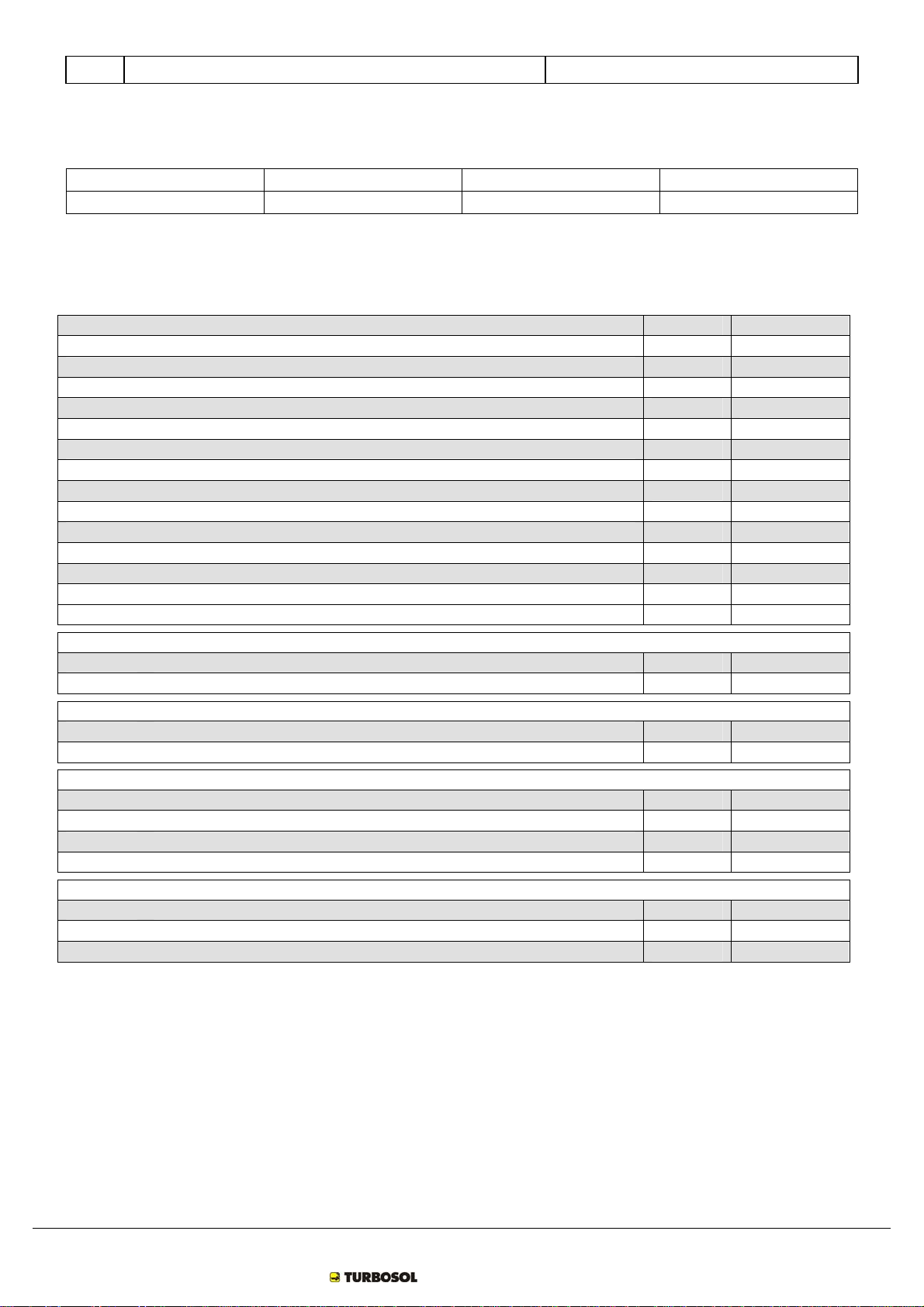

INDEX

THIS MANUAL IS PROPERTY OF - ANY TOTAL OR PARTIAL REPRODUCTION IS STRICTLY FORBIDDEN

1 CE DECLARATION .................................................................................................................................................1

1.1 CE DECLARATION OF CONFORMITY...........................................................................................................1

2 GENERAL INFORMATION......................................................................................................................................1

2.1 IMPORTANCE OF THE MANUAL....................................................................................................................1

2.2 ABBREVIATIONS ............................................................................................................................................1

2.3 INFORMATION FOR CONSULTING THE MANUAL........................................................................................1

2.4 DESCRIPTION OF THE SYMBOLS.................................................................................................................1

2.5 MACHINE OFF.................................................................................................................................................2

2.6 GENERAL AND CONTACT INFORMATION....................................................................................................2

3 TECHNICAL DESCRIPTION...................................................................................................................................1

3.1 NAME OF MACHINE........................................................................................................................................1

3.2 DIMENSIONS OF MACHINE...........................................................................................................................2

3.3 TECHNICAL DATA ..........................................................................................................................................2

3.4 INTENDED USES............................................................................................................................................2

3.5 PRODUCTS USED FOR WORKING...............................................................................................................3

3.6 NAME OF THE COMPONENTS ......................................................................................................................4

4 TRANSPORT AND HANDLING...............................................................................................................................1

4.1 TRANSPORT...................................................................................................................................................1

4.2 LIFTING ...........................................................................................................................................................1

5 INSTALLATION.......................................................................................................................................................1

5.1 POSITIONING THE MACHINE ........................................................................................................................1

5.2 PIPING.............................................................................................................................................................2

5.3 FITTINGS.........................................................................................................................................................2

5.4 CONNECTIONS...............................................................................................................................................3

6 SAFETY...................................................................................................................................................................1

6.1 SAFETY DEVICES USED................................................................................................................................1

6.2 SAFETY SIGNS...............................................................................................................................................1

6.3 INDIVIDUAL PROTECTION DEVICES............................................................................................................2

6.4 RESIDUAL RISKS............................................................................................................................................3

6.5 SAFETY RECOMMENDATIONS .....................................................................................................................3

7 USE AND OPERATION...........................................................................................................................................1

7.1 OPERATING PRINCIPLE ................................................................................................................................1

7.2 PUMPABLE MATERIALS.................................................................................................................................1

7.3 CHECKS BEFORE START-UP........................................................................................................................2

7.4 CONTROLS .....................................................................................................................................................4

7.5 STARTING THE MACHINE..............................................................................................................................5

7.6 CLEANING AND THE END OF A WORK SESSION.......................................................................................7

7.7 REPLACING THE PUMPING UNIT................................................................................................................10