Skid Pro LXG210S-SKD Manual

SETUP INSTRUCTIONS

Rev Dec-2023 Part number: Z97920-SI

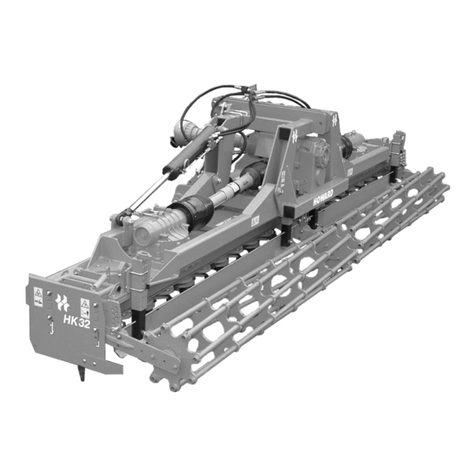

LXG210S-SKD

LXG210SB-SKD

2

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

Safety

WARNING!

Do not assemble the machine before you read

the assembly instructions in this manual. Make

sure that you understand the safety information

and each step of the procedure before you

assemble the machine.

Keep this manual with you and available

for frequent reference as you assemble the

machine.

WARNING!

Use a hoist when to lift machine components

that weigh 50 lb (23 kg) or more. Do not lift

machine components that weigh more than you

can lift without strain or injury.

WARNING!

Use lift equipment with a lift capacity that

is more than the weight of the machine

component. Put jack stands or wood blocks

under the machine to make it safe while you

assemble the machine.

WARNING!

Use the correct tools and equipment to

assemble the machine. The use of incorrect

tools can create safety hazards. A tool that

breaks or slips during assembly risks personal

injury. Repair or replace equipment or tools that

are broken or defective.

WARNING!

All lifting equipment (for example, straps,

slings, chains, or ratchet blocks) must comply

with the applicable local laws, standards, and

regulations. Skid Pro Attachments does not

accept responsibility for the use of unsafe

equipment and work practices.

WARNING!

Know the location of and keep away from

overhead power lines and obstructions when

you lift the machine. Contact with power lines

can cause electrocution. Contact with overhead

obstructions can damage the machine or

components.

WARNING!

Do not start or operate the machine before you

read the Operator's Manual. Make sure that

you fully understand all safety, operation, and

maintenance information before you operate

the machine.

Keep the Operator's Manual with the machine at

all times and available for frequent reference.

WARNING!

Make sure that all the fasteners are installed

and torqued to the correct specications. For

more information, see Specications on page

9.

CAUTION!

Keep the assembly area clean and free of debris

to prevent slips, trips, or falls.

IMPORTANT! Inspect the machine for damage from

shipping. Contact the shipping company immediately if you

find any damage to the machine.

Some components are attached to the skid with

screws. Make sure that you only discard the

shipping brackets.

Put the crate in a large, open area so that you can

access the machine components from all sides

during assembly.

Learn what the safety labels mean and know the safety

hazards.

