ASC X-frame 190 User manual

This manual is property of:

ASC Group

Leerlooierstraat 32

4871 EN Etten-Leur

The Netherlands

+31 (0)76 5413 019

Manual

X-frame 1.0

Conform NEN-EN 1004 – IM – NL x EN x DE x FR

X-frame 1.0

All rights reserved. No part of this publication may be reproduced, stored in a database, or transmitted in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior permission of ASC Group.

2

Disclaimer

This documentation has been provided with the utmost care by ASC Group.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission from ASC Group. This publication may only be used

for ASC Group products. Typesetting and printing errors reserved.

Authors: Sanne Knolle and Jasper Engelen

Editors: Sanne Knolle and Carla Stiekema

Translator: Ruud Stiekema

If you have any questions, please contact ASC Group.

Table of contents

1

Overview 3

Application 3

List of components or different types 3

2

Assembly and use 3

Positioning of the Mobile Tower 3

Personal protective equipment 3

Assembly 3

Assembling instructions 4

Use 4

Relocation 4

Chemical products 4

3

Inspection, care and maintenance 5

Annual control 5

Self-inspection 5

Damage 5

What to do in the event of damage 5

Repair 5

Transport 5

Maintenance 5

Storage 5

All rights reserved. No part of this publication may be reproduced, stored in a database, or transmitted in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior permission of ASC Group.

3

1Overview

Application

The X-frame is a hip and knee guardrail that offers optimal security during the assembling of a Mobile

Tower. The X-frame is therefore not intended to be a structural integral part of a Mobile Tower.

