DANS01 – Installation Guide

Issue: 02 complete, approved

Page 9 of 12

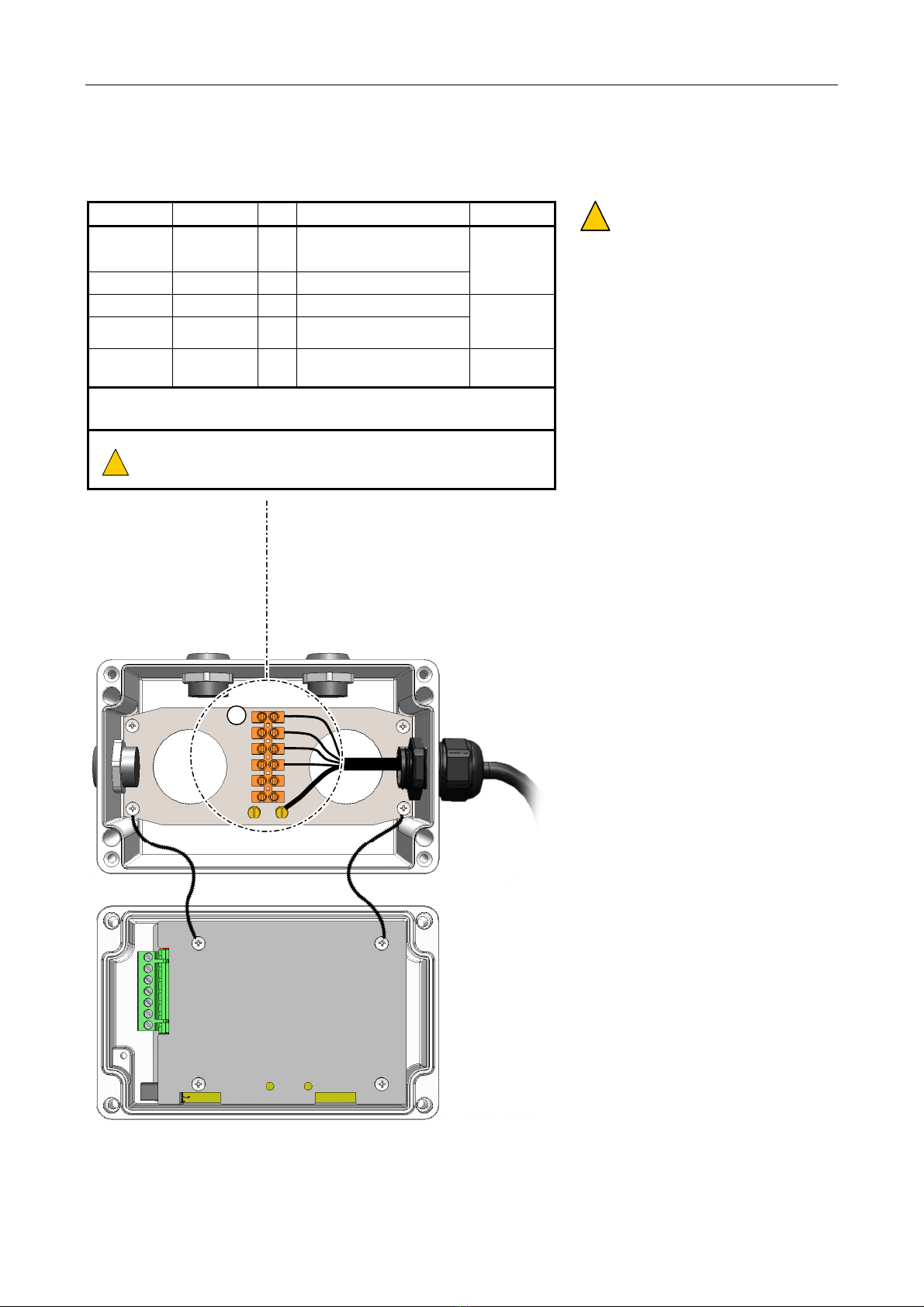

2 Connections

Terminal Signal I/O Description Connect

1 AUDIO+ O/P

Balanced audio output (+VE)

0 dBu (nominal) / 66 Ω

2 AUDIO- O/P As above, but -VE

To Router

3 0V Power I/P 0 V supply from system

4 +24V Power I/P +V supply (18 V – 40 V)

To power

supply from

rack

BRASS

TERMINALS - - Earth terminal Cable

screen

For cabling requirements, see Section “External Cabling

Requirements”.

!

!

1) The cable screen should be terminated to the earth terminal

provided on the back box.

2) All screen tails must be <3 cm.