3

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

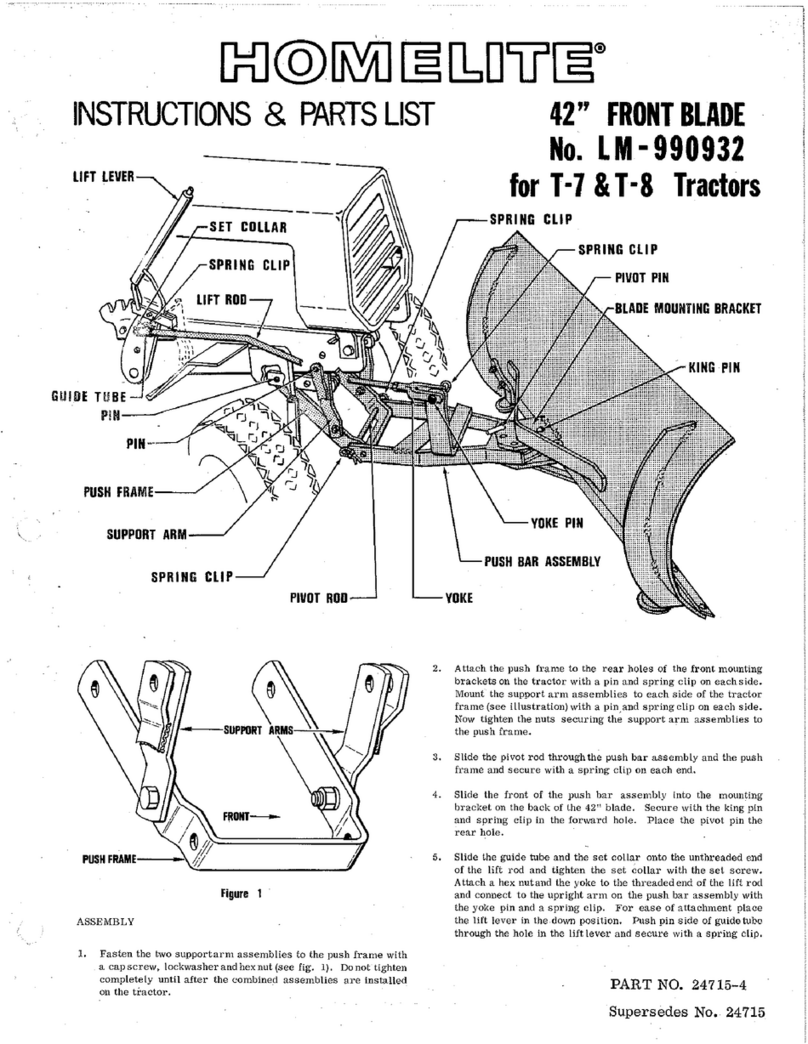

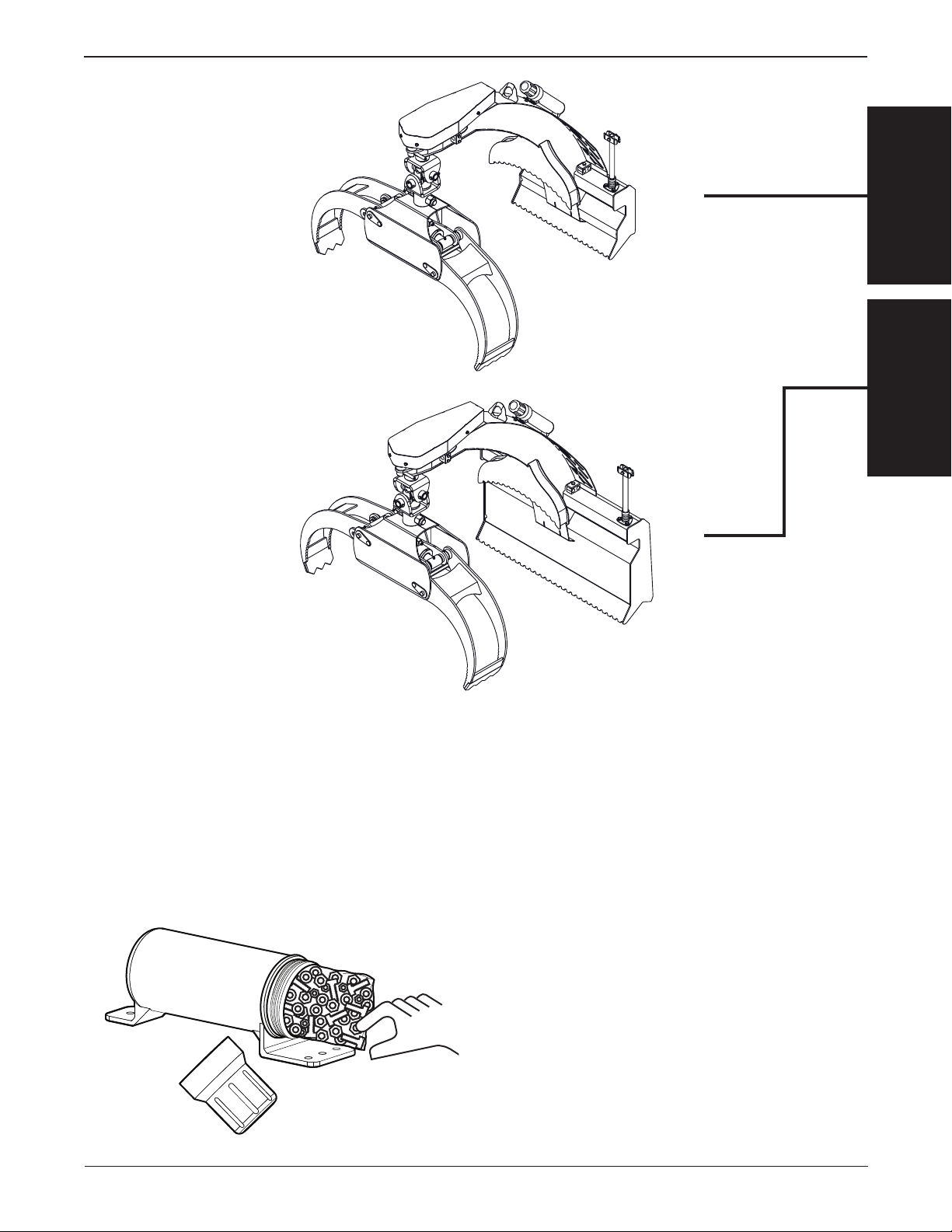

LXG210S-SKDLXG210SB-SKD

LXG210S-SKD

LXG210SB-SKD

The assembly hardware is inside the Operator's Manual

storage tube.

