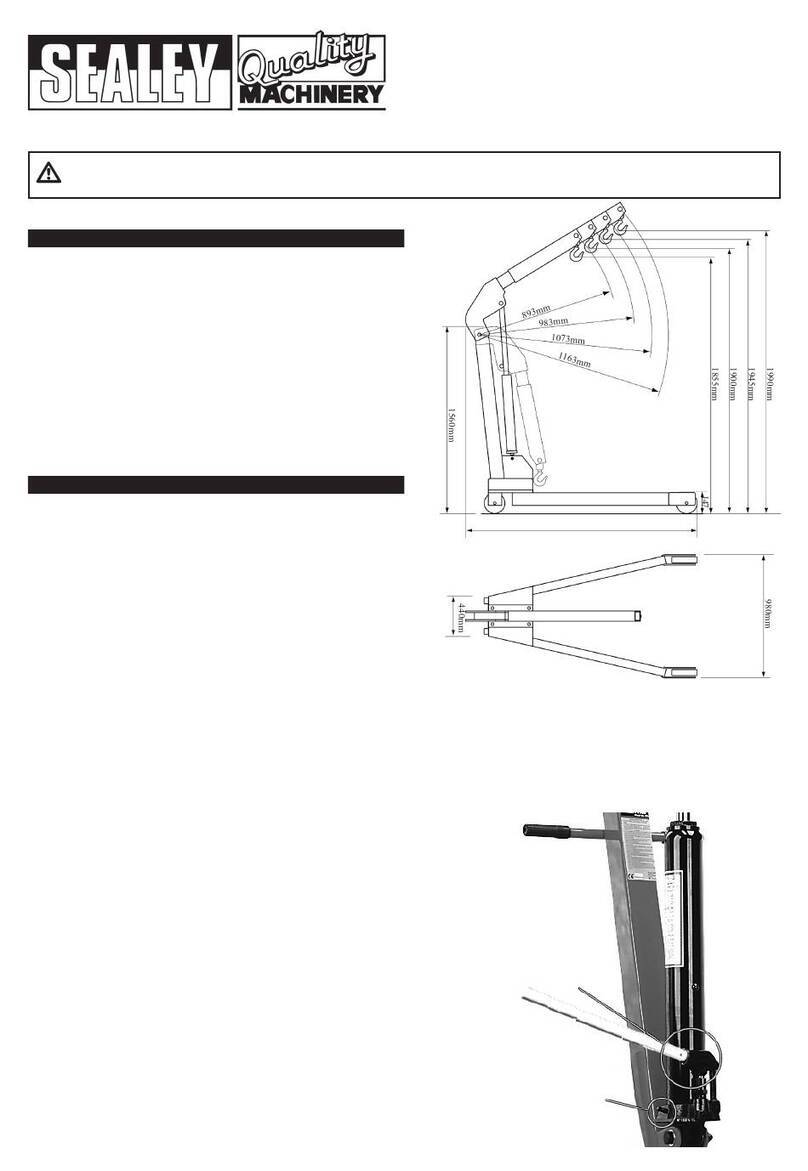

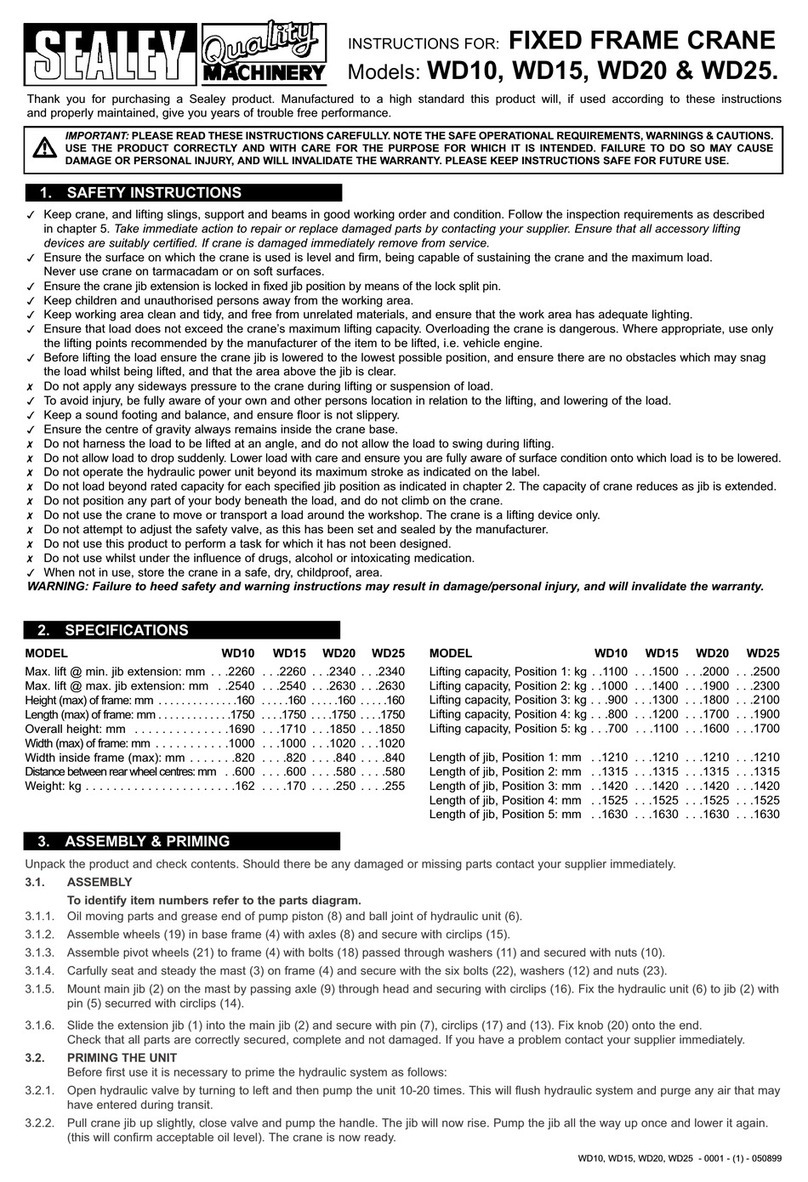

INSTRUCTIONS FOR

PREMIER ENGINE CRANE 1TONNE & 2TONNE

- FOLDING

MODEL NO: PFC101, PFC201

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9Keep crane, lifting slings, support and beams in good working order and condition. Take immediate action to repair or replace damaged

parts by contacting your supplier. Ensure that all accessory lifting devices are suitably certified.

WARNING! If crane is damaged, remove from service immediately.

9Ensure the surface on which the crane is used is level, firm and capable of supporting the weight of the crane with maximum

load - we recommend concrete. Never use the crane on tarmacadam or other soft surfaces.

9Ensure the crane legs and arms are locked in position before use.

9Keep children and unauthorised persons away from the working area.

9Keep working area clean and tidy, free from unrelated materials and ensure that there is adequate lighting.

9Ensure that load does not exceed the maximum lifting capacity of the crane. Overloading the crane is dangerous. Where appropriate, use

only the lifting points recommended by the manufacturer of the item to be lifted, e.g. vehicle engine.

9Before lifting the load ensure that the crane jib is in the lowest practical position, that there are no obstacles which may snag the load

whilst it is being lifted and that the area above the jib is clear.

9To avoid injury, be fully aware of your own and other persons locations in relation to the lifting and lowering, of the load.

9Keep a sound footing and balance, and ensure the floor is not slippery.

9Ensure jib extension is locked in position before lifting.

9Ensure the centre of gravity always remains inside the crane base.

8DO NOT harness the load at an angle or use any attachments not verified as fit for purpose.

8DO NOT allow the load to swing during lifting.

