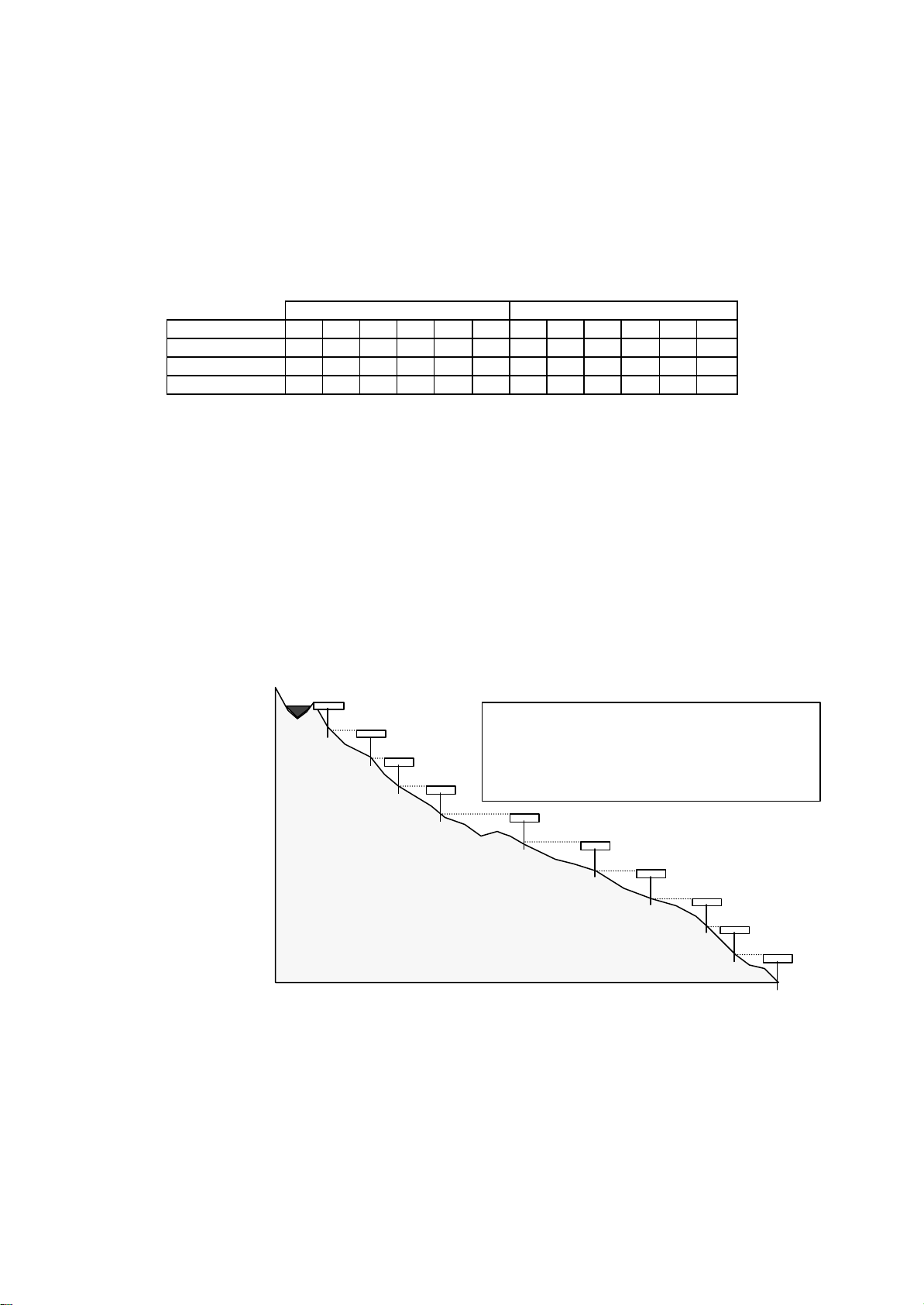

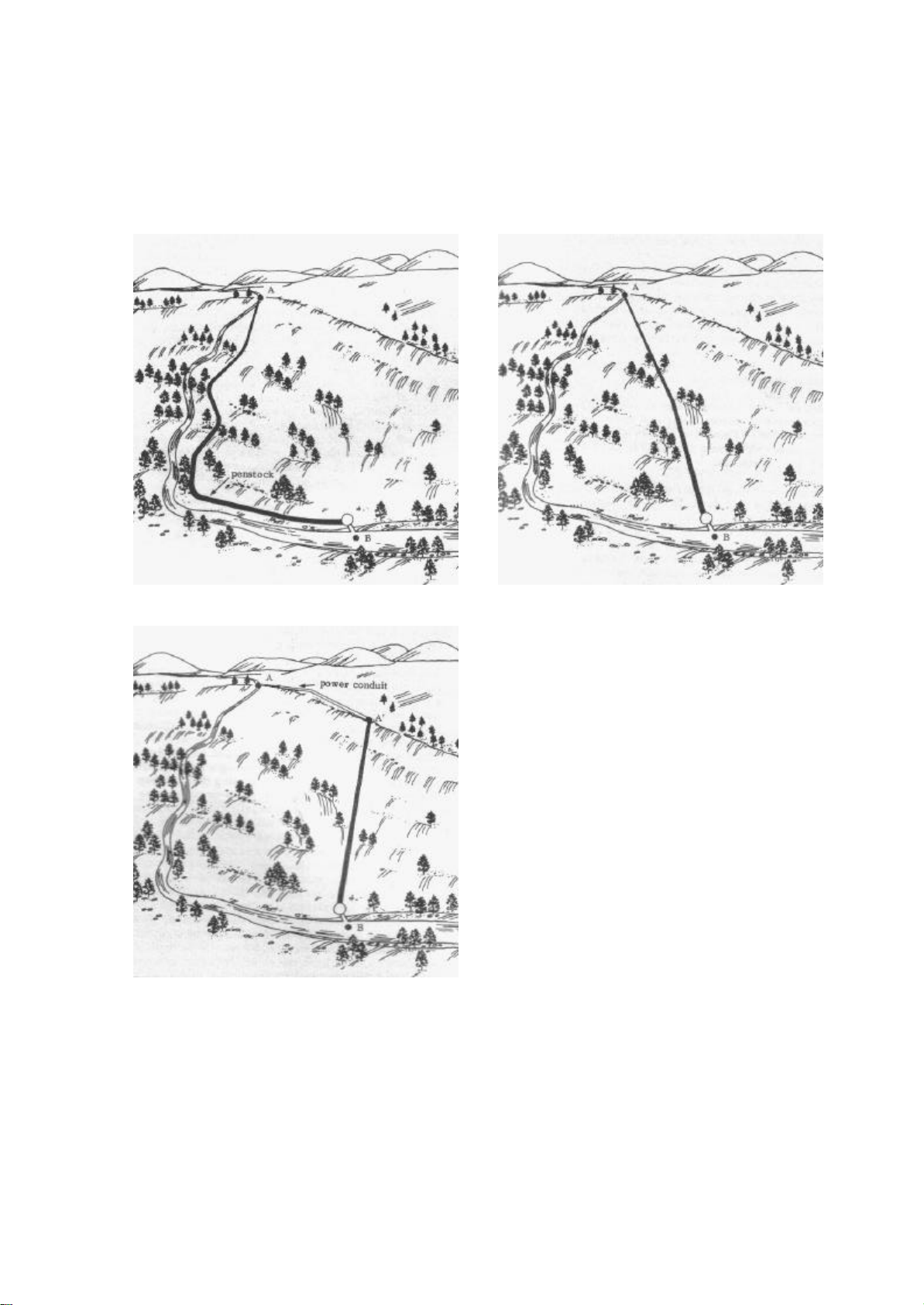

The top of the penstock is typically placed not at the bottom but some way up the

forebay wall so that the bottom of the forebay acts as a sink for rotting leaf litter,

deposited sand and mud etc. This sink may need periodic cleaning out. Another good

idea is to cover the end of the penstock with a piece of wire mesh (debris screen) to

keep leaves etc. from flowing in and clogging the turbine. See Appendix B for the

ideal forebay design.

