i AU108850 D7A

TABLE OF CONTENTS

TO THE OWNER . . . . . . . . . . . . . . . . . . . . . . . . . 1

DD-3238 EARTHPRO DIRECTIONAL DRILL . . . . . . . . 1

RIGHT, LEFT, FRONT AND REAR OF MACHINE . . . . . 2

IDENTIFICATION NUMBERS . . . . . . . . . . . . . . . 3

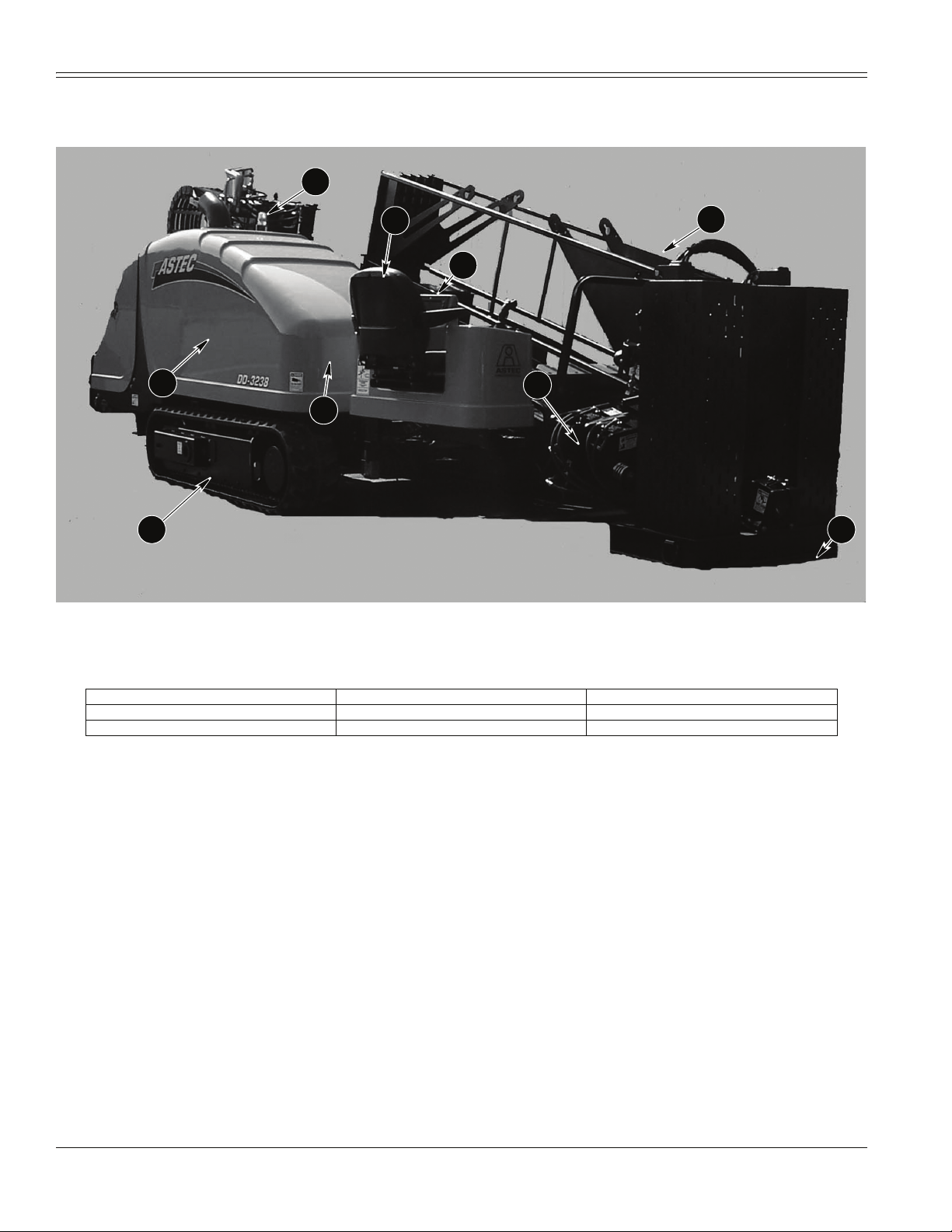

MACHINE COMPONENTS . . . . . . . . . . . . . . . . . . . . 4

SAFETY/DECALS/HAND SIGNALS . . . . . . . . . . . 5

SAFETY MESSAGE . . . . . . . . . . . . . . . . . . . . . . . . . 5

PERSONAL SAFETY . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . 5

UTILITY SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ELECTRIC STRIKE ALERT SAFETY . . . . . . . . . . . . . . 6