8DO NOT allow the load to drop suddenly. Lower load with care, ensuring that you are fully aware of the condition of the surface onto

which the load is to be placed.

8DO NOT load crane beyond its rated capacity for each specified jib extension position as indicated on the adhesive label. The capacity of

the crane reduces as the jib is extended.

8DO NOT position any part of your body beneath the load.

8DO NOT use the crane to move or transport a load other than for repositioning. The crane is a lifting device only.

8DO NOT apply any sideways pressure to any part of the crane during lifting or when a load is suspended.

8DO NOT attempt to adjust the safety valve, which has been set and sealed by the manufacturer.

8DO NOT use this product to perform a task for which it is not designed.

8DO NOT use whilst under the influence of drugs, alcohol or intoxicating medication.

8DO NOT climb on the crane.

9When not in use fold the crane down and store in a safe, dry, childproof area.

9This crane is designed for lifting within a garage or workshop environment.

WARNING! Failure to heed safety and warning instructions may result in damage and/or personal injury and will invalidate the warranty.

2. INTRODUCTION

Professional 1tonne (2tonne) folding crane with parallel legs for various lifting situations and heavy-duty forged hook. Features dead man’s

control to prevent accidental lowering. Lowers rapidly with no load whilst providing a smooth, controlled lowering under load conditions. Beam

can be set in four positions, with a capacity of 700kg (1250kg) at its full extension of 1300mm (1610mm). Swivel pump aids use where space

is limited. fast folding for easy storage and transportation. Weights 81kg (145kg) and is suitable for workshop use or by the serious motoring

enthusiast.

PFC101,PFC201 | Issue 1 19/08/16

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear protective

gloves

Wear safety

footwear

Wear protective

clothing