ASAHI ASV-320D User manual

16

ASV-320D

Model:

UserManual

SaveTheseInstructions.

Thank you for purchasing this product.

Read this User’s Manual before using this

product, and make sure to use the product

correctly.

Misuse may result in malfunction or

unexpected accidents or hazards.

TableofContents page

SafetyWarning 2

AdditionalSafety

Instructions 3

Specifications 4

Accessories 4

Features 4

Cleaning 11

VacuumingTips 10

SealMode 9

Care 14

VacuumMode 6

OperatingInstructions 6

AvailableBags 5

Troubleshooting 15

Check 16

Warranty 16

Check

Toprolongtheeffectivelifeoftheappliance,pleaseperformadailyperformancecheck.

Productname:Two-in-one automatic vacuum sealer ModelNo.:ASV-320D

1-11-22, YONBAN, ATSUTA-KU, NAGOYA, AICHI, JAPAN

TEL : 81-52-671-5193 FAX : 81-52-671-5196

Warranty

Warranty period

Model No.

Manufacturing No.

(Serial No.)

Name

Address:

TEL:

Store of purchase

Date of purchase

*Fill in the required information and keep in a safe place.

: months

: ASV-320D

:

:

:

:

:

:

Weguaranteequalityonlyforuseundernormalconditionsduringthewarrantyperiod.Iftheproductmalfunctions

duringthewarrantyperiod,wewillrepairitatnochargeusingourprescribedmethods.Bringtheproductalong

withthewarrantytothestorewhereyoupurchasedtheproduct.

Inthefollowingcases,wewillchargeafeeforrepairevenduringthewarrantyperiod.

(1)Ifnowarrantyisshown

(2)Iftherequiredinformationisnotfilledinorisrewritten

(3)Ifthemalfunctionwascausedbymisuse

(4)Ifthemalfunctionwascausedbyimpactduringshipmentormovementbythecustomer

(5)Malfunctionanddamagecausedbynature,pollution,abnormalvoltage,orotheroutsidefactor

Ifitisdeterminedthatthecustomerindependentlyalteredorrepairedtheproduct,itwillnotbeacceptedfor

repairduringthewarrantyperiod.

Repairsandreplacementsofsupplies(HeatingWires,PTFTstrips)thatareconsumedordeterioratewillincura

chargeevenduringthewarrantyperiod.

Thecompanywillnotbeliablefordirectorindirectdamagecausedbymalfunctionoruseoftheproduct.

Expensesforsendingorbringingaproductforrepairaretheresponsibilityofthecustomer.

Keepthewarrantyinasafeplace.Warrantieswillnotbereissued.

1.

2.

3.

4.

5.

6.

7.

UserManual&Warranty

■Doyoudetectthefollowingsigns?

-Dustisaccumulatedontheoutlet,the

connectororelectricoutlet. Removedust.

Thepowercordorplugisextraordinarilyhot.

Thepowercordorplughasdeepscratchesor

deformation.

Thereisasmellofburning.

Movingthepowercordmayinterrupttheelectric

current.

Anelectricshockisexperiencedwhentouchingtheunit.

Otherabnormalitiesorfailuresarefound.

-

-

-

-

-

Topreventfailuresoraccidents,turn

thepowerswitchoffandunplugthe

appliancefromtheoutlet.Consult

ourcompanyorthestorewhereyou

madethepurchaseforinspection

andrepair. Two-in-one automatic vacuum sealer

-Highlyversatilemodel-

SAMPLE

2 3

SafetyPrecautions ImportantSafeguards

▼ItemsshownherearecategorizedasWarningorCaution.

EvenitemscategorizedasCautionmayleadtoseriousresultsdependingonthe

circumstances.Importantinformationaboutsafetyiswritteninallcasesandmustbeobserved

withoutfail.

WarningThisindicatesdeathorseriousinjurymayresultifthislabelisnot

heededandtheproductisusedimproperly.

Caution Thisindicatesthatinjuryorpropertydamagemayresultifthislabelis

notheededandtheproductisusedimproperly.

Warning

Avoidcontactwithwater,whichcanresultinashortorelectricshock.

Donotusetheapplianceiftapeisnotplacedonthesealstrip.

Thismaycausefire,electricshock,orburnsandinjuries.

Closesupervisionisnecessarywhenanyapplianceisusednearchildren.

Childrenshouldnotoperate.

Onlyacertifiedrepairmanshouldperformanydismantling,repairsor

modifications.

Fireorabnormaloperationmayresultininjury.

Alwaysunplugtheappliancefromtheoutletforrepair.

Usetheoutletonlyforthisappliance(3.15Aormore).

Overloadedoutletsmaycauseoverheatingorfire.

Wipeawayanydirtontheplug.

Grimemaycausefire.

Besuretogroundthegroundingterminalproperly

topreventelectricshock.

Useadesignatedpartforthesealarea.

ApplythePTFTstripafterreplacement.

Inappropriatereplacementcancauseoverheating,fireorelectricshock.

Cleanorreplacethesealingstripafterturningofftheswitchand

unpluggingtheunit.

Donotpluginorunplugelectricalequipmentwithwethands.

●

●

●

●

●

●

●

●

●

Donotholdnearflameoruseinanunstablelocation.

Thismayresultinfire,injuryordeformation.

Whenvacuumpacking,donotvacuumliquidwithoutattachingtheliquidcatch

canister.

DonotputfingersonthePTFTstrip.

Closingthesealbarmaypinchorburnfingers.

Usetheunitonlywhenthebagisplacedinposition.

Thiscancauseoverheatingorfire.

Usetheapplianceonlyforitsintendeduse.

Improperusemaycauseelectricshock,shortorfire.

Donotallowtheunittovacuumflammableliquidorgas.Firemayresult.

Qualityofvacuumpackingisnotguaranteed.

Conditionssuchaspackagedfoodshelflifeandvacuummethodmaycausefood

degradationorrot.

Graspplugtoremovethecordfromthereceptacleoutlet.

