• #6957,

.050'

• #6956,

1/

16

' • #6961, 2.5mm

• #6959, 5/64. • #6960,

3132"

• A 3116'

nut

driver will make Installing the ball ends and

upper arm turnbuckles easier. (#SP-66)

• A 1/4' nut driver will

make

installing the 4-40 nuts easier.

(#SP-65)

•

An

11/32'

nut

dr

i

ver

will make installing and adjustlng the

8·32 rear axle diff nut easi

er

. (#SP-82)

• A precision rulerwith decimal inches

or

metric measure.

WARNING/

Do

not

use a powerscrewdriver to in-

stallscrewsIntonylonparts.

The

rotation speedis too fast,

and causes the screws to heat up when being driven into

plastic

or

nylon parts, then strips them out.

0

Step

6

IF

DYEING YOUR PARTS. The

ny

lon parts

in

your

kit

are

made from virgin material, so they can be

dyed according to the followingprecautions:(1)

To

keepthe

color consistent on a

ll

of the parts, the container should

hold all

of

the parts

at

the same time. (2) Use Dylon (true

nylon

or

plastic dye)

or

clothing dyes (liquid

or

powder) of

yourchosen color.

Follow

t

he

dye

company's

safety

pre-

cautions

and

Instructions.

(3)

To

preventwarpinganycriti-

cal parts, bolt the transmissi,on case halves togethe

r.

After

dyeinghas

beencompleted, thecase

ha

lvescanbeunbolted.

0

Step

7 F

INAL

NOTES:

(1)

Fo

r you experienced buildersandracers:please

build

the

car

our

way

flrstll

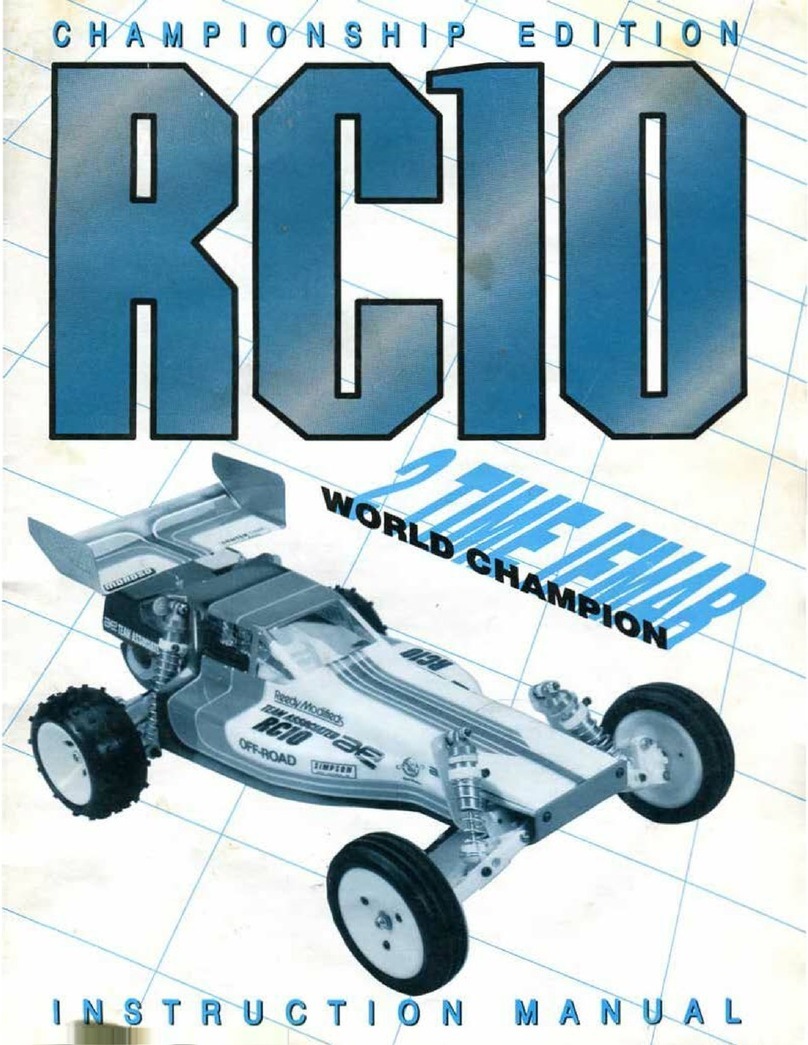

The ACtO Worlds

Car

is a

remarkab

ly

fast buggy right out of the box. There's a good

reasonfor everythi

ng

on thecar,andvery few compromises

were made in its design. If

you

build

it

our

wayfirstyou can

see what your car is capable of before you make changes

and you will then have a base pointto compare against.

