ASCOM NUDL Series Assembly instructions

P/N PM000199A • Rev. 3 • ISS 25APR2018 1 of 5

© 2018 Ascom, Inc.

NUDL-Series Dome Light Installation Sheet

Models NUDL2S-H and NUDL4S-H

Description

The NUDL-series dome light devices are bright, easy-to-

see visual annunciators that signal call events and provide

power connections for modules attached to a room bus.

The dome lights connect to the hallway bus. The series

includes the NUDL2S-H (two-section dome light) and the

NUDL4S-H (four-section dome light). It also includes an

auxiliary I/O connector with two inputs and one relay

output. The relay is only available in the NUDL4S-H model.

Installation

Note: Before beginning the installation, ensure all the

necessary cables are available and are properly

terminated. RJ-45 connectors should be terminated in

accordance with the T568B or EIA 568B connection

standard.

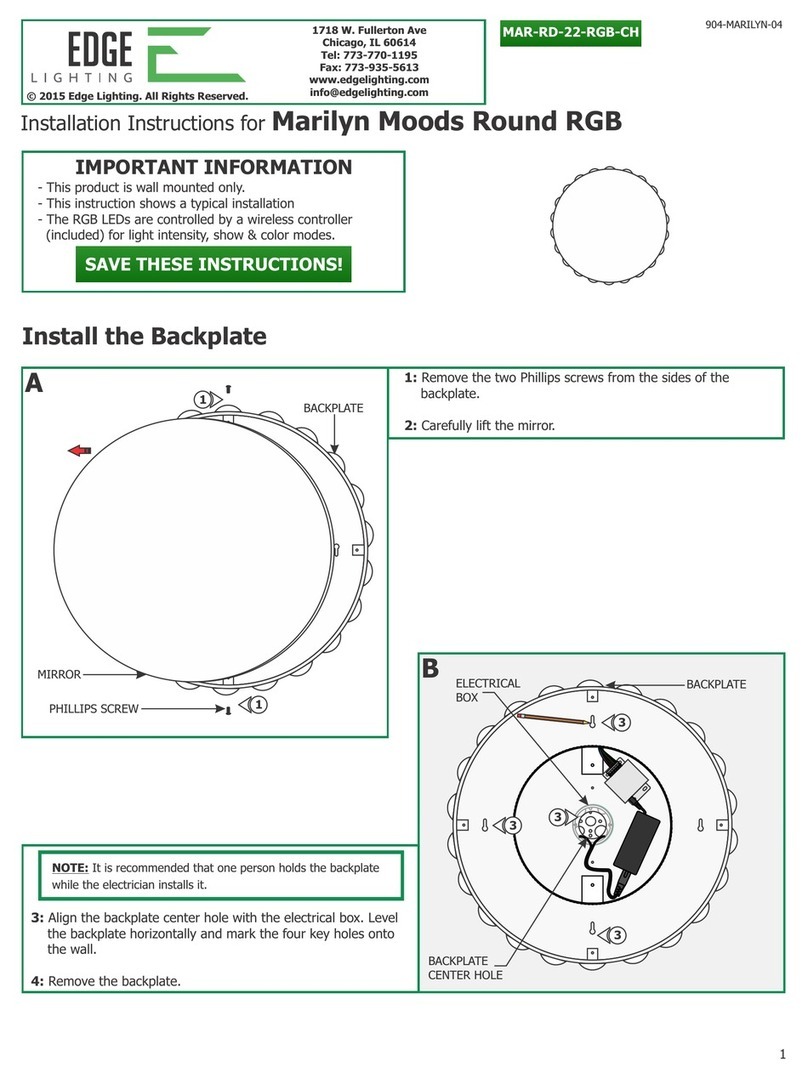

Mounting with Backplate and Spacers

The dome light mounts to a backbox using a backplate

(included) that supports the device. Each backplate

includes an array of holes that allow for mounting on

North American- and EU-style backboxes. In areas where

no backboxes are available, you can use backplate spacers

to mount the devices directly to flat wall surfaces.

Backplate spacers are sold separately.

To mount the backplate on a backbox:

1. Place the backplate over the backbox with the arrow

facing up.

