Rev 13.0/5-19 1 MRTALPCH6-DC: #35054

TABLE OF CONTENTS

SPECIFICATIONS............................................................................................................ 3

WARNINGS ..................................................................................................................... 4

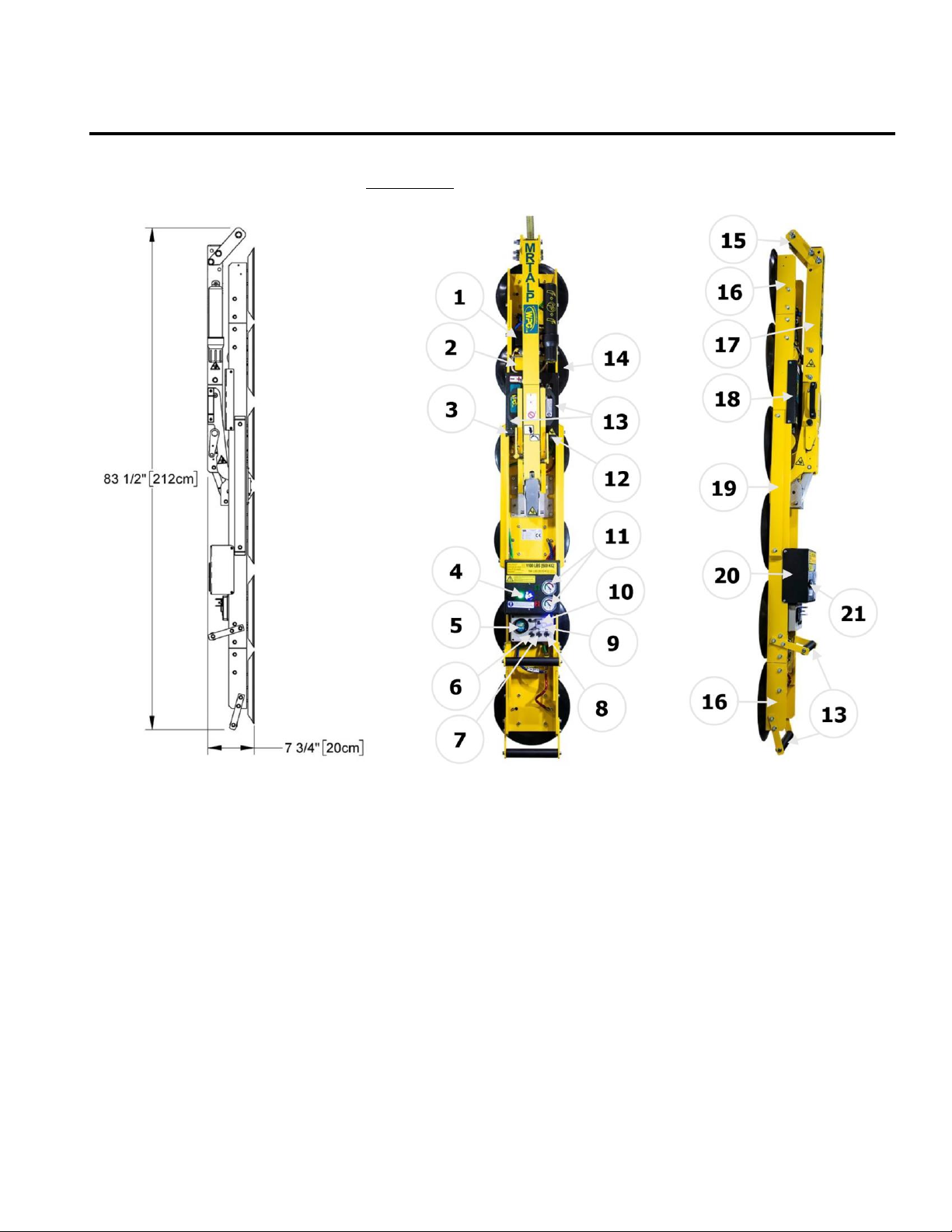

OPERATING FEATURES................................................................................................... 5

ASSEMBLY....................................................................................................................... 6

TO SET UP THE LIFTER ................................................................................................................6