(2) Put a check mark in the box ( 0 ) at each step

after

you

finish it. Then when you stop during assembly,

it

will

be

easier to find where

you

need to

co~tinue

from.

(3)

To

help you identify certain parts, occasionally

an actual-size drawing will accompany the photo. (See

ex

-

ample infig. 2.) You

can

place

your

part

on topof the draw-

ing to

be

sure

you

have picked

up

the right part. Mostlikely

you will end

up

with spare parts and fasteners,

but

this

is

nothing to worry, about because we have deliberately left

you with some spare items.

(4)

We

have

used

some

spec

ial

abbrev

ia

tions

througholllthismanualfor the various typesofscrewsused.

Thefollowing listidentifieswhattheabbreviationsstand for:

• FHMScrew: Flat Head

Ma

chine Screw. Standard thread

screwwhich requires a Phillips screwdriver.

• FHSScrew: Flat Head Socket Screw. Standard thread

screw which requ

ir

es

a Allen wrench

or

driver. The same

type

of

tool is used for the two following fasteners:

• BHSScrew: Button Head Socket Screw.

• SHCScrew: Socket Head

Cap

Screw.

(5) In ordertokeep a sense

of

direction when build·

lngthecar,

we

use

thefollowing descriptions

to

standardi

ze

the right and left sides of the vehicle. The driver's side

or

leftside: with the driversitting in thedriver'sseat facing the

front

of

the car, his left hand is the driver's side. The pas-

senger

or

right sidewill

be

the driver's right hand side.

(6)Thefollowing typesofspecial instructions,

in

/tal·

ics, will

be

used throughout the manual:

•

Racer's

Tip: This

is

a trick used

by

some

of

the

Team

drivers to improve their car's handling

or

performance,

or

simplifyits maintenance.

• Note: Alternate ways to assemble the kit, including tips

tor

smoothing

out

difficultassemb/ias.

• WARNING/ This alertsyou to be careful to preventdam-

age to parts

or

use

of

wrong parts that

may

reduce perfor-

mance.

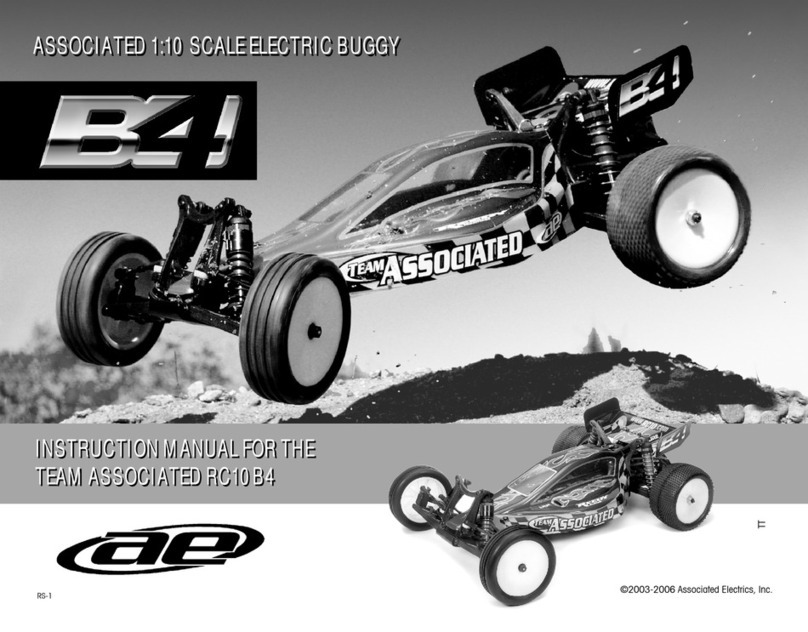

SAVE THIS MANUAL! This

Is

more

than an In·

structlon

manual.

ft

Is

also

a

handy

supplement

to

the

Team

Associated

1:10

scale

off

road

buggy

catalog.

