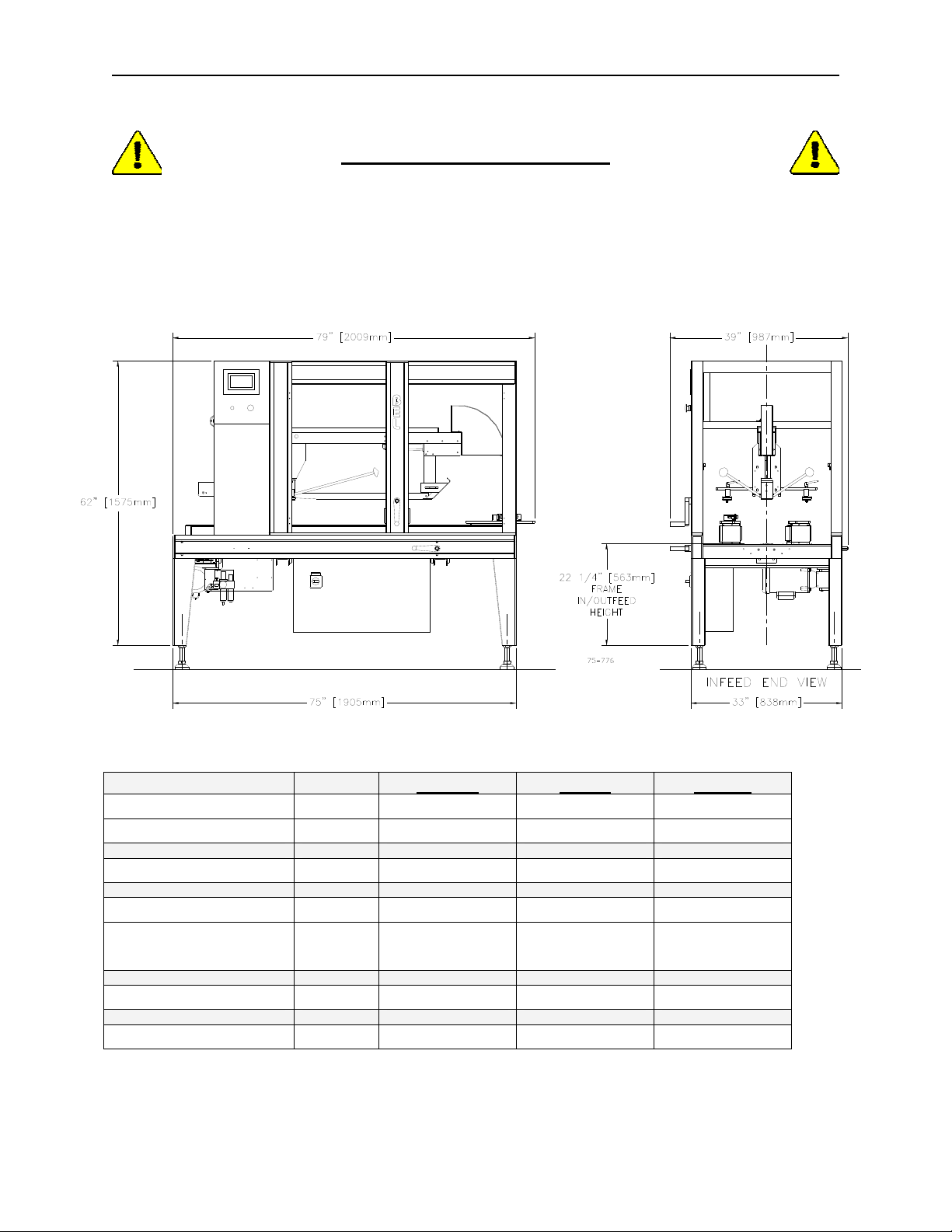

BEL 290 FULLY AUTOMATIC CASE TAPE SEALER 3

TABLE OF CONTENTS

INSTALLING THE BEL 290.....................................................................................................................................4

LEVELING THE MACHINE...........................................................................................................................................4

INSTALLING THE TAPE HEADS ..................................................................................................................................5

POWER CONNECTIONS.............................................................................................................................................5

Electric ................................................................................................................................................................5

Compressed Air.................................................................................................................................................5

MACHINE ADJUSTMENTS......................................................................................................................................6

CASE HEIGHT ADJUSTMENT.....................................................................................................................................7

Case Dimension ‘H’ Adjustment......................................................................................................................7

