3 of 7

KIT INSTALLATION

1. Park the vehicle on a flat, level surface.

2. Once a mounting configuration has been decided

upon, make a temporary mark of some kind on the

ROPS tubing for locating where to fasten the

ROPS brackets. It is recommended that you take

measurements off of a common feature on the

ROPS so that the brackets will be in line with each

other.

3. Cut the supplied 4-inch long piece of adhesive

backed foam rubber in half. Per figures 3 and 4,

adhere one of the 2-inch long pieces of foam

rubber to the face of the ROPS bracket that will be

against the vehicle ROPS. Select either the inside

or outside surface. Position the foam rubber

between the 4 guide notches provided in the

bracket. Repeat for second bracket.

In order to accommodate various sized ROPS profiles,

two different lengths of U-bolt have been provided.

Please select the most appropriate size for your ROPS

and discard the other two.

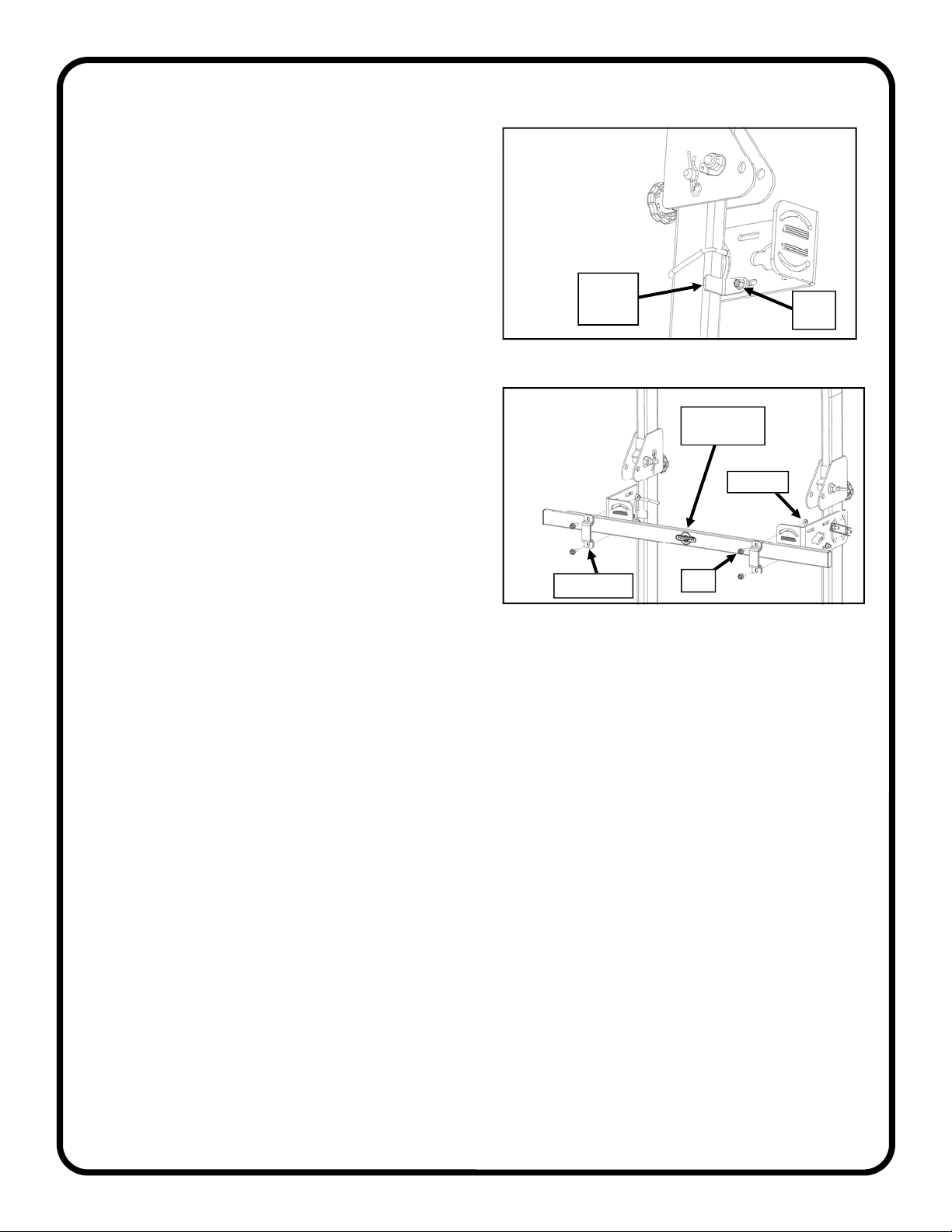

