IMPORTANTWARNING

Whenever the product has been lying horizontally during

transportation, it should be left to stand upright for at least six

hours before it is switched on, otherwise it may be noisy when

it is in operation.

IMPORTANT

Before plugging the appliance in, make sure that the power

supply voltage corresponds to the value shown on the product

data plate. Plug the appliance into the electricity mains supply.

The display will flash, showing the default temperature set by

the manufacturer (-16°C):

After a few seconds the display will show the actual temperature

of the refrigerator compartment. If the symbol “--” appears on

the display, the appliance is plugged in but switched off.

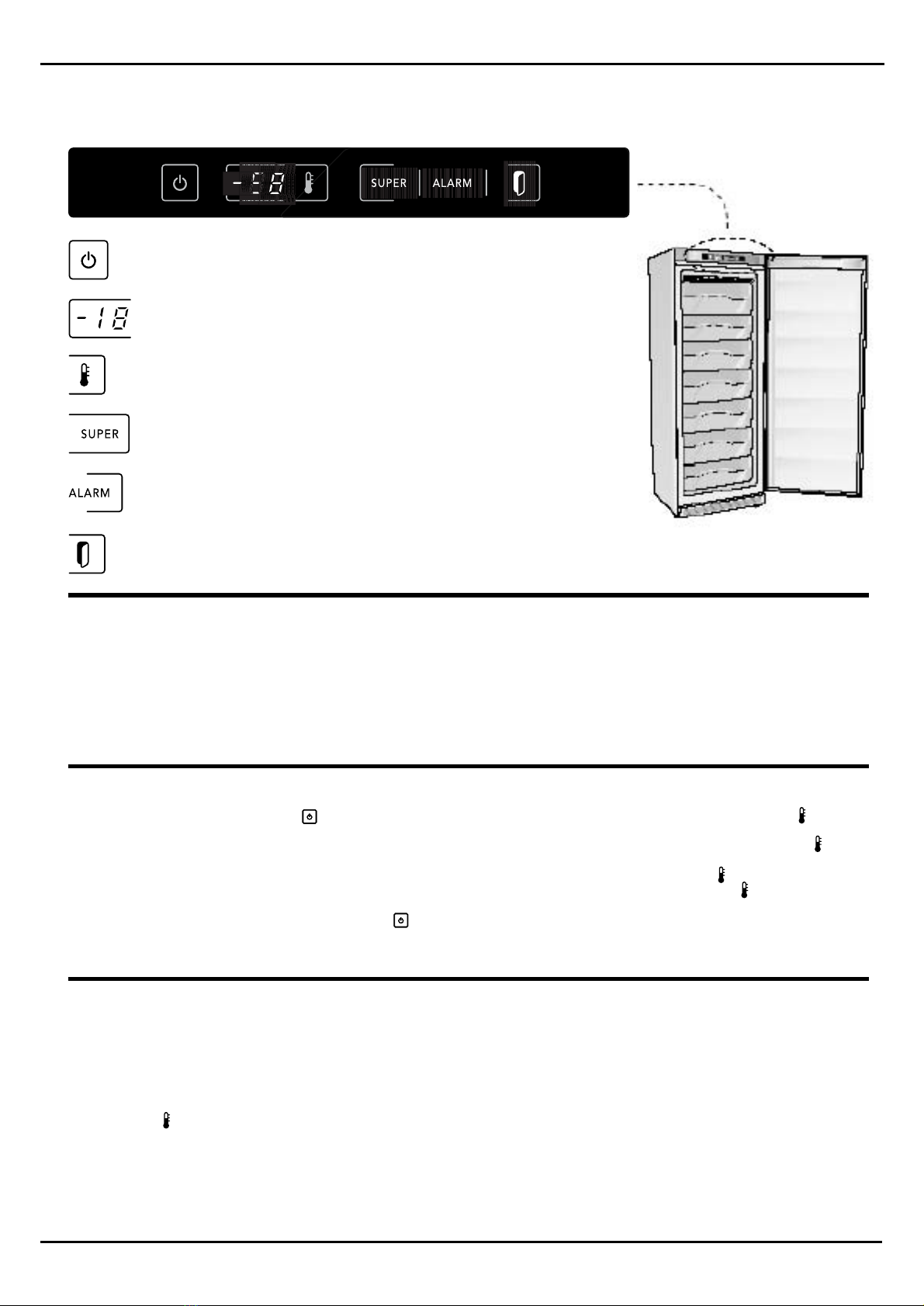

SWITCHINGTHE APPLIANCE ON

Switch the product on by touching the symbol for at least 0.5

seconds.

During operation, the temperature inside the refrigerator appears

on the display, which can indicate temperature values of between

+20°C and -40°C. Temperatures of over +20°C inside the

refrigerator (for example, +21°C), are indicated on the display

by the letter“H”:The temperature may be set to a value between

-16°C and -24°C.To switch off the product, touch the symbol

for 5 seconds.

SETTINGTHETEMPERATURE

The temperature may be adjusted by touching the symbol; it

may be set to a value between -16°C and -40°C.

When the refrigerator is switched on, if you touch the symbol

the set temperature value will flash on the display for 6 seconds.

To set a new temperature, touch the symbol and, while the

display is flashing, touch the same symbol repeatedly until the

desired temperature value has been reached; the new setting

will be stored after the display has stopped flashing (6 seconds).

N.B.: an option should be selected after taking into account

the frequency with which the door is opened,the temperature

of the room in which the appliance is installed and the

quantity of food contained inside the product.

For room temperatures of between 20 to 25°C, we

recommend setting the freezer temperature at -18°C.

CHECKINGTHE PROGRAMMEDTEMPERATURE

If you touch the symbol just once, the programmed temperature

will flash on the display for 6 seconds; after this the actual

temperature inside the refrigerator compartment will be displayed.

The set functions remain stored in the memory of the appliance,

even after they have been switched off or disconnected from the

electricity supply; when they are switched back on again the

temperature value set most recently will flash on the display for

6 seconds.

SUPER FUNCTION

The Super function was designed to reduce the temperature

inside the refrigerator compartment in the shortest possible time;

if you touch the text “SUPER”for at least 0.5 seconds the function

will be activated for a period of 30 hours, during which time the

text “SUPER” will be lit up in white.After this 30-hour period, the

Super function will be deactivated automatically. However, if you

wish to manually deactivate the function before the 30-hour

period has elapsed, simply touch the text “SUPER” for at least

0.5 seconds; when the function has been deactivated the text

“SUPER” will no longer be illuminated. While the appliance is

operating in Super mode, all other settings are temporarily

disabled. While the appliance is operating in Super mode, all

other freezer compartment settings are temporarily disabled.

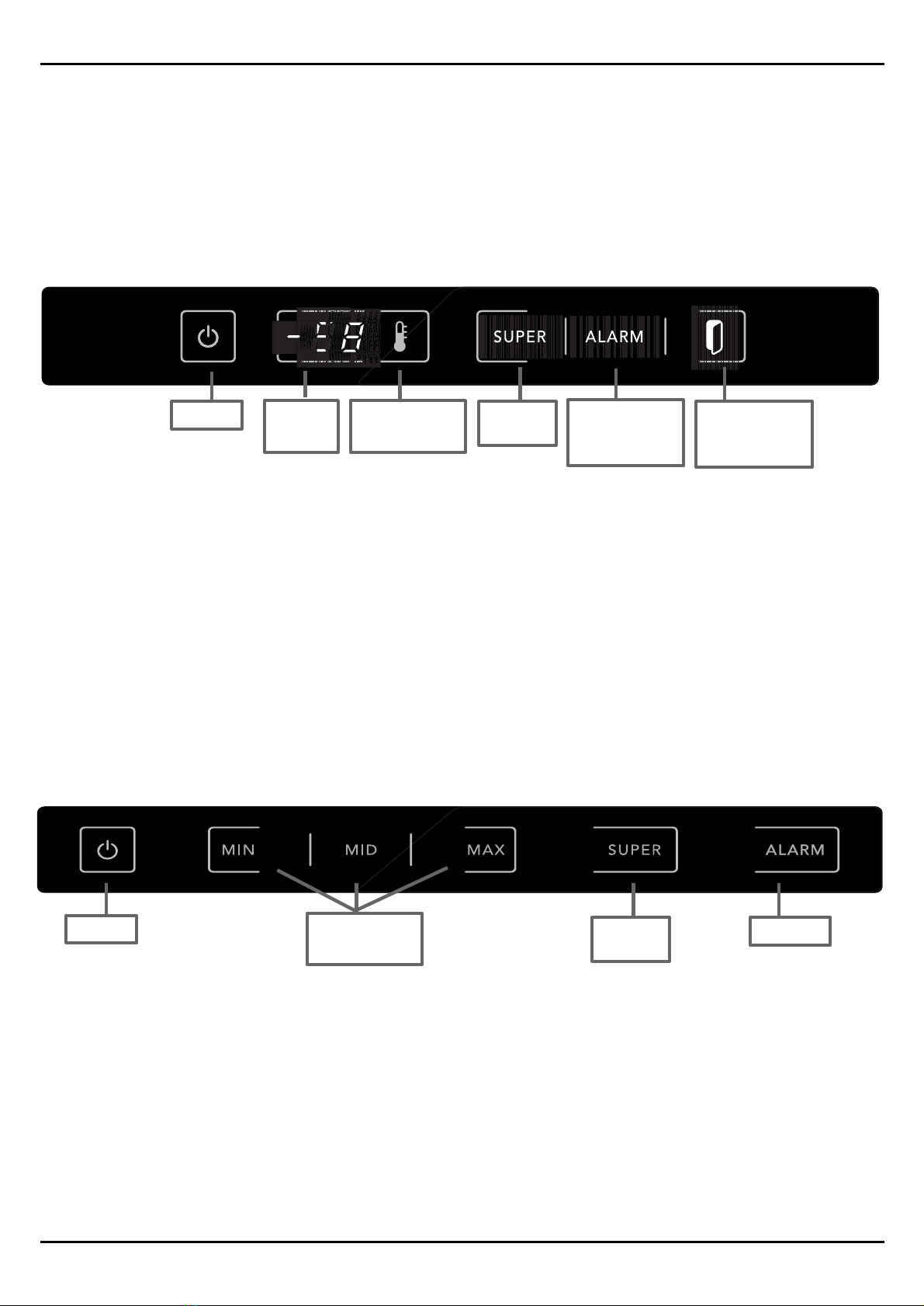

STARTINGTHE APPLIANCE - F2583NF TOUCH-DISPLAY

ON / OFF

TEMPERATURE ADJUSTMENT

SUPER FUNCTION

PREALLARME E ALLARMETEMPERATURA

DOOR OPEN ALARM

DISPLAY FREEZER