ELECTRICAL LINE SAFETY . . . . . . . . . . . . . . . . . . . 6

GAS LINE SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . 7

WATER LINE SAFETY . . . . . . . . . . . . . . . . . . . . . . . 7

COMMUNICATION LINE SAFETY . . . . . . . . . . . . . . . 7

BEFORE OPERATIONS . . . . . . . . . . . . . . . . . . . . . . 7

NOISE LEVEL SAFETY . . . . . . . . . . . . . . . . . . . . . . . 8

MACHINE SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . 8

FAILURE IN OPERATION . . . . . . . . . . . . . . . . . . . . . 9

PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . 9

CAST DUCTILE IRON . . . . . . . . . . . . . . . . . . . . . . . 9

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BATTERY SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . 10

PRESSURIZED HYDRAULIC FLUID AND GREASE . . . 10

HYDRAULIC HOSE WEAR AND TEAR . . . . . . . . . . . 10

HAZARDOUS CHEMICALS . . . . . . . . . . . . . . . . . . . 10

FIRE OR EXPLOSION PREVENTION . . . . . . . . . . . . 11

ROLL-OVER PROTECTION . . . . . . . . . . . . . . . . . . . 11

FIRE EXTINGUISHER . . . . . . . . . . . . . . . . . . . . . . 11

READ OPERATOR’S MANUAL . . . . . . . . . . . . . . . . . 11

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INSTRUMENTS AND CONTROLS . . . . . . . . . . . . 21

LEFT CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . 21

RIGHT CONTROL PANEL . . . . . . . . . . . . . . . . . . . . 24

REAR CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . 26

TRAVEL CONTROL PENDANT . . . . . . . . . . . . . . . . . 27

LIFE JACKET PENDANT . . . . . . . . . . . . . . . . . . . . . 28

DD-3238 OPERATORS DISPLAY . . . . . . . . . . . . . . . 29

SYSTEM BOOT SCREEN . . . . . . . . . . . . . . . . . . . . 30

MAIN OPERATING SCREEN . . . . . . . . . . . . . . . . . . 31

DRILL OPERATING SCREEN . . . . . . . . . . . . . . . . . 32

DRILL FORCE SCREEN . . . . . . . . . . . . . . . . . . . . . 33

ADDITIONAL INFORMATION SCREEN . . . . . . . . . . 34

MACHINE INFORMATION SCREEN . . . . . . . . . . . . . 35

GENERAL SYSTEM HELP SCREEN . . . . . . . . . . . . . . 36

READ ERROR CODES SCREEN . . . . . . . . . . . . . . . . 37

DIAGNOSE AND UPDATE SCREEN . . . . . . . . . . . . . 38

ERROR CODE DESCRIPTIONS . . . . . . . . . . . . . . . . 39

OPERATORS SEAT AND PLATFORM . . . . . . . . . . . . 40

HOOD LATCHES . . . . . . . . . . . . . . . . . . . . . . . . . . 40

BATTERY DISCONNECT SWITCH . . . . . . . . . . . . . . 40

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . 41

ZAP-ALERT ELECTRIC STRIKE ALARM SYSTEM . . . . 41

ZAP-ALERT ALARM INSTALLATION . . . . . . . . . . . . . 41

ZAP-ALERT ALARM TESTING . . . . . . . . . . . . . . . . . 41

es!lok® MACHINE LOCKOUT SYSTEM . . . . . . . . . . 42

INSTALLATION/CONFIGURATION . . . . . . . . . . . . . . 42

SPECIFICATIONS R130 RECEIVER/T50 TRANSMITTER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

