Contents

CONTENTS

Laser Safety ................................ 1

1.0 Hazard Information....................... 1

2.0 Terms & Warning Symbols ........... 1

3.0 Acronyms and Abbreviations ....... 1

4.0 General Hazards .......................... 2

5.0 Other Hazards.............................. 3

6.0 Disposal ....................................... 3

7.0 Safe Operation of the Laser ......... 3

8.0 Additional Safety Information ....... 4

Safety Labels.............................. 5

1.0 Laser Head................................... 5

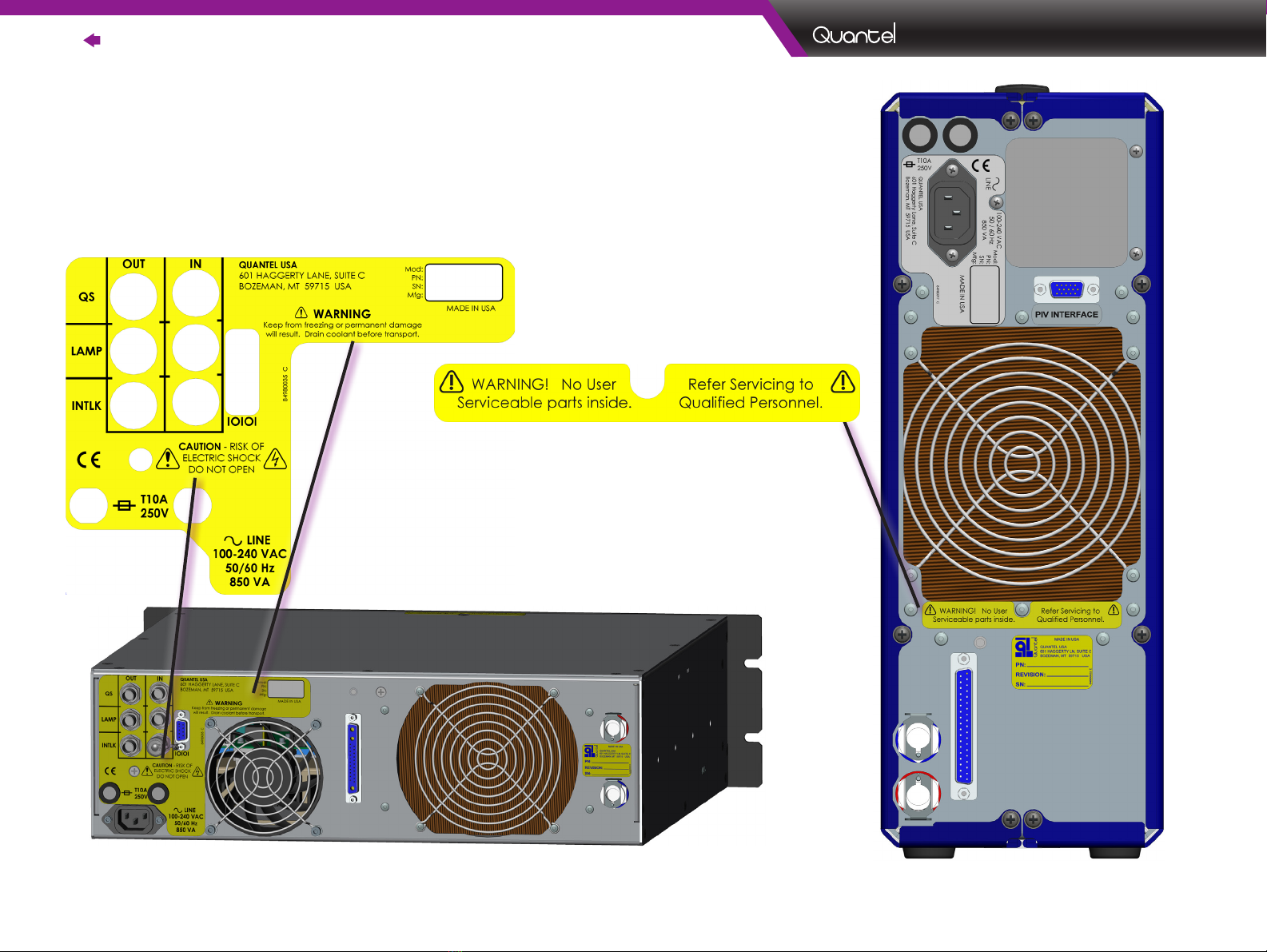

2.0 ICE450 ......................................... 6

3.0 Part/Serial Numbers ..................... 7

Setup ................................................ 8

1.0 Mounting the Laser Head............. 8

2.0 Connecting................................... 9

3.0 Filling the Standard ICE450.......... 11

4.0 Filling the Rack ICE450 ................ 12

Functions....................................... 13

1.0 ICE450 Front Panel Controls ........ 13

2.0 ICE450 Rear Panel ....................... 15

Operation....................................... 16

1.0 Safety ........................................... 16

2.0 Precautions .................................. 16

3.0 Remote Interlock .......................... 16

4.0 Manual Shutter ............................. 17

5.0 Remote Box.................................. 18

6.0 Remote Box Navigation................ 19

7.0 Remote Box Menu,

Detailed Descriptions ................... 20

8.0 Operating Modes ......................... 27

9.0 Manual Modes.............................. 27

10.0 Automatic Mode (INT/INT) ......... 28

11.0 External Modes (EXT) ................ 30

12.0 Example Start-Up Procedure ..... 33

13.0 Shutdown Procedure ................. 33

14.0 Decreasing Output Energy ........ 34

15.0 Increasing Output Energy.......... 34

Software......................................... 35

1.0 Serial Interface ............................. 35

2.0 Serial Command Reference ......... 36