4. See figures 4a, 4b, and 4c. Attach the ROPS

bracket to the ROPS with the bent flange facing

rearward of the vehicle, using one U-bolt, one U-

bolt clamp, and 2 locknuts. The U-bolt clamp

should sit flat on the outside face of the ROPS

bracket. The U-bolt should be rotated in the curved

slots in the ROPS bracket so that the legs of the U-

bolt contact each side of the ROPS tube. Leave

locknuts loose, but snug. Repeat for the second

ROPS bracket.

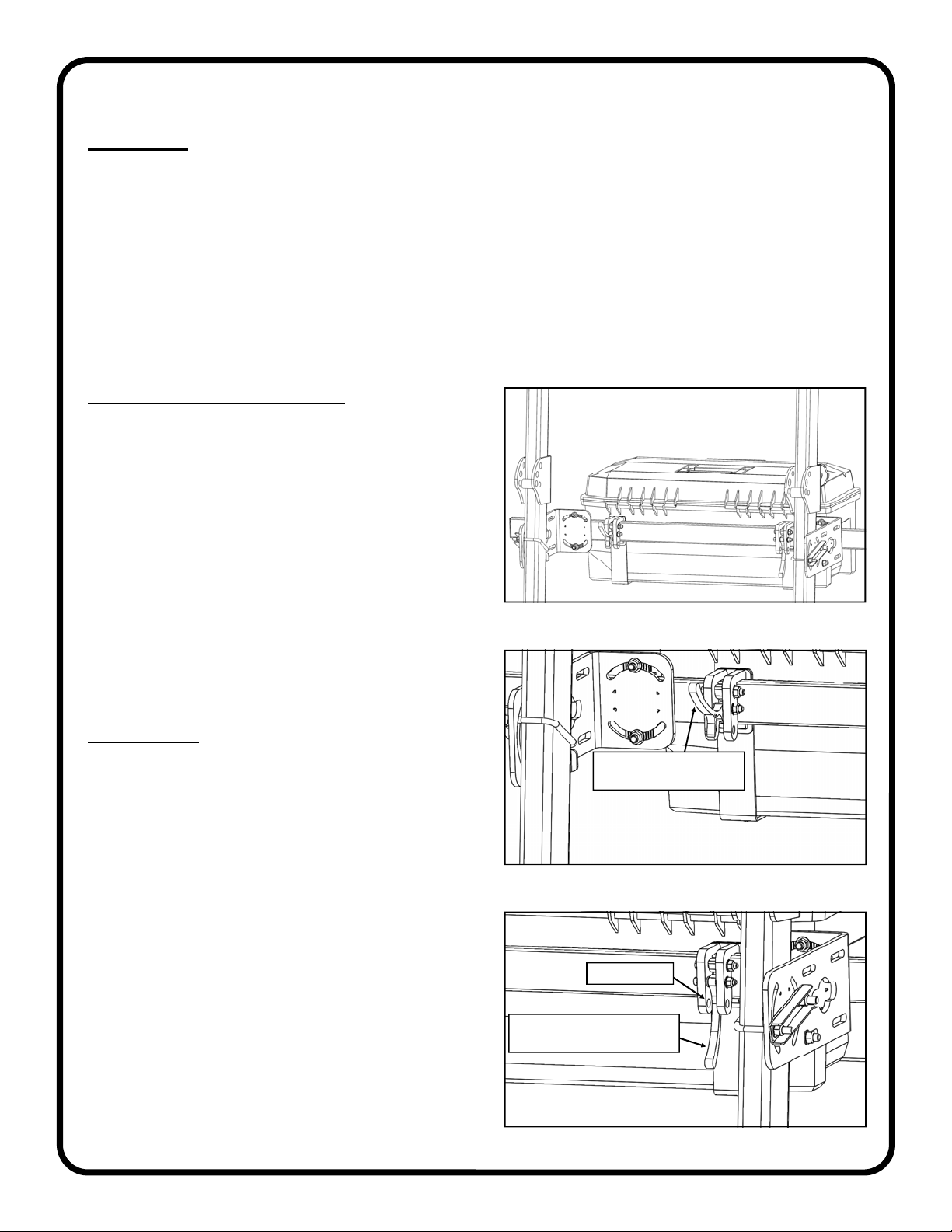

5. Using a level and/or a tape measure, confirm that

the straightness is good and the desired height was

achieved for both brackets. The mounting bar/tube

from this kit may be used along with a level to

make sure the two brackets are even. Tighten all 4

locknuts in an alternating pattern. NOTE: It is

recommended to use a C-clamp to clamp the

ROPS bracket to the ROPS tube prior to tightening

the fasteners. This helps to prevent bracket rotation

while tightening.