2. For North American-style backboxes, insert the screws

though the backplate and into the backbox.

–or–

For EU-style backboxes, loosen the screws so that

approximately 5mm extend from the backbox so that the

heads of the screws can pass through the keyhole slots.

3. Turn the backplate until its top is level.

4. Tighten the screws until they are snug. Do not over-

tighten.

5. Pull the cables from the backbox through the backplate

hole.

Mounting the Dome Light Without a Backbox

When no backbox is available, you can mount the device

directly to a flat wall surface using four screws suitable for

the wall type. Cable wires should enter and leave the dome

light’s housing through the hole in the center of the

backplate spacer, or through the knockouts in the top and

sides of the backplate spacer. Depending on the number of

wires entering the backplate spacer, you may need to

remove a portion of the cable’s jacket to ensure it will fit

through the knockout and in the backplate spacer.

When choosing a wall location for a dome light, consider

where the connecting cables are located. If the cables are run

inside the wall, locate the dome light over the hole where the

cables exit from the wall. If the cables are run in a channel

outside the wall, locate the dome light below and to the right

or left of the channel, where the cables exit the channel. The

cables should enter the through the knockout holes in the

dome light’s backplate spacer.

Note: Do not distort or twist the backplate when mounting it

to a wall. If the backplate is distorted, the dome light will not

fit properly and may fall off.

2 of 5 P/N PM000199A • Rev. 3 • ISS 25APR2018

Figure 1: Backplate directional arrow and knockouts

Legend

(1) Arrow indicator

(2) Top knockouts

(3) Side knockouts

To remove the knockouts:

1. Locate the knockouts to be removed from the top or sides

of the backplate. See Figure 1, items 2 and 3.

2. Using a cutter or pliers, carefully remove the excess plastic

from the knockouts.

To mount a backplate spacer on a wall:

1. Place the backplate spacer against a flat wall and orient it

so that arrow is pointing up and that the backplate is level.

(See Figure 1, item 1.) Use a leveling device to check, if

necessary.

2. Using the backplate spacer as a template, mark four holes

for the screws using the fitting holes located in the

backplate spacer.

3. Remove the backplate spacer and drill holes for the

screws that will be used, such as wood, concrete, or

drywall screws, or screws with anchors.

4. Place the backplate spacer (with the knockouts

removed) over the holes, insert the screws, and then

tighten.