Failuretodosomayresultincorddamage,electricshock,shortorfire.

Donotuseanunstableoutletoradamagedcordorplug.

Failuretodosomayresultinelectricshock,shortorfire.

Donotplaceheavyobjectsonthepowercord,applyexcessiveforce,deformor

bundleit.Damagingthepowercordmaycauseelectricshockorfire.

Donottouchhotsurfaces,whichmaycauseburn.

Unplugtheappliancefromtheoutletwhennotinuse.

Aburn,electricshock,shortorcircuitfiremayresult.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

Caution

Shouldyourproductnotperformproperly,restartit.

Holdthebottomoftheunitwhilecarrying.

Handlethenozzlecarefully.

Whenyouarevacuumpackingmoistfood,emptytheliquidcatch

canisterbeforefillingitmorethanhalfwithwater.

Unplugtheappliancefromtheoutletwhennotinuse.Storetheunit

withthevacuumnozzlehousedandthesealbarraised.

Donotusestrongsolventssuchasbenzeneorthinnerwhencleaning.

Donotdroporsubjecttheappliancetoastrongshock.

Donotplaceobjectsontheappliance.

AdditionalSafetyInstructions

4 5

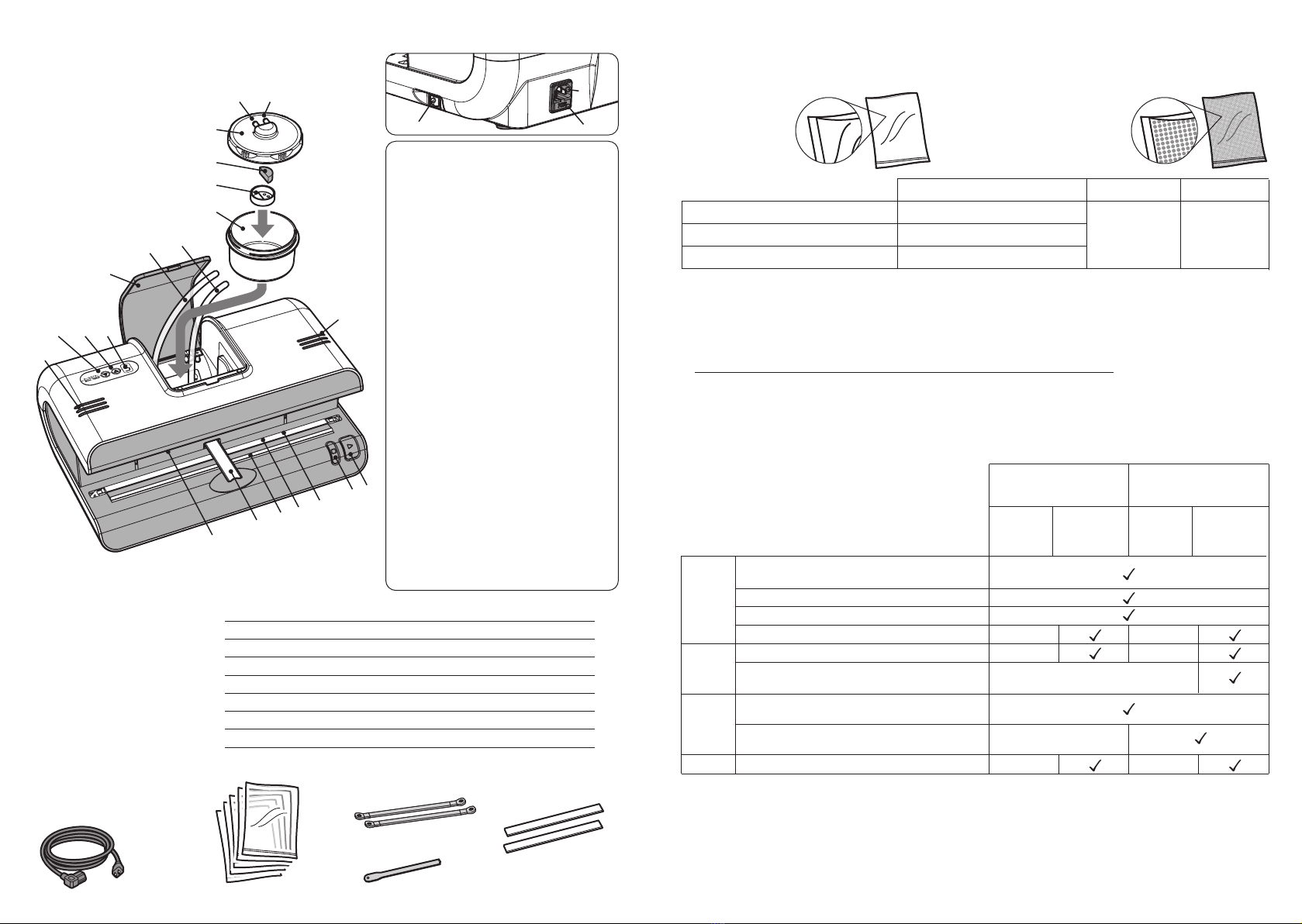

・UserManual ・SampleBags

(Clearbags)

・PowerCord

・NozzleCleaningTool

・TwoPTFEtapes・TwoHeatingWires

Accessories

Specifications

Backsideofthecontainerbody

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

ApplianceInlet

Fuse

Powerswitch

Startbutton

Select/PauseButton

PTFEtape

HeatingWire

(Thisislocatedunder6.)

Gaskets

Therearethreegaskets

onupperandlowersides.

Nozzle(Slidesbackandforth.)

TheSealBar

(Movesupordown.)

IndicatorLight

+TimerButton

−TimerButton

ManualVacuumModeLight

(Green)

AutomaticVacuumMode

Light(Red)

LiquidCatchCanisterCover

TubeofNozzleSide

(Connectsto19A.)

TubeofUnitSide

(Connectsto19B.)

