7

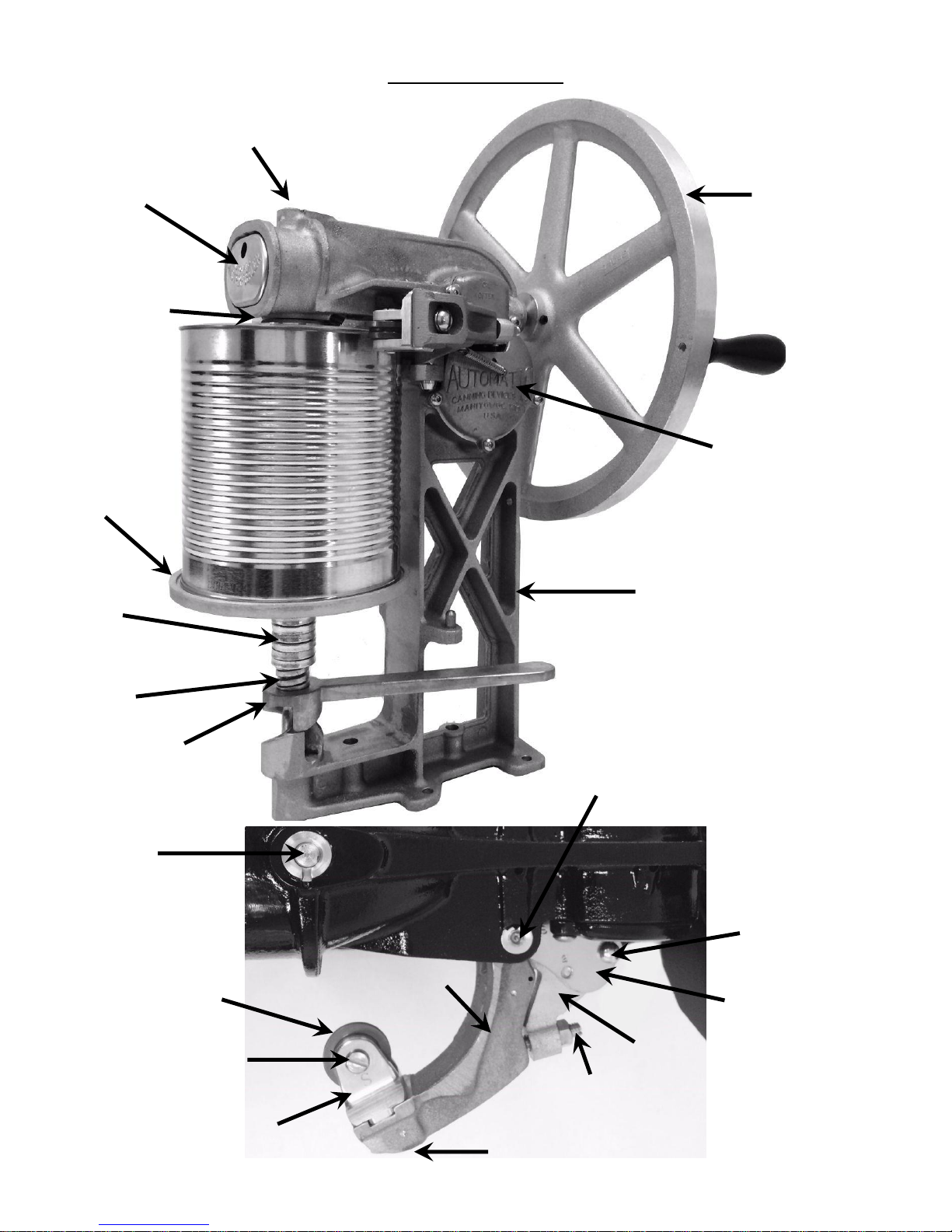

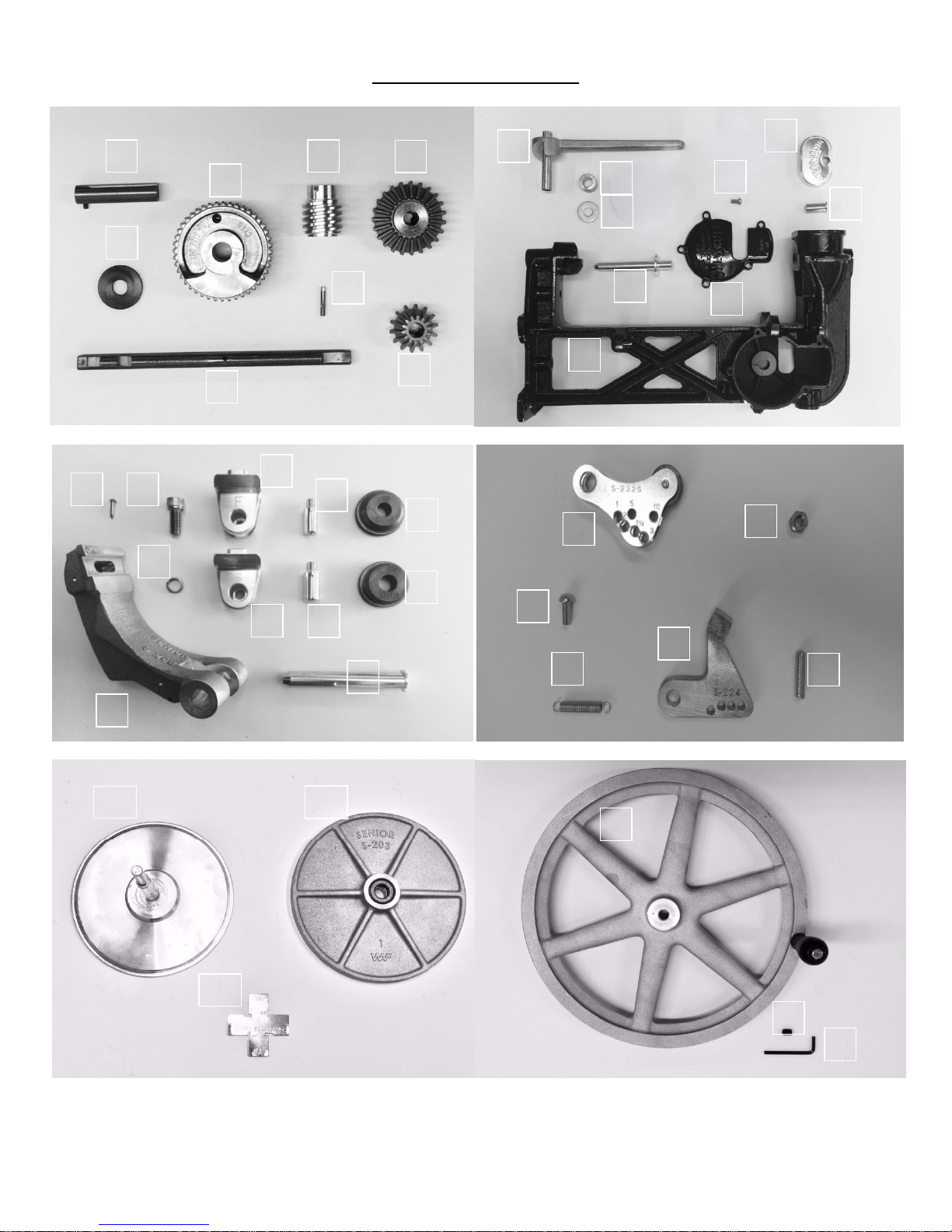

Instructions for Setting & Adjusting Senior Can Sealers

For 202, 208, 300, 301 and 303 Diameter Cans

To set up a Senior Can Sealer for “special” size cans, you will have to take the following steps in order to

achieve a proper seal:

Sealing Cans With a 202 or 208 Diameter:

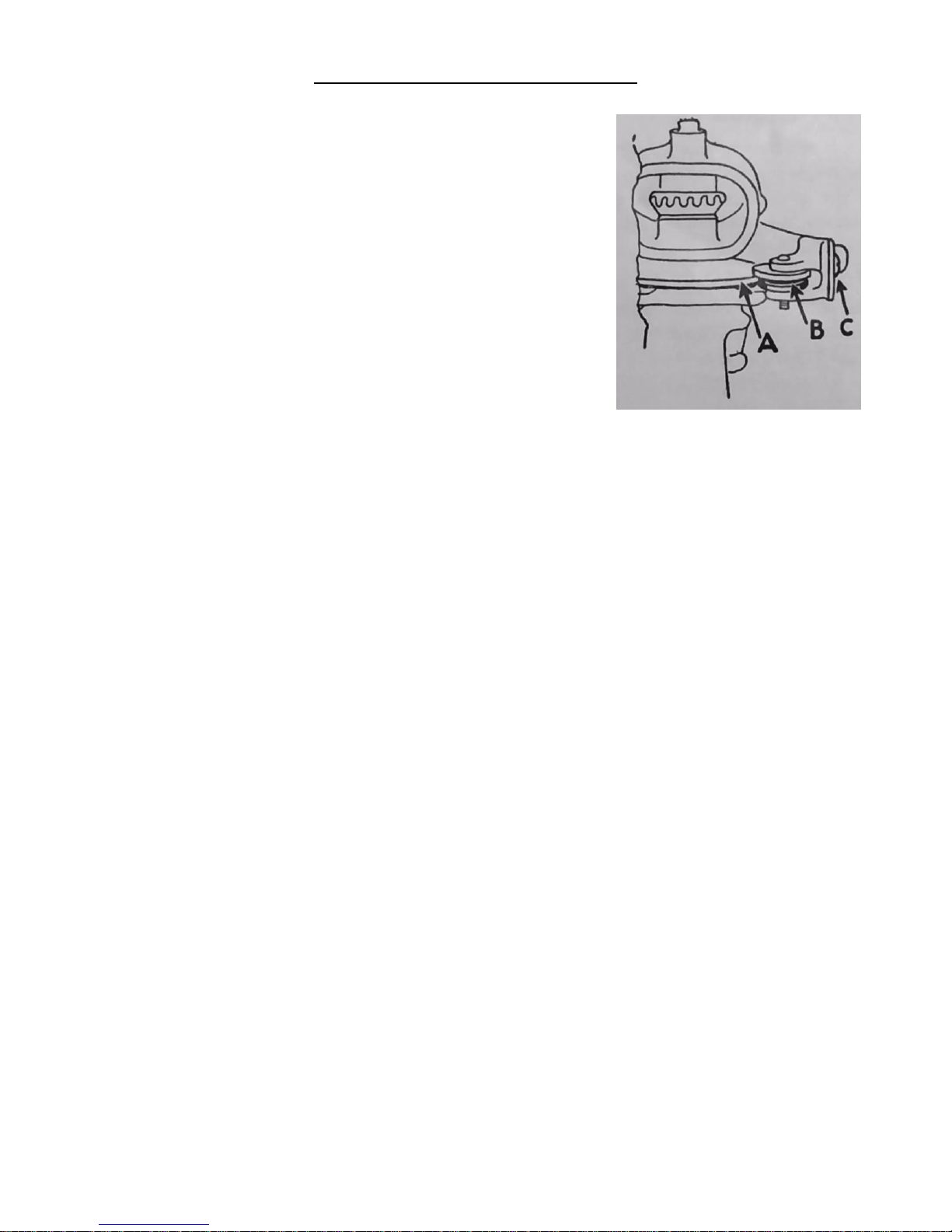

1. Remove both CY-22R Rivets from the S-222 Cam Roller Lever and S-224 Adjusting Levers.

2. Remove existing chuck from sealer and replace with proper chuck for diameter desired.

3. Adjust the height washers so that you obtain proper tension and height of cans to be sealed.

Note: you may have to use a special base plate with grooves machined out in order to fit your

can.

4. Replace CY-22R Rivet in the hole labeled “1” on the S-222 Cam Roller Lever and corresponding

hole on the S-224 Adjusting Lever. Note: Only replace the CY-22R Rivet on the first operation

(the first operation is on the opposite side of the machine when the flywheel of the machine is

at your right).

