3.1

3. TECHNICAL DESCRIPTION

GENERAL

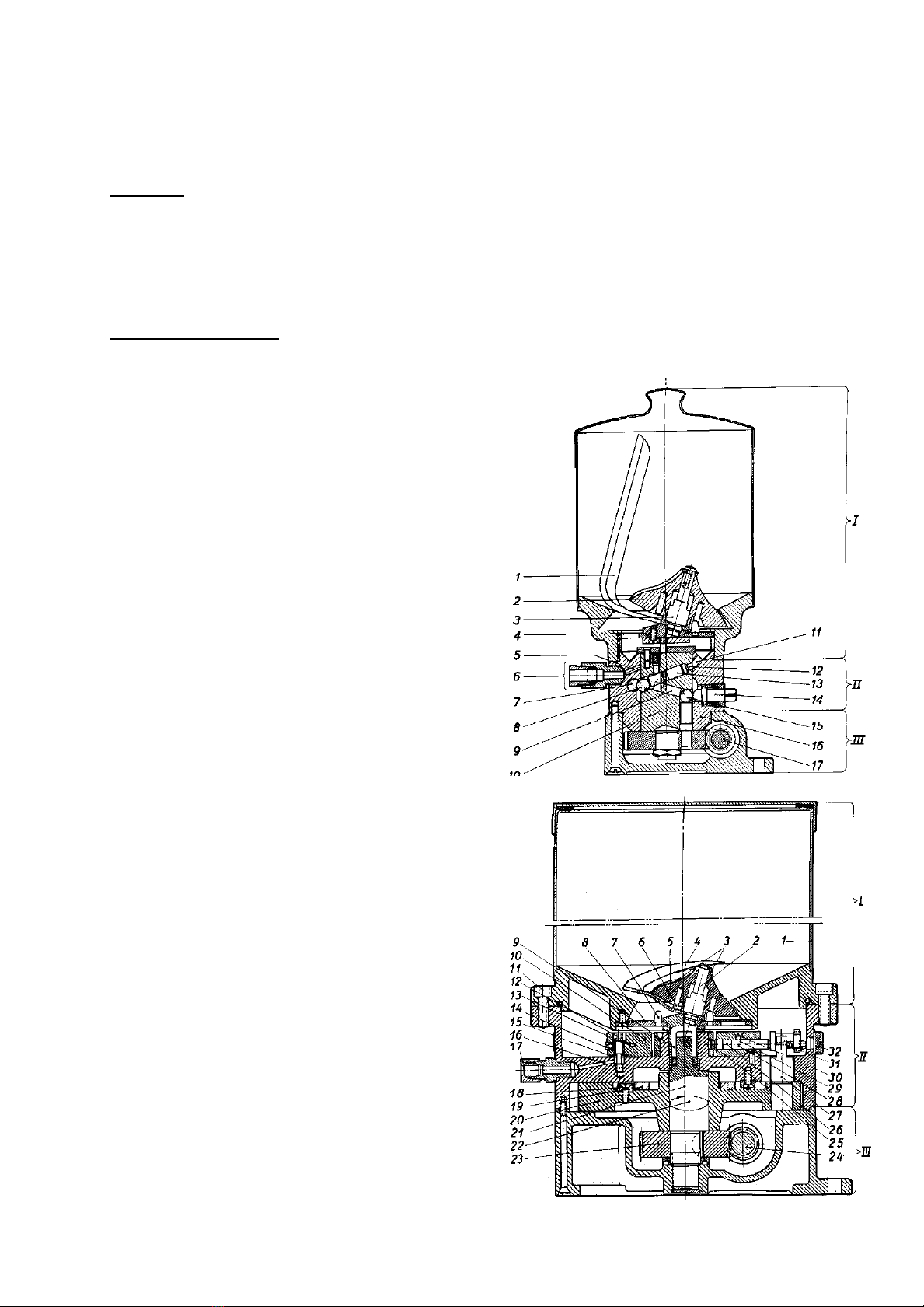