LiquidCatchCanisterLid

Filter

ProtectionRubber

LiquidCatchCanister

Usablebags

NamesofParts

6

14

18

16

17

19

20

21

A B

22

1

23

4

5

7

8

9

10

111213

15

:ASV-320D

:100〜240V50/60Hz

:W394xD266xH175mm

:4.35kg

:200W

:-80kPa

:300mm

:1.8m

Model

Power

Dimensions

Weight

Powerconsumption

Pumpefficiency

Seallength

Lengthofcords

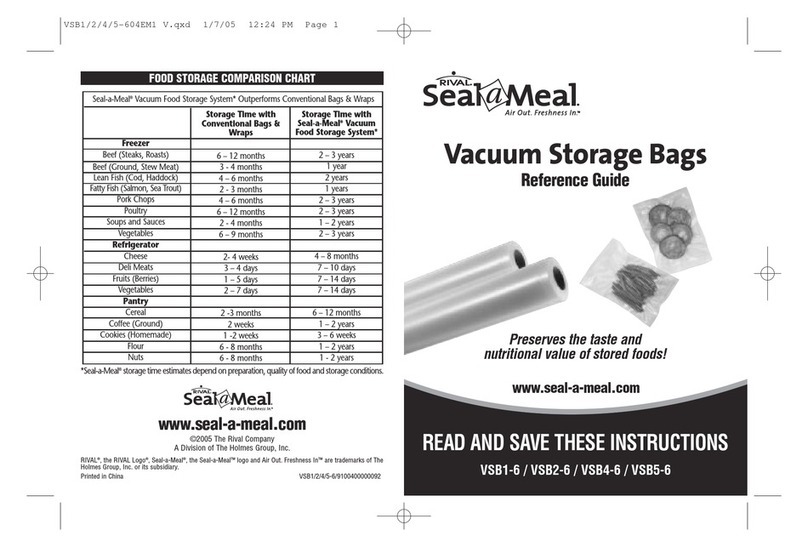

Usethevacuumbagwhenvacuumpackagingitems.

Thevacuumbagismadeofnylon-polyfilmoraluminum.Fordetails,checkthebag

performancesuchasair(oxygen)penetration.

Incaseofheatsterilizationorfreezingstorageaftervacuumpacking,selectasuitablebagforthese

purposes.Thecorrespondingfreezingtemperatureandboilingtimeaftervacuum-packingdiffer

dependingonthespecificationsofthevacuumbags.

Settheembossedbaginthemachinewiththeembossedsidefacingdown.

Forrolledembossedbags,cuttoanappropriatelength,sealonesideofthebaginsealmode,and

performvacuumpacking.

Therearebagsof

varioussizes,

thicknessesand

specifications,

withasmooth

surface.

−

−

−

− −

−

Whenstoringfood,choosetheusagepurposeoftheunitinconsiderationoffoodtypeorshelflife.

Avoidpackingunsanitaryitems.

Avoidusingthesameunitforfood,dailynecessitiesandindustrialparts.

Industrialoil,etc.thatmayadverselyaffecttheplasticpartscannotbesucked.

Alwayskeepthenozzleandliquidcatchcanisterclean.

〜240μ

〜180μ

〜280μ(approx.) 〜300mmFlatbags

Standardvacuumbags

Standard

vacuumbags

Standardvacuumbags

Aluminumvapordepositionbags

Embossedvacuumbags

Embossed

vacuumbags

Embossedvacuumbags

Thickness(totalthickness) Shape Width

Thefilmononesideof

thebagisembossed

withapattern,making

iteasiertovacuumthe

air.Rolledbagsarealso

usable.

Settingofbagandvacuummodesuitable

forthecontents

Variousitemscanbevacuumpacked.

Someitemsrequiretheuseofan

embossedbag.

●

●

●

●

●

●

●

●

●

●

Soup,itemsofhighviscositysuchassauce

andcurry,etc.

Solid

Liquid

Powder

Others

Foodstuffssuchasmeat,fish,vegetables,

etc.,cookedfoodstuffs,hotfoods

Industrialproducts

Water,hotwater

Grains

(Riceandsoforththatislargerthanthenozzlesuctionport)

Powders

(Powdersmallerthanthenozzlesuctionport)

− −

Softfoodssuchasbread,fragilefoods

Useofoxygenabsorbers,trays,etc.

Delicateitemssuchaselectronicparts

※Ifthereisalotofmoistureanditisdifficulttovacuum,anembossedbagisrecommended.

※Forhighlyviscousliquid,vacuum-packitaftersemi-freezing,oruseanembossedbagandsealit

beforethenozzlesuckstheliquid.

Automatic

Vacuum

Mode

Manual

Vacuum

Mode

(Adjustablemode)

Automatic

Vacuum

Mode

Manual

Vacuum

Mode

(Adjustablemode)

※

※

Setthecontentsclosetothenozzle.

76

Checkthatthecanisterortubeisnotleakingair.

Makesuretoclosethelidoftheliquidcatchcanisterandconnectthetube.

Setthesealingtime.

Setthesealtimertakingbagthicknessand

materialintoaccount.

(Sealtimernumber:1=1sec、2=2sec...)

Checkingthesealcondition,settheappropriate

sealtimeasfollows.

Placeitem(s)inthebag.

BeforePlacingItemsinBags・・・

-

-

-

-

-

※Inautomaticvacuummodeormanualvacuummode,makesurethenozzleisout.

Thickness(μm) 60μ 70μ 80μ 90μ 120μ

4 4 5 5 7Sealingtime(sec.)

Sealingtime(sec.)

+Button−Button

Select/PauseButton

OperatingInstructions

※Ifthenozzlevacuumsthebagoritscontents,vacuummodemayautomaticallyswitch

tosealmodeevenifthebagcontainsair.(See“OperatingInstructions”,page8.)

