Page 5 of 10

INSTALLATION

1. Make sure power supply breaker is switched off. Installation must adhere to the regulations of the

current edition of the local wiring code having jurisdiction. Installation should be performed only

by a qualified electrician.

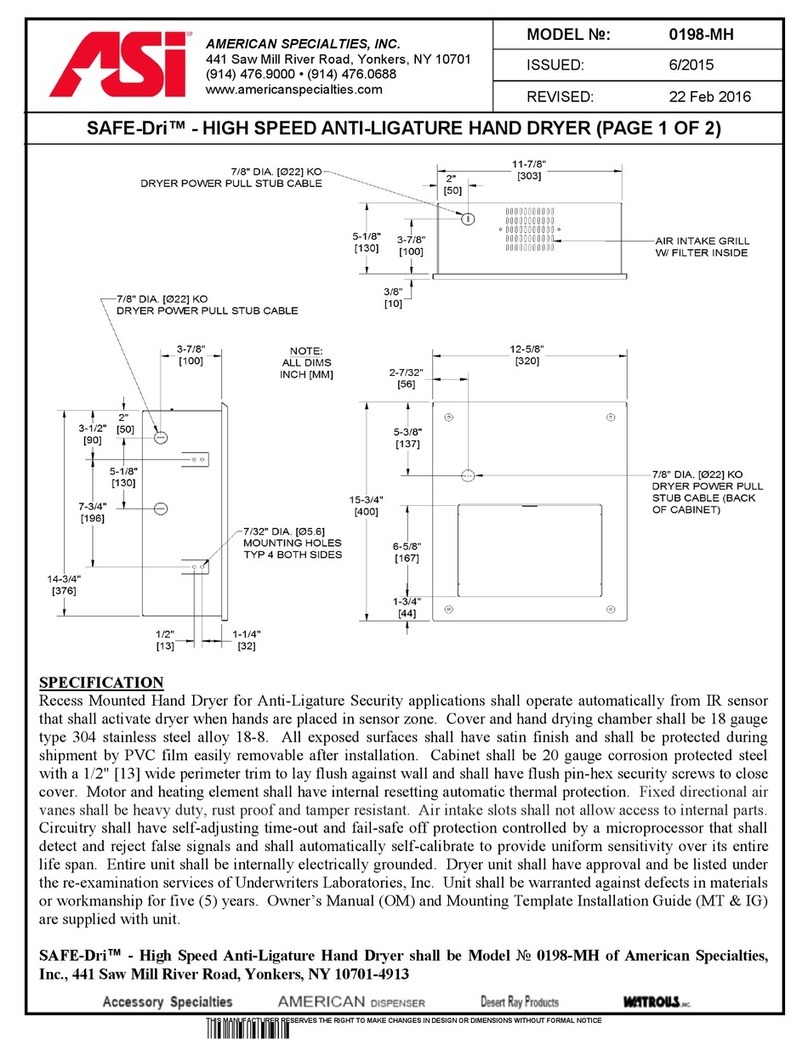

2. Place template against wall at desired height (see mounting height recommendations on MT) and

mark location of four (4) mounting holes and wire service entry at knockout (KO) location if unit is

to be hardwired. Ensure the holes are level and pattern is square.

NOTE: For two (2) or more dryers placed adjacently, units should be no closer than 24" [610]

on centers.

3. Remove and properly discard transport safety screw on rear of dryer chassis.

4. Remove and retain two (2) screws with hex socket on cover sides with hex key provided. Remove

cover and retain in safe place to avoid damage during next steps of installation.

5. Install the dryer chassis on the wall (see OM, pg 6, Fig 4, Step 5):

a. Insert the wall anchors provided so the heads are flush with the wall surface

b. Use the screws and washers provided to attach the chassis and snug up securely.