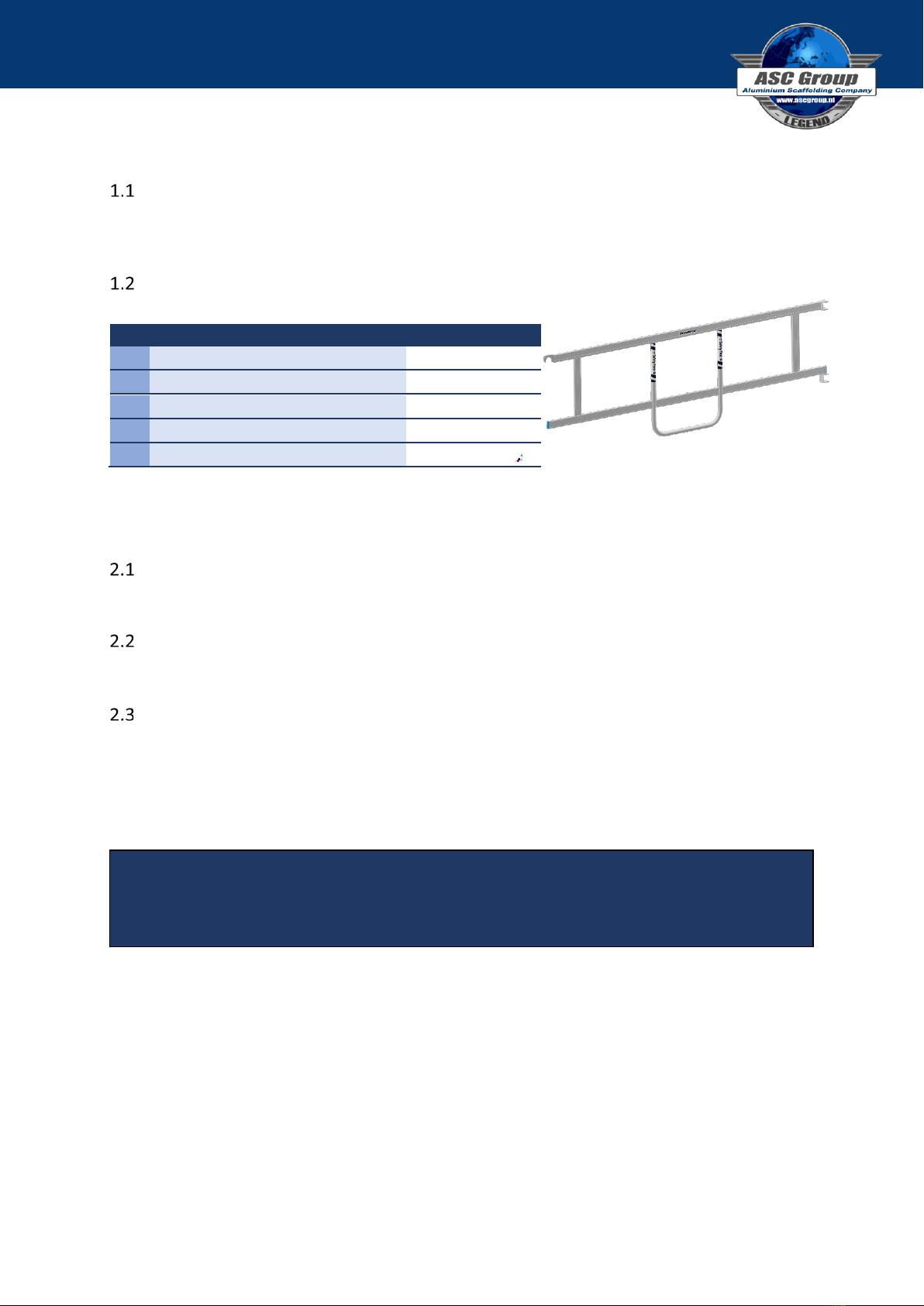

List of components or different types

2Assembly and use

Positioning of the Mobile Tower

Make sure you have the correct length for your product. Consult the product manual for the sizes.

Personal protective equipment

•Always wear work gloves, safety shoes and a safety helmet.

•Use a lifeline when working at heights.

Assembly

Aluminium Mobile Towers may only be erected by people with sufficient, proven experience.

According to the regulations, every rigger must also be in the possession of a valid certificate

"Scaffolding rigger (aluminium)"; this is in accordance with Dutch legislation and regulations.

In the country where you use this material, you must comply with the applicable regulations of that

country.

For checking for damage: see section 3.1.

There are no tools required for assembling a Mobile Tower. Use a drilling machine and a

spanner set when the Mobile Tower has to be anchored at the wall. For Mobile Towers from five

meters onwards, it can be useful to use a rope (with or without an accessory) to lift the

components.

Mobile Towers are not designed to be hoisted.

Nr.

Component

Number

1

X-frame 190

X190

2

X-frame 250

X250

3

X-frame 305

X305

4

X-frame 400

X400

Check all components ( use the list of components) that are required for

assembly, are present and undamaged. Damaged components should not be

used.

All rights reserved. No part of this publication may be reproduced, stored in a database, or transmitted in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior permission of ASC Group.