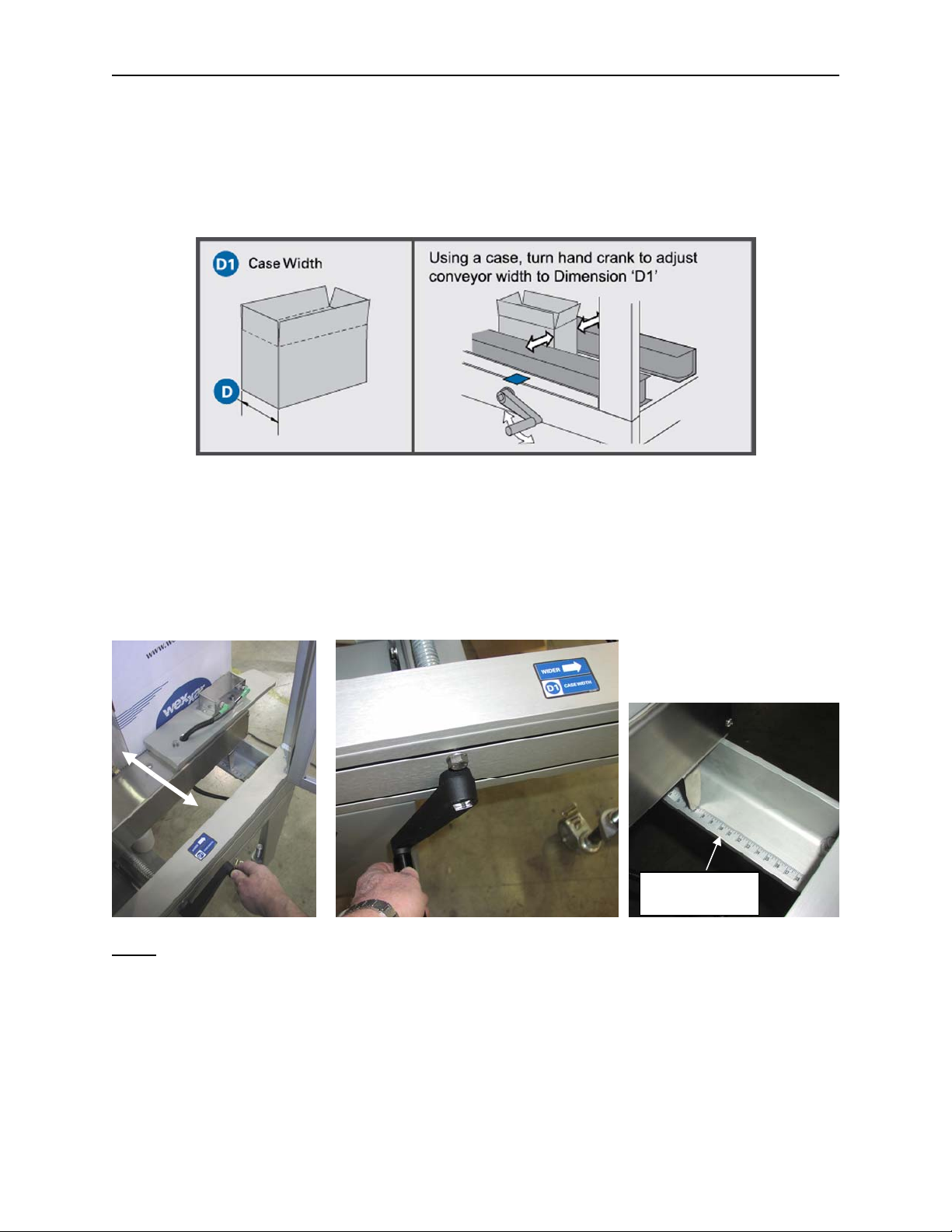

CASE WIDTH ADJUSTMENT ......................................................................................................................................8

Case Dimension ‘D1’ (Conveyor Adjustment)...............................................................................................8