SYSTEM INSTALLATION

Mechanical Aspects

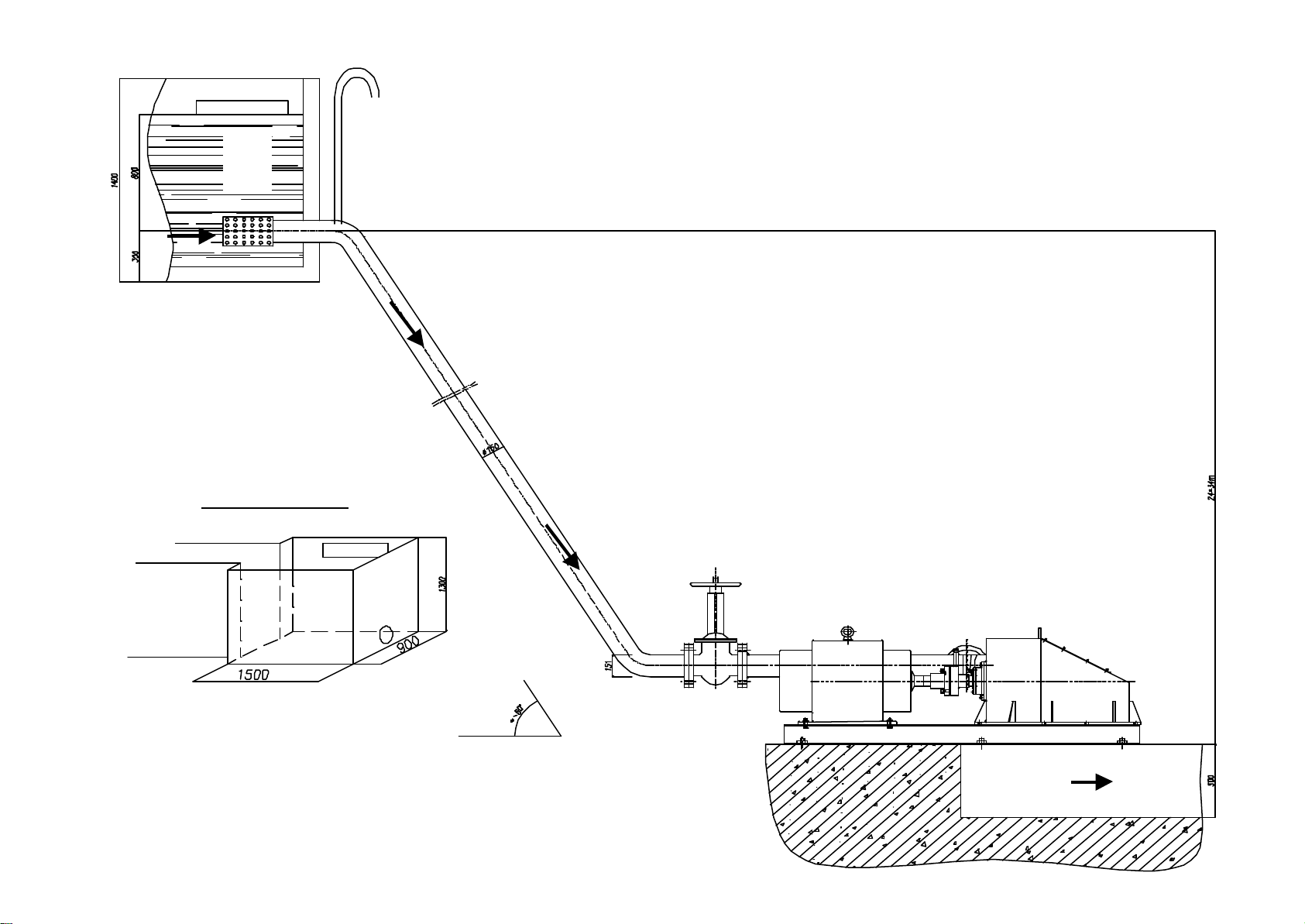

After locating a suitable site and completing the civil works, your PowerPal is ready

for installation. To do this:

1. Bolt the turbine to a turbine stand or base which allows at least 500mm clearance

between the turbine and the ground. This clearance is required to prevent

splashback that will disrupt turbine performance. The turbine stand should be

made from concrete with the six M24 foundation bolts embedded.

2. Attach the gate valve to the nozzle injector pipe followed by a ~120° elbow bend

which will connect to the penstock. The angle will depend on the site slope.

3. Affix a 120° (or other) elbow bend into the forebay wall. This should be fitted

with an atmospheric vent (hollow bent pipe), which allows air to escape from the

penstock. The upper opening of the atmospheric vent should be higher than the

water level in the forebay. Divert water away from the forebay or else block the

top of the penstock pipe during the installation procedure.

4. Start installing the penstock. Assembly can begin from either direction. The

penstock should be well secured i.e. supported or buried at regular intervals to

support its weight when full – this is particularly important at the bottom of the

penstock so that PowerPal cannot be knocked over. Several people may be

required to install the penstock until it is fitted into both elbow bends.

Electrical Aspects

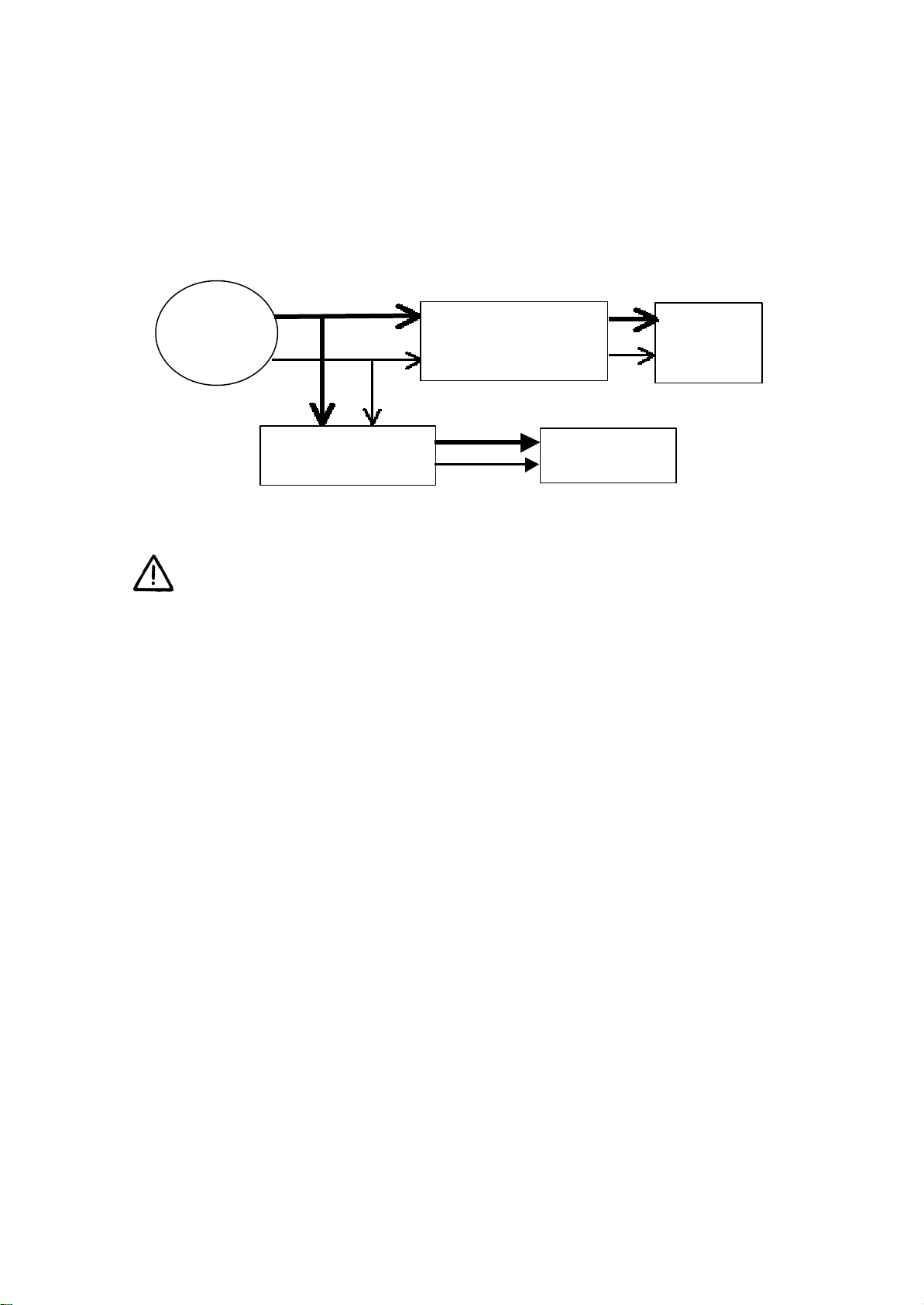

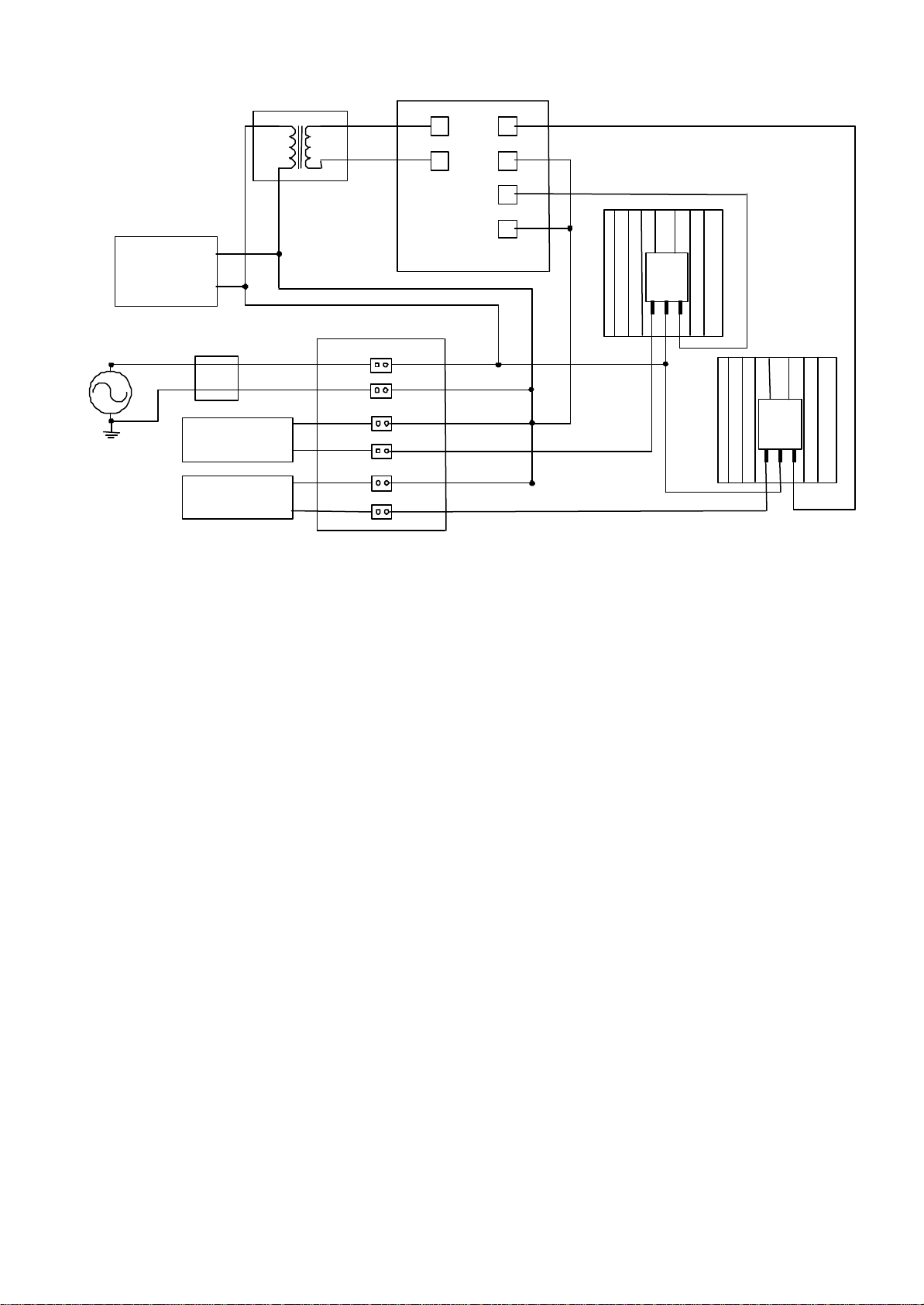

The generator is of permanent magnet, synchronous type. Load is controlled by an

electronic load controller (ELC) which is installed as part of the control box. The ELC

is designed to maintain constant voltage and near-constant frequency by keeping a

constant electric load on the generator. To do this, the ELC switches any power not

being used by the consumer to air-heating ballast loads (supplied) where the surplus

energy is burnt off as heat.

Two ballast loads are supplied, one main and one supplementary. The main ballast

load accounts for 66% of the total while the supplementary ballast load account for

33%. Although optional, the supplementary ballast allows the generator to run at a

lower temperature. The wave form distortion caused by switching off the triac or

thyristors causes the generator to run hot. This can be reduced by having part of the

ballast load switched to zero so that the voltage across the ballast gives a good

PowerPal™T8 & T16 Turgo 8