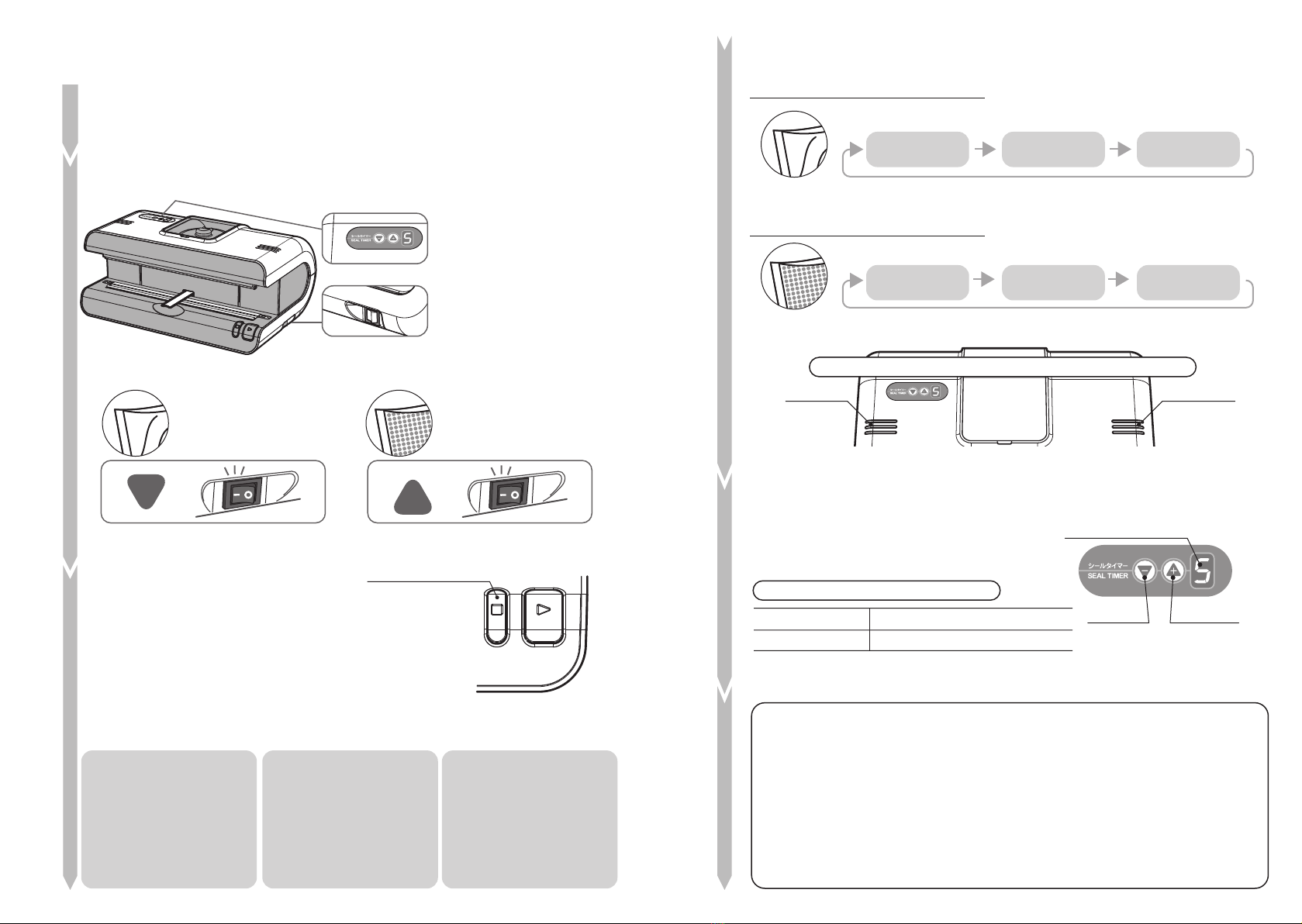

GreenlightRedlight

Automatic

VacuumMode SealMode

Manual

VacuumMode

※Intheautomaticvacuummodeinembossedbagmode,switchingtothesealmodeispossible

bypressingthestartbutton.

Timerbutton

Powerswitch

2

1

Checktheoperationmode.

3

Whenitemvolumesaresmallforthebagsizeorbagsareremarkablythin,itmay

makethevacuumingprocessdifficult.Iftheitemvoluumeissmall,prepareabag

ofappropriatesizeoruseanembossedbag.

Pleaseuseanembossedbagforpowdersorhighlyviscousitemssuchascurry,

sauce,etc.

Whenyouplaceitem(s)inthebag,preventwatercontactwiththesealareaof

thebag.

Somevegetablesemitgasesduringstorage.Thebagmayinflateaftervacuumsealing.

Usebagswithhighpinholeresistancewhenpackingitemswithprotrusion.

5

4

6

Beginvacuumingafter

placingthebaginposition.

Aftervacuumingprocess,

sealmodewillturnon

automatically.

Checkingthedegreeof

vacuum,thismodecan

switchtotheuserʼsselected

sealmode.Afterthebagis

inserted,vacuummode

continues.Pressthestart

buttonagainandturnon

sealmode.

Thismodesealsthebag

only.Usethismodewhen

itemsdonotneedvacuum

oryouwanttoperformthe

sealingprocessmanually.

Thelightonthecovertopindicatesoperatingmodeandprogress.

Manual

VacuumMode Seal

Mode

Automatic

VacuumMode

Manual

VacuumMode Seal

Mode

Automatic

VacuumMode

-Standardvacuumbagsmode-

-Standardvacuumbagmode-

-Embossedvacuumbagsmode-

-Embossedvacuumbagmode-

Plugthepowercordintothereceptacleoutlet.

Setthebagtypeasrequiredwhenturningontheswitch.

Turnonthepowerswitch

whilepressingdownthe

mainus(−)button.

Thelightturnson.

Turnonthepowerswitch

whilepressingdownthe

plus(+)button.

Thelightblinksslowly.

Toselectthebagmode,turn

onthepowerswitchwhile

pressingdownthe+(plus)

buttonor-(minus)buttonof

thetimer.

Ifturningonthepower

withoutpressingthetimer

button,thepreviouslyused

modewillbecontinued.