4

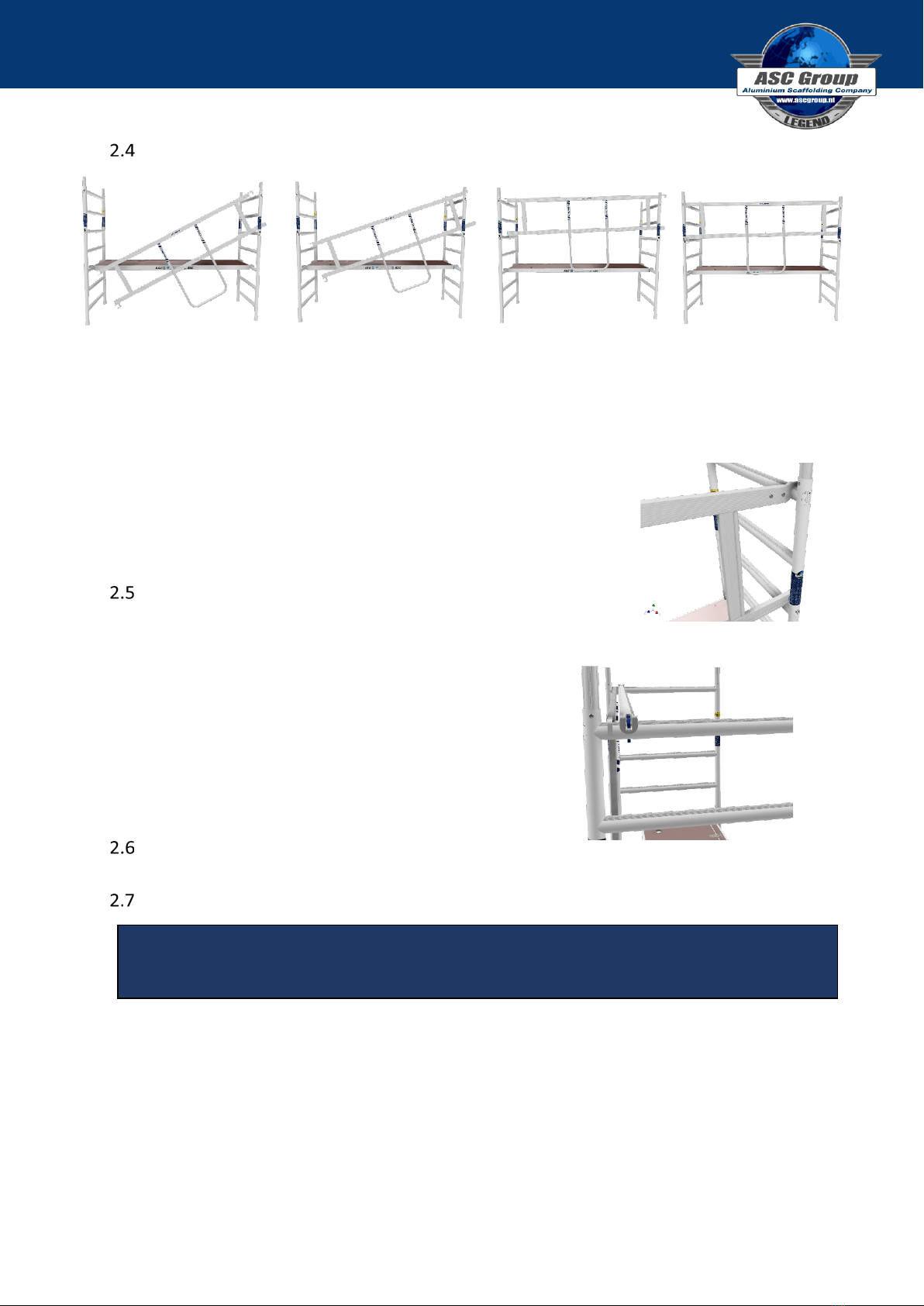

Assembling instructions

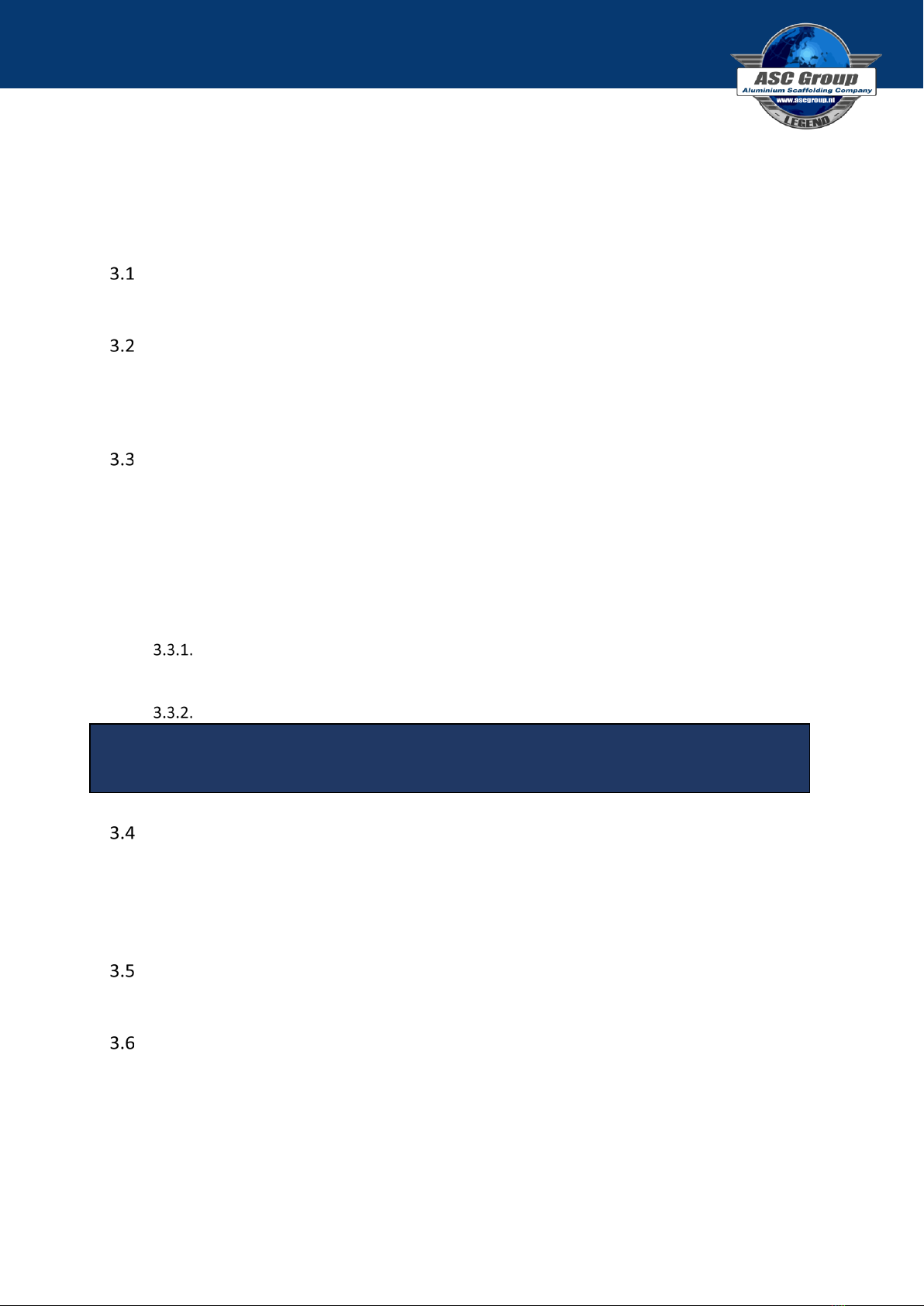

1. Extend the U bracket from the X-frame and secure it.

2. Insert the X-frame through the vertical Mobile Tower frame. Place the lower beam (the side of

the bracket) two rungs higher than where the platform will be or already has been placed.

3. Turn the X-frame until you can properly insert the top beam on the other side of the hook

around the fourth sport above the platform.

4. Put the upper beam around the sport and pull the hook on the other

side up to the sport.

Use

This manual is an addition to manual of the Mobile Towers. Consult

the correct manual for your product.

The X-frame is intended as a construction aid to prevent

falls. The frame is therefore not designed to reinforce

your scaffolding; preferably remove it after building the

scaffolding. The X-frame can possibly remain seated,

provided that this is clamped between a horizontal brace

and two uprights.

Relocation

You must remove the X-frame before moving the Mobile Tower; it can vibrate and fall.

Chemical products

Avoid contact with acids and chemical products. These can cause corrosion to

the aluminium, which can affect the strength of the aluminium

All rights reserved. No part of this publication may be reproduced, stored in a database, or transmitted in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior permission of ASC Group.

5

3Inspection, care and maintenance

According to the regulations one must work safely at heights. On an ASC Mobile Tower, it is not

obligatory to wear extra fall protection (provided that the recommendations in this manual have

been followed).

Annual control

Your ASC Mobile Tower must be inspected for any defects annually by an expert. The ASC Group can

perform this control for you.

Self-inspection

The ASC Mobile Tower can be inspected by yourself. Before each use, always check the components

for any damage (see section 2.5). We certainly recommend larger companies to do a monthly