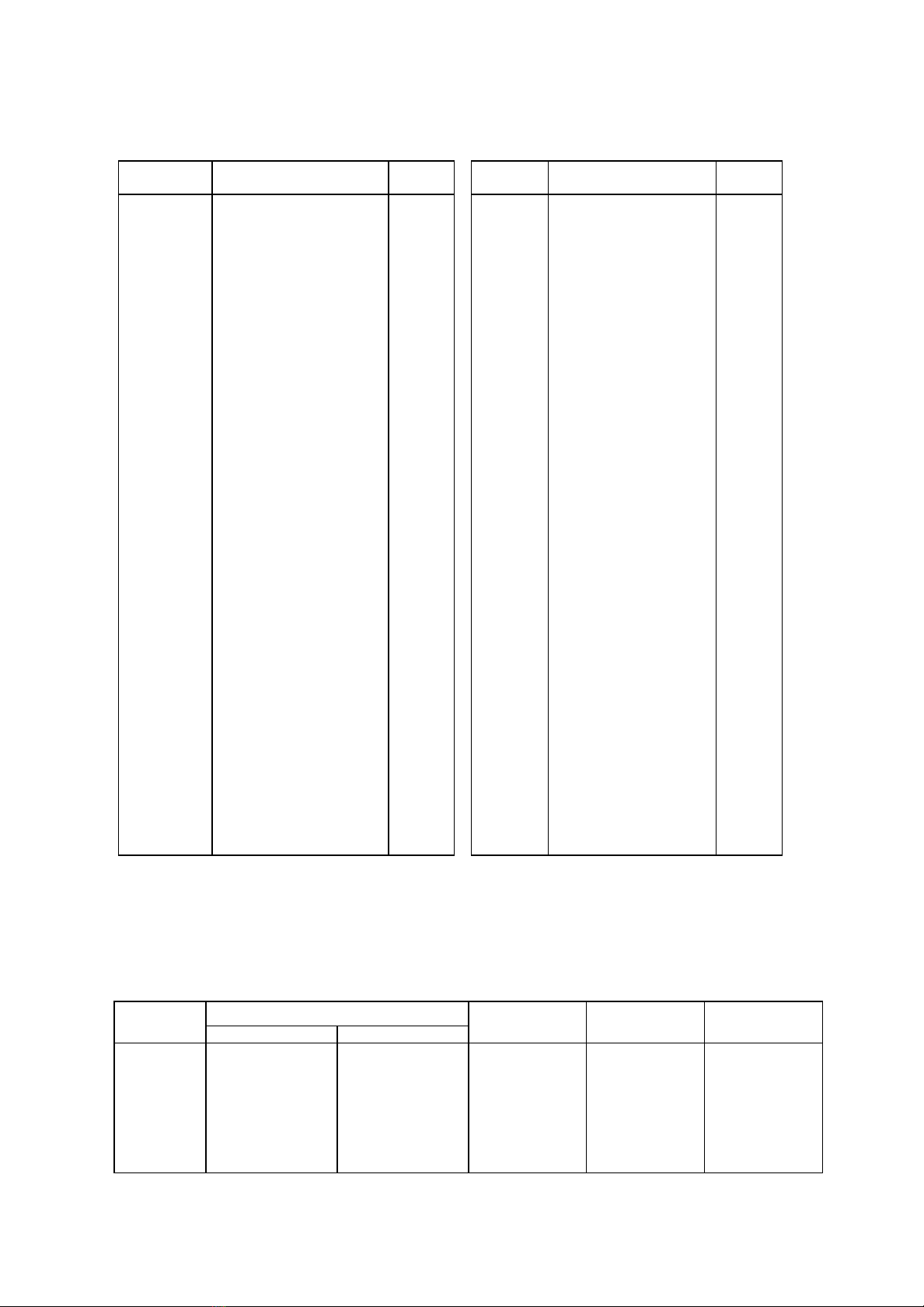

The two types of lubricator are of similar design and consist of:

Top section I –lubricant reservoir with pre-feeder

Intermediate section II –pump mechanism

Bottom section III –drive unit

MODE OF OPERATION

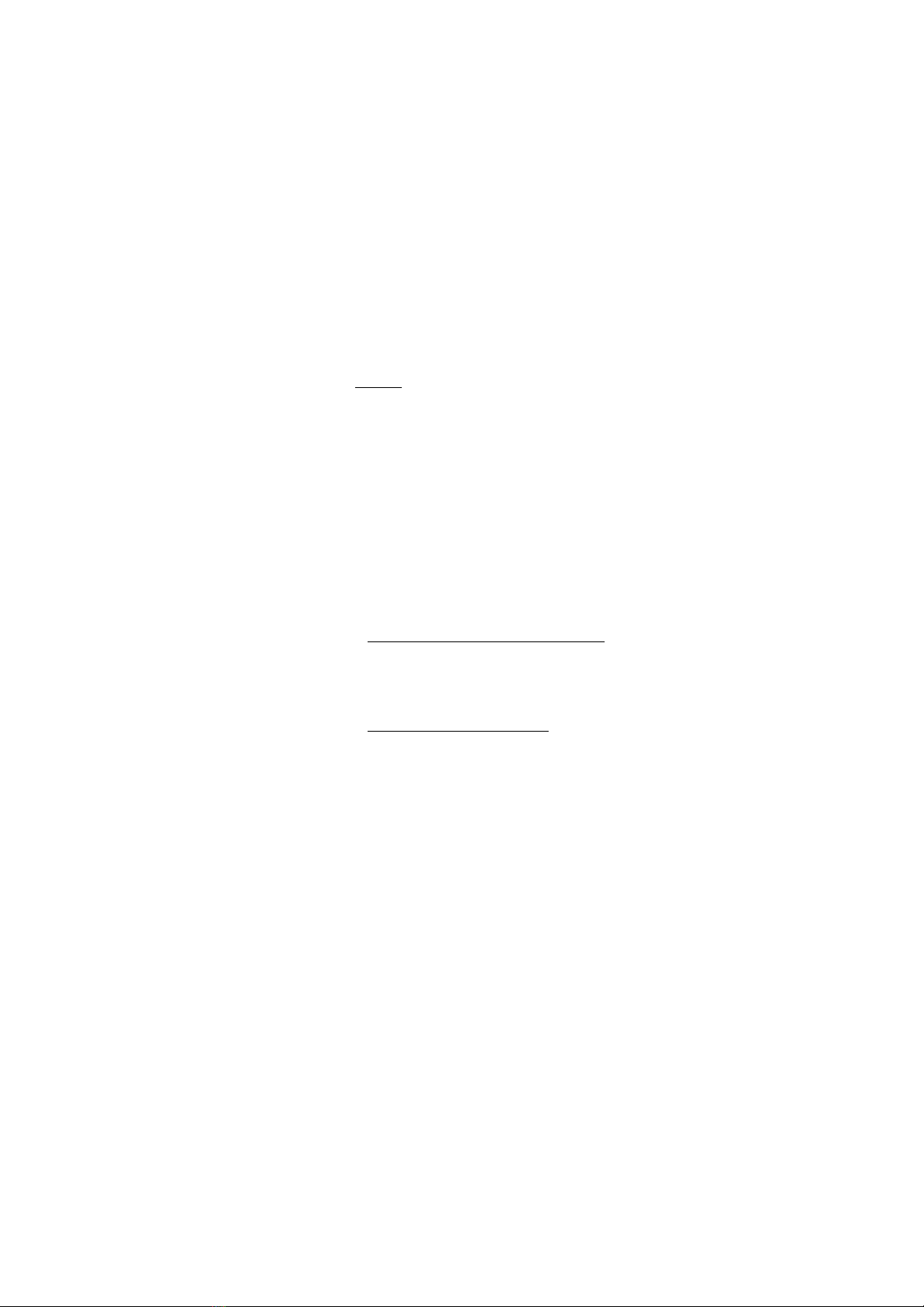

Type FL

When the central shaft 10 rotates, driven by shaft 17, the

pre-feeder (consisting of vane 1, pre-feed roller 2and

angled pin 3) feeds lubricant from the reservoir down

through the strainer 4to the cylinder pump 13 via the inlet

passages 11 in the pump body 16. The figure shows the

situation when the pump cylinder is being filled with

lubricant. When the central shaft continues to rotate, the

pump plunger pressure ball 8presses the pump plunger

upwards when it passes the pressure ball of the

respective outlet. At the same time, the orifice 12 of the

cylinder passage also passes one of the outlet passages

5in the pump body and the lubricant is forced out into

the line to the lubricating point via outlet 6. The pump

plunger then gets its suction movement from pin 9when

the guiding ball 15 in the central shaft engages with the

setting screw 14. Each outlet has a pressure ball 7, a

setting screw 14, an inlet passage 11 and an outlet

passage 5. The setting screws 14 adjust the length of the

pump plunger stroke and thus the lubricant discharge.

The lubricant discharge rate set for each outlet is

completely independent of those of the other outlets.

Type FE

When the central shaft 21 rotates, driven by shaft 24,

the pre-feeder 2–6feeds lubricant from the reservoir

through the strainer 8to the inlet 30 of the respective

pump unit 10. At the same time, the eccentric on the

central shaft and the guide plate 19 impart a plane-

parallel circular motion to the pump disc 20. By this

means the pressure studs 27 give the pump plungers

28 their axial suction and pressure motion, with the

rotational motion at dead centre which places the pump

unit cylinder 26 alternately in communication with the

intake opening 30 and the discharge connection 17 via

passages 13 and 16.

The central shaft drives the pre-feeder via the driver 9.

The pre-feeder homogenizes the grease and renders it

free from air.

The discharge rate is set individually for each pump unit

by adjusting the stroke of the pump plunger with the

setting screw 31. The setting screws are accessible

after removal of the protective plugs 32.

The pump units are readily accessible for replacement

after removal of the top section.