000.100.530 2/50

Table of Contents

TABLE OF CONTENTS................................................................................................................................................ 2

1. INTRODUCTION................................................................................................................................................ 4

1.1. GENERAL INFORMATION ............................................................................................................................ 4

1.2. SAFETY INSTRUCTIONS ............................................................................................................................. 5

1.2.1. General instructions ............................................................................................................................. 5

1.2.2. Specific instructions ............................................................................................................................. 5

1.3. WARRANTY INFORMATION ......................................................................................................................... 6

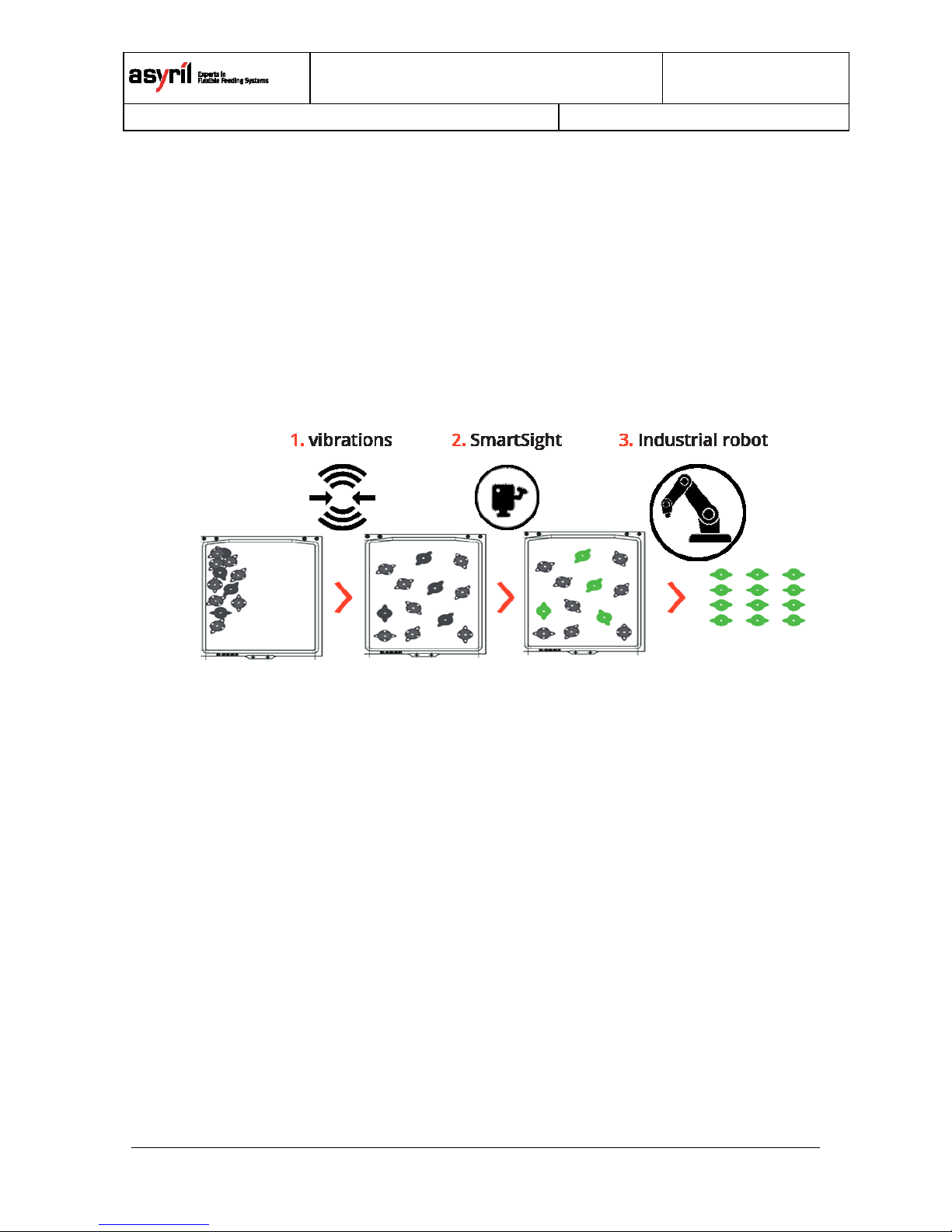

2. DESCRIPTION ................................................................................................................................................... 7

2.1. PRODUCT OVERVIEW................................................................................................................................. 7

2.2. GENERAL CHARACTERISTICS .................................................................................................................... 9

2.2.1. Vision specifications........................................................................................................................... 10

2.2.2. General characteristics...................................................................................................................... 12

2.2.3. Architecture ......................................................................................................................................... 14

2.3. ELECTRICAL INTERFACES ........................................................................................................................ 14

2.3.1. Diagrams of basic configurations ..................................................................................................... 14

2.3.2. Control unit .......................................................................................................................................... 20

2.3.3. EasyConnect Box............................................................................................................................... 23

2.4. MECHANICAL INTERFACES....................................................................................................................... 29

2.4.1. Control unit .......................................................................................................................................... 29

2.4.2. EasyConnect Box............................................................................................................................... 29

2.4.3. Vision Kit.............................................................................................................................................. 31

2.4.4. Asycube ............................................................................................................................................... 33

2.5. ACCESSORIES AND OPTIONAL MODULES ................................................................................................. 34

2.5.1. Lighting ................................................................................................................................................ 34

2.5.2. Control camera ................................................................................................................................... 39

2.5.3. Switch for multi-Asycube connection............................................................................................... 40

2.5.4. Calibration plate.................................................................................................................................. 40

3. TRANSPORTATION, HANDLING AND INSTALLATION......................................................................... 44

3.1. PACKAGING OF THE PRODUCT,TRANSPORTATION AND HANDLING .......................................................... 44

3.2. UNPACKING INSTRUCTIONS ..................................................................................................................... 44

3.3. INSTALLATION AND STORAGE ENVIRONMENT ........................................................................................... 44

3.3.1. Installation environment..................................................................................................................... 44

3.3.2. Storage environment.......................................................................................................................... 45

4. MAINTENANCE AND REPAIR ..................................................................................................................... 46

4.1. SAFETY INSTRUCTIONS ........................................................................................................................... 46

4.1.1. General instructions ........................................................................................................................... 46

4.2. PERSONNEL RESPONSIBLE FOR MAINTENANCE OR REPAIR OPERATIONS ................................................ 46

4.3. MAINTENANCE......................................................................................................................................... 47

4.3.1. Maintenance schedule....................................................................................................................... 47