000.100.533 2/68

Table of Contents

TABLE OF CONTENTS..............................................................................................................................2

1. INTRODUCTION...............................................................................................................................4

1.1. GENERAL INFORMATION...........................................................................................................4

1.2. OTHER MANUALS......................................................................................................................4

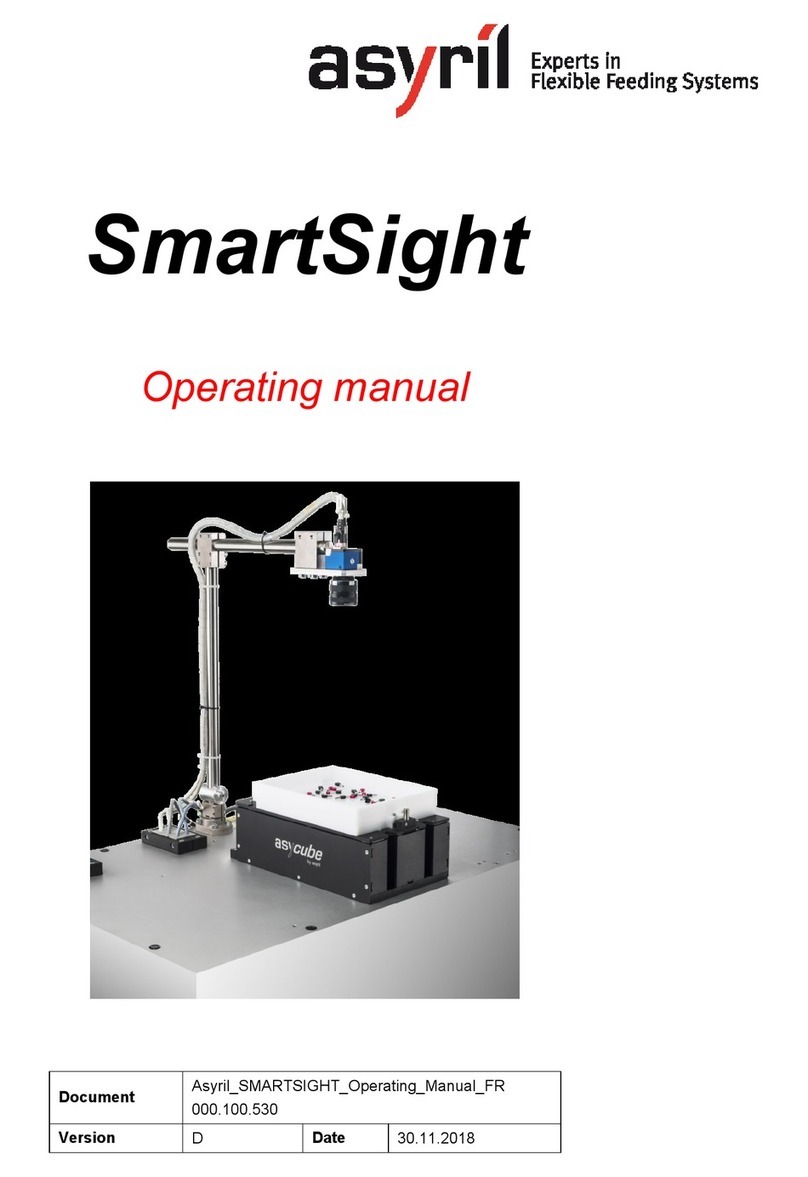

2. STRUCTURE OF THE SMARTSIGHT..........................................................................................6

2.1. IMAGE CONFIGURATION AND RECIPES......................................................................................7

2.1.1. Definition of the image configuration concept ..................................................................7

2.1.2. Defining the image configuration to use..........................................................................12

2.1.3. Recipes................................................................................................................................12

3. CONFIGURING THE SYSTEM ....................................................................................................13

3.1. PIXEL/MM CALIBRATION..........................................................................................................15

3.2. CALIBRATING THE FEEDER .....................................................................................................17

3.3. CALIBRATING THE PROCESS...................................................................................................18

4. CREATION AND CONFIGURATION OF A NEW RECIPE .....................................................20

4.1. CONFIGURING THE ASYCUBE.................................................................................................21

4.1.1. Vibration of the Asycube platform and reservoir............................................................21

4.1.2. Configuring the vibration process.....................................................................................21

4.1.3. Configuring the process for two components and two hoppers ..................................24

4.2. CONFIGURATION OF THE VISION SYSTEM...............................................................................26

4.2.1. Selection of the vision analysis type................................................................................26

4.2.2. Configuring the illumination parameters..........................................................................27

4.3. PROGRAMMING THE VISION MODEL........................................................................................30

5. PROGRAMMING THE VISION MODEL.....................................................................................31

5.1. OVERVIEW ..............................................................................................................................31

5.1.1. Tips and shortcuts..............................................................................................................32

5.2. PRE-LOCALIZATION.................................................................................................................32

5.2.1. Overview..............................................................................................................................32

5.2.2. Configuring the tool: "Model" tab......................................................................................33

5.2.3. Configuring the tool: "Bounding Box" tab........................................................................38

5.2.4. Advanced mode..................................................................................................................39

5.3. MODEL FINDER.......................................................................................................................40

5.3.1. Overview..............................................................................................................................40

5.3.2. "Settings" tab.......................................................................................................................40

5.3.3. Configuring the tool: "Detection" tab................................................................................42

5.3.4. Configuring the tool: "Detection (advanced)" tab...........................................................45

5.3.5. Configuring the tool: "ControlSettings" tab .....................................................................46