5. Pull the cables through the knockout holes.

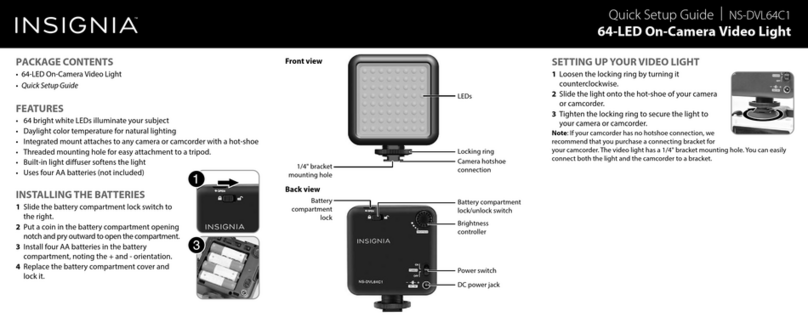

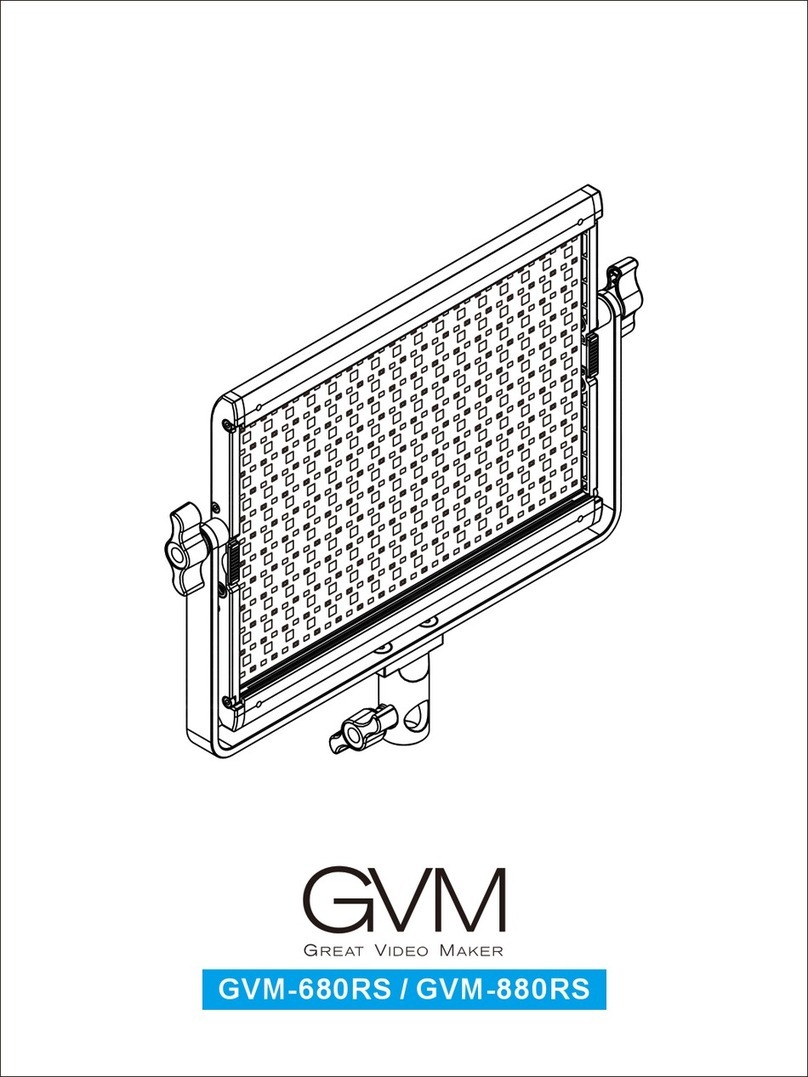

Connections and DIP Switch Settings

Before attaching the dome light to its backplate, make all

wire connections and set the DIP switches. Be sure that

each cable is properly terminated. The figure below shows

the terminating locations for each cable.

Figure 2: NUDL-series dome light connections

Legend

(1) 2x RJ-45 connection to hallway bus

(2) DIP switches for hallway bus addressing

(3) Auxiliary I/O terminal for auxiliary inputs

(4) Buzzer

(5) 36VDC power connection

(6) Status LED

(7) 2x RJ-45 connections to active room buses

Setting the Hallway Bus Address

The dome light connects to an active hallway bus. Hallway

bus addressing can be handled in either of two ways, using

the System Configuration Tool, or using DIP switches. When

setting the address using the System Configuration Tool,

all DIP switches on the device must be set to “0” (OFF).

mp

P/N PM000199A • Rev. 3 • ISS 25APR2018 3 of 5

When using DIP switches for hallway bus addressing, all

attached hallway devices must be addressed using their DIP

switches.

Determine the bus address for your dome light before setting

the DIP switches. If you are unsure of the device’s address,

check with your system designer. The default setting for all

DIP switches is “0” (OFF).

When replacing dome lights that are addressed with DIP

switches, copy the DIP settings to the new device. If the DIP

switches were not used for addressing, be sure all the DIP

switches are in the OFF position on the back of the module.

Next, configure the device using the System Configuration

Tool to activate the replacement unit in the system.

The following figure illustrates the DIP switches found on the

back of a hallway device.

Figure 3: DIP switches on the dome light (default OFF)

The following table shows the DIP switch settings for all

addresses.

Note: DIP switches 1 and 2 are mode switches and must

remain in their default positions (OFF).

Table 1: DIP switch settings for all hallway bus addresses

To set a DIP switch:

1. Set the DIP switches to the address chosen for the dome

light. Use the address table above to determine the

correction positions (ON or OFF) for the DIP switches.

2. Using a small screwdriver, gently slide the switch up for

“ON” or slide it down for “OFF.”

