Associated Electrics TEAM ASSOCIATED RC10B4 User manual

Other Associated Electrics Motorized Toy Car manuals

Associated Electrics

Associated Electrics RC10 B4.2 User manual

Associated Electrics

Associated Electrics RC10T6.1 Team Kit User manual

Associated Electrics

Associated Electrics 8019 User manual

Associated Electrics

Associated Electrics SC10B RS RTR User manual

Associated Electrics

Associated Electrics RC10 T4.2 User manual

Associated Electrics

Associated Electrics TEAM ASSOCIATED RC10B4 User manual

Associated Electrics

Associated Electrics RC10GT2 User manual

Associated Electrics

Associated Electrics RC19T User manual

Associated Electrics

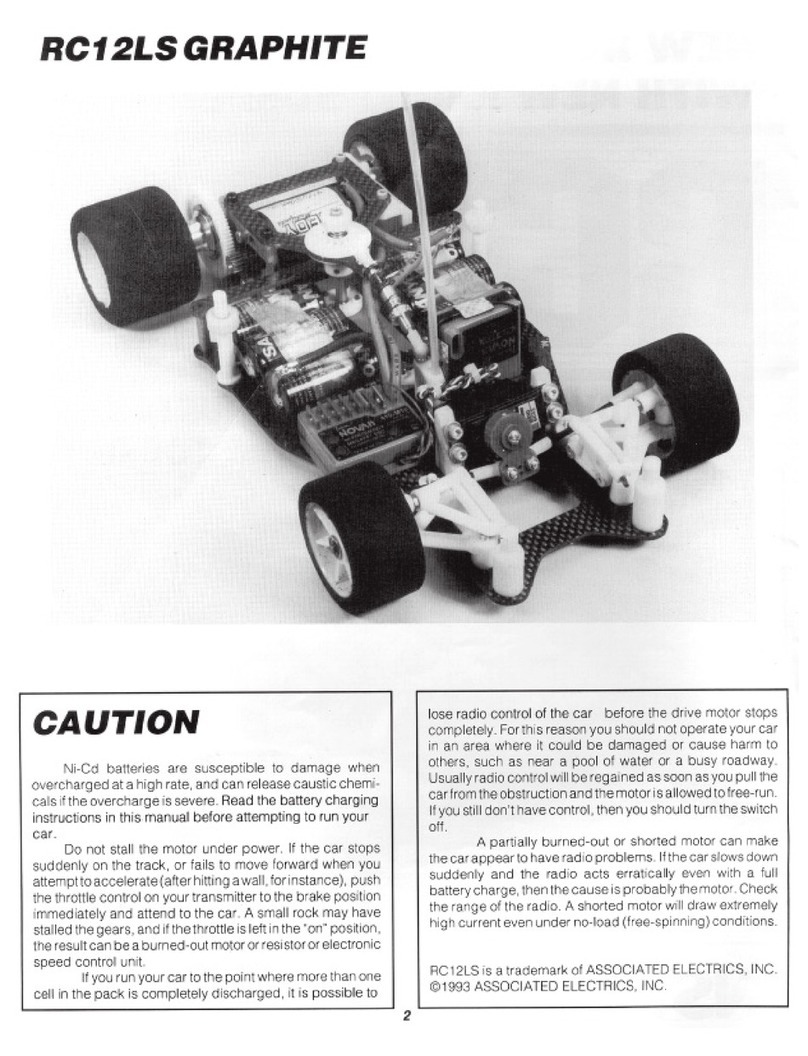

Associated Electrics RC12LS Graphite User manual

Associated Electrics

Associated Electrics RC10B3 User manual

Associated Electrics

Associated Electrics RC10B6.2D KIT User manual

Associated Electrics

Associated Electrics 2033 User manual

Associated Electrics

Associated Electrics TC5F Factory Team User manual

Associated Electrics

Associated Electrics PRO2 LT10SW SHORT WHEELBASE User manual

Associated Electrics

Associated Electrics RC8B3.2e User manual

Associated Electrics

Associated Electrics RC12 L3 User manual

Associated Electrics

Associated Electrics MGT 8.0 User manual

Associated Electrics

Associated Electrics APEX2 SPORT User manual

Associated Electrics

Associated Electrics RC10 B6.4D TEAM KIT User manual

Associated Electrics

Associated Electrics PRO4 SC10 User manual