Service manual DW90

10

Inlet valve

The inlet valve has an electrical connector

that is coded to ensure it is not mixed up. It is

fitted with a filter, which can be removed for

cleaning. Both single and safety valves are used

as inlet valves. The inlet valve contains a filter

to stop particles then a flow limiter to limit

the flow to a maximum of 4 L (1 gallon)/min.

It opens when the water pressure exceeds 0.3

bar (4.3 psi) and provides full flow at about 2

bar (29 psi). It has a pressure range of 0.3 bar

(4.3 psi) to 10 bar (145 psi). The inlet valve is

fitted to the air gap and can be replaced from

the rear of the machine.

Purpose: To ensure that the machine

is supplied with water for the different

dishwashing cycles.

Safety valve

The safety valve has two independent valve seats,

each controlled by a separate electromagnet. The

valve seats are connected in series. This doubles

the safety factor. The electromagnets are also

connected in series (electrically), which means each

magnet’s rated voltage is half the mains voltage (e.g.,

a 230 V valve = 2 x 115 V coils)

Single valve

The single valve comprises an electromagnet

and a valve seat.

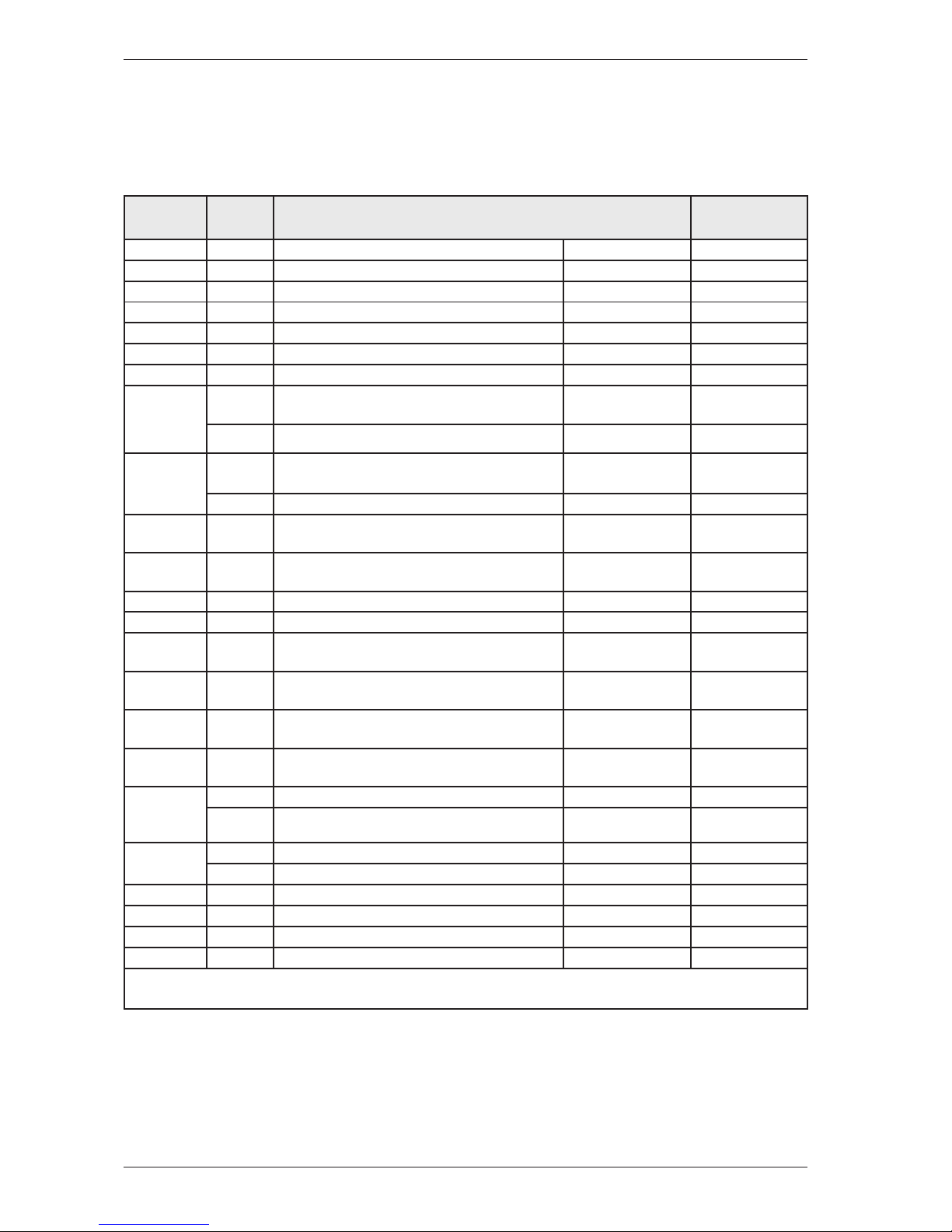

Components and function description

Here we describe the function and

specification of the most important

components. Certain components are found

only in more highly specified machines or in

particular markets. See the Troubleshooting

section for fault and information codes.

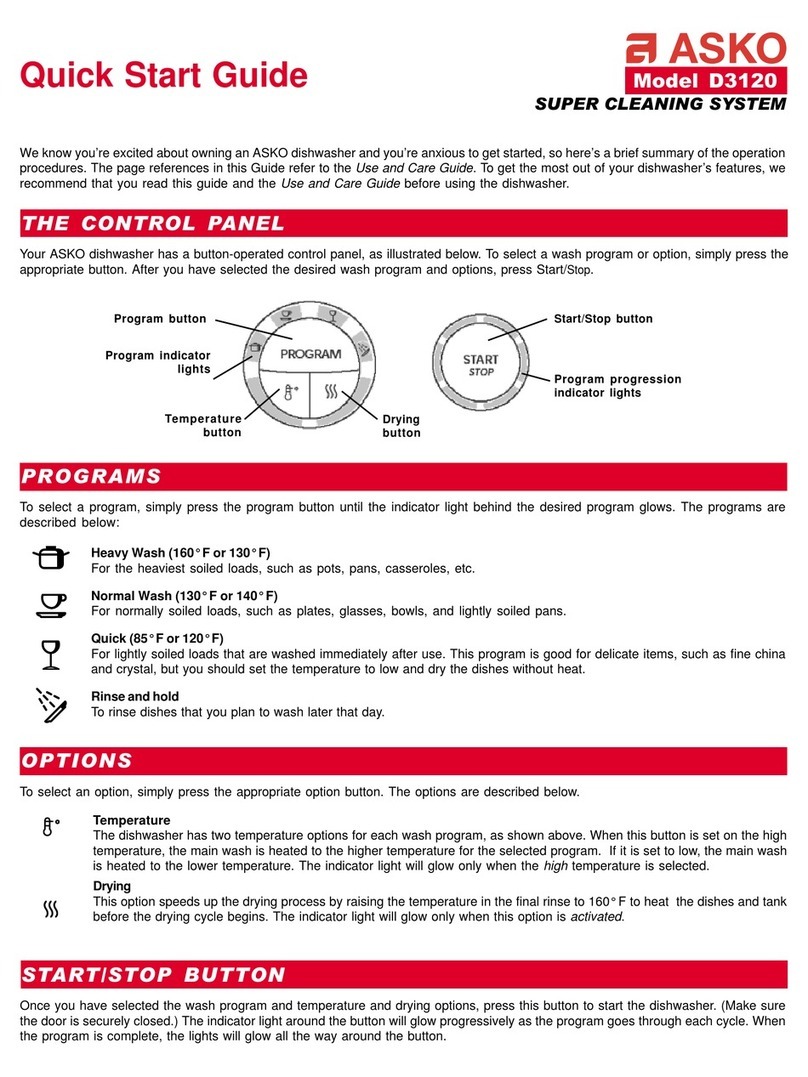

CU, Control Unit

The CU, or Control Unit, is a unit that functions

as both a control panel and a logic component.

The control panel is fitted with a display and touch

buttons for selecting programs, options and Start/

Stop. The control panel is an integrated part of

the CU and cannot be replaced separately. The

logic component manages functions needed for

dishwashing programs and diagnosis. The CU

has an internal power supply for the logic. In the

event of a fault, the CU can diagnose a number of

components and functions and display fault codes.

To facilitate troubleshooting the service menu

includes a component diagnostics function, which

activates the outputs in a particular sequence.

Accelerometer

The control unit in DW90.2 contains an accelerometer,

a sensor that senses position and acceleration. It controls

the touch buttons and the brightness of the light. The

accelerometer turns off at a specific angle to avoid causing

a distraction when seen from the worktop. It is calibrated

when the door is closed.

If this symbol appears on the display

the door is not open enough. Open

the door until the display lights up.

Component description