iii

INDEX

1.1 IMPORTANT SAFETY INFORMATION .......................................................................................................ii

MACHINE INTRODUCTION.......................................................................................................................................4

1.2 INTRODUCTION TO MACHINE & MODELS...............................................................................................4

INSTALLATION..........................................................................................................................................................4

2.1 Transport, handling, unpacking, location................................................................................................4

2.2 Manufacturer’s identification label description......................................................................................5

2.3 Installation and assembly ........................................................................................................................5

2.3.1 UNCRATING .....................................................................................................................................6

2.3.2 INSTALLATION OF LEGS (IF APPLICABLE).........................................................................................6

2.4 Gas Connections ......................................................................................................................................6

2.4.1 MANUAL SHUT OFF VALVE..............................................................................................................7

2.4.2 PRESSURE REGULATOR....................................................................................................................7

2.4.3 THIS APPLIANCE IS EQUIPPED FOR NATURAL GAS..........................................................................7

2.5 Location ...................................................................................................................................................9

2.6 AIR SUPPLY & VENTILATION ....................................................................................................................9

OPERATION........................................................................................................................................................... 10

3.1 General information. ............................................................................................................................ 10

3.2 LIGHTING INSTRUCTIONS ..................................................................................................................... 10

3.3 DAILY SHUT-DOWN............................................................................................................................... 10

MAINTENANCE ..................................................................................................................................................... 11

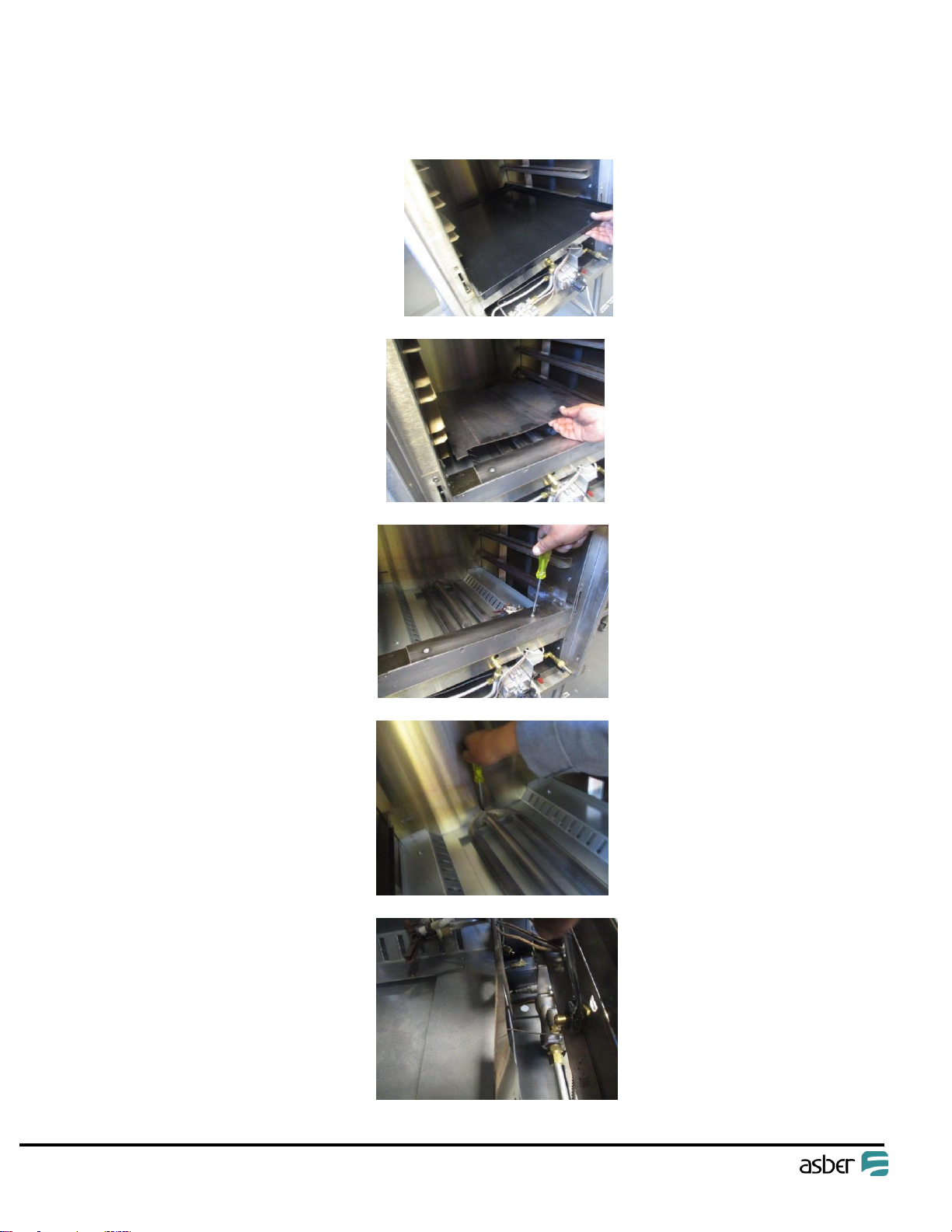

4.1 CLEANING ............................................................................................................................................. 11

4.1.1 DAILY............................................................................................................................................. 11

4.1.2 STAINLESS STEEL PARTS................................................................................................................ 11

TROUBLE SHOOTING ............................................................................................................................................ 13

WARRANTY ........................................................................................................................................................... 14

5.1 Limited Warranty.................................................................................................................................. 14