6. If the unit is to be hard-wired (see OM, pg 4, Fig 3, Step A) to verify the correct location, gage and

length of cable has been provided prior to installation of the dryer. If correct, proceed to prepare

stub cable to attach to terminal block through KO in chassis and under strain relief clamp. See

OM pg 6, Fig 4, Step 6 for illustration. Tighten terminal block screws securely.

a. Connect live wire (color may be Brown, Red or Black) to terminal block at mark “L”

b. Connect neutral wire (color may be Blue or Black) to terminal block at mark “N”

c. Connect ground wire (color may be Green or Yellow) to terminal block at mark “E”

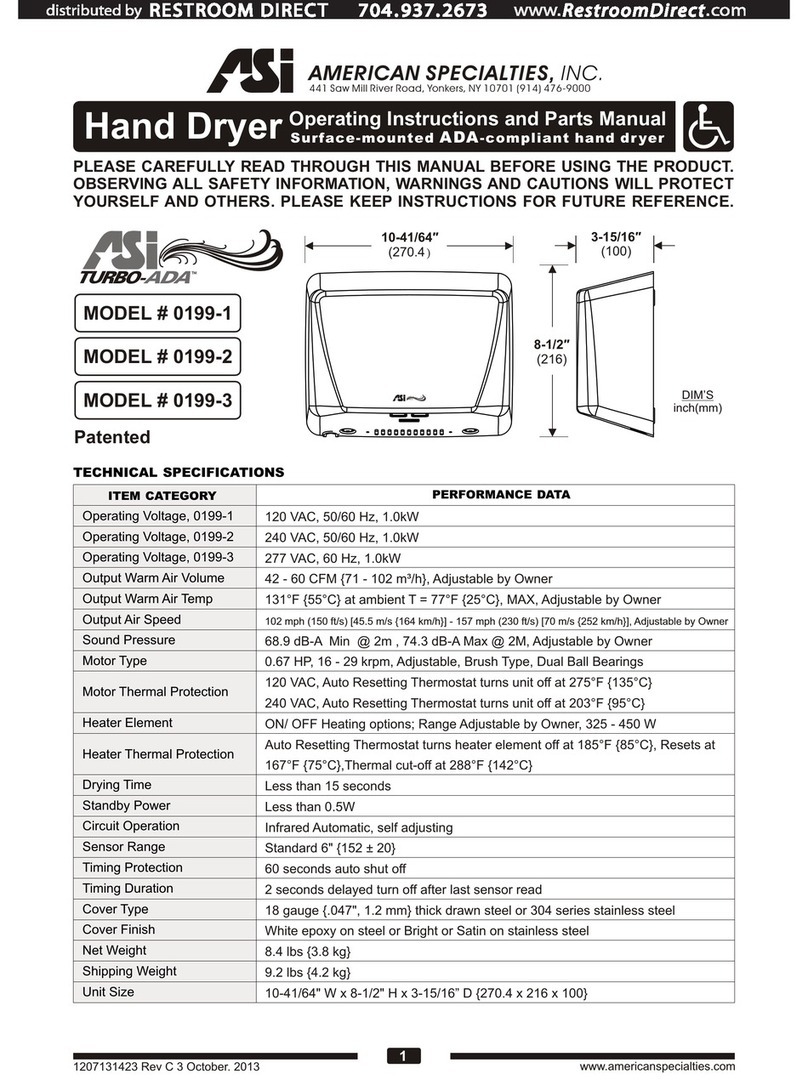

7. Owner may choose to exercise options for heater ON or OFF as per OM Pg 7, Fig 5, Step 7 and Pg

8, Fig 7, Step A.

8. Owner may choose to exercise options for Sensor Range adjustment as per OM Pg 7, Fig 5, Step

8 and Pg 8, Fig 7, Step B.

9. Reinstall the cover (retained in step 4 above) with the saved security hex socket screws and the

hex key provided. Do not over-tighten the screws.

10. If the unit is powered with a short cord to a nearby {suggested within 8" [203] max distance} then

plug it in correctly and reinstate power at circuit breaker. Clean up installation debris; turn OM

and hex key over to Owner.

11. Test unit operation. Walk away happy.