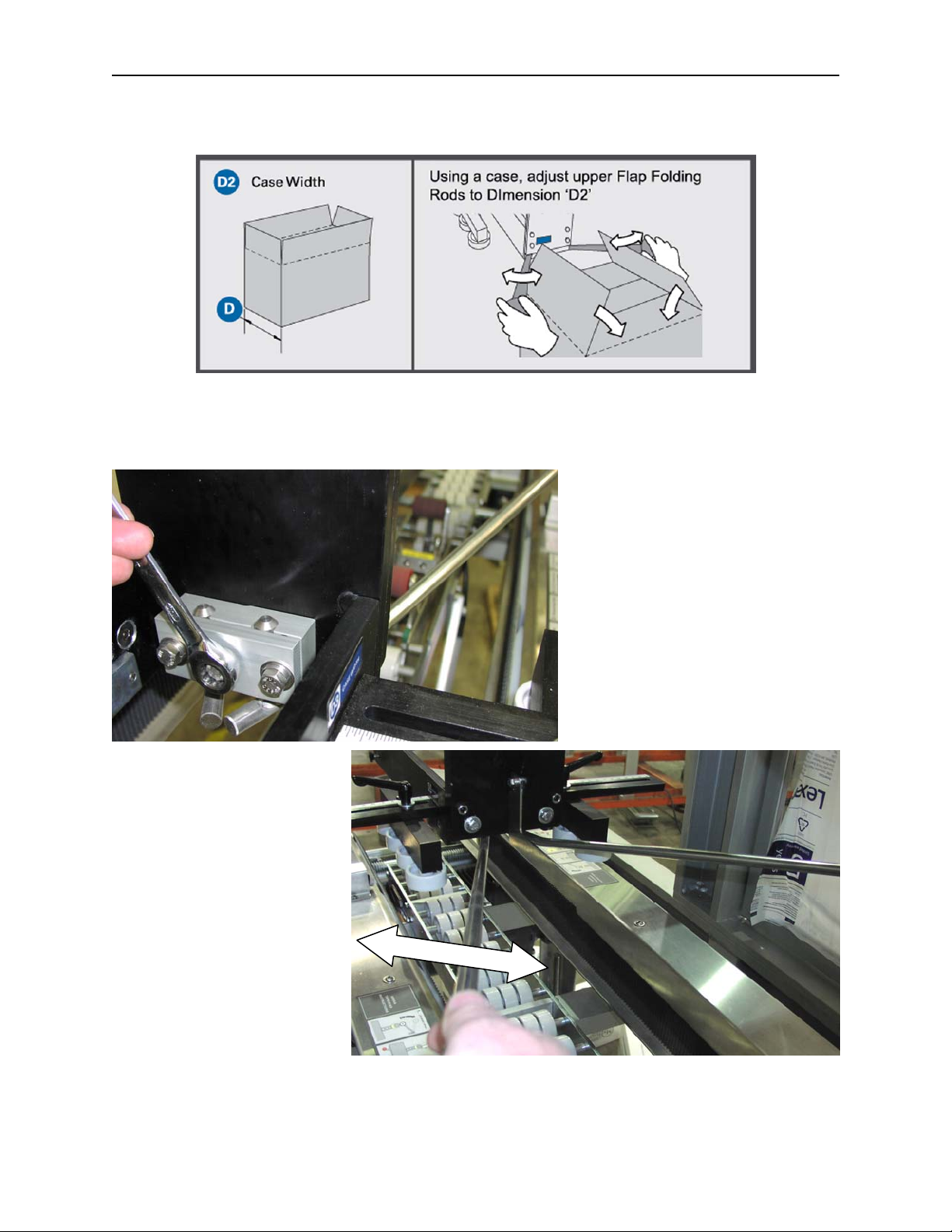

Case Dimension ‘D2’ (Major Flap-folding Rods) ..........................................................................................9