To terminate a 4-pole or 6-pole connector for an auxiliary

I/O cable:

1. Terminate the auxiliary I/O cable with a 4-pole connector,

or a 6-pole connector, as required.

Note: You must use the 4-pole connector (P/N NICT-4AA)

with the NUDL2SH and the 6-pole connector

(P/N NICT-6AA) with the NUDL4S-H. The connectors are

not included.

To connect a dome light:

1. Set the dome light’s DIP switches according to your

installation’s bus addressing scheme. See the Figure 2,

item 2.

Note: If your installation does not require DIP switches,

skip this step and use the Software Configuration Tool.

The DIP switches must remain in their OFF position.

2. If you are connecting an auxiliary I/O to the dome light,

terminate the wires from the auxiliary device to the proper

terminals on the 4- or 6-pole connector; otherwise, skip

this step. Ensure the connector is seated properly on the

terminal pins. See Figure 2, item 3.

3. Insert the RJ-45 connector from the hallway bus (IN) into

the COMM IN jack on the back of the light, and then insert

the RJ-45 connector to the next device on the hallway bus

(OUT) into the COMM OUT jack.

4 of 5 P/N PM000199A • Rev. 3 • ISS 25APR2018

4. Insert the RJ-45 connector from the room bus cable into

an RJ-45 jack on the back of the dome light. If you are

cabling a second room bus, insert the other RJ-45 cable

connector into the open room bus jack. Note that both

room bus jacks share a common data line; however, each

jack can supply a 500mA current (maximum) for the line.

5. Using a 2-pole screw-type block connector (sold

separately), connect the positive wire from the hallway

bus to +36VDC on the dome light’s header pin. Connect

the negative wire to GND.

6. Mount the block connector to the 2-pole terminal on the

NUDL’s power terminal. See Figure 2, item 5.

To mount the dome light to the backplate:

1. Ensure that all cable connections are properly secured to

the jacks and terminals on the back of the dome light.

2. Place the dome light onto the two top fasteners of the

backplate.

3. Press the dome light firmly against the backplate so that

the dome light’s bottom fasteners snap closed on the

backplate.

4. Insert the locking screw into the bottom of the dome

light, and then tighten the screw until it is snug, as

shown below. Do not over tighten.

Removal

Follow the steps below to remove NUDL-series dome lights

from the backplate.

Caution: Failure to follow the proper removal

procedure may result in damage to the dome light.

1. Remove the locking screw from the bottom of the dome

light.

2. Insert a 6mm flat-blade screwdriver into the notch at the

bottom of the dome light, and then apply light upward

pressure.

P/N PM000199A • Rev. 3 • ISS 25APR2018 5 of 5

3. Gently twist the screwdriver to disengage the dome light

latch from the backplate. Do not use excessive force while

twisting.

4. Remove the dome light from the backplate.

LED Status Indicator

The dome light is equipped with a status LED indicator

located at the bottom of the front cover.

Figure 4: Status LED

The following table identifies the LED color, the blinking rate,

and what this indicates.

Table 2: LED colors and blinking rate

Status LED

Color

Blinking Rate What it Indicates

Off None No power

Blue Solid Normal operation

Blue Fast (8 times

per sec.)

Missing connection to

Gateway II (Safe Mode)

Blue Slow (approx.

once per sec.)

Firmware upgrade

Any other color

than blue

Solid (or

alternating

colors)

DIP switches (Factory or

Mode DIP switches are

not set correctly)

Specifications

Wire/terminations Cat 5/5e/6/7 U/UTP with RJ-45

connectors

Note: Cat 6/7 cable may be too stiff

for some back boxes.

Compatible

electrical boxes

(metal or plastic)

North America RACO models (or equivalent)

1-gang: 690, 695

2-gang: 691, 696

Australia Clipsal models (or equivalent)

1-gang: 157, 157/1, 157/1A, 157/1X

2-gang: 157/2

European Union EU box (or equivalent)

Single backbox with mounting holes

60mm (2.36in.)

United Kingdom MK Honeywell models (or equivalent)

1-gang: 861ZIC, 866ZIC, 877ZIC

This manual suits for next models

2

Table of contents

Other ASCOM Lighting Equipment manuals