AMERICAN SPECIALTIES, INC.

441 Saw Mill River Road, Yonkers, NY 10701

(914) 476.9000 • (914) 476.0688

www.americanspecialties.com

THIS MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES IN DESIGN OR DIMENSIONS WITHOUT FORMAL NOTICE

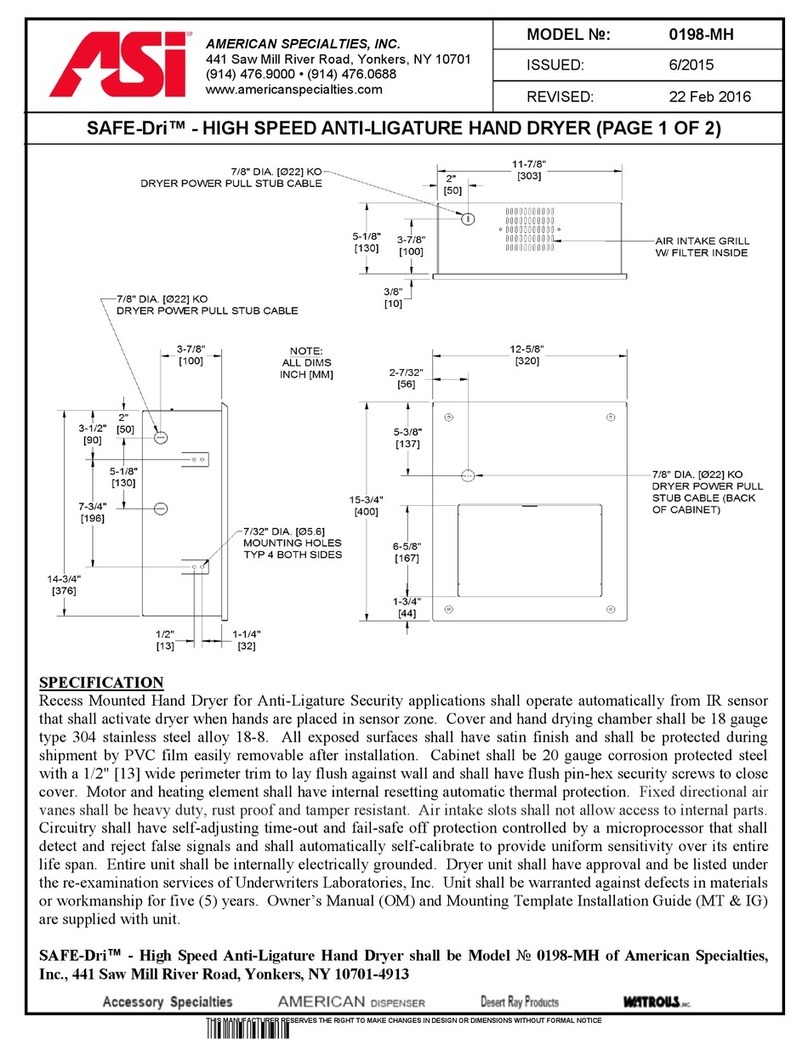

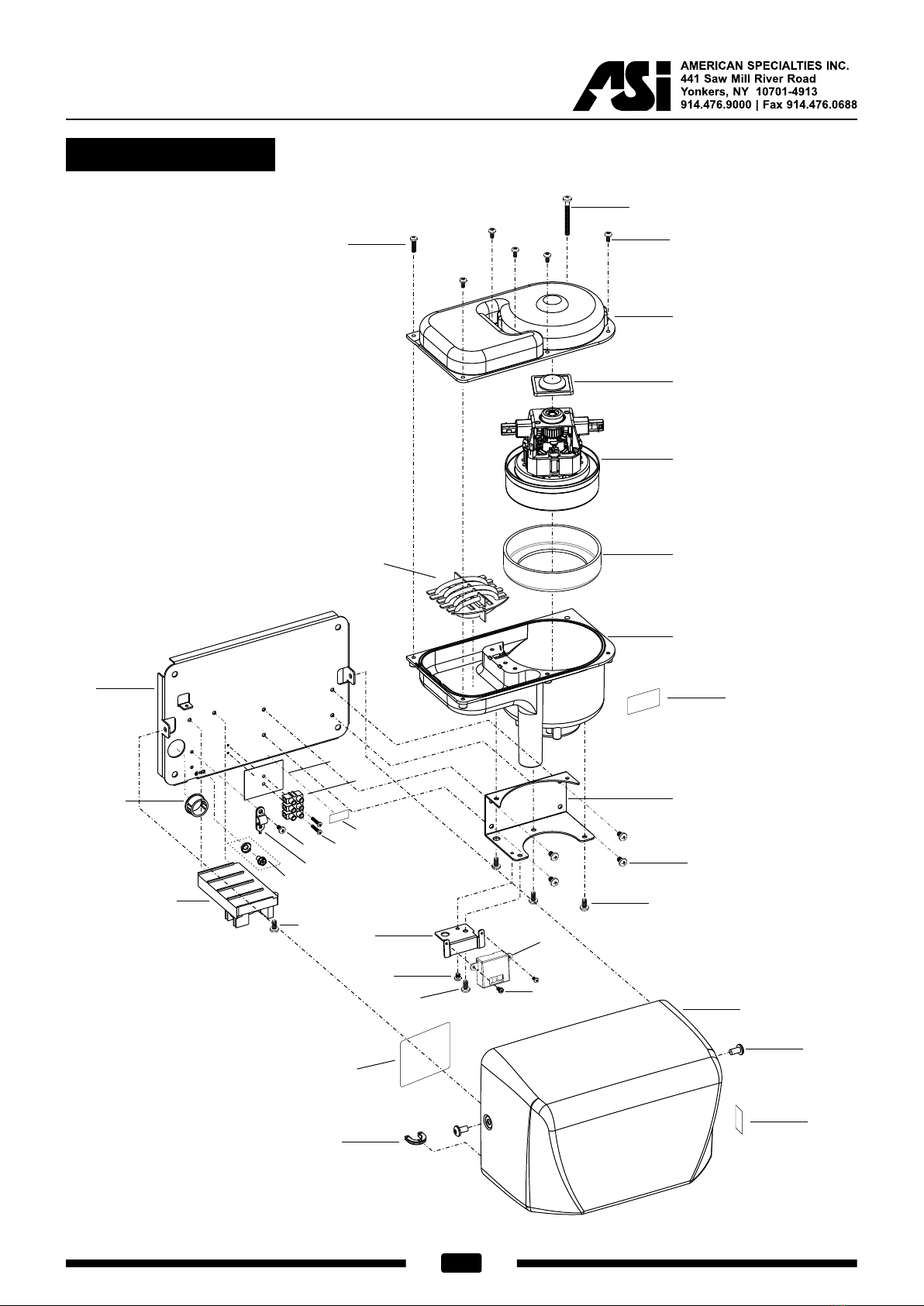

SAFE-Dri™ - HIGH SPEED ANTI-LIGATURE HAND DRYER (PAGE 2 OF 2)

MODEL : 0198-MH

ISSUED: 6/2015

REVISED: 22 Feb 2016

INSTALLATION

Mount unit cabinet in wall recess with four (4) 10 [M5] screws (not supplied) into suitably prepared mountings

(by others) or other suitable mounting hardware (by others) to suit wall conditions. For masonry walls use

expansion bolts or anchors for 1/4" [M6] screws. See unit diagram for electrical service cable rough-in location.

Electric service of 100-240VAC 20A 50/60 Hz (provided by others) is brought to RWO at location for dryer

indicated on diagram above and is hooked up (by others) in accordance with schematic and Owner’s Manual

provided with unit. Electrical service is supplied and connected (by others) prior to installing cover. Cover is

secured to cabinet with four (4) pin-hex socket flat head security screws (supplied). For compliance with ICC/

ANSI A-117.1 and 2010 ADA Accessibility Standards install unit with top of dryer hand chamber 48" [1219]

maximum above finished floor (MAX AFF) if clear floor reach access is provided or 46" [1168] MAX AFF if side

reach access over an obstruction (e.g. vanity) with reach depth greater than 10" [254] and less than 25" [635] is

only provided or 44" [1118] MAX AFF if forward reach over an obstruction (e.g. commode) with reach depth

greater than 20" [508] and less than 25" [635] is only provided. For general utility install unit so that top of dryer

hand chamber is 44" to 50" [1118 to 1270] AFF. Note that top of RWO is 9/32" [7] below top of unit. For

installation of two or more dryers, dryers should be no closer than 24" [610] on center. See OM and Template MT

& IG supplied with unit.