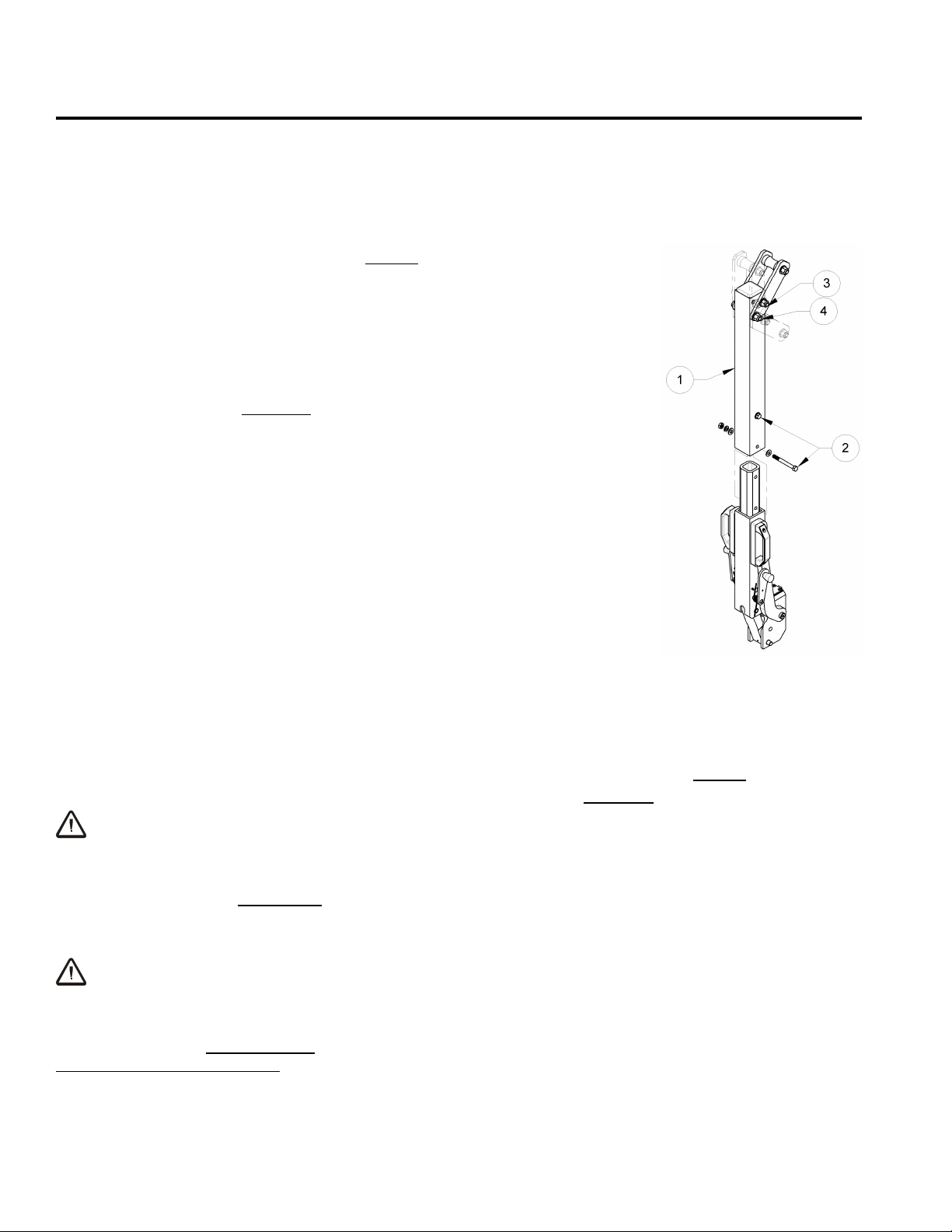

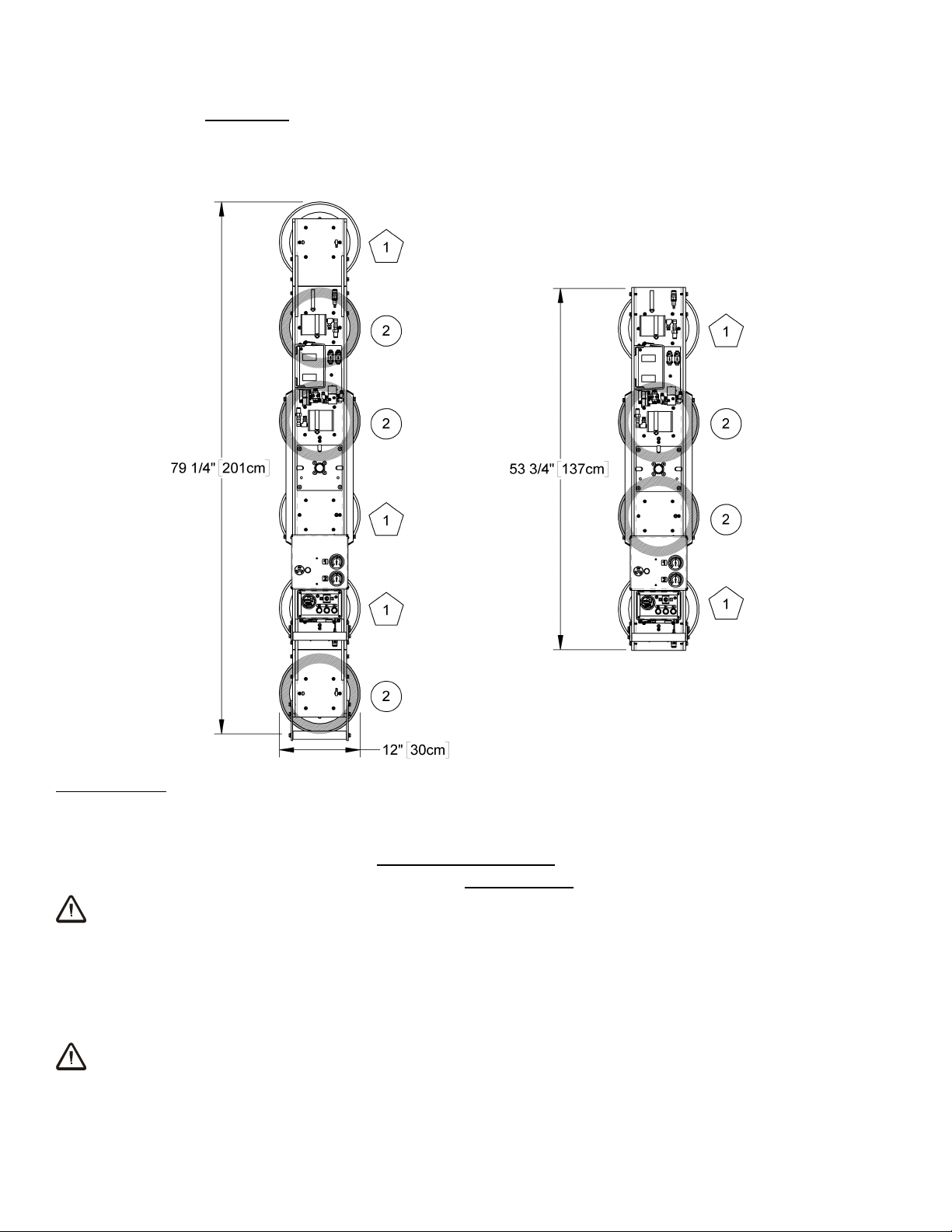

TO CHANGE THE PAD FRAME CONFIGURATION ................................................................................8

To Install/Remove Pad Frame Extensions ......................................................................................................9

To Connect/Disconnect Vacuum Hoses..........................................................................................................9

To Route Vacuum Hoses ............................................................................................................................10

INTENDED USE ............................................................................................................. 11

LOAD CHARACTERISTICS ........................................................................................................... 11

OPERATING ENVIRONMENT .......................................................................................................12

DISPOSAL OF THE LIFTER ..........................................................................................................13

OPERATION .................................................................................................................. 14

BEFORE USING THE LIFTER........................................................................................................14

Taking Safety Precautions ..........................................................................................................................14

Performing Inspections and Tests ...............................................................................................................14

Confirming the Pad Frame Configuration .....................................................................................................15

Preparing to Use the Optional Remote Control System .................................................................................15

TO ATTACH THE PADS TO A LOAD................................................................................................16

Positioning the Lifter on the Load ...............................................................................................................16

Powering up the Lifter................................................................................................................................16

Reading the Vacuum Gauges ......................................................................................................................17

Vacuum Level on Optimal Surfaces .............................................................................................................17

TO LIFT AND MOVE THE LOAD ....................................................................................................19

Positioning the Lift Bar ...............................................................................................................................19

Interpreting the Warning Buzzer and Lift Light ............................................................................................19

Monitoring Vacuum Indicators ....................................................................................................................19

Monitoring the Low Vacuum Warning Buzzer ...............................................................................................20

Controlling the Lifter and Load....................................................................................................................20

In Case of Power Failure ............................................................................................................................20

TO ROTATE THE LOAD EDGEWISE................................................................................................21

TO TILT THE LOAD ...................................................................................................................22

TO RELEASE THE PADS FROM THE LOAD .......................................................................................22

AFTER USING THE LIFTER..........................................................................................................23

Storing the Lifter........................................................................................................................................23

MAINTENANCE.............................................................................................................. 24

INSPECTION SCHEDULE.............................................................................................................24

Every-Lift Inspection ..................................................................................................................................24

Frequent Inspection ...................................................................................................................................24