TIP: If it is anticipated that very heavy accessories

(exceeding 50 lbs.) will be used on this mounting

bar, then it is suggested to orient the mounting

brackets with a slight upward pitch to

accommodate any sagging or settling that may

occur due to the weight.

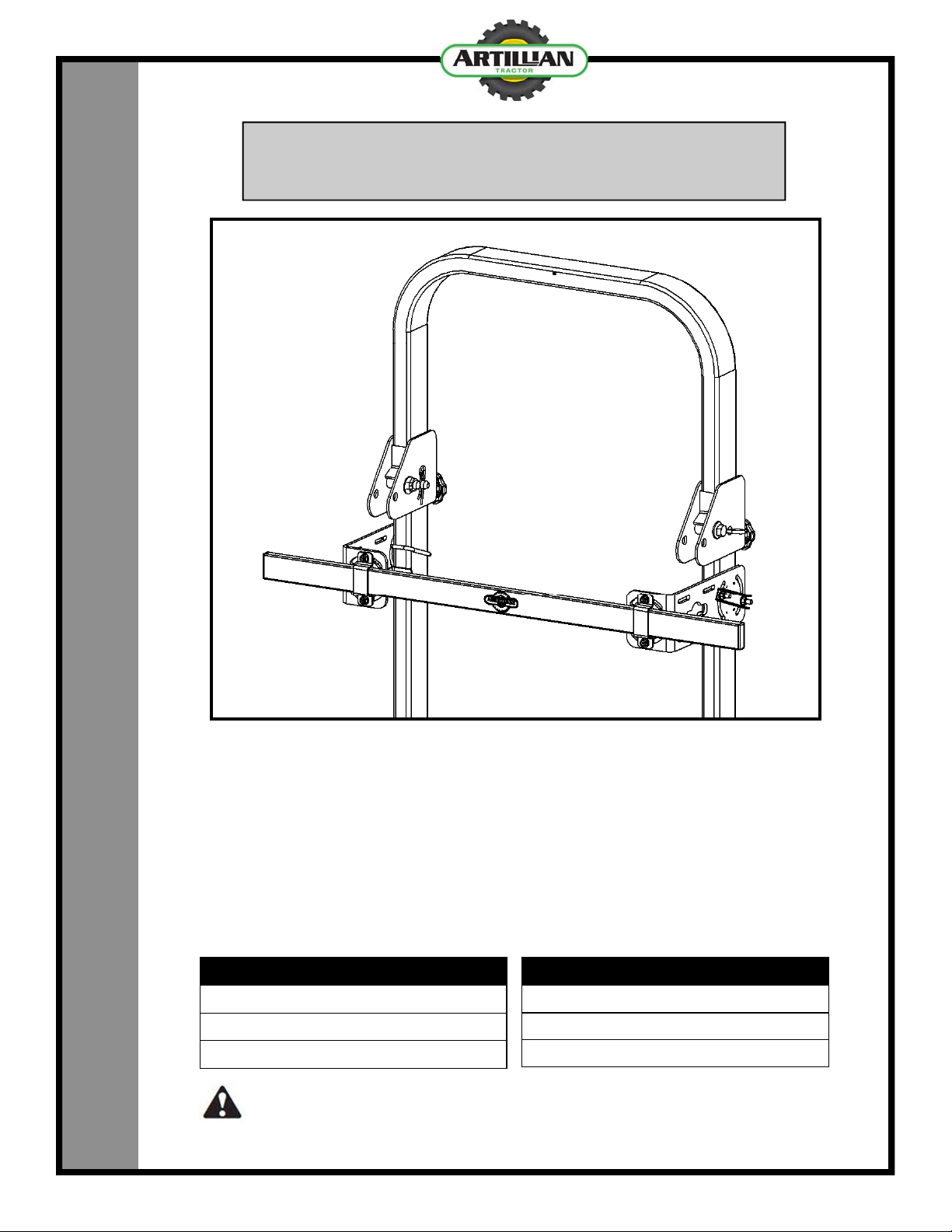

Fig. 3 (Adhere foam rubber to one surface)

