Phone

Fax

800-587-0045

419-281-1096

1919 Cellar Dr. Ashland, Ohio 44805

www.ashlandconveyor.com 3

Warranty Statement

ACP will replace parts that are damaged during the course of normal operation due to

mechanical defect, excluding normal wear and tear and damage due to storing conveyors

exposed to the outside elements or use of the equipment other than as specied by ACP. The

warranty extends for a period of two years on all mechanical components from the date of

shipment.

This warranty does not cover damage due to accident, misuse, abuse and negligence. It

also does not cover damage due to improper operation or maintenance, or attempted

modication.

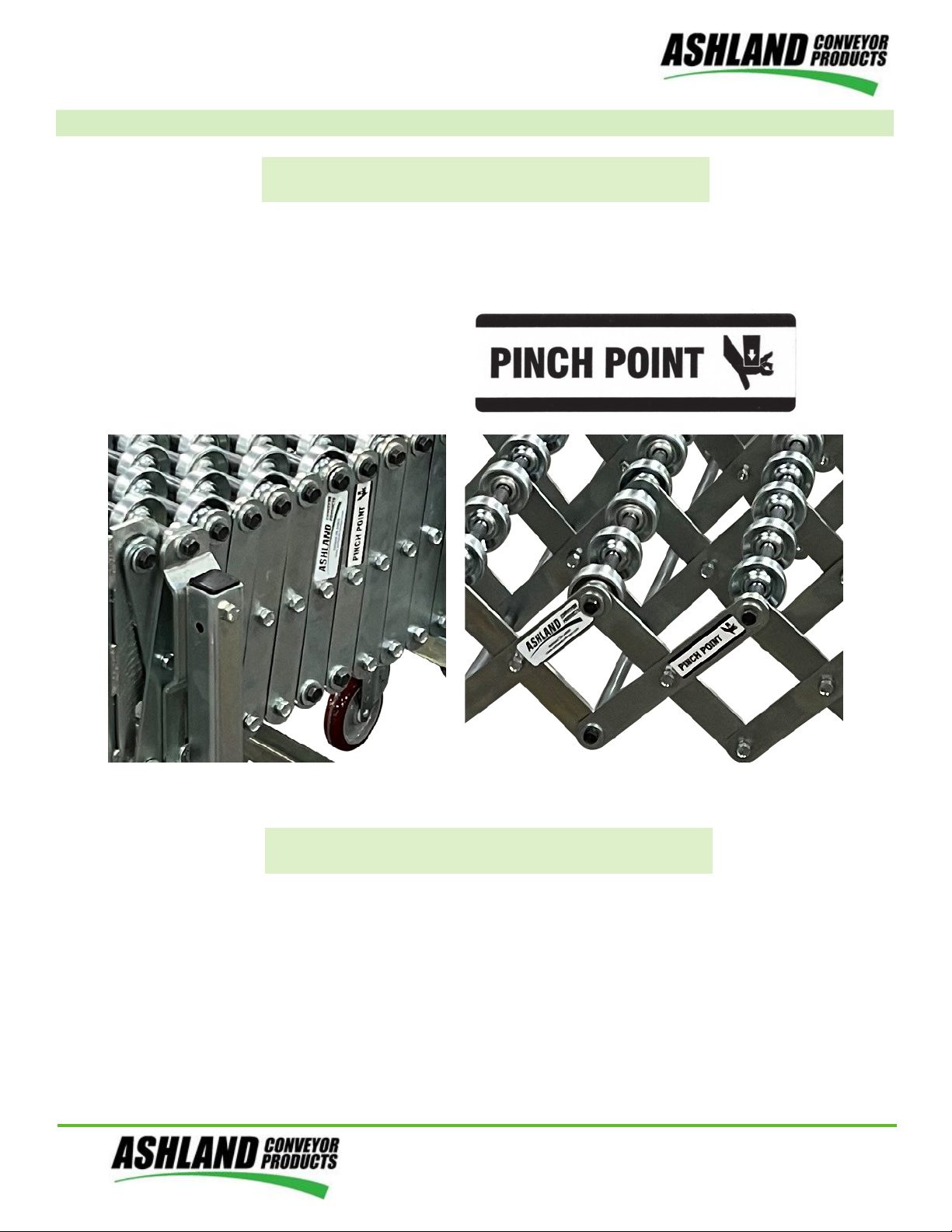

Safety

Operators shall receive training by the employer on proper equipment operation of this

conveyor.