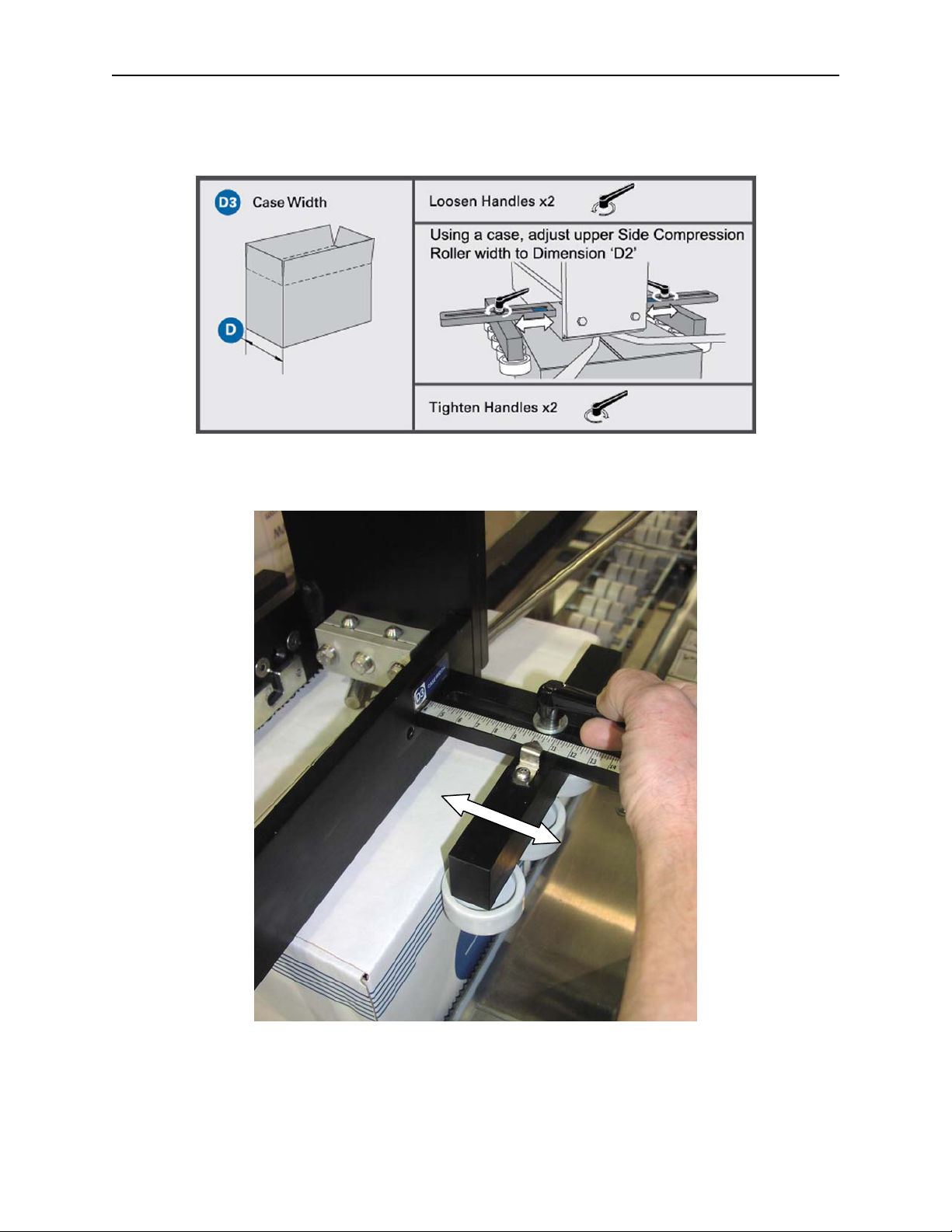

Case Dimension ‘D3’ (Case Side Compression)........................................................................................10

TOP SKI FLAP WIDTH ADJUSTMENT ‘G’.................................................................................................................11

STARTING THE MACHINE....................................................................................................................................12

COMPRESSED AIR ..................................................................................................................................................12

ELECTRICAL SWITCHING ........................................................................................................................................13

CONTROLS...............................................................................................................................................................14

CONTROLS OVERVIEW ...........................................................................................................................................14

CONTROLS DESCRIPTION.......................................................................................................................................15

FEEDING CASES INTO THE MACHINE.............................................................................................................26

STOP GATE (OPTION).............................................................................................................................................26

SERVICE AND MAINTENANCE PROCEDURES..............................................................................................27

EQUIPMENT SAFETY...............................................................................................................................................27

PREVENTIVE MAINTENANCE...................................................................................................................................28

Weekly Inspection...........................................................................................................................................30

Monthly Inspection..........................................................................................................................................30

SIDE-BELT CONVEYOR SYSTEM.............................................................................................................................31

Chain Drive Tension .......................................................................................................................................32

Gear Reducer...................................................................................................................................................32

Side-belt Replacement...................................................................................................................................33

TROUBLESHOOTING GUIDE...............................................................................................................................36

SECTION 1-CORRUGATED CASE QUALITY &SPECIFICATIONS............................................................................36

SECTION 2-CONVEYOR BELT SYSTEM.................................................................................................................37

SECTION 3-GENERAL TAPING CONDITIONS.........................................................................................................39

SECTION 4-CASE INFEED .....................................................................................................................................40

MACHINE CONTROLS..............................................................................................................................................41

65-35-1 02/26/10