inspection of all components of the Mobile Towers and to record this inspection. If you are in doubt

about damage, consult an accredited inspector.

Damage

Examples of the most common damages on aluminium Mobile Towers:

Loszittende onderdelen: zit een haak of een sport los, dan is het frame afgekeurd.

•Components: if a claw or a sport is loose, the mobile tower must be rejected.

•Dents and or holes: if there is a big dent in the aluminium or even a crack or hole, the Mobile

Tower must be rejected.

•Contamination: if there is too much concrete, paint or other non-removable contamination

on the components, the Mobile Tower must be rejected; after all, you can no longer judge

whether the components are still intact.

What to do in the event of damage

If there is any damage, which cannot be repaired, the component must be taken out and replaced.

If repairing is possible, please contact ASC Group for further information.

Repair

Transport

•Always transport the components in accordance with the locally applicable legislation.

•Stack the components correctly for transport; never place the heavy components on top.

•Transport the components of a Mobile Tower, preferably standing, f.e in a carrier.

•Handle the material with care. Do not drop components onto a hard surface; this can reduce

the quality of the material.

Maintenance

Ensure that the material is clean, in particular the locking pins. The frames must be assembled and

disassembled easily.

Storage

Store components of the Mobile Tower preferably in a dry, clean, dark and frost-free place.

Repairing a component must be carried out by a certified body or person.

This manual suits for next models

7

Table of contents

Popular Construction Equipment manuals by other brands

Altrad

Altrad Belle RPC 45/60 Honda GX270 Operator's manual

Minnich

Minnich A-3 Operators & service manual

Fayat Group

Fayat Group DYNAPAC CC425 instruction manual

Farmi Forest

Farmi Forest FARMI 4571 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Turbosol

Turbosol GIOTTO Use and maintenance manual

Dynapac

Dynapac CP142 instruction manual