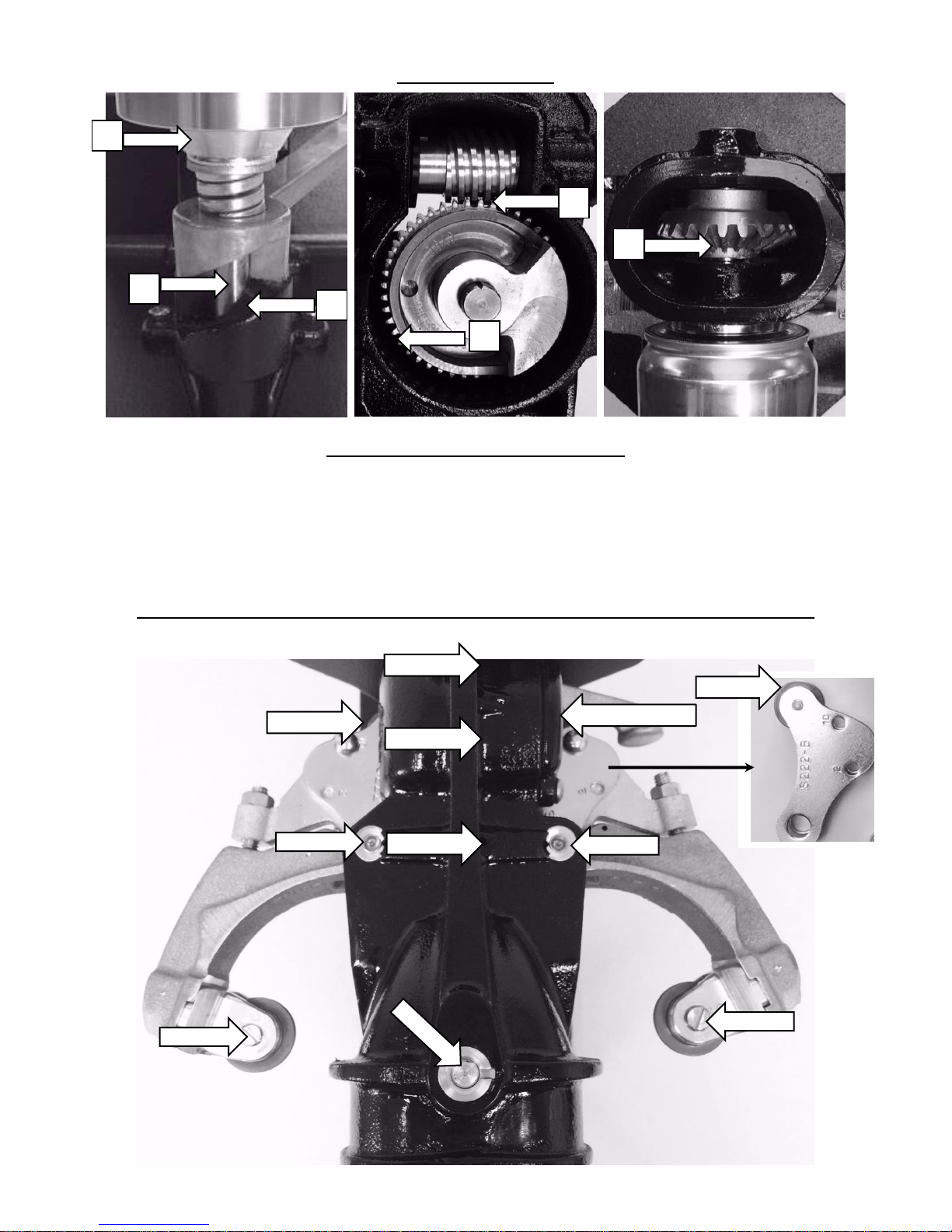

5. With a wrench, loosen the CY-24LN Lock Nut so that you can tighten the tension of the CY-14

Seaming Roller by turning the CY-24AS Adjusting Screw clockwise. We suggest that you

tighten the CY-24AS one-quarter turn at a time until can seam fits into CY-38 Seam Gauge

properly. After this is obtained, tighten CY-24LN Lock Nut again.

6. Remove CY-22R Rivet from first operation and replace rivet in No. “1” hole on second

operation side. Note: The second operation is on the side you are facing.

7. Repeat step “5” until properly adjusted. Then replace CY-22R Rivets in the No. “1” holes on

both sides and can sealer is set up to seal your desired can.

Sealing Cans With a 300, 301 and 303 Diameter:

1. Same as for 202 and 208 cans.

2. Same as for 202 and 208 cans.

3. Same as for 202 and 208 cans.

4. Same as for 202 and 208 cans except that the CY-22R Rivets should be placed in the hole

labeled “2”.

5. Same as for 202 and 208 cans. If you were sealing a 202 or 208 diameter can on this machine

previously, you may have to loosen the tension instead of tighten.

6. Same as for 202 and 208 except that the CY-22R Rivet should be placed in the hole labeled

“2”.

7. Same as for 202 and 208 with the exception as listed in step “5” for sealing 300, 301 and 303

cans.