RWO required is 12-1/4" W x 15-3/16" H x 5-1/4" D minimum [311 x 386 x 133]

OPERATION

User activates dryer by placing hands under sensor. Dryer automatically shuts off after time-out when user

removes hands from sensor zone.

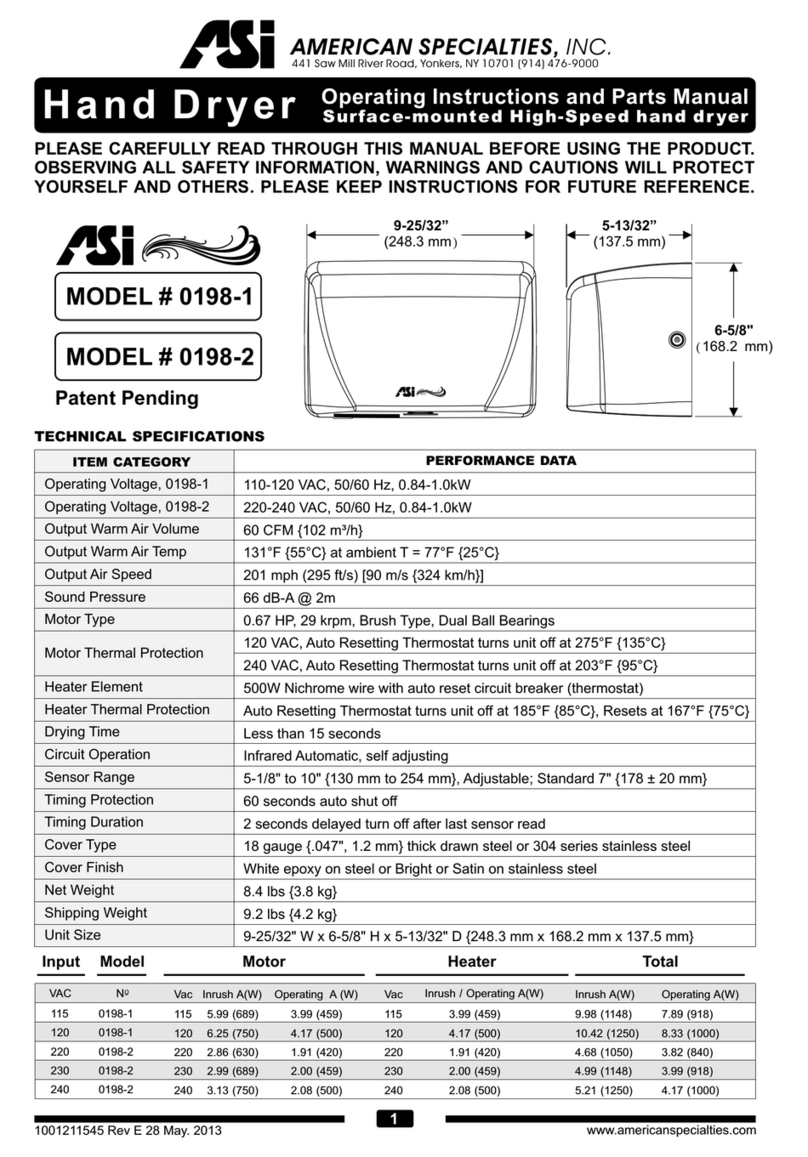

MODEL TYPE TIMING SUPPLY

AC VOLTS HERTZ (HZ)

AMPS

(MAX)

WATTS

X1000 COVER

0198-MH-1

Hand Automatic

115-120 50/60 10.4 0.84-1.0 Satin Finish;

Vertical Grain;

304 Stainless Steel

0198-MH-2208-240 50/60 5.2 0.84-1.0

MOTOR H/P RPM FAN TYPE AIR FLOW HEATING ELEMENT HEAT TEMP.

Brush Type

Dual Ball

Bearings

0.67 29 Multi-Inlet

Centrifugal

60 CFM

[102 m3 /h]

230 ft/s

[70 m/s]

500 Watt with auto reset

circuit breaker

131º F ± 5 @ 77º F

[55º C ± 2.8 @ 25ºC]

Ambient room temperature