−+++

Settheoperationmode.

Therearethreeoperationmodesfor

thestandardvacuumbagmodeand

embossedbagmoderespectively.

Eachtimetheselectbuttonispressed,

thelightindicatorchangesonthecover,

andthemodewillchangeasfollows.

Theredlight

turnson

Theredlight

blinksslowly

Thegreenlight

turnson

Thegreenlight

blinksslowly

TheBothlights

turnon

Thebothlights

blinkslowly

ex.Standardnylon-polyvacuumbag

98

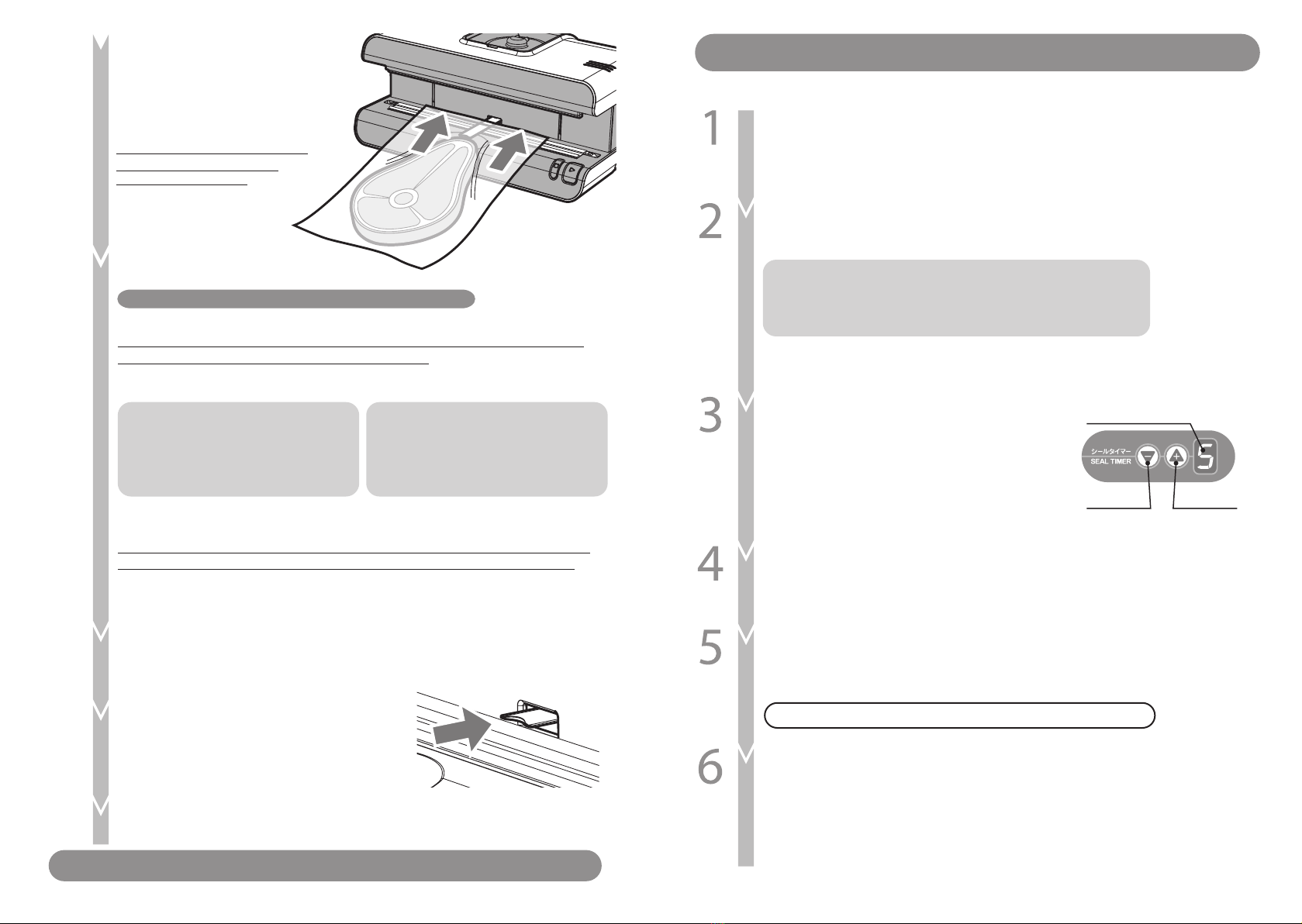

SealMode

Shouldyourproductnotperformproperly,restartit.

Checknozzleandoperatingmode.

See“BeforePlacingItemsinBags”,page7topreparethebag.

InsertthebagfartherthanthepositionofthePTFTstrip,untilthetipofthebag

contactstheendoftheunit.

Whensettinganembossedbag,besuretoplaceitwiththeembossedsidedown.

Pressthestartbuttontobeginthesealingprocess.

Pressthestartbuttonatthebottomrightoftheunit,andthesealbarmoves

downtobeginthesealingprocess.Whentheprocessiscomplete,thesealbar

movesupautomatically.

Makesureredandgreenlightsatbothsidesofthecovertopareilluminatedand

nozzlesarehoused.Inothermodes,presstheselectbuttontochangethemode.

Pluginthepowercordandturnonthepower.

Thepowerswitchisontherightsurfaceoftheunit.

Makesuretoindicatethenumberonthecover.

Redlight(Left) :AutomaticVacuumMode

Greenlight(Right) :ManualVacuumMode

Red&greenlights :SealMode

Setthesealingtime.

Setthesealtimertakingbagthicknessand

materialintoaccount.

(Sealtimernumber:1=1sec、2=2sec...)

Sealingtime(sec.)

+Button−Button

Checkingthesealcondition,settheappropriate

sealtime.

Placeitem(s)inthebag.

Placethebag.

Placethebag.

Thebagispositionedsothatit

straddlesthevacuumnozzle.

Besuretoinsertthebagasfar

aspossible.

Pressthestartbutton.

Makesurethesealingprocessiscompleteand

removethebag.

