DRICO slife FU 12 Operating Manual

_______________________________________________________________________________________________________________________________________

DIN EN ISO 9001 status: 31.03.2017 / Rev. 01 page 3 of 48

Contents

1General information................................................................................ 5

1.1 Symbol explanation ......................................................................................... 5

1.2 Overview of revisions ...................................................................................... 5

1.3 Terminology, definitions and abbreviations...................................................... 6

1.4 List of figures................................................................................................... 6

2Safety instructions.................................................................................. 7

3Function description and connections .................................................... 8

3.1 Requirements.................................................................................................. 8

3.2 Technical characteristics ................................................................................. 8

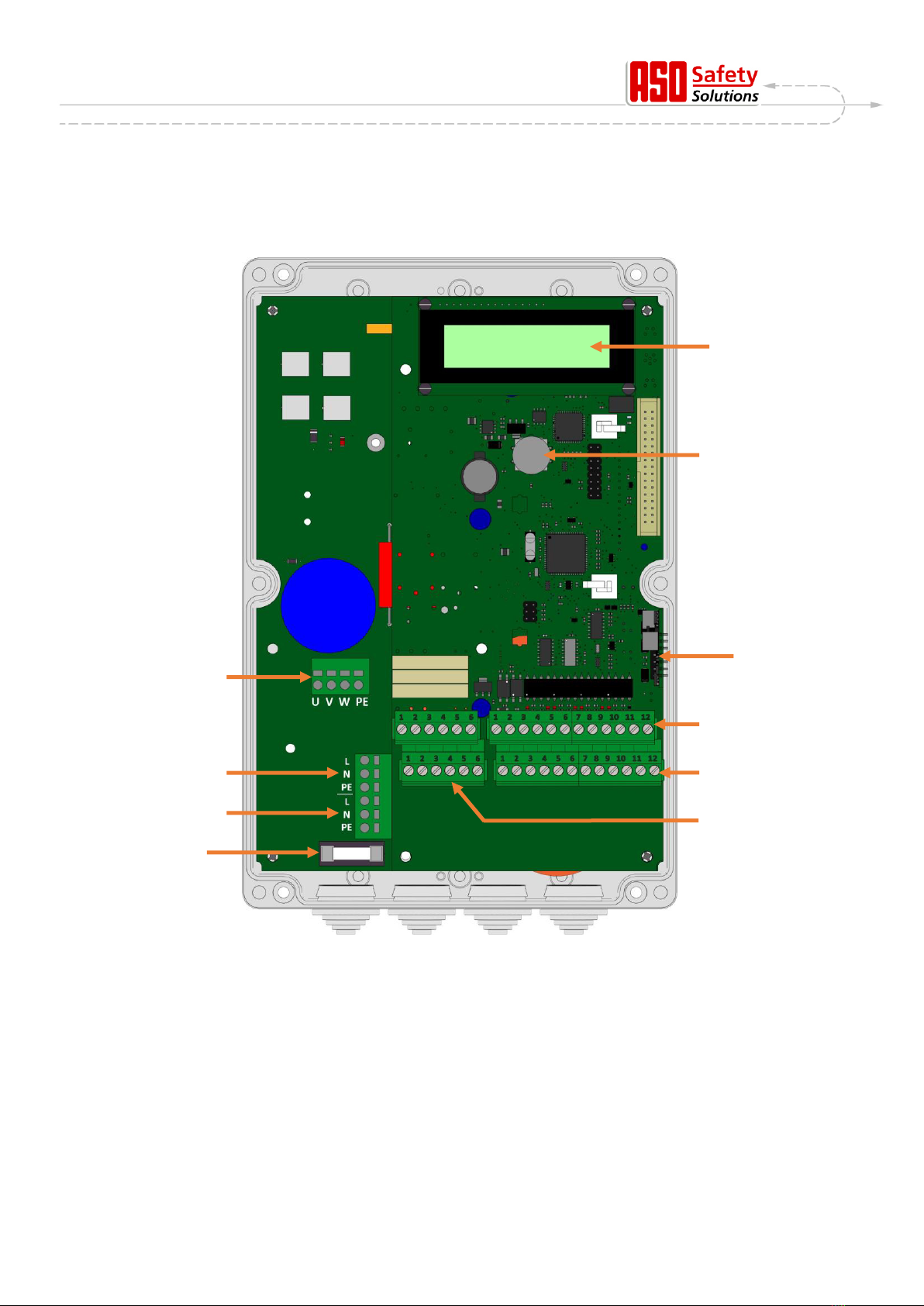

3.3 General view of the control system.................................................................. 9

3.4 Operating modes: Function and operation......................................................10

3.4.1 Deadman operation ...................................................................................................... 10

3.4.2 Automatic operation...................................................................................................... 10

3.4.3 Automatic change of the operating modes ................................................................... 11

3.5 Connectable auxiliary equipment....................................................................11

4Installation............................................................................................ 12

4.1 Control system assembly ...............................................................................12

4.2 Electrical connection.......................................................................................13

4.2.1 Power supply and drive motor connection.................................................................... 13

4.2.2 Instructions for suitable EMC installation...................................................................... 14

4.2.3 Supply for external consumers with 230 V AC ............................................................... 14

4.3 Input and output wiring ...................................................................................15

4.3.1 Power supply for external devices with 24 V DC............................................................ 15

4.3.2 Connection of the control devices and end switches ................................................... 15

4.3.3 Immobile safety contact edges ..................................................................................... 16

4.3.4 System connection INDUS ........................................................................................... 16

4.3.5 Light barrier connection ................................................................................................ 17

4.3.6 Overview of input installation plan ................................................................................ 18

4.4 Relay output wiring.........................................................................................18

4.4.1 Relay outputs with 24 VDC or with 230 VAC ................................................................... 19

5Operating elements and displays ......................................................... 20

5.1 Rotary and selection switch............................................................................20

5.2 LCD display....................................................................................................20

5.2.1 Depiction of operating modes ....................................................................................... 20

5.2.2 LCD sensor depiction ................................................................................................... 21

5.2.3 Error / event presentation ............................................................................................. 21

5.3 Information on menu display...........................................................................22

5.3.1 Menu system selection ................................................................................................. 23

5.4 Menu structure and displayed texts ................................................................23

6Parameter settings ............................................................................... 25

6.1 General instructions on parameterization .......................................................25

6.1.1 Navigating in menu ....................................................................................................... 25

6.2 Setting up the gate .........................................................................................26

6.2.1 Installation of the command keys for deadman operation............................................ 26

6.2.2 Change drive‘s direction of rotation .............................................................................. 27

6.2.3 Parameterize immobile safety contact edges............................................................... 27

6.2.4 Parameterize accompanying safety contact edges ...................................................... 27

6.2.5 Installation of the gate‘s end switches .......................................................................... 27

6.2.6 Programming the gate‘s runtime between the end positions ....................................... 28

6.3 Additional function parameters .......................................................................28