DIAGNOSTICS - T50 TRANSMITTER . . . . . . . . . . . . 46

UNDERSTANDING DIRECTIONAL DRILLING . . . . . . 51

HOLE LENGTH/DEPTH CHART . . . . . . . . . . . . . . . . . 53

DRILL TRACKING ELECTRONICS . . . . . . . . . . . . . . 54

ENGINE OPERATION . . . . . . . . . . . . . . . . . . . . . . 55

RUN-IN MAINTENANCE SCHEDULE . . . . . . . . . . . . 56

OPERATING IN HOT WEATHER . . . . . . . . . . . . . . . 56

OPERATING IN COLD WEATHER . . . . . . . . . . . . . . 56

STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . 57

ENGINE SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . 57

BOOSTER BATTERY CONNECTIONS . . . . . . . . . . . 57

PARKING AND STOPPING THE ENGINE . . . . . . . . . 58

HYDROSTATIC BRAKES . . . . . . . . . . . . . . . . . . . . 58

MACHINE OPERATION . . . . . . . . . . . . . . . . . . . . . 58

MOVING THE MACHINE . . . . . . . . . . . . . . . . . . . . 58

TRANSPORTING THE MACHINE . . . . . . . . . . . . . . 59

MOVING A DISABLED MACHINE . . . . . . . . . . . . . . 59

ELECTRONIC TRACKING SYSTEM . . . . . . . . . . . . . 60

DATA LOGGING . . . . . . . . . . . . . . . . . . . . . . . . . 60

HYDRAULIC OIL WARM UP . . . . . . . . . . . . . . . . . . 60

TESTING INDICATOR LAMPS . . . . . . . . . . . . . . . . 60

ZAP ALERT STROBE . . . . . . . . . . . . . . . . . . . . . . . 61

THRUST FRAME POSITION AND DRILLING LOCATION

61

POWER STAKEDOWN . . . . . . . . . . . . . . . . . . . . . 62

CHANGING PIPE CARRIER . . . . . . . . . . . . . . . . . . 62

PIPE LOADER OPERATION . . . . . . . . . . . . . . . . . . 63

CHANGING PIPE STACKING ROWS . . . . . . . . . . . . 63

LOADING PIPE CARRIER . . . . . . . . . . . . . . . . . . . 63

ACCESSORIES AND OPTIONAL EQUIPMENT . . . . . . 64

LOADING DRILL PIPES TO DRILL . . . . . . . . . . . . . 64

INSTALL DRILL HEAD AND FIRST DRILL PIPE . . . . 64

OPERATIONAL HOOKUP CONNECTION . . . . . . . . . 65

DRILLING PRECAUTIONS . . . . . . . . . . . . . . . . . . . 65

POWER WRENCH OPERATION . . . . . . . . . . . . . . . 65

PILOT BORE OPERATION . . . . . . . . . . . . . . . . . . . 66

BORE ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

HORIZONTAL REACH BORING . . . . . . . . . . . . . . . 67

BACKREAMING AND PULLBACK . . . . . . . . . . . . . . . . 67

PRESSURE WASHING THE MACHINE . . . . . . . . . . . 69

UNLOADING DRILL PIPE DURING BACK REAM / PULL

BACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . 71

GENERAL SAFETY BEFORE SERVICING MACHINE . . 71

PLASTIC AND RESIN PARTS . . . . . . . . . . . . . . . . . 71

ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ENGINE HOURS . . . . . . . . . . . . . . . . . . . . . . . . . 71

CAPACITIES AND LUBRICANT SPECIFICATIONS . . . 72

LUBRICATION/MAINTENANCE CHART . . . . . . . . . . 73

OIL VISCOSITY/TEMPERATURE USAGE CHART . . . 74

ENGINE OIL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

AIR FILTERING SYSTEM . . . . . . . . . . . . . . . . . . . . 76

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

HYDRAULIC OIL SYSTEM . . . . . . . . . . . . . . . . . . . 79

ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . 80

TRACK PLANETARY DRIVE . . . . . . . . . . . . . . . . . . 82

DRILL FLUID PUMP OIL LEVEL . . . . . . . . . . . . . . . 83

ROTARY DRIVE GEARBOX . . . . . . . . . . . . . . . . . . 84

ADJUSTMENT/MAINTENANCE . . . . . . . . . . . . . 85

FASTENER INSPECTION . . . . . . . . . . . . . . . . . . . . 85

SHUTDOWN MAINTENANCE . . . . . . . . . . . . . . . . . 85

POWER WRENCH INSPECTION . . . . . . . . . . . . . . . 85

TRACK TENSION AND ADJUSTMENT . . . . . . . . . . . 85

HYDRAULIC HOSES AND FITTINGS INSPECTION . . 86

FIRE EXTINGUISHER . . . . . . . . . . . . . . . . . . . . . . 86

ROTARY DRIVE SPINDLE SAVER SUB . . . . . . . . . . 86

PRESSURE WASHING THE MACHINE . . . . . . . . . . . 86