Thesealbarmovesdownandholdsthebag.

Whenthesealingprocessiscomplete,thesealbarwillmoveupautomaticallyand

theunitwillstop.

Housethenozzle.

Housethenozzlebeforeshuttingoffthe

appliance.

Presstheselectbuttonandthenozzle

willmovedown.

Turnoffthepower.

Becarefulthatthebardoesnotpinchyourfingers.

AutomaticVacuumMode ManualVacuumMode

Whentheunitvacuumsfor60secsor

thevacuumingiscomplete,the

sealingprocesswillbegin

automatically.

Pressthestartbuttonagainandturn

onsealmode.

Toavoidwrinkling,stretchthebagsidewayswhileinserting.

7

8

9

10

11

Whensettinganembossedbag,

besuretoplaceitwiththe

embossedsidedown.

Intheembossedbagmode,switchingtothesealingoperationispossibleby

pressingthestartbutton.

Intheautomaticvacuummodeofembossedbag,ifthemachinedoesnotmove

tothesealmodeeventhoughthesuctionissufficient,pressthestartbutton.

Pleaseadjustthesealtimerandusethethinnerembossedbagswhenthesealing

processwillnotbeginintheautomaticembossedbagvacuummode.

Thesealbarmovesdownandbeginsvacuumingitems.

Duringvacuuming,bringingthecontentsclosetothenozzleexpeditestheloss

ofairfromthebaginstandardvacuumbagsmode.

Intheembossedbagmode,pre-sealingbeginsfirstwhenthebarmovesdown,

thenvacuumingisperformed.

10 11

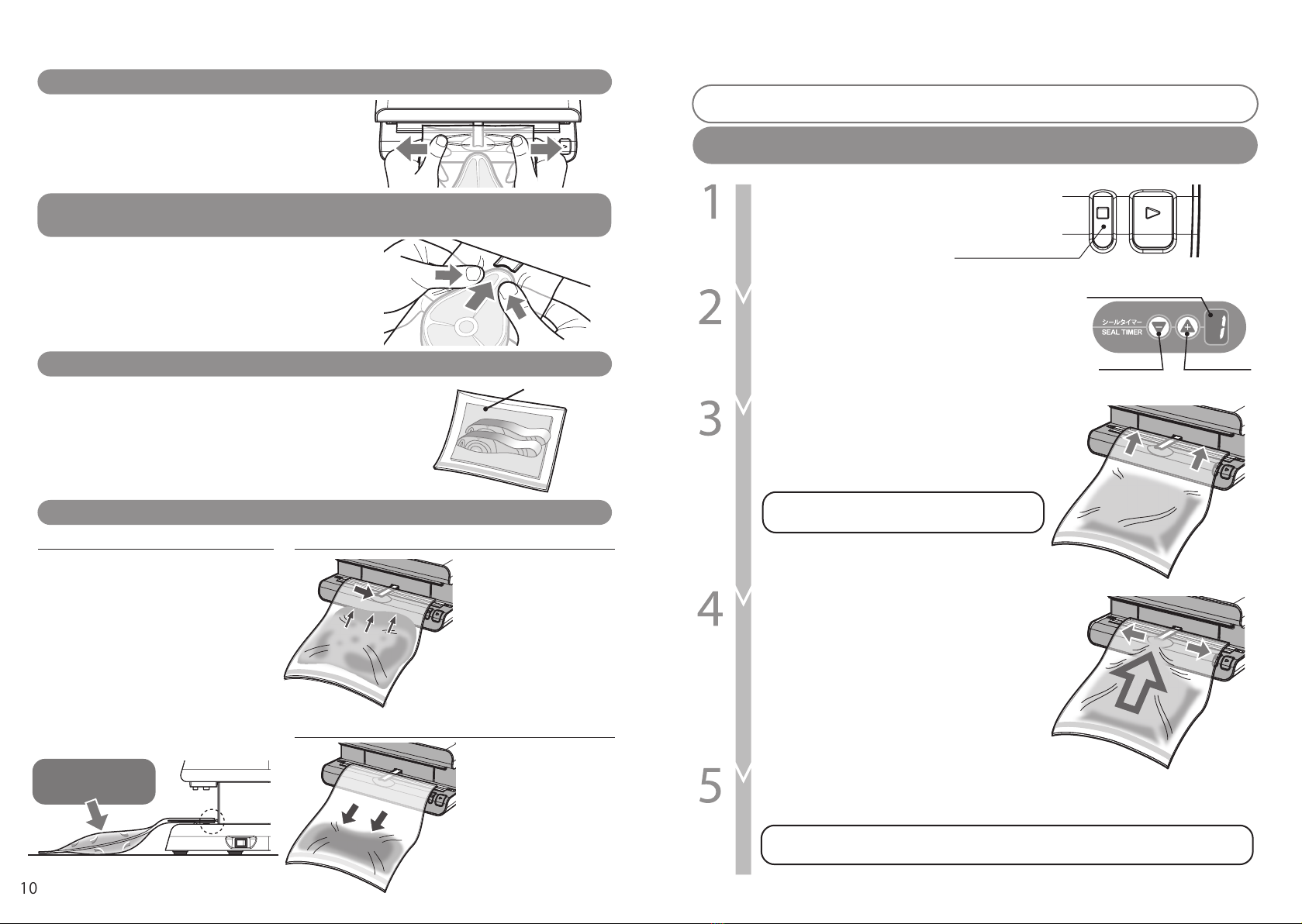

VacuumingTips HintsforBestVacuumingPerformance

Afterpressingthestartbutton,stretchthebag

sidewayswithhandstoavoidwrinkles.

Placethebagata

positionlowerthan

sealarea.

Papertowel

Sealing

position

Whenthesealbarmovesdownandgraspsthebag,

pressthepausebuttonimmediately.

Next,bringcontentsclosetothenozzlewiththeunit

stopped.Pressthepausebuttononceagaintorestartthe

vacuumprocess.

Thismakestheairvacuumingprocessfasterandeasier.

Vacuumpackagingmeatorfishmaycomplicatetheair

vacuumingprocessbecausemoisturemaycausebagstostick

instandardvacuumbagmode.

Placeapapertowelinthebagtoabsorbexcessmoistureand

juicesduringthevacuumpackagingprocessinorderto

vacuumpackageitemsneatlyorvacuum-packingwithan

embossedbagisrecommend.

Vacuumandsealliquidinmanual

vacuummode.

Afterthesealbarmovesdownand

graspsthebag,placethebagata

positionlowerthanthesealarea.

Thismakesairaccesstothenozzle

tipeasier.

Vacuumasmuchairaspossibleby

vacuumingliquidandairatthe

sametime.

Becarefulnottospillliquidduring

operation.

PlacementofBags

PreparationGuidelinesforMeatandFish

PreparationGuidelinesforLiquidsandPowderyFoods

Pausetheunitimmediatelyafterthevacuumingbeginsandbringcontents

closetothenozzleinstandardvacuumbagmode.

Cleaning

●Cleanthenozzleafterusetopreventclogging.

Cleaningwithlukewarmwater

Vacuuminglukewarmwatercleanstheinsideofthenozzleortube.

Acloggednozzlemayweakenorhaltvacuuming.

Toomuchlukewarmwatermayoverflow

theliquidcatchcanister.

Whenexcessliquidhasfilledtheliquidcatchcanister,liquidenteringthe

unitmayleakfromthebottom.

Presstheselectbuttonandcheck

thatthegreenlightflashes.

Pressthesealtimerbuttonandset

itat“1”.

Pour50°Corless,150mloflukewarm

waterandplacethevacuumnozzle

betweenthebag.

Pressthestartbuttontovacuum

lukewarmwater.

Cleantheinsideofthenozzleortube.

Whensettingthebag,stretchitsidewayswith

handstokeepthewarmwaterfromspilling.

Pressthestartbuttonagaintoraisethesealbar.

Checktheliquidcatchcanister.Ifwaterisuncleanwhenvacuumed,repeat

steps3and4untilwaterbecomesclean.

Sealingtime(sec.)

+Button−Button

Select/PauseButton

ForLiquid

ForPowder

Forhighlyviscousliquidssuchascurry

Forhighlyviscousliquids

suchascurry,etc.,

vacuum-packafter

semi-freezing,orusean

embossedbagandsealit

beforethenozzlesucks

theliquid.

Whenpackingfine

particlessuchaswheat

flour,useanembossed

bagtovacuum-packwith

thepowderatthebottom

ofthebag.

Cleanthenozzleandtube

ifthepowdergetssucked

in.

Turnmanualvacuummodeon.

Setthesealtimeat“1”(onesecond).

Pourlukewarmwaterintothebagand

insertittotheunit.

1312

2Removethenozzlefromthemainunit.

Removetherear-mountedrubbercapoftheremoved

nozzletocleantheinside.

Cleanthenozzlewiththeaccessorynozzlecleaningtoolandwashitoffwithwater.

Reinstallthenozzle.

Installtheliquidcatchcanisteran

cleaningiscomplete.

Whenremovingthenozzle,holditsbaseand

carefullyremovetherightandleft

fixedpartsinorderfromrighttoleft.

3

4Wipemoisturefromthenozzle,

replacetherubbercap,and

reinstallit.

Removethenozzlewithcautionbecause

roughtreatmentmaydamageparts.

Becarefulnottoletwaterordustintotheunit.

Removeparts

markedwith

anarrowfrom

onesideand

thentheother.

Removedustwiththenozzle

cleaningtoolandwashitwithwater.

CleaningtheFilter

Removethefilterfromthelidandwashitwithwater.

CleaningtheNozzle

CleaningtheFilter

Removethenozzlefromtheunit.

Makesuretoturntheunitoffbeforecleaning.

Makesuretoturntheunitoffbeforecleaning.

1

2

Openthecoveroftheliquid

catchcanistertoremoveit

anditslid,andremoveits

protectionrubber.

Connectionbetweentubeandlid

※Ifthereissevere

contaminationorscratches

onthefilter,itneeds

replacement.Pleasecontactthe

storewhereyoumadethepurchase.

Removethefilterfrom

thecanisterandwash

inwater.

Connectthetube

tothenozzle.

Connectthefilter-side

nozzletotheunit.

Filter

Preparingtoremovethenozzlefromtheunit.

Setoperatingmodetosealmodeandhouse

thenozzle.

Opentherearcoveroftheunitandremove

theliquidcatchcanistertorevealthenozzle

underneaththecover.

Revealingthenozzle

underneaththecover.

Removethecanister

withitslid

※Donotremovethetube.

Nozzlecleaningtool Nozzle

Rubbercap

Donotholdthemetalpartof

thenozzletoavoidbending.

Pleaseuseaflathead

screwdriveras

illustratedifitis

difficulttodetach

byhand.

Caution

Pleasehold

therootpart

andpullout

thenozzle.

15

14

MalfunctionsandCauses Problemsolving.

Problem Checkpoint Procedure

Theunitdoes

notoperate.

Makesurethepowercordis

correctlypluggedintothe

electricaloutlet.

Checkthecircuitbreakers. Checkthecircuitbreakers.

Makesurethefuseisnotblown.

Replugthepowerpluginto

theelectricoutlet.

Checkthefuseofthe

applianceinlet.

P5

P8

P14

P14

Theunit

cannotseal

thebag,or

thebagis

notsealed

sufficiently.

Makesurethebagis

appropriate.

Makesurethebagisplaced

correctly.

Makesurethefoamgasketisnot

deformed.

Useabagoftheproper

materialorsize.

Placethebagcorrectly.

ReplacethePTFTstrip.

Pleasecontactthestorewhere

youmadethepurchase.

CheckthePTFTstripforwrinkles

orcracks.

Makesuretheadjustmentofthe

sealingfunctionisproper.

Makesuretheoverheating

protectivedeviceisnotactivated.

*Ifactivated,theredandgreen

lightsflashalternately.

P7

Replacetheheatingwire.

Restarttheunit.

Setthesealtime

property.

P14

Makesuretheadjustmentofthe

sealingfunctionisproper. P7

P5

Thesealed

partmelts.

Makesurethebagis

appropriate.

Makesuretherearenoholesin

thePTFTstrip.

Useabagoftheproper

materialorsize.

Setthesealtimeproperty.

ReplacethePTFTstrip.

P5,P7

P8

P14

Theunitdoes

notvacuum,

orairisnot

completely

removed

fromthe

bag.

Makesurethebagisnottoo

largeforthevolumeofcontents.

Makesurethebagisplaced

correctly.

Checkthebottomfoamgasket

forcracks.

Cutorchangethebagtothe

appropriatesize.

Placethebagproperly.

ReplacethePTFTstrip.

Pleasecontactthestore

whereyoumadethepurchase.

CheckthePTFTstripforwrinkles

orcracks.

Makesurethenozzleorthetube

fortheliquidcatchcanisteris

connectedproperly.

Makesurethenozzleortubeis

notclogged.

Makesurethelidoftheliquid

catchcanisterisclosed.

P11,P13

Resetthelidoftheliquid

catchcanister.

Cleantheinsideofthe

nozzleortube.

Reconnecteverytube.

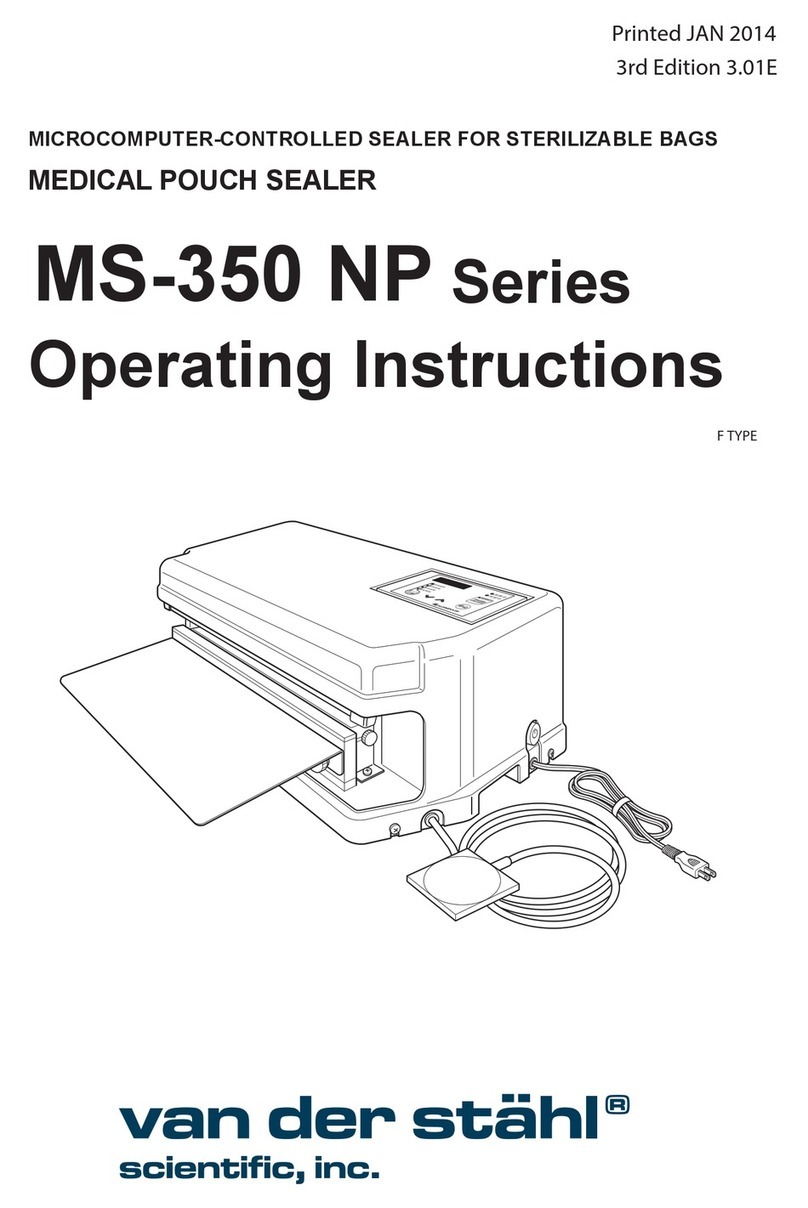

Care

ReplacementofthePTFTStrip ReplacethePTFTstripwhenitisdamagedandcomesoff.

RemovetheoldPTFTstripandinstalla

newone.

ReplacementofHeatingWire

Replacetheheatingwirewhenthesealingweakensorthewireisbroken.

AfterremovingthePTFTstrip,unscrew

theheatingwirefromtheelectrodesand

installanewone.

Tips

Heatingwire

ForsurfaceswherethePTFTstrip

becomessoiledwithoilordust,

cleanthesurfaceandreplacethe

strip.

Becarefulnottowrinklethestrip.

Positionthestripsothatitcovers

theelectrodes.

Setscrewsareplacedonbothsides

ofthestrip.

ReplacePTFTstripunderthe

heatingwire.

Placethestripundertheheating

wiretomakesurethattheheating

wiredoesnottouchtheunit.

Theheatingwireisfixedbythe

electrodes.Asshownintheright

illustration,adjustingtheelectrodes

inwardwithaflatheadscrewdriver

makesreplacementeasierwhen

installing.

Beforeoperatingtheapplianceunplugthepowercordfromtheoutlet.

Warning

Warning

-

-

-

-

-

-

PTFTstrip

Adjusttheterminalsinward

withaflatheadscrewdriver.

Checktheheaterforbreaks.

Whensettinganembossed

bag,besuretoplaceitwith

theembossedsidedown.

Table of contents

Other ASAHI Food Saver manuals