4

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

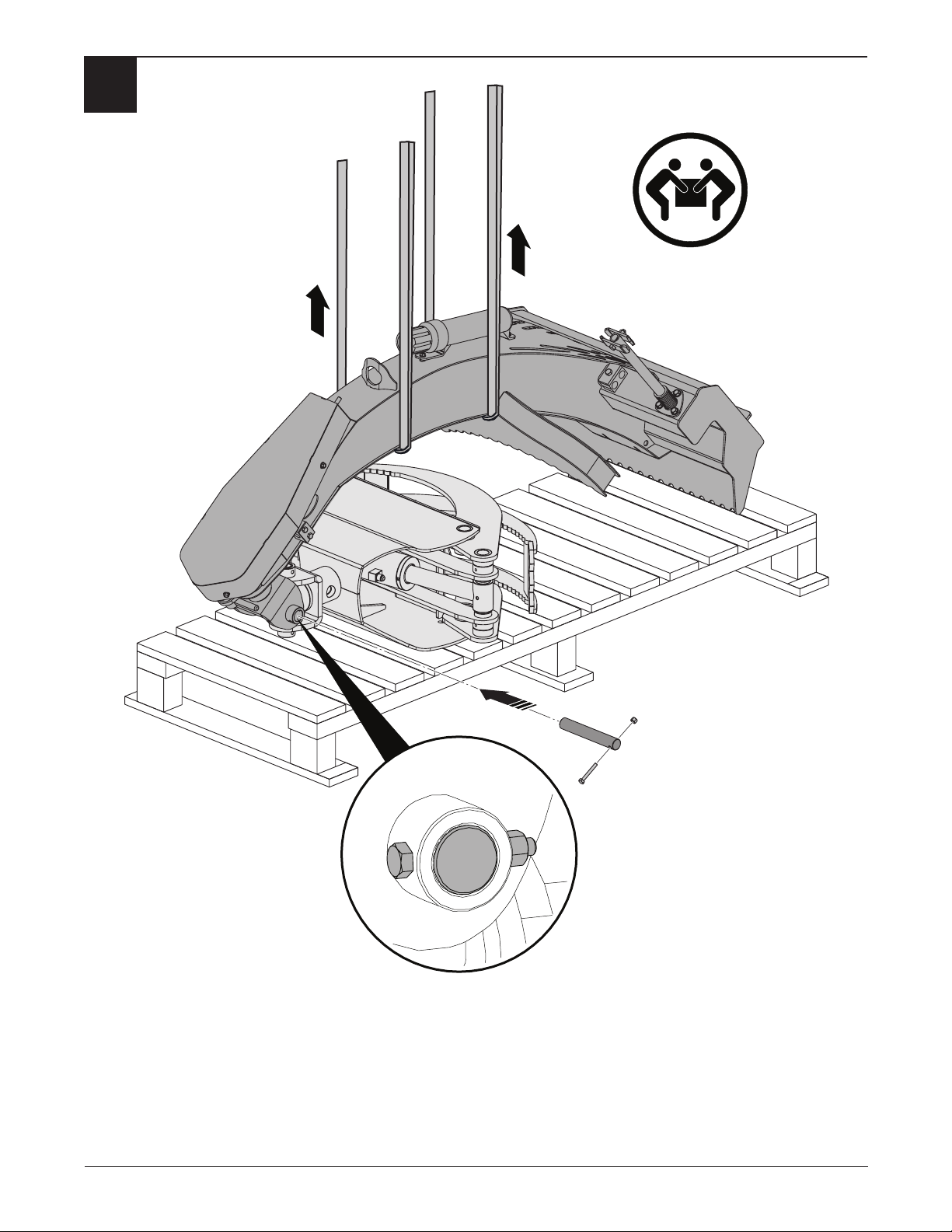

1

2

5

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

3

6

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

4

7

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

5

8

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

Pre-delivery Inspection Checklist

Do the following pre-delivery inspections (PDI).

Pivot assembly moves freely.

Rotator functions correctly.

Grapple functions correctly.

Hydraulic system functions correctly.

Hydraulic connections are tight, and hoses and fittings are

in good condition.

There are no hydraulic fluid leaks.

All fasteners are torqued to the correct specifications.

All grease locations are lubricated.

Operator's Manual is in the storage tube.

Safety Checks

All safety labels are applied and legible.

All guards and shields are installed.

Operating and safety instructions were reviewed.

9

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

Specications

Bolt Torque

IMPORTANT! If you replace hardware, use fasteners

of the same grade.

IMPORTANT! The torque specifications in these

tables are for non-greased or non-oiled threads. Do

not grease or oil fastener threads unless otherwise

indicated. When using a thread lock, increase the

specified torque 5%.

Bolt grades are identified by the marks on top

of the bolt head.

These bolt torque specification tables give the correct

torque settings for common bolts and capscrews. Tighten

all bolts to the torque that is specified in the table, unless

otherwise indicated. Check the bolt tightness periodically.