You

can

use

the

manual

photos

and

descriptions

to

Identify

part

numbers

and

names

to

help

you

order

parts. Use

the

current

catalog

for

pricing.

....r-~_...,.....,.....,

FRONT

END

ASSEMBLY

page 5

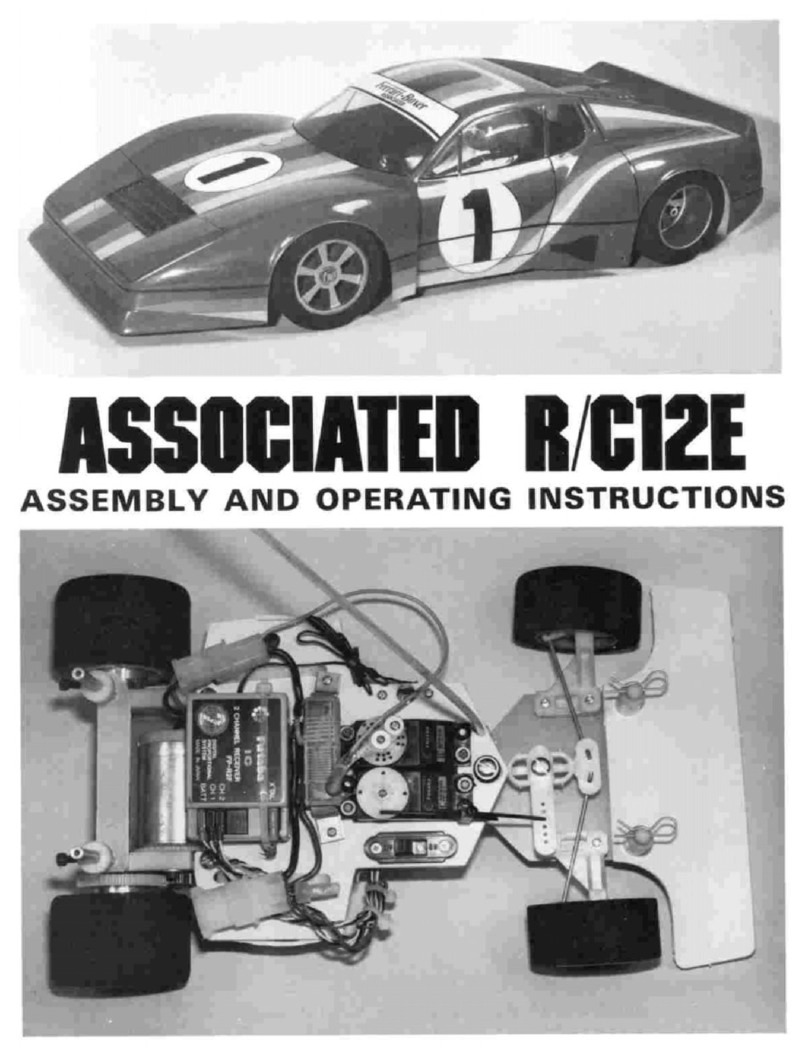

0 Fig. 1 Read pages four

and

five entirelybeforepro-

ceeding!

We'

ll start

by

removing t

he

#6309 black anodized

aluminum nose plate from

bag

#6·4

. It will look like

fiQ

.

1.

Fig.

1

0 Fig. 2 In bag #6·1

you

will find the #6207 front sus·

pension mounts (they

are

connected

by

a molding runner)

and six #6280

8·32

x 1/2' alumi

num

FHMScrews. Fig. 2

shows the left side frontsuspension mount Installed. It also

shows the right mount and the three #6280 screws used to

mount

it

to the noseplate.

Click part number

to search eBay