000.100.530 2/50

Table of Contents

TABLE OF CONTENTS................................................................................................................................................2

1. INTRODUCTION................................................................................................................................................4

1.1. GENERAL INFORMATION............................................................................................................................4

1.2. SAFETY INSTRUCTIONS .............................................................................................................................5

1.2.1. General instructions.............................................................................................................................5

1.2.2. Specific instructions.............................................................................................................................6

1.3. WARRANTY INFORMATION.........................................................................................................................6

2. DESCRIPTION...................................................................................................................................................7

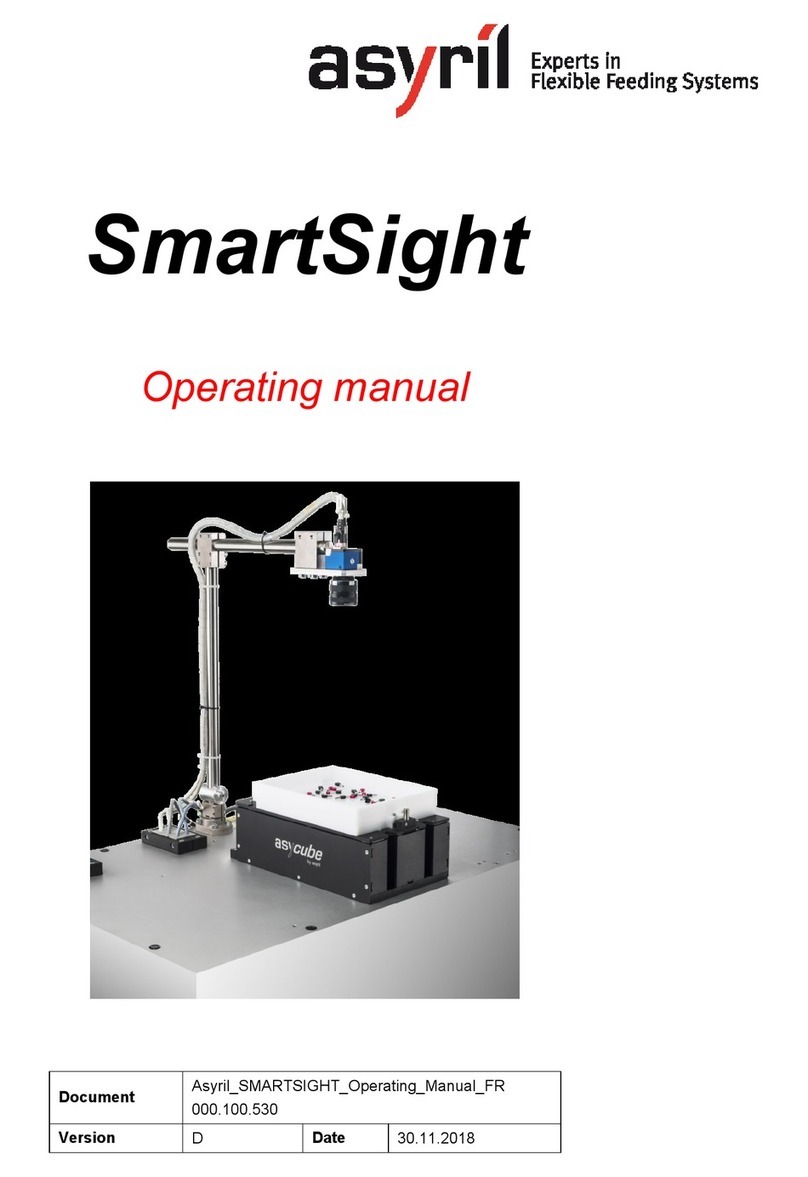

2.1. PRODUCT OVERVIEW ................................................................................................................................7

2.2. GENERAL CHARACTERISTICS ....................................................................................................................9

2.2.1. Vision specifications...........................................................................................................................10

2.2.2. General specifications.......................................................................................................................12

2.2.3. Architecture.........................................................................................................................................14

2.3. ELECTRICAL INTERFACES........................................................................................................................16

2.3.1. Diagrams of basic configurations.....................................................................................................16

2.3.2. Control unit..........................................................................................................................................21

2.3.3. EasyConnect Box...............................................................................................................................24

2.4. MECHANICAL INTERFACES ......................................................................................................................30

2.4.1. Control unit..........................................................................................................................................30

2.4.2. EasyConnect Box...............................................................................................................................30

2.4.3. Vision Kit..............................................................................................................................................32

2.4.4. Asycube...............................................................................................................................................34

2.5. ACCESSORIES AND OPTIONAL MODULES .................................................................................................35

2.5.1. Lighting................................................................................................................................................35

2.5.2. Control camera...................................................................................................................................40

2.5.3. Switch for multi-asycube connection...............................................................................................41

2.5.4. Calibration plates................................................................................................................................41

3. TRANSPORTATION, HANDLING AND INSTALLATION ........................................................................43

3.1. PRODUCT PACKAGING,TRANSPORTATION AND HANDLING ......................................................................43

3.2. UNPACKING INSTRUCTIONS.....................................................................................................................43

3.3. INSTALLATION AND STORAGE ENVIRONMENT...........................................................................................43

3.3.1. Installation environment ....................................................................................................................43

3.3.2. Storage environment .........................................................................................................................44

4. MAINTENANCE AND REPAIR.....................................................................................................................45

4.1. SAFETY INSTRUCTIONS ...........................................................................................................................45

4.1.1. General instructions...........................................................................................................................45

4.2. PERSONNEL RESPONSIBLE FOR MAINTENANCE OR REPAIR OPERATIONS ................................................45

4.3. MAINTENANCE.........................................................................................................................................46

4.3.1. Maintenance schedule.......................................................................................................................46