3.0 Quick Reference .......................... 47

Technical Specifications..... 48

1.0 General Specifications ................. 48

2.0 Data Summary Sheet.................... 49

3.0 RS-232 Cable Wiring.................... 50

4.0 External Trigger Signal Req.......... 52

5.0 Timing Diagrams .......................... 53

Optional Equipment................ 56

1.0 Variable Attenuator (MVAT)........... 56

2.0 MVAT Command Set..................... 57

3.0 Hyperterminal Setup for MVAT ..... 58

Drawings........................................ 59

1.0 Cooling System Diagram.............. 59

2.0 Laser Head, 1064nm.................... 60

3.0 Laser Head, 532/355/266 nm

Ultra Stable................................... 61

4.0 Laser Head with GRM, 1064nm ... 62

5.0 Laser Head with GRM

532/355/266nm............................ 63

6.0 Laser Head with Dichroics

532/355/266nm............................ 64

7.0 Laser Head with GRM & Dichroics

532/355/266nm............................ 65

8.0 Laser Head, 1574nm

Ultra Stable.................................. 66

9.0 Laser Head with MVAT

Ultra 1064nm ............................... 67

Maintenance................................ 68

1.0 Scheduled Maintenance .............. 68

2.0 Draining the ICE450 ..................... 68

3.0 Draining a Rack ICE450 ............... 70

4.0 Replacing the DI Cartridge .......... 72

5.0 Transporting the System............... 73

6.0 Replacing the ICE450 Fuses........ 73

7.0 Flashlamp Replacement............... 74

8.0 Nitrogen Purge for the Ultra ......... 76

9.0 Nitrogen Purge for FOLA.............. 77

Troubleshooting ........................ 78

1.0 General Information...................... 78

2.0 Interlocks...................................... 78

3.0 Resolving Interlock Faults ............ 79

4.0 Serial Communications

Troubleshooting ............................ 86

5.0 Diagnosing Problems ................... 87

Warranty......................................... 91

Certificates .................................. 92