Table of contents

Table of contents...................................................................................................................................... 3

Commands and parameters of the VLM500-MID....................................................................................... 5

List of figures............................................................................................................................................ 7

List of tables .............................................................................................................................................8

1General information ................................................................................................................................. 9

1.1 Information on how to work with this manual......................................................................................................9

1.2 Safety instructions...............................................................................................................................................9

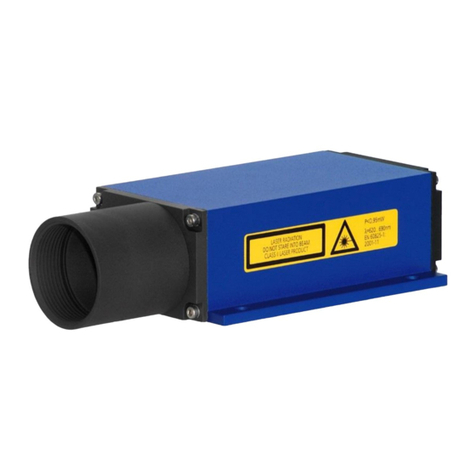

2Device description .................................................................................................................................. 10

2.1 Intended use ..................................................................................................................................................... 10

2.2 Two components –one device........................................................................................................................... 10

2.3 Measuring principle........................................................................................................................................... 11

2.4 LED-Indicators ...................................................................................................................................................13

2.5 Software integrity and software identification....................................................................................................14

2.6 Preset length outputs ........................................................................................................................................15

3Operating modes.................................................................................................................................... 16

4Device models ........................................................................................................................................ 17

5CDB Handling.......................................................................................................................................... 18

5.1 Keypad..............................................................................................................................................................18

5.2 Switch-on procedure ......................................................................................................................................... 18

5.3 Menu structure .................................................................................................................................................19

5.4 Measurement display ........................................................................................................................................21

5.5 Stored data .......................................................................................................................................................22

5.5.1 Measurement list ......................................................................................................................................22

5.5.2 Storage period and memory size................................................................................................................22

5.5.3 Measurement details.................................................................................................................................22

5.5.4 Searching for specific measurement data................................................................................................... 23

5.5.5 Invalid measured values ............................................................................................................................24

5.6 Device information ............................................................................................................................................24

5.7 Settings.............................................................................................................................................................26

6Performing a measurement process........................................................................................................ 28

7Assembly................................................................................................................................................ 30

7.1 VLM500.............................................................................................................................................................30

7.2 CDB...................................................................................................................................................................32

8Connections and Interfaces..................................................................................................................... 33

8.1 General ............................................................................................................................................................. 33

8.2Power supply and grounding.............................................................................................................................. 34

8.3 Switching in- and outputs ..................................................................................................................................34

8.4 Service interface USB.........................................................................................................................................35

8.5 Printer connection.............................................................................................................................................36

8.6 Protocol output (not legally relevant, optional) .................................................................................................. 36

8.6.1 Serial interface ..........................................................................................................................................38

8.6.2 Profinet IO................................................................................................................................................. 39

8.6.3 EtherNet/IP............................................................................................................................................... 41

8.6.4 Ethernet....................................................................................................................................................41

8.7 Analog output (not legally relevant, optional)..................................................................................................... 42

8.8 Pulse output for encoder emulation (not legally relevant, optional)....................................................................42

8.8.1 Open Collector ..........................................................................................................................................42

8.8.2 Push Pull 5V (IP5V) .................................................................................................................................... 42

8.8.3 Push Pull 24V (IPPP)...................................................................................................................................43