Fig. 4c (U-bolt clamp fully assembled)

Fig. 4a (Example of bracket assembly)

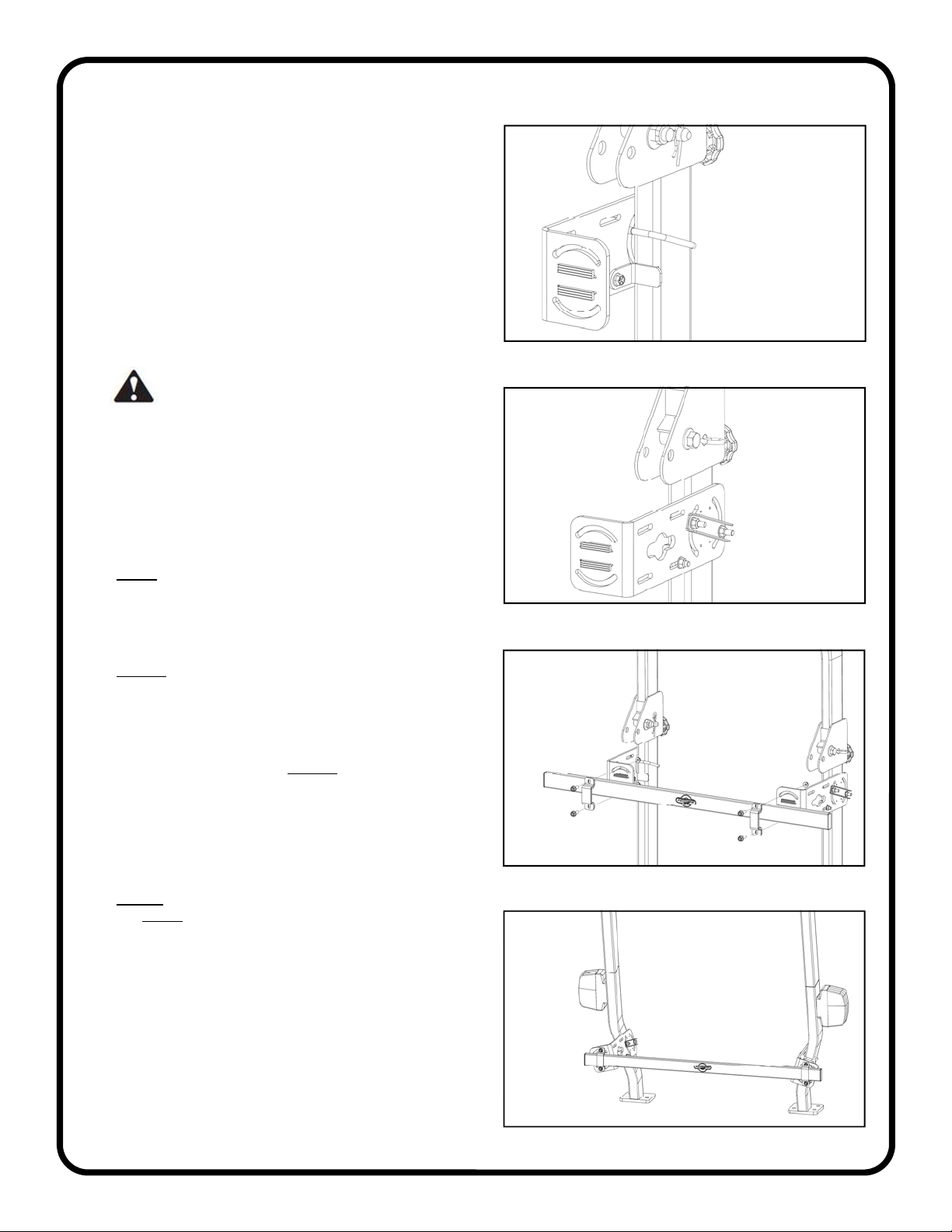

Fig. 4b (Orientation of U-bolt clamp)

In this example, the foam

will be on the inside

surface of the bracket

Flat surfaces

against each other

U-bolt clamp

Inside

surface

Outside

surface

U-bolt

clamp

Guide

notches