Butterfly Valve Type-57P

Butterfly_Valve_Type57P_Install Rev. B

Operating procedure

- Open and Close the valve by turning handle slowly. Turn clockwise to Close, counterclockwise to

Open.

- Lever Type – The direction of the handle is the same as the disc

For full Closed position, the handle is perpendicular to the piping

For Full Open position, the lever handle is parallel to the piping system.

- Gear type

For full Closed, the indicator shows Shut.

For full Open, the indicator shows Open.

General operating Instructions

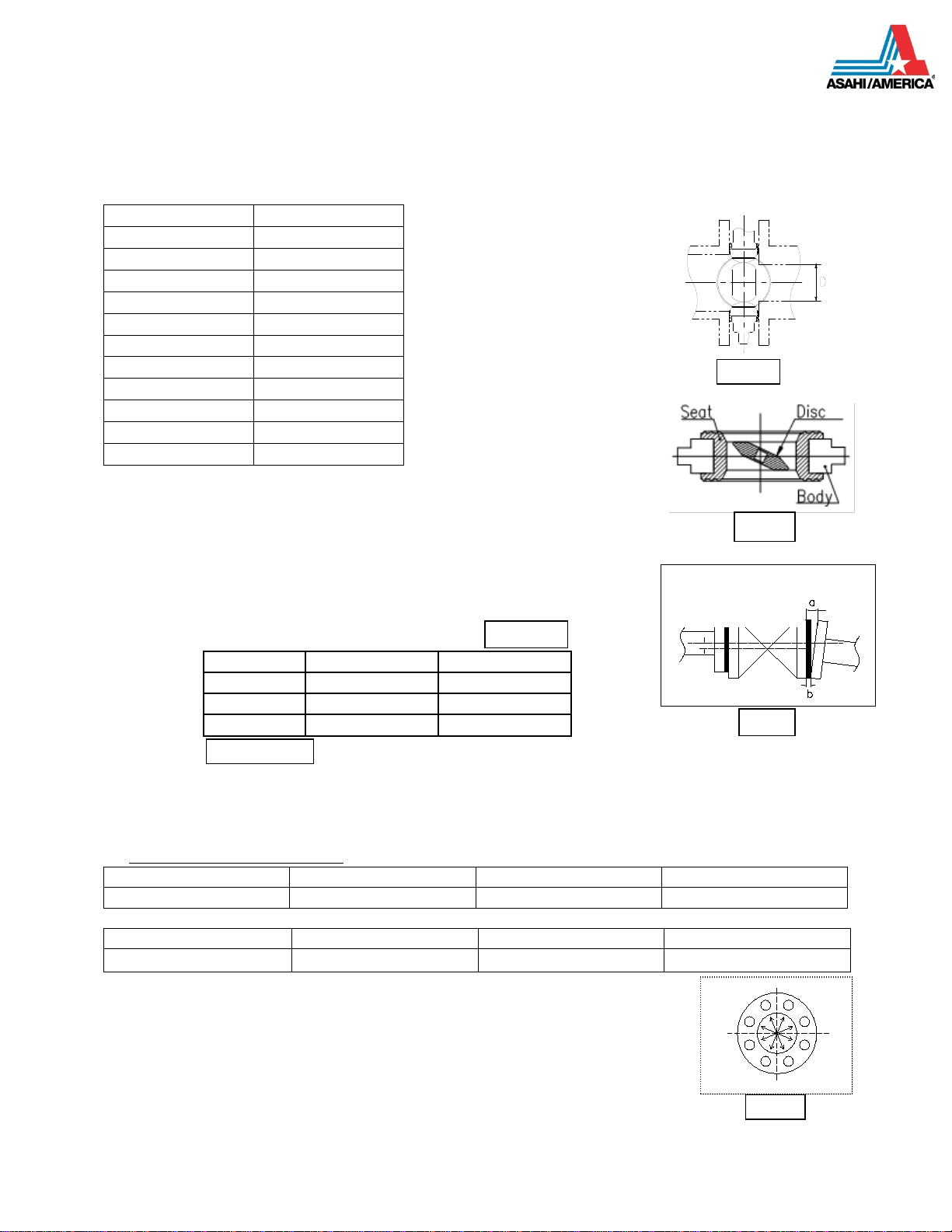

- Operate the valve within the pressure vs. Temperature range as per table below, otherwise the

valve can be damaged

- Select a valve material that is suitable for the media. (Refer to Chemical Resistance on AV Valve)

- Do not step on valve or apply excessive weight (the valve can be damaged)

- Allow sufficient space for maintenance and inspection

- Keep the valve away from excessive heat or fire. (Valve can become deformed or destroyed)

- Make sure to properly dispose of used valves. (Poisonous gas is generated when burned

improperly)

Caution: Do not attempt to repair or replace parts while valve is under pressure.

Refer to Asahi/America Type-57P Operation and Maintenance manual for Disassembly/Assembly or valve

repair.

General Instructions for Transportation, Unpacking and Storage

- Keep the valve packed in original carton box as delivered until installation

- Keep the valve away from any coal, tar, creosote (antiseptic for wood) termite insecticide,

vermicides and paint. (Could cause swelling and damage to the valve)

- Do not impact or drop the valve (It can be damaged)

Visual Maintenance Inspection

1) Check for flaws, cracks, or deformation of the valve.

2) Check for any leaks to the outside of the valve.

3) Check for seat/disc deformation due to improper installation of the valve.

4) Check for smoothness of handle operation.

Troubleshooting

Fluid leaks in the closed Position

1) Travel stop is not properly set

2) The seat is damaged or worn

3) Foreign materials are trapped

4) the disc is damaged or worn

5) Flange bolt torque uneven/wrong

Replace the seat

Remove material

Replace the disc

Fluid leaks to the outside

1) The seat is damaged or worn

2) Flange bolts are not tight or

Replace the seat

Properly torque flange bolts

The Handle does not operate

smoothly

1) Foreign materials on disc/seat

2) Gear-op is damaged

3) Flange bolts are overtightened

Repair and Replace

Valves do not operate

1) The gear-operator is damaged

2) The stem is damaged

Replace Gear operator

Replace the stem