5

shaded module may rise due to hot spot effect,

burning the module and causing fire hazard in

severe cases.

For PV modules used in deserts or windy and

sandy areas, it is recommended to use connector

dust caps before installation, or take other measures

to prevent sand and dust from entering the

connectors, otherwise it may cause insertion

problems or electrical safety hazards.

3.2 Operation safety measures

Avoid package damaging and falling during

transportation and storage. Ensure the packing

cases are well ventilated, water-proof and dry.

After the arrival, carefully open the outer package

and prevent scratches and bumps of PV modules.

When stacking PV modules, strictly follow the

stacking requirements in chapter 4.3.

Avoid impact or scratches on any part of the PV

module, otherwise the reliability and safety of the

PV module will be affected; standing or walking on

the PV module is prohibited; at the same time, in

order to avoid glass damage, it is forbidden to

apply excessive load or distorted PV modules.

Do not install or carry PV modules by one person.

It is forbidden to pick up, drag, or move PV

modules by grabbing the junction box (including

the box body, cables, and connectors); when

placing a PV module on a flat surface, it must be

operated carefully and be aware of bumps in the

corners.

When installing or repairing the PV system, do not

wear any metal accessories to avoid the risk of

electric shock; if it is installed far above the ground,

please wear a seat belt.

When operating PV modules in the sun, please use

insulated tools, and wear rubber gloves and

protective clothing. At the same time, in order to

avoid the risk of arc and electric shock, do not

directly touch the junction box and the end of the

output cable (connector) with bare hands.

For electrical connection, choose a dry and

weak-light morning or evening; or use opaque

materials to completely cover the surface of the PV

modules to prevent current generation.

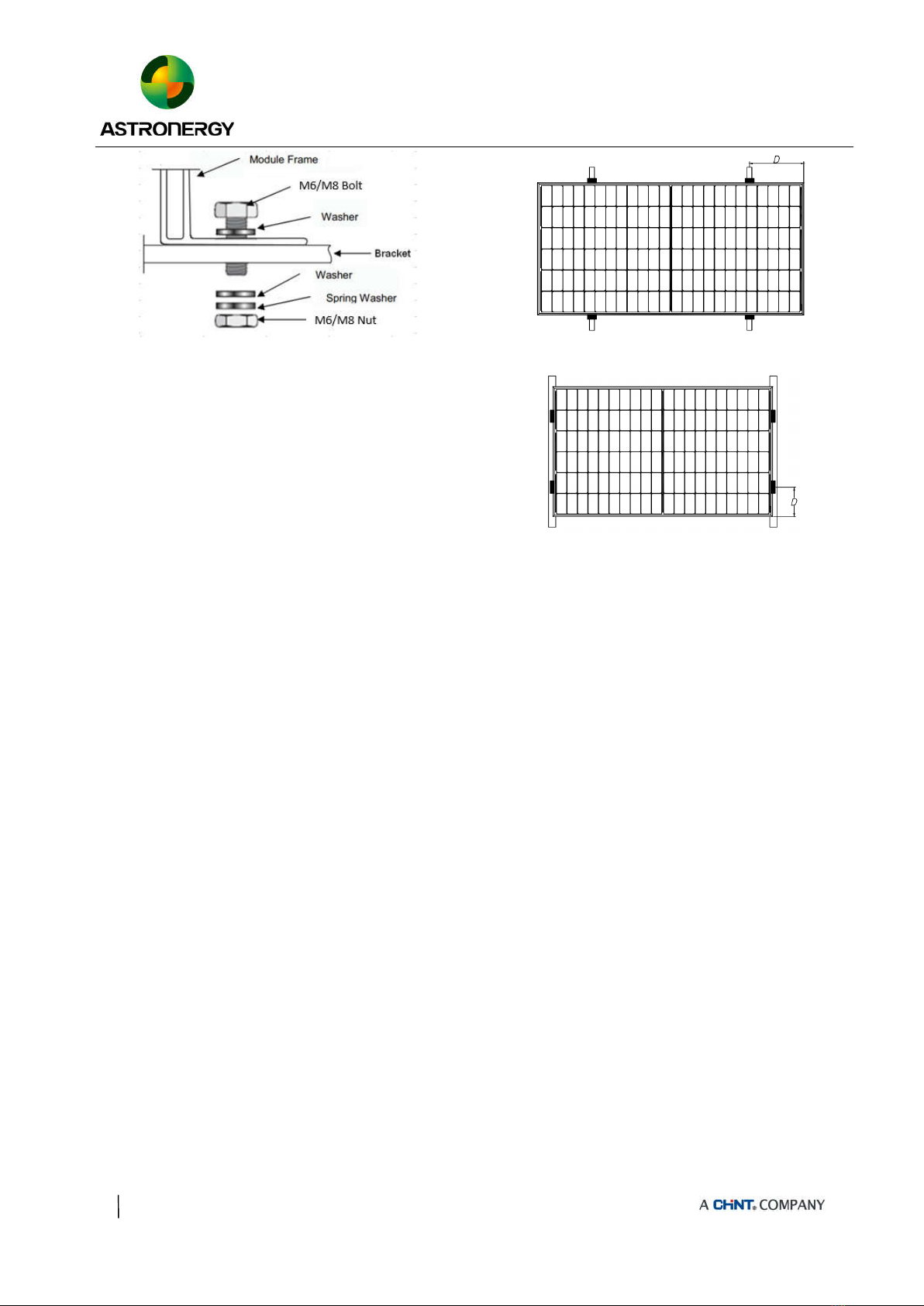

A certain distance between the PV module and the

installation surface should be kept to prevent the

installation surface from touching the junction box.

When installing on the roof, comply with the fire

protection requirements of the building. It is

recommended to install PV modules on a fireproof

and insulated roof covering, and ensure adequate

ventilation between the PV modules and the

installation surface. In order to ensure the fire

rating on the roof, the minimum distance between

the frame of the PV module and the roof surface is

10cm.

The connector must be fully mated when wiring. If

the cable is too long, it is recommended to fix the

cable to the rack system with a UV-resistant nylon

cable tie. When fixing the cable to the rack, the

bending radius of the cable should not be less than

48mm.

Avoid directly exposing cables and connectors to

sunlight. Please use anti-UV cables.

Do not disconnect the electrical connection when