SCOV SV600 Series User manual

SV880 系列

Users’ Manual

SV600 Series

Ver.1.0

SHENZHEN SCOV ELECTRIC TECHNOLOGIES CO., LTD

SV600 Series User Manual Version: V1.0-01

Foreword

Thank you for purchasing and using SV600 Series frequency inverter.

SV600 series inverter is a general-purpose vector inverter, which is mainly used to control and

adjust the speed of three-phase AC asynchronous motor. It adopts space SVPWM vector control

technology to achieve high torque output at low speed. With good dynamic characteristics and

overload capacity, it can meet the various needs of users.

This series of inverters is suitable for most motor-driven fields, including: textile, papermaking,

packaging, food, fans, water pumps and various automatic production equipment. As a speed

control device, it has strong load adaptability, stable operation and good reliability.

The manual provides users with relevant precautions such as installation and wiring, parameter

setting, operation debugging and daily maintenance. In order to ensure the correct installation

and operation of the inverter, please read this manual carefully before use.

If any difficulties or special requirements during the use, please contact the distributors or our

company directly, we will serve you wholeheartedly.

SV600 Series User Manual Version:V1.0-01

Content

1 Safety information and precautions...............................................................................................................1

1.1 Safety precautions......................................................................................................................................1

1.1.1 Safety precautions before installation..................................................................................1

1.1.2 Safety precautions for transporting and installation ....................................................1

1.1.3 Safety precautions for wiring....................................................................................................2

1.1.4 Safety precautions for debugging and operation ............................................................3

2 Product Introduction.............................................................................................................................................4

2.1 SV600 models introduction ...................................................................................................................4

2.2 Inverter nameplate.....................................................................................................................................4

2.3 Product models list ....................................................................................................................................5

2.4 Product technical specifications..........................................................................................................9

3 Mechanical Installation .....................................................................................................................................12

3.1 Installation ..................................................................................................................................................12

3.1.1 Installation Environment.........................................................................................................12

3.2 Installation direction and space........................................................................................................13

3.2.1 Installation Space.........................................................................................................................13

3.2.2 Installation direction..................................................................................................................15

3.3 Installation Guidance .............................................................................................................................15

3.3.1 Wall-mounted Installation ......................................................................................................16

3.4 Disassembly and installation of keyboard...................................................................................16

3.4.1 Disassembly of the keyboard .................................................................................................16

3.4.2 Installation of the keyboard....................................................................................................16

3.5 SV600 appearance and installation dimensions.......................................................................17

3.6 Keyboard appearance and installation dimensions................................................................21

4 Electrical wiring and precautions ................................................................................................................23

4.1Main circuit electrical wiring ..............................................................................................................23

4.1.1 Arrangement and definition of main circuit terminals..............................................23

4.1.2 Installation size and wire selection of power terminals...........................................26

4.2 Description of control terminals ......................................................................................................28

4.2.1 Connection Function Description of Conversion Terminal .....................................30

4.2.2 Wiring method of frequency inverter electric control circuit ................................32

4.2.3 Wiring description of control signal terminals .............................................................33

4.3 EMC.................................................................................................................................................................34

4.3.1 Definitions of related terms....................................................................................................34

4.3.2 Introduction of EMC standards.............................................................................................35

4.3.3 Installation of EMC input filter on Power supply input.............................................35

4.3.4 Installation of AC input reactor on power supply input ...........................................35

4.3.5 Installation of AC output reactor on frequency inverter output ...........................36

4.3.6 Installation of external DC reactor ......................................................................................36

4.3.7 Shielded cable................................................................................................................................36

Version:V1.0-01 SV600 Series User Manual

5 Operation and keyboard display...................................................................................................................40

5.1 Function and operation of keyboard ..............................................................................................40

5.1.1 Function and name of each part ...........................................................................................40

5.1.2 Description of LED indicators................................................................................................41

5.1.3 Description of function code viewing and modification method .........................41

5.2 Setting and self-learning of motor characteristic parameters ...........................................42

5.2.1 Motor parameters need to be set .........................................................................................42

5.2.2 Self-learning of motor parameters......................................................................................43

6 Parameters List .....................................................................................................................................................44

7 Parameters Description ....................................................................................................................................77

Group P0:Basic Function Parameters ................................................................................................77

Group P1: Motor 1 Parameters

...................................................................................................................84

Group P2: Motor 1 vector control parameters ..................................................................................86

Group P3: V/F Control Parameters

..........................................................................................................89

Group P4: Input Terminals..........................................................................................................................94

Group P5: Output Terminals ...................................................................................................................104

Group P6: Start/Stop Control .................................................................................................................110

Group P7: Keyboard and Display ..........................................................................................................114

Group P8: Auxiliary Functions ...............................................................................................................118

Group F9: Fault and Protection.............................................................................................................. 128

Group PA: PID function

............................................................................................................................... 137

Group Pb: Swing frequency, fixed length and count functions

.................................................. 142

Group PC: Multi-segment instruction, simple PLC functions

..................................................... 144

Group Pd: Communication parameters

...............................................................................................148

Group PP: Function Code Management

............................................................................................... 150

Group A0: Torque Control Parameters

................................................................................................152

Group A1: Virtual IO

..................................................................................................................................... 154

Group A2: Motor 2 Parameters

............................................................................................................... 157

Group A5: Control Optimization Parameters

.................................................................................... 160

Group A6: AI Curve Setting

....................................................................................................................... 163

Group AC: Correction of AI and AO

........................................................................................................ 165

Group U0: Monitor Parameters..............................................................................................................167

8 Maintenance and Fault Diagnosis ............................................................................................................. 172

8.1 Daily and periodic inspection .........................................................................................................172

8.1.1 Wearing parts replacement .................................................................................................172

8.1.2 Inverter storage .........................................................................................................................172

8.2 Warranty Agreement........................................................................................................................... 173

8.3 Faults and Solutions ............................................................................................................................173

8.4 Common faults and solutions.......................................................................................................... 177

Appendix A: Braking............................................................................................................................................ 179

A.1 Selection of braking unit and braking resistor ....................................................................... 179

A.1.1 Selection of braking resistor resistance ........................................................................179

A.1.2 Selection of braking resistor power ................................................................................179

SV600 Series User Manual Version:V1.0-01

A.1.3 Brake Resistance Wiring....................................................................................................... 181

Appendix B: Modbus Communication ........................................................................................................183

B.1 Modbus communication....................................................................................................................183

B.1.1 Support protocol....................................................................................................................... 183

B.1.2 Interface mode........................................................................................................................... 183

B.1.3 Format of protocol ...................................................................................................................183

B.1.4 Modbus Functions.................................................................................................................... 183

B.1.5 CRC16 function.......................................................................................................................... 185

B.2 Function code parameter addressing rules .............................................................................186

B.3 Description of communication parameters for Pd Group................................................. 189

SV600 Series User Manual 1 Safety information and precautions

1

1 Safety information and precautions

1.1 Safety precautions

Users should familiar with the manual and other related technical materials and be sure to

follow the safety precautions required in this chapter when installing, operating, and

maintaining the product. At the same time, you should also know about the mechanical

knowledge, safety information, precaution and so on.

In the manual, safety precautions are classified into <Danger> and <Warning> two categories:

DANGER: Failure to comply with the notice will result in fire, serious injury or even

death.

WARNING: Failure to comply with the notice will result in personal injury or devices and

property damage, even accidents.

Both marks which used in the manual indicate that there is an important content of safety.

Failure to comply with those notices may lead to death, serious injury, damage to the products

and related machines and systems. SCOV will assume no liability or responsibility for any

injury, damage or loss caused by improper operation.

1.1.1 Safety precautions before installation

DANGER

To avoid damage expanding and injury, please don't install the frequency inverter if you find water

seepage, component missing or damaged.

Do not install it if the packing list not conform to the product.

WARNING

Do not touch the components with your hands. Electrostatic may cause damages.

The withstand voltage test has been done before leaving the factory. The users do not need to perform

the test on the inverter again. It may cause damage to the inverter insulation and internal components.

Do not use the product when the rated value in the nameplate is inconsistent with the order

requirements.

1.1.2 Safety precautions for transporting and installation

DANGER

Install the equipment longitudinally on incombustible objects such as metal, and keep it away from

combustible materials. Otherwise it may result in a fire.

Install the equipment in the place that can bear the weight to avoid danger of injury due to falling. Do

not install the equipment in an environment containing explosive gas. It may has danger of explosion.

1 Safety information and precautions SV600 Series User Manual

2

WARNING

Lift and handle the inverter gently when carrying, do not hold the front cover with one hand only. It

may hurt your feet or damage the inverter if it falls off.

Prevent conductive objects such as screws and metal shavings from falling into the inverter during

installation. It may cause the inverter to malfunction or be damaged.

Avoid places with harsh environments such as oil mist, dust suspension, vibration, etc. When

installing in a cabinet, please ensure that the ambient temperature in the cabinet is within the allowed

temperature range of the inverter. Otherwise it may cause the inverter to malfunction or be damaged.

1.1.3 Safety precautions for wiring

DANGER

Do not perform wiring work expect for electrical construction professionals. Otherwise it has risk of

electric shock and fire.

Before wiring the inverter terminals, you must cut off all power connected to the inverter. The waiting

time after the power is cut off is not shorter than the time marked on the inverter. Also ensure the DC voltage

between +1 ~- or +2~- is less than 30V. What's more, the inverter must properly regulate the ground wire.

Otherwise it has a danger of electric shock.

Please connect the input power cable and the motor cable correctly. Never connect the input power to

the output terminals (U, V, W) of the inverter. Pay attention to the marks on the terminals and do not connect

the wrong wires. Otherwise it has risk of damage to the inverter.

Never connect the braking resistor directly between the DC bus positive terminal +1 or +2 and the

negative terminal -. Otherwise it has risk of fire and damage to the inverter.

The main circuit terminal wiring screws must be tightened well. For the wire diameter, please refer to

the recommendations in the manual. Otherwise it has risk of fire and damage to the inverter.

It is forbidden to connect AC220V voltage level signals to terminals except for the control terminals

TA, TB, TC, otherwise is has risk of damage to the inverter.

WARNING

Ensure that the rated voltage of the inverter is consistent with the voltage of the AC power supply.

Otherwise it may cause damage to the inverter.

The encoder signal line should uses shielded wire, and the single end of the shield layer should

reliably grounded. Otherwise it may cause the inverter to malfunction.

SV600 Series User Manual 1 Safety information and precautions

3

1.1.4 Safety precautions for debugging and operation

WARNING

Do not touch the fan, radiator or braking resistor directly. May cause mechanical injury and burns.

Do not use the input contactor on/off frequently to control the start and stop of the frequency inverter.

May cause damage to the inverter.

Check the allowable operating range of the motor and machine before operating as it is very easy for

the inverter to drive the motor from low speed to high speed. Otherwise it may cause equipment damage.

DANGER

Ensure the front cover installed well before connect the input power supply. After power-on, do not

open the cover and operate it as there is a high voltage inside. Otherwise it has a danger of electric shock.

Please ensure the safety and reliability around the motor and mechanical load during motor electric

parameters auto-tuning and the inverter operation. Otherwise it has risk of injury.

Non-professional technicians are prohibited from testing signals during power-on. Otherwise it has

risk of electric shock and damage to the inverter.

Forbidden to repair the motor and mechanical equipment during power-on. Otherwise it has risk of

electric shock and personal injury.

2 Product Introduction SV600 Series User Manual

4

2 Product Introduction

2.1 SV600 models introduction

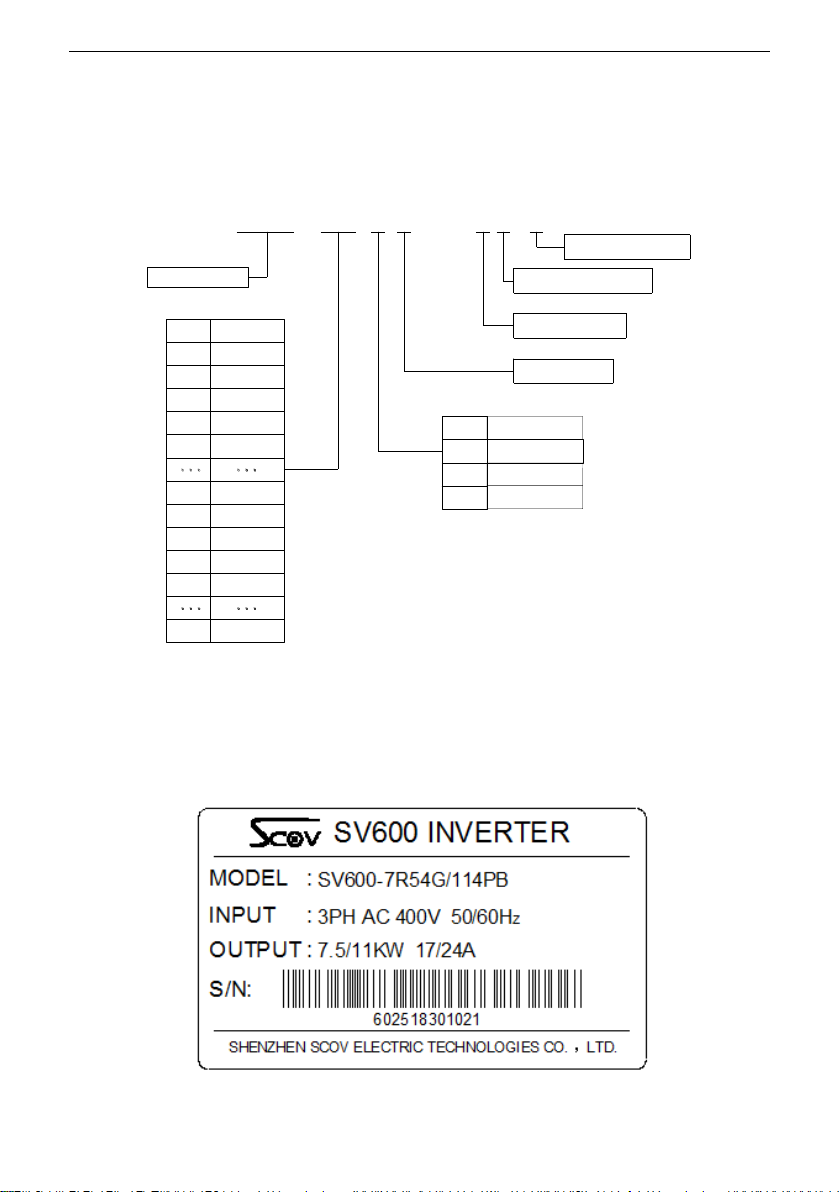

Fig. 2-1 Model description

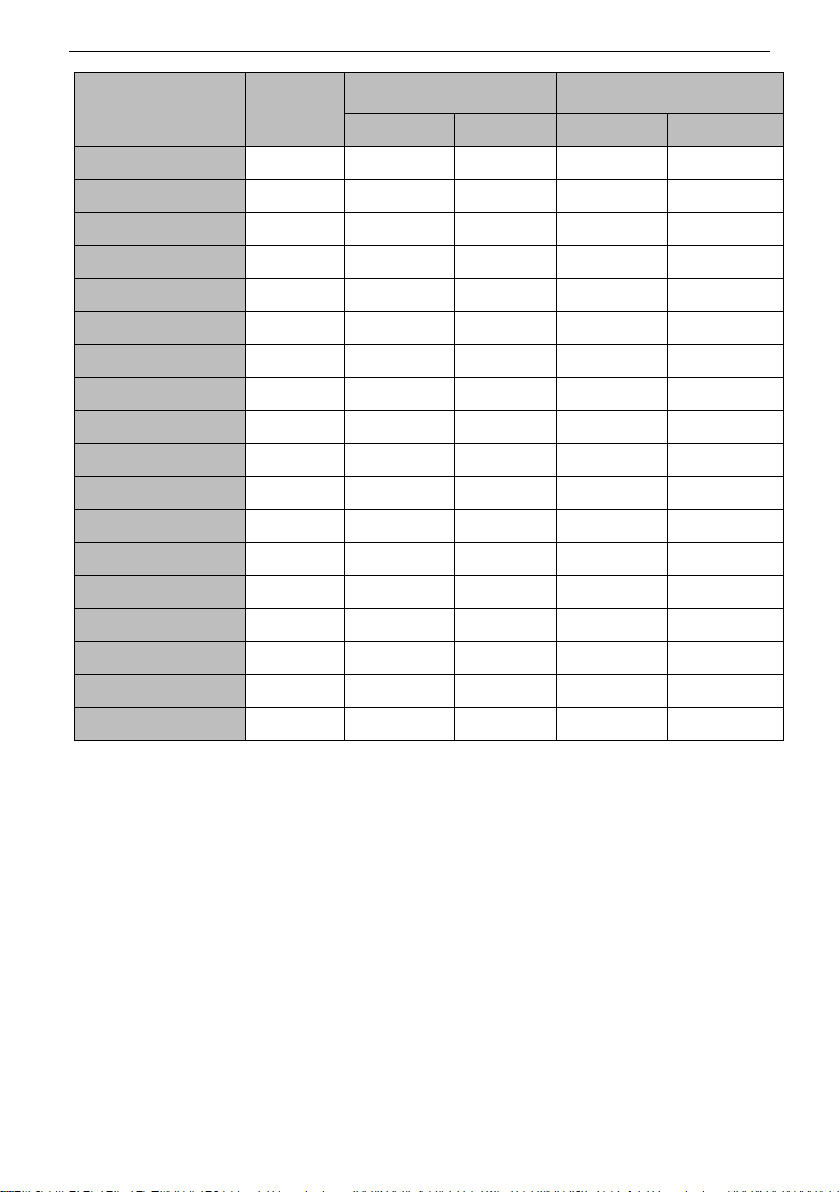

2.2 Inverter nameplate

A nameplate indicating the type and rating of the inverter is affixed to the right side of the

inverter case. The nameplate example of SV600 series is as follow:

Fig. 2-2 SV600 inverter nameplate

55KW

90 90KW

630

5R5

630KW

132KW

75KW

11

110KW110

7R5

132

75

Mark Power

4R0

7.5KW

11KW

55

5.5KW

4

5

3PH AC 380V

3PH AC 480V

Mark AC 230V

-

Note:For AC 230V grade,it has two types for choose.

1PH 230V input and 3PH 230V input.

The model with -S mark is 1PH AC 230V type.

The model without -S mark is 3PH AC 230V type.

SV600

4.0KW

S

S:Single phase input

P:Pump/Fan Type

B:Built-in braking unit

2

-4 G / 11 4 P B

G:General Type

Voltage grade

SV600 series

7R5

2R2 2.2KW

SV600 Series User Manual 2 Product Introduction

5

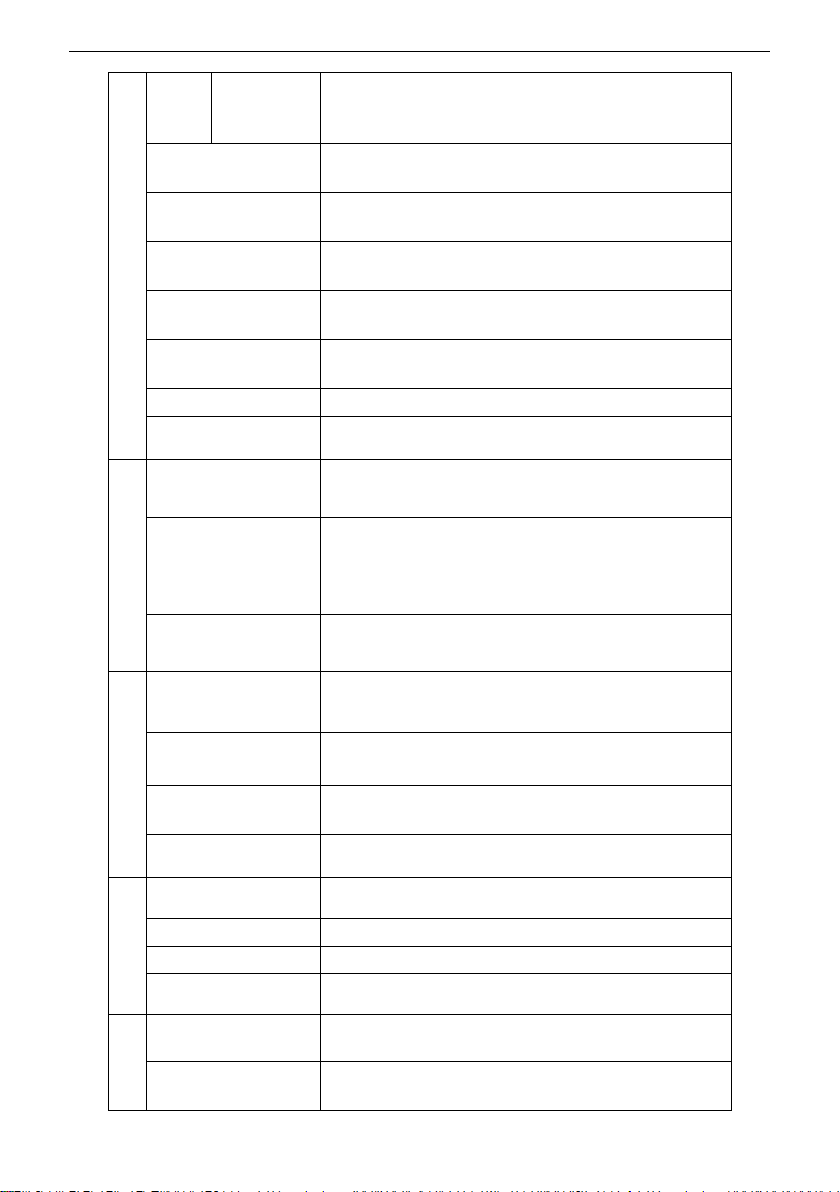

2.3 Product models list

Table 2-1 Models and Specifications for 230V grade

Inverter model

Power supply capacity

KVA

Input current

A

Rated Output

current A

Adapted Motor

KW

Single-phase power supply: 230V(-15%~+20%) 50/60 Hz

SV600-0R752GB-S

1.5

8.2

4.04

0.75

SV600-1R52GB-S

3

14

7.3

1.5

SV600-2R22GB-S

4

23

9.6

2.2

SV600-4R02GB-S

7

33

17

4.0

SV600-5R52GB-S

12

55

24

5.5

SV600-7R52GB-S

15

70

32.5

7.5

SV600-112GB-S

20

95

46

11

SV600-152GB-S

29

130

62.5

15

SV600-18R52G-S

35

160

75.5

18.5

SV600-222G-S

42

190

92.5

22

SV600-302G-S

50

230

111

30

Three phase power supply: 230V(-15%~+20%) 50/60 Hz

SV600-0R42GB

1.5

3.4

2.5

0.4

SV600-0R752GB

3

5

4.04

0.75

SV600-1R52GB

5.9

10.5

7.3

1.5

SV600-2R22GB

5.9

10.5

10

2.2

SV600-4R02GB

11

20.5

17

4.0

SV600-5R52GB

17

26

24

5.5

SV600-7R52GB

21

35

32.5

7.5

SV600-112GB

30

46.5

46

11

SV600-152GB

40

62

62

15

SV600-18R52G

57

76

76

18.5

SV600-222G

69

92

92

22

SV600-302G

85

113

111

30

SV600-452G

134

180

169

45

2 Product Introduction SV600 Series User Manual

6

Inverter model

Power supply capacity

KVA

Input current

A

Rated Output

current A

Adapted Motor

KW

SV600-552G

160

214

210

55

SV600-752G

192

256

246

75

SV600-902G

231

307

300

90

SV600-1102G

243

385

370

110

SV600-1322G

318

468

460

132

SV600-1602G

355

525

510

160

SV600-1852G

396

600

600

185

Table 2-2 Models and Specifications for 380V and 480V grade

Inverter model

Power supply

capacity

KVA

Output current

A

Adapted motor

KW

G type

P type

G type

P type

Three-phase power supply: 380V(-15%~+20%) 50/60 Hz

SV600-0R754G/1R54PB

1.5

2.5

4.04

0.75

1.5

SV600-1R54G/2R24PB

3

4.04

5.5

1.5

2.2

SV600-2R24G/4R04PB

4

5.5

10

2.2

4.0

SV600-4R04G/5R54PB

5.9

10

13

4.0

5.5

SV600-5R54G/7R54PB

8.9

13

17

5.5

7.5

SV600-7R54G/114PB

11

17

24

7.5

11

SV600-114G/154PB

17

24

32.5

11

15

SV600-154G/18R54PB

21

32.5

38

15

18.5

SV600-18R54G/224PB

24

38

46

18.5

22

SV600-224G/304PB

30

46

62.5

22

30

SV600-304G/374PB

40

62

75.5

30

37

SV600-374G/454P

57

75.5

92.5

37

45

SV600-454G/554P

69

92.5

111

45

55

SV600-554G/754P

85

111

146

55

75

SV600-754G/904P

114

146

169

75

90

SV600-904G/1104P

134

169

210

90

110

SV600-1104G/1324P

160

210

246

110

132

SV600 Series User Manual 2 Product Introduction

7

Inverter model

Power supply

capacity

KVA

Output current

A

Adapted motor

KW

G type

P type

G type

P type

SV600-1324G/1604P

192

246

300

132

160

SV600-1604G/1854P

200

300

350

160

185

SV600-1854G/2004P

231

350

370

185

200

SV600-2004G/2204P

243

370

415

200

220

SV600-2204G/2504P

273

415

460

220

250

SV600-2504G/2804P

318

460

510

250

280

SV600-2804G/3154P

355

510

600

280

315

SV600-3154G/3554P

396

600

660

315

355

SV600-3554G/4004P

500

660

740

355

400

SV600-4004G/4504P

500

740

820

400

450

SV600-4504G/5004P

565

820

920

450

500

SV600-5004G/5604P

625

920

990

500

560

SV600-5604G/6304P

690

990

1160

560

630

SV600-6304G

770

1160

/

630

/

Three phase power supply: 480V(15%~+15%) 50/60 Hz

SV600-0R755G/1R55PB

1.5

2.5

4.04

0.75

1.5

SV600-1R55G/2R25PB

3

4.04

5.5

1.5

2.2

SV600-2R25G/4R05PB

4

5.5

10

2.2

4.0

SV600-4R05G/5R55PB

5.9

10

13

4.0

5.5

SV600-5R55G/7R55PB

8.9

13

17

5.5

7.5

SV600-7R55G/115PB

11

17

24

7.5

11

SV600-115G/155PB

17

24

32.5

11

15

SV600-155G/18R55PB

21

32.5

38

15

18.5

SV600-18R55G/225PB

24

38

46

18.5

22

SV600-225G/305PB

30

46

62.5

22

30

SV600-305G/375PB

40

62

75.5

30

37

SV600-375G/455P

57

75.5

92.5

37

45

SV600-455G/555P

69

92.5

111

45

55

2 Product Introduction SV600 Series User Manual

8

Inverter model

Power supply

capacity

KVA

Output current

A

Adapted motor

KW

G type

P type

G type

P type

SV600-555G/755P

85

111

146

55

75

SV600-755G/905P

114

146

169

75

90

SV600-905G/1105P

134

169

210

90

110

SV600-1105G/1325P

160

210

246

110

132

SV600-1325G/1605P

192

246

300

132

160

SV600-1605G/1855P

200

300

350

160

185

SV600-1855G/2005P

231

350

370

185

200

SV600-2005G/2205P

243

370

415

200

220

SV600-2205G/2505P

273

415

460

220

250

SV600-2505G/2805P

318

460

510

250

280

SV600-2805G/3155P

355

510

600

280

315

SV600-3155G/3555P

396

600

660

315

355

SV600-3555G/4005P

500

660

740

355

400

SV600-4005G/4505P

500

740

820

400

450

SV600-4505G/5005P

565

820

920

450

500

SV600-5005G/5605P

625

920

990

500

560

SV600-5605G/6305P

690

990

1160

560

630

SV600-6305G

770

1160

/

630

/

SV600 Series User Manual 2 Product Introduction

9

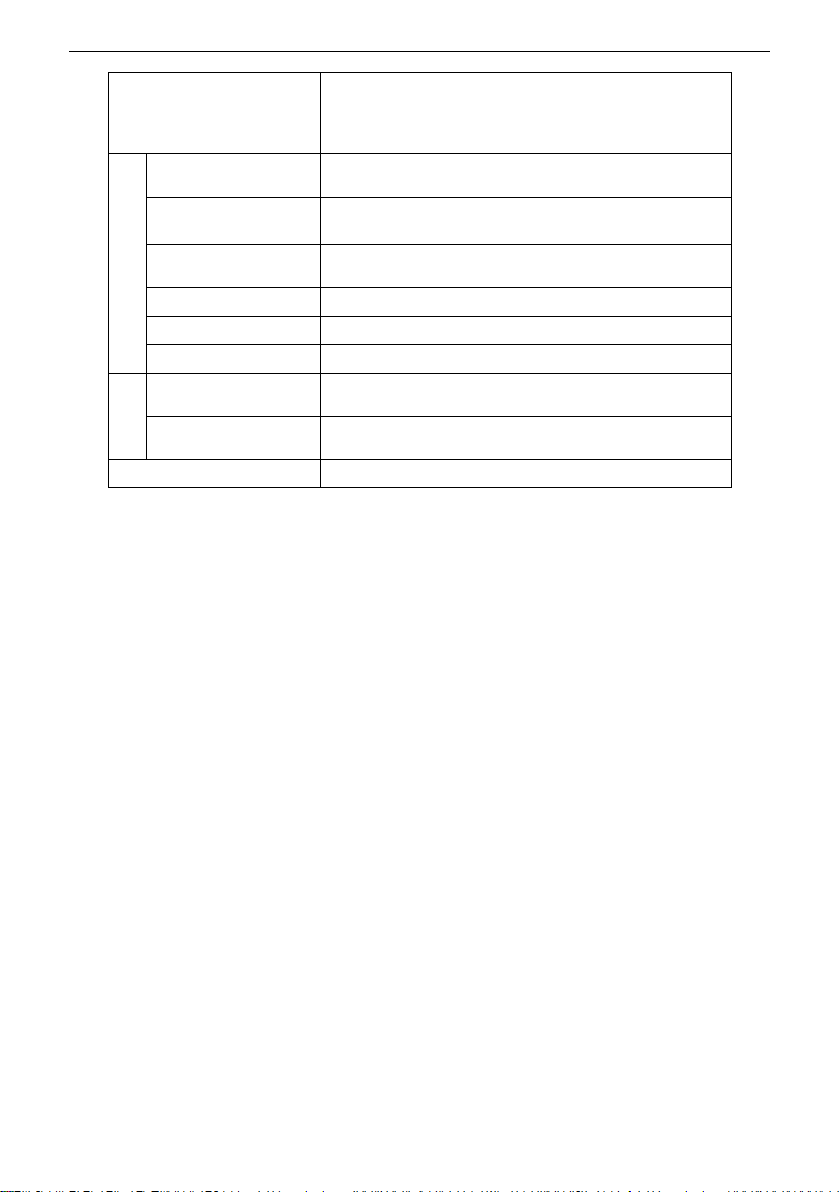

2.4 Product technical specifications

Item

Specifications

Input

Voltage and frequency

Single phase 230V,50Hz/60Hz

Three phase 230V, 50Hz/60Hz

Three phase 380V, 50Hz/60Hz

Three phase 480V, 50Hz/60Hz

Allowed volt. range

Single phase 230V:200V~260V;

Three phase 230V, 200V~260V;

Three phase 380V, 320V~460V;

Three phase 480V, 380V~528V;

Output

Voltage

3PH 0~Input voltage

Frequency

0~300Hz(SVC vector control)

0~3200Hz(V/F control)

Overload capacity

G type:150% for 1mint, 180% for 3s.

P type:120% for 1 mint, 150% for 3s.

Control performance

Control mode

Speed sensorless vector control(SVC)

V/F control

Speed regulation range

1:100(SVC control mode)

1:50(V/F control mode)

Start-up torque

0.5Hz/150%(SVC control mode)

1.0Hz/150% (V/F control mode)

Speed stability accuracy

≤±0.5% of rating synchronous speed (SVC)

Frequency precision

Digital setting:max. frequency*±0.01%;Analog setting:Max.

frequency*±0.5%

Frequency

resolution

Analog

setting

0.1% of Max. frequency

Digital setting

The precision less than 100HZ:0.01Hz

High pulse

setting

0.1% of Max. frequency

Torque boost

Manual torque boost: 0.1~12.0%

V/F curve

Straight-line V/F curve;

Multi-point V/F curve

N-power V/F curve (1.2-power, 1.4-power, 1.6-power, 1.8-power,

square)

V/F separation

Complete separation

Half separation

Acceleration/Deceleration

curves

Linear and “S” curves acceleration and deceleration for selection

Four groups ofAcc./Dec. time available.

Braking

Power

consumption

braking

The model with “B” mark has built-in braking unit. Install braking

resistor between P+ and PB when needed.

For model without braking unit, you can add external braking unit

and braking resistor.

2 Product Introduction SV600 Series User Manual

10

DC braking

DC braking frequency: 0.00 Hz to maximum frequency

Braking time: 0.0–36.0s

Braking action current value: 0.0%–100.0%

JOG RUN

JOG frequency range: 0.00–50.00 Hz

JOG acceleration/deceleration time: 0.0–6500.0s

Multi-speed

Total 16 speeds can be selected by simple PLC function or the

combination of 4 DI terminals.

PID control

Be convenient to make closed-loop system which used for constant

pressure water supply or air compressor.

Automatic voltage regulate

(AVR)

Automatically keep constant output voltage when the power supply

voltage changes.

Automatic current limiting

Automatic current limiting avoids the malfunction of frequent

overcurrent causing trip during operation

Carrier modulation

Modulate carrier automatically based on the characteristic of load.

Speed tracking

Smoothly restart the rotating motor without overcurrent

Running function

Control command

Keyboard control, terminal control, communication control

supported and can be selected by many methods.

Frequency setting

source

Main and auxiliary frequency setting, analog, high pulse input,

communication setting and so on.

Those frequency setting sources also can be switched over by

terminals DI or keys on the keyboard.

Binding function

The control command and frequency setting source can be bond

arbitrarily, changes synchronously.

Input and output char-acter

Digital input channel

6 digital input (DI)

6 virtal digital input (VDI).

The function selection of each DI, please refer to Group P4.

Analog input channel

AI1: 4~20mAor 0~10V

AI2: 4~20mAor 0~10V

Pulse output channel

HDOP:High pulse output,0~20kHz

Analog output channel

AO1:4~20mAor 0~10V

AO2:0~10V

Unique feature

Rapid current limiting

Limit the output current of the inverter during operation and avoids

overcurrent fault occurs.

Fixed length control

Can realize fixed length control

Timing control

Timing control function:setting time range:0.1Min ~6500.0Min

Virtual terminal

6 virtal digital input (VDI) and 4 virtal digital output (VDO) for

choose, realizing simple logical control.

Keyboard

LED display

5 LED display for showing setting frequency, output frequency,

output voltage, output current and so on.

Lock the button

Lock all or part of the keys on the keyboard.

SV600 Series User Manual 2 Product Introduction

11

Protection function

Short circuit detection, short circuit to ground detection, input and

output loss phase detection, overcurrent, overvoltage,

undervoltage, overheat, overload, underload, contactor protection,

terminals protection and so on.

Ambient

Use ambient

Indoor, not bare to sunlight, no dust, no corrosive gas, no

flammable gas, no vapor, no water drop or salt etc.

Altitude

Less than 1000 meters.(10% de-rating using for each 1000 meters

when over 1000 meters.)

Ambient temperature

-10℃ ~ +40℃(under ambient temperature 40℃ ~ 50℃,please

reduce the volume or strengthen heat sink)

Ambient humidity

Less than 95%RH,without condenses

Vibration

Smaller than5.9m/s ²(0.6g)

Storage temperature

-40℃~+70℃

Structure

Defending grade

IP20

Cooling mode

Forced air cooling and fan controls with temperature

Mounting mode

Wall hangning or install in cabinet

3 Mechanical Installation SV600 Series User Manual

12

3 Mechanical Installation

3.1 Installation

3.1.1 Installation Environment

The installation environment is very important for the long-term maintenance of the

performance and function of the frequency inverter. Please install the inverter according to the

below Table 3-1.

Table 3-1 Installation Environment

Item

Requirements

Installation site

Indoor

Ambient

temperature

-10 to +40 °C

In order to improve the reliability of the inverter, please use it in the place where

the temperature does not change drastically.

When using it in a closed space such as a control cabinet, please use cooling fan

or cooling air conditioner to cool it and prevent the internal temperature from exceeding

the condition temperature.

Please avoid the inverter freezing.

Humidity

95% RH or below

Please avoid condensation on the inverter.

Storage

temperature

-20 ~ + 60 °C

Environment

Please install the inverter in the following locations.

Locations free from oil mist, corrosive gases, flammable gases, dust, etc.

Locations that metal powder, oil, water and other external objects can not enter

the inverter (Do not install the inverter on flammable materials such as wood).

Location without radioactive materials and flammable materials

Place without harmful gases and liquids

Place with less salt erosion

Place without direct sunlight

Altitude

Less than 1000m, derating 1% for each 100 meters when higher than 1000m. <1>

Note 1: Please do not install transformers or other equipments around the inverter which generate

electromagnetic waves or interference, otherwise it will cause the inverter to malfunction. If you need to

install such equipment, you should install shield plate before the inverter.

Note 2: Please use cloth or paper to cover the upper portion of the frequency inverter to prevent metal

debris, oil and water from entering into the frequency inverter during installation. After finish the job, be

sure to remove the cloth or paper, and if it still covered, the ventilation will become poor and causes the

frequency inverter to abnormally heat.

SV600 Series User Manual 3 Mechanical Installation

13

3.2 Installation direction and space

3.2.1 Installation Space

The surrounding installation space and clearance should be reserved varies with the power

levels of the SV600 series inverter.

Single inverter installation

Fig. 3-1 Single inverter installation

Table 3-2 Installation clearance requirements

Power level

Dimension requirements (Unit:mm)

2.2 KW ~ 22KW

A1 ≥ 10

B1 ≥ 200

C1 ≥ 40

30 ~ 37KW

A1 ≥ 50

B1 ≥ 200

C1 ≥ 40

≥ 45 KW

A1 ≥ 50

B1 ≥ 300

C1 ≥ 40

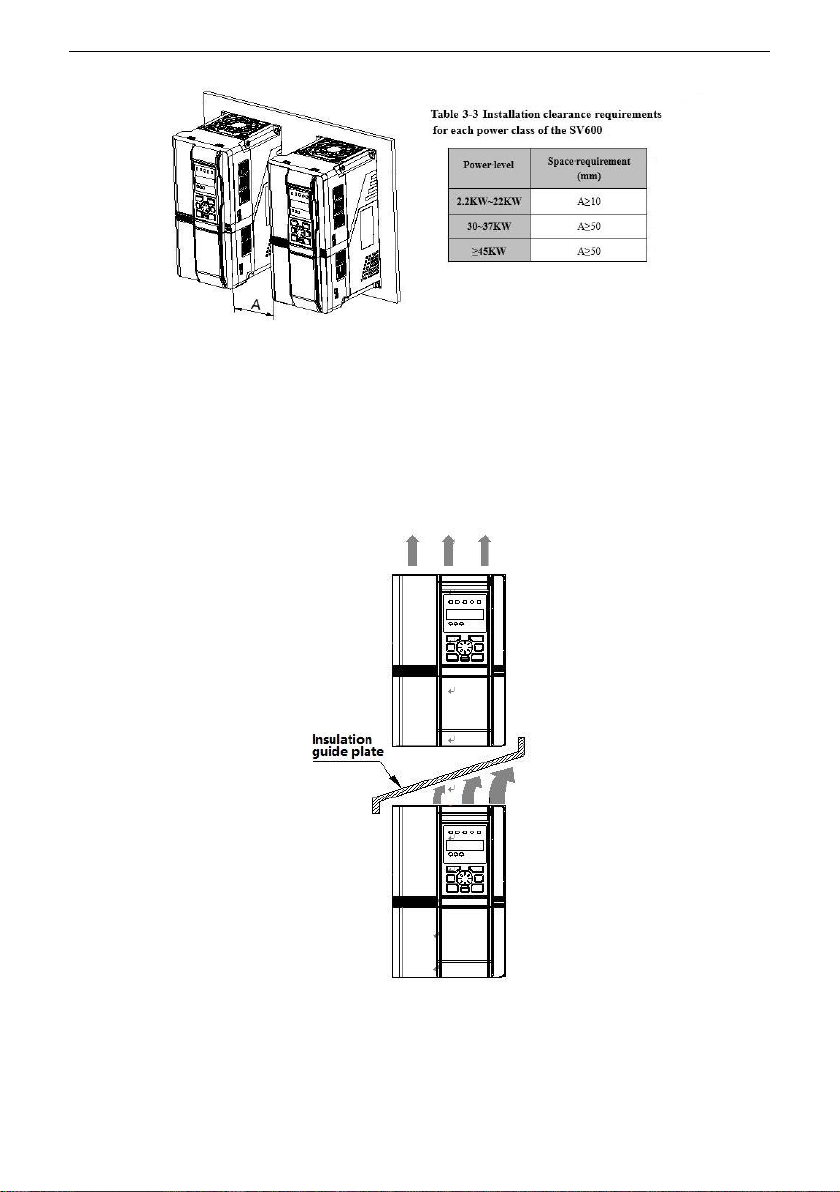

Multi-inverter installation

The SV600 series inverter dissipates heat from the bottom to the top. When multiple inverters

work together, please install them side by side and the upper of the inverter should be aligned.

Clearance should be reserved between each inverter as shown in Fig.3-2:

Vertical upward

B1

B1

A1

(Side view)

C1

A1

(Front view)

3 Mechanical Installation SV600 Series User Manual

14

Fig. 3-2 Installation clearance of multiple inverters

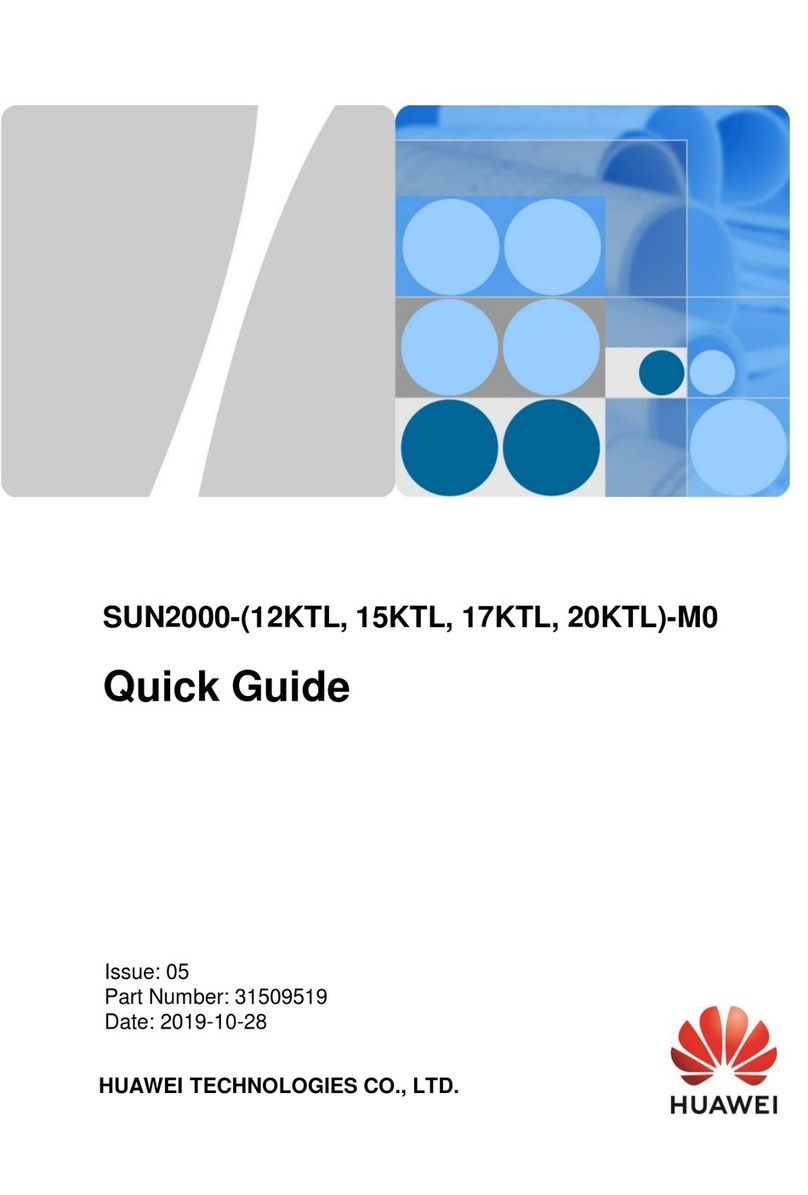

Different rows installation

If one row of inverters need to be installed above another row, please install insulation guide

plate to prevent the heat from the lower row inverters which will cause the temperature of the

upper row inverters to raise, even over-heat and overload fault occurs. Measures as shown in

Fig.3-3:

Fig.3-3 Up and down row installation

This manual suits for next models

30

Table of contents

Other SCOV Inverter manuals

Popular Inverter manuals by other brands

Lenze

Lenze SMD Series operating instructions

Salicru

Salicru EQUINOX EQX2 2001-S user manual

Toshiba

Toshiba ACE-tronics G9 ASD quick start guide

Huawei

Huawei SUN2000 Series quick guide

Go Power! Electric

Go Power! Electric GP-DC-KIT2 owner's manual

Toshiba

Toshiba TOSVERT VF-S11 Instruction manual supplement