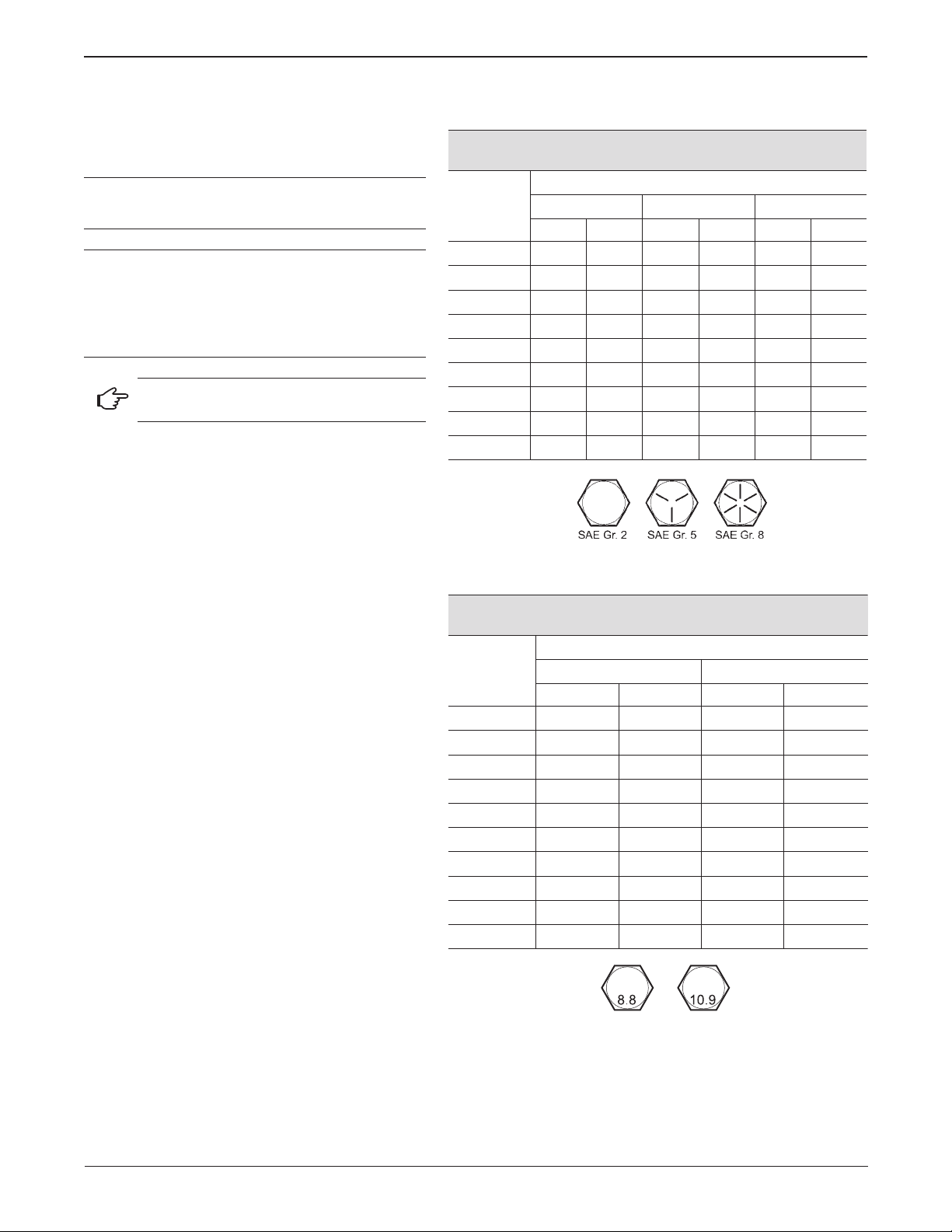

Imperial Bolt Torque Specifications

Bolt

Diameter

Torque

SAE Gr. 2 SAE Gr. 5 SAE Gr. 8

lbf•ft N•m lbf•ft N•m lbf•ft N•m

1/4 inch 6 8 9 12 12 17

5/16 inch 10 13 19 25 27 36

3/8 inch 20 27 33 45 45 63

7/16 inch 30 41 53 72 75 100

1/2 inch 45 61 80 110 115 155

9/16 inch 60 95 115 155 165 220

5/8 inch 95 128 160 215 220 305

3/4 inch 165 225 290 390 400 540

7/8 inch 170 230 420 570 650 880

Metric Bolt Torque Specifications

Bolt

Diameter

Torque

Gr. 8.8 Gr. 10.9

lbf•ft N•m lbf•ft N•m

M3 0.4 0.5 1.3 1.8

M4 2.2 3 3.3 4.5

M6 7 10 11 15

M8 18 25 26 35

M10 37 50 52 70

M12 66 90 92 125

M14 83 112 116 158

M16 166 225 229 310

M20 321 435 450 610

M30 1,103 1,495 1,550 2,100

10

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

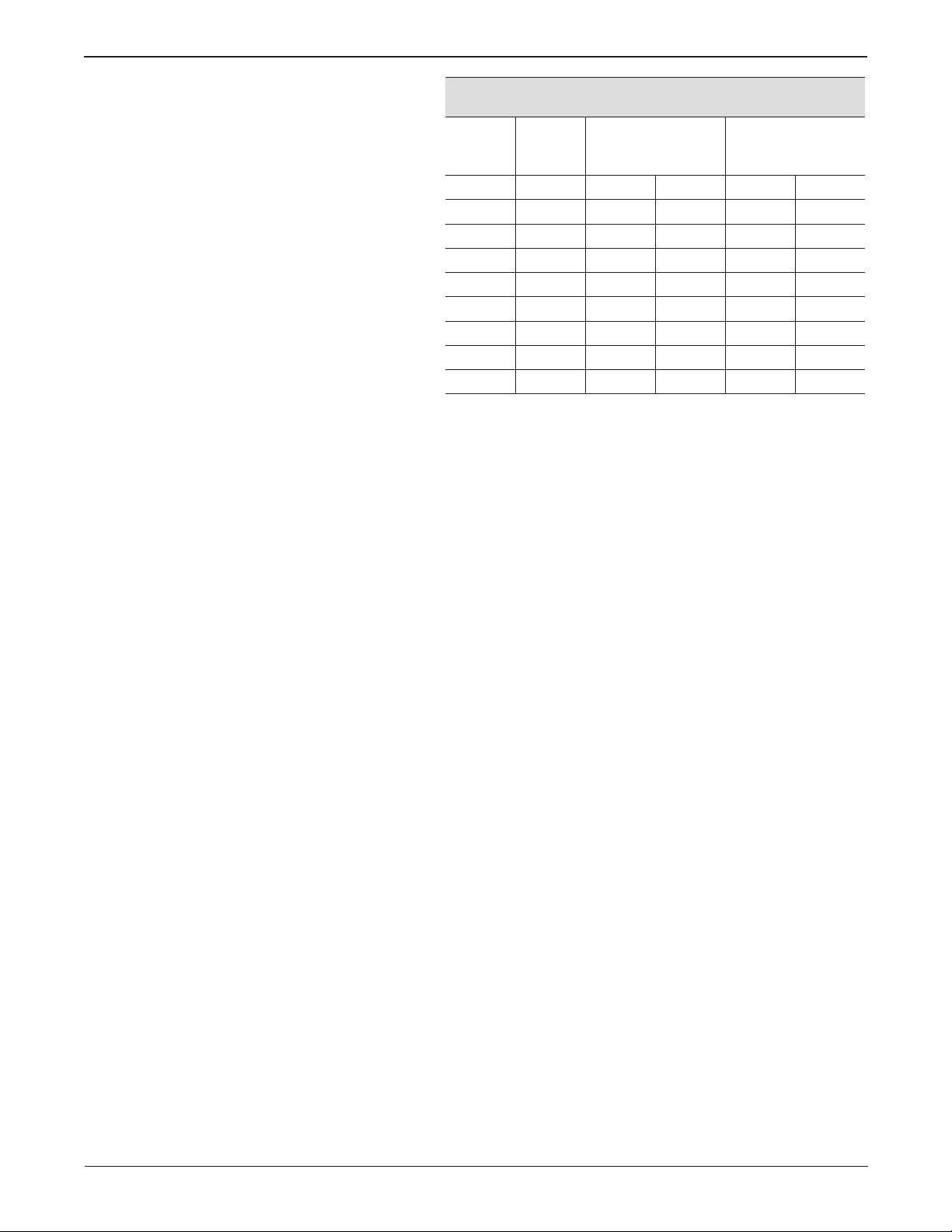

Hydraulic Fitting Torque

Tighten flare-type tube fittings:

1. Check the flare and flare seat for defects that might

cause leaks.

2. Align the tube with the fitting before tightening.

3. Hand-tighten the swivel nut until it is snug.

4. To prevent the tube from twisting, use two

wrenches. Place one wrench on the connector body

and tighten the swivel nut with the second wrench.

Torque the fitting to the correct specification.

If a torque wrench is not available, use the flats from

finger tight (FFFT) method.

Hydraulic Fitting Torque Specifications

Tube size

OD

Hex size

across

flats Torque

Flats from finger

tight

Inches Inches lbf•ft N•m Flats Turns

3/16 7/16 6 8 2 1/6

1/4 9/16 11–12 15–17 2 1/6

5/16 5/8 14–16 19–22 2 1/6

3/8 11/16 20–22 27–30 1-1/4 1/6

1/2 7/8 44–48 59–65 1 1/6

5/8 1 50–58 68–79 1 1/6

3/4 1-1/4 79–88 107–119 1 1/8

1 1-5/8 117–125 158–170 1 1/8

Specifications are for non-lubricated connections.

11

LXG210S-SKD / LXG210SB-SKD

Log Grapple

Setup Instructions

Skid Pro

This manual suits for next models

1

Table of contents