‐2‐12‐1015rev‐B User’sManualVersion14.12

Table of Contents

1.0 Introduction-----------------------------------------------------------------------------------------

1.1 12-1015 REV-B (Battery Electrical System Analyser) ---------------------------------------------3

1.2 Specifications---------------------------------------------------------------------------------------------------4

2.0 Safety Measures----------------------------------------------------------------------------------------

2.1 Safety Precautions--------------------------------------------------------------------------------------------5

2.2 Other Precautions---------------------------------------------------------------------------------------------6

3.0 Working with Batteries------------------------------------------------------------------------- 7

4.0 The Battery Electrical System Analyser-----------------------------------------------------

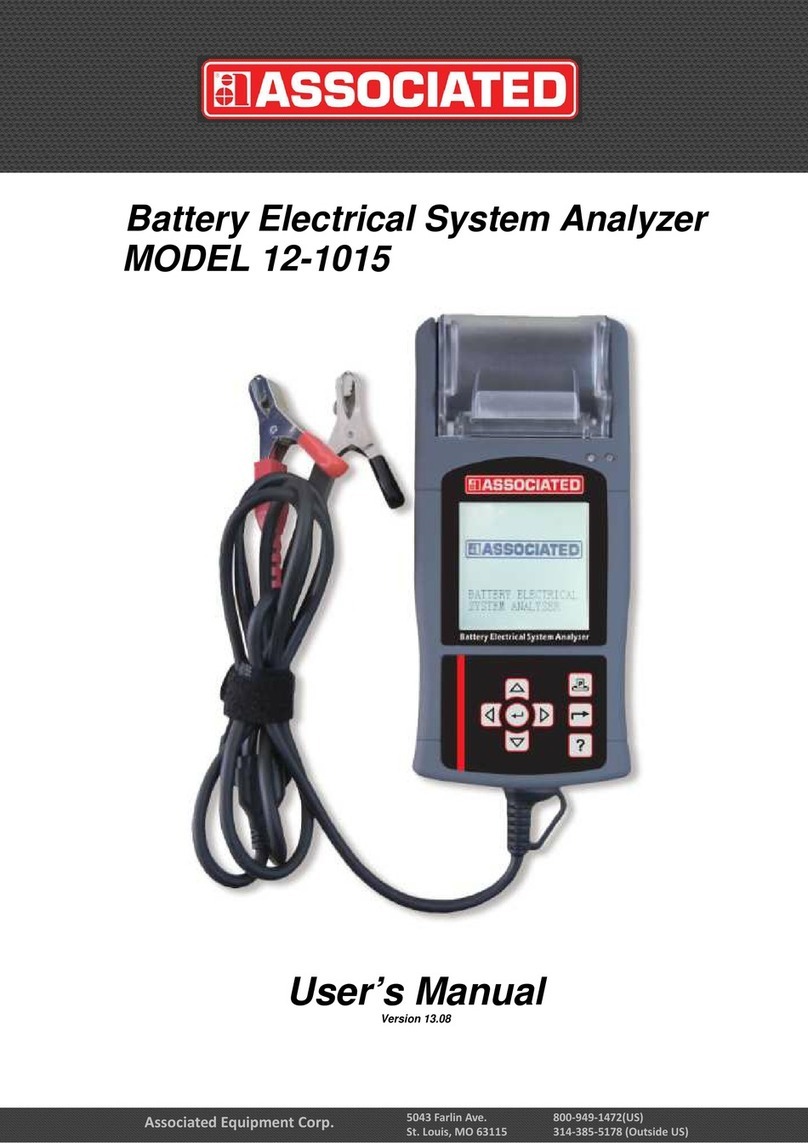

4.1 12-1015 REV-B---------------------------------------------------------------------------------------------------9

4.2 Key Functions----------------------------------------------------------------------------------------------------9

4.3 Functions of Individual Key--------------------------------------------------------------------------------10

5.0 Initial Setup -----------------------------------------------------------------------------------------

5.1 Paper Installation----------------------------------------------------------------------------------------------11

5.2 Setup Menu -----------------------------------------------------------------------------------------------------11

5.3 LCD Brightness------------------------------------------------------------------------------------------------12

5.4 Printer-------------------------------------------------------------------------------------------------------------12

5.5 Set Date & Time------------------------------------------------------------------------------------------------13

5.5 PC Link------------------------------------------------------------------------------------------------------------13

5.7 Erase Memory -------------------------------------------------------------------------------------------------14

6.0 Battery Test--------------------------------------------------------------------------------------14

6.1 Testing on Stand Alone Batteries-------------------------------------------------------------------------14

6.2 Begin Battery Test (Automotive) -------------------------------------------------------------------------17

7.0 Continue Testing ---------------------------------------------------------------------------------

7.1 Battery Test-----------------------------------------------------------------------------------------------------28

7.2 Starter Test------------------------------------------------------------------------------------------------------28

7.3 Charging Test---------------------------------------------------------------------------------------------------30

Starts with No Load testing at 3,000 RPM-------------------------------------------------------------30

Testing with electrical load at 2,000 RPM-------------------------------------------------------------32

Diode

Ripple Test----------------------------------------------------------------------------------------------34

7.4 Grounding Test-------------------------------------------------------------------------------------------------36

8.0 Stored Results --------------------------------------------------------------------------------------

8.1 Recalling and viewing previous Test Results--------------------------------------------------------40

9.0 Printing the Test Result from Stored memory-----------------------------------------42

10.0 PC Link----------------------------------------------------------------------------------------------

10.1 Installing driver -------------------------------------------------------------------------------------------------43

10.2 Printing Results from PC Printer--------------------------------------------------------------------------48

10.3 Saving Results to PC------------------------------------------------------------------------------------------48

11.0 Warranty Information----------------------------------------------------------------------------

11.1 Limited Warranty-----------------------------------------------------------------------------------------------49

11.2 Limitations of Warranty--------------------------------------------------------------------------------------50