: K = 70

Measurment

range: MB1

Characteristic: linear or square rooted linear

Analogue

output: 0...10 V / 0...20 mA or 2...10 V / 4...20 mA 0...10 V /

0...20 mA

Limit value:

• Differential pressure from 0% up to 100% of

measuring range.

• Volume flow from 5% up to 100% of measuring

range, k-factor is considered.

OFF

alarm delay

time

Switching delay time adjustment range:

1...60 seconds or 2....15 minutes 10 s

Switching

logic Switching logic MIN or MAX MAX

Contact logic Contact logic active high or active low active high

MBI MB2 MB3 MB4

DS200-2 - 200 Pa 150 Pa 100 Pa 50 Pa

DS200-10 - 1.000 Pa 500 Pa 300 Pa 200 Pa

DS200-60 - 6.000 Pa 4.000 Pa 3.000 Pa 2.000 Pa

Volume flow calculation according to: V = k · √Δp

with:

• V = Volume flow in m3/h or cfm

• k = flow factor, adjustment range: 1...10,000

• Δp = differential pressure in Pa or InH20

Calculation up to: 999,999 m3/h (587.999 cfm)

Maximum volume flow (Vmax):

Measuring range: 200 Pa, k=10.000

Vmax = 141.421 m3/h; (83.155 cfm)

Measuring range: 1000 Pa, k=10.000

Vmax = 316.228 m3/h; (185.942 cfm)

Measuring range: 6000 Pa, k=10.000

Vmax = 774.597 m3/h; (37.188 cfm)

5.2 Adjustable parameters - Software