Installation/Operating Instructions ATB – HBA(-C)

ATB WATER GmbH, Südstraße 2, 32457 Porta Westfalica, Germany, www.atbwater.com

Version: 01.04.2022 / Page 3 of 30

Content

1. Safety regulations............................................................................................................................ 4

2. Product overview............................................................................................................................. 5

2.1. Description............................................................................................................................. 5

2.2. Working principle.................................................................................................................... 6

2.3. Exclusion of fields of application............................................................................................. 6

3. Receiving and handling................................................................................................................... 7

3.1. Receiving and acceptance ..................................................................................................... 7