• Do not exceed the conveyor load capacity, as it may result in possible operator injury or

conveyor damage.

• Broken or worn parts must be replaced immediately to ensure the conveyor system

remains in a safe, proper working condition.

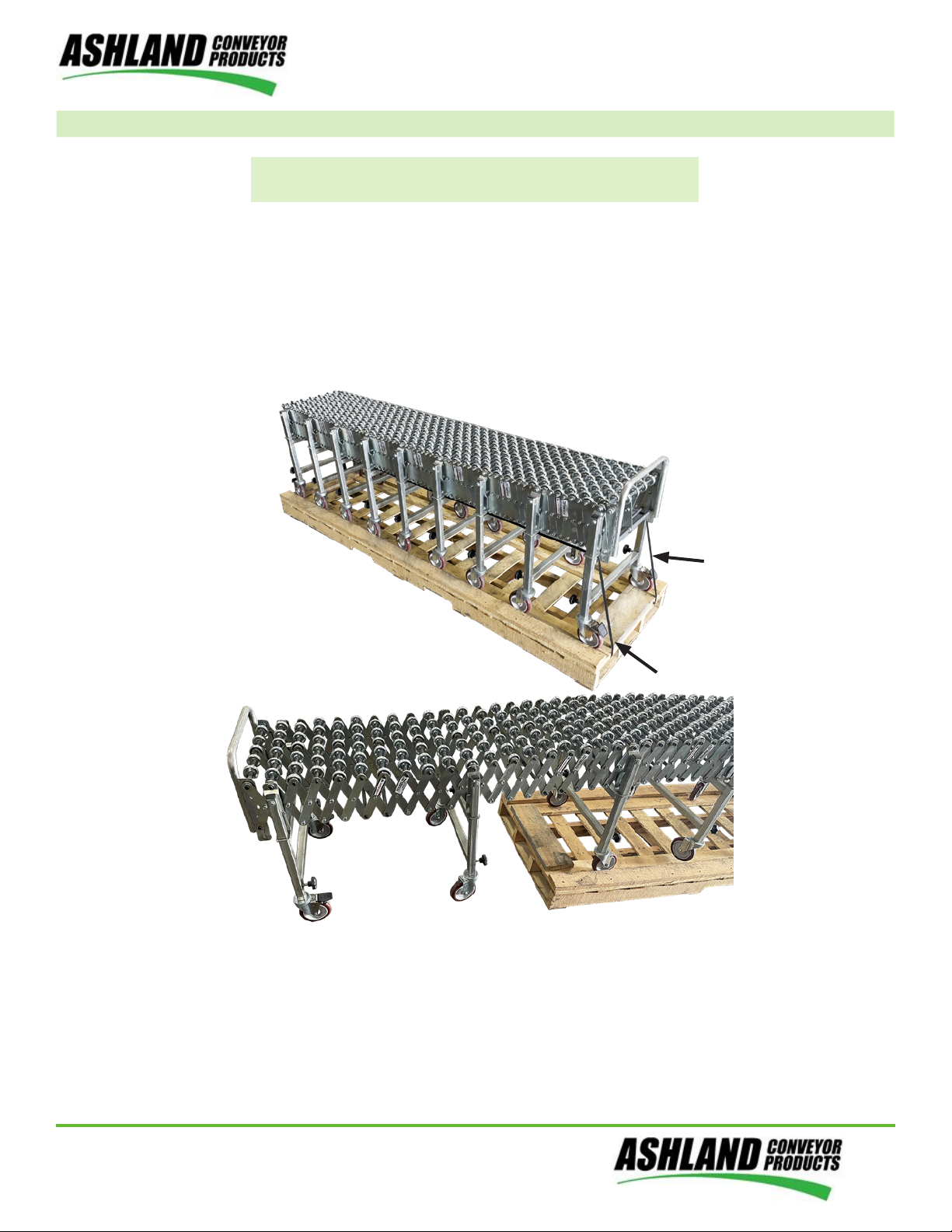

• To extend or contract a conveyor, unlock all locking casters and use the handle on end

carton stop.

• To move a conveyor to a new location, unlock all locking casters and use the handle on the

end carton stop.

• Lock all locking casters to prevent motion during use once conveyor has been positioned

in the desired location.