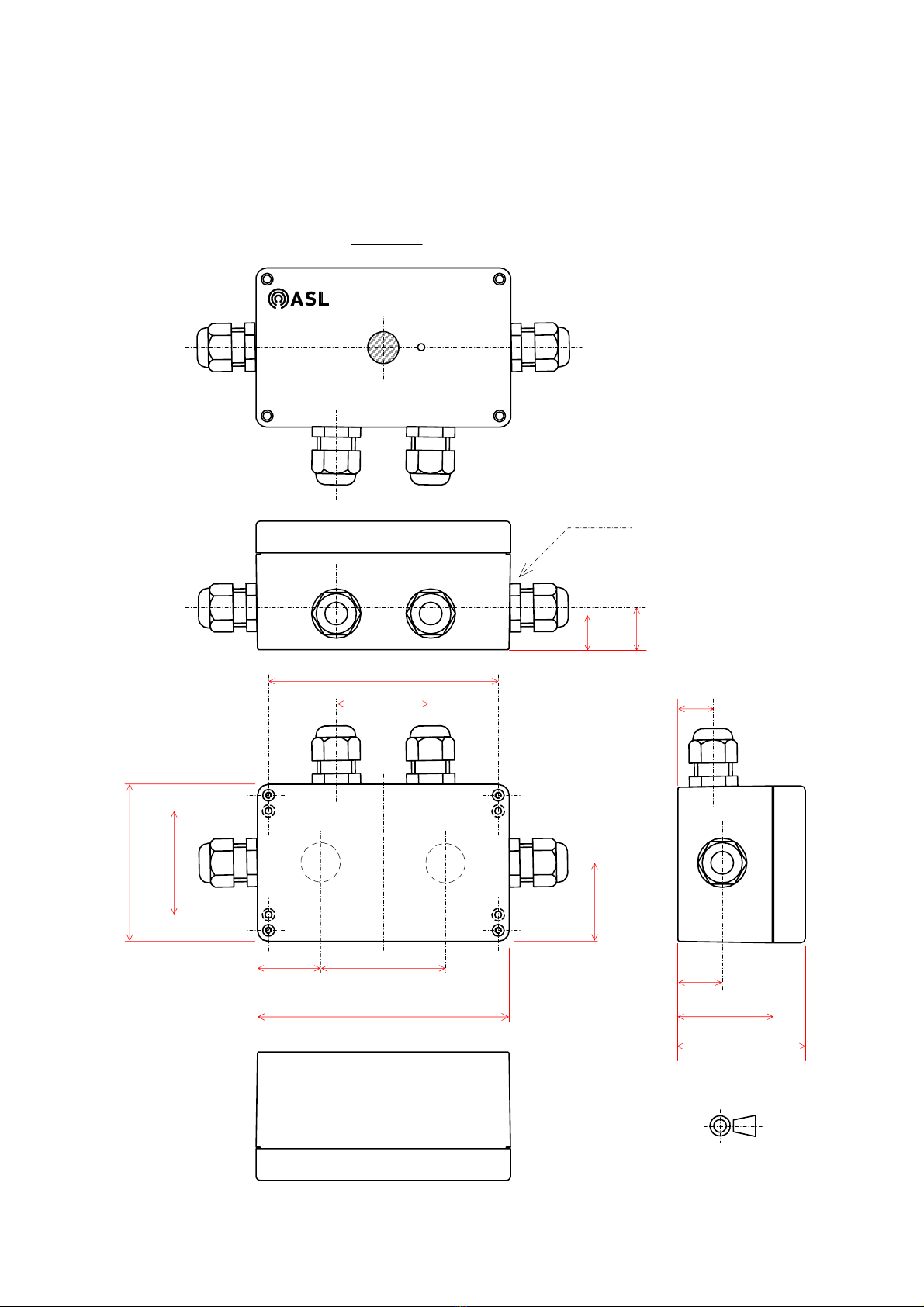

Internal wiring not shown for clarity.

Gland and cable entry point shown as example only.

FIELD WIRING

TO ROUTER

AND RACK

1

BACK BOX

FRONT PANEL

!

!

In order to deploy DANS sensors the

system should meet the followin

design requirements:

1) The DANS sensors require

VAR12 or VAR20 Routers with

MKII hardware.

Refer to ASL for details of VAR

software versions supportin

the DANS System.

2) Each DANS sensor requires one

microphone input on an Expand

Unit:

• Inputs 5 to 12 on VAR12

• Inputs 5 to 20 on VAR20

3) The DANS sensor must be

connected to a microphone

input located on the same

Expand Unit as the output(s)

that it controls.

4) Each DANS sensor also

requires an output on that

Expand Unit to be unused.

5) Up to three DANS sensors can

be connected to each Expand

Unit.

6) The Expand Units with DANS

sensor(s) do not support DVAs.

7) DANS sensors cannot be

combined with normal ANS

sensors on any zone or

roup of

zones.

8) Up to two DANS sensors can be

used to control the same

output(s).

9) DANS sensors can control more

than one output (e.

. if a zone is

separated into separate sub-

zones for other reasons).

10) Ideally if there are two DANS

sensors then they should be

connected to:

• Inputs 10 and 11 on VAR12

or VAR20, or

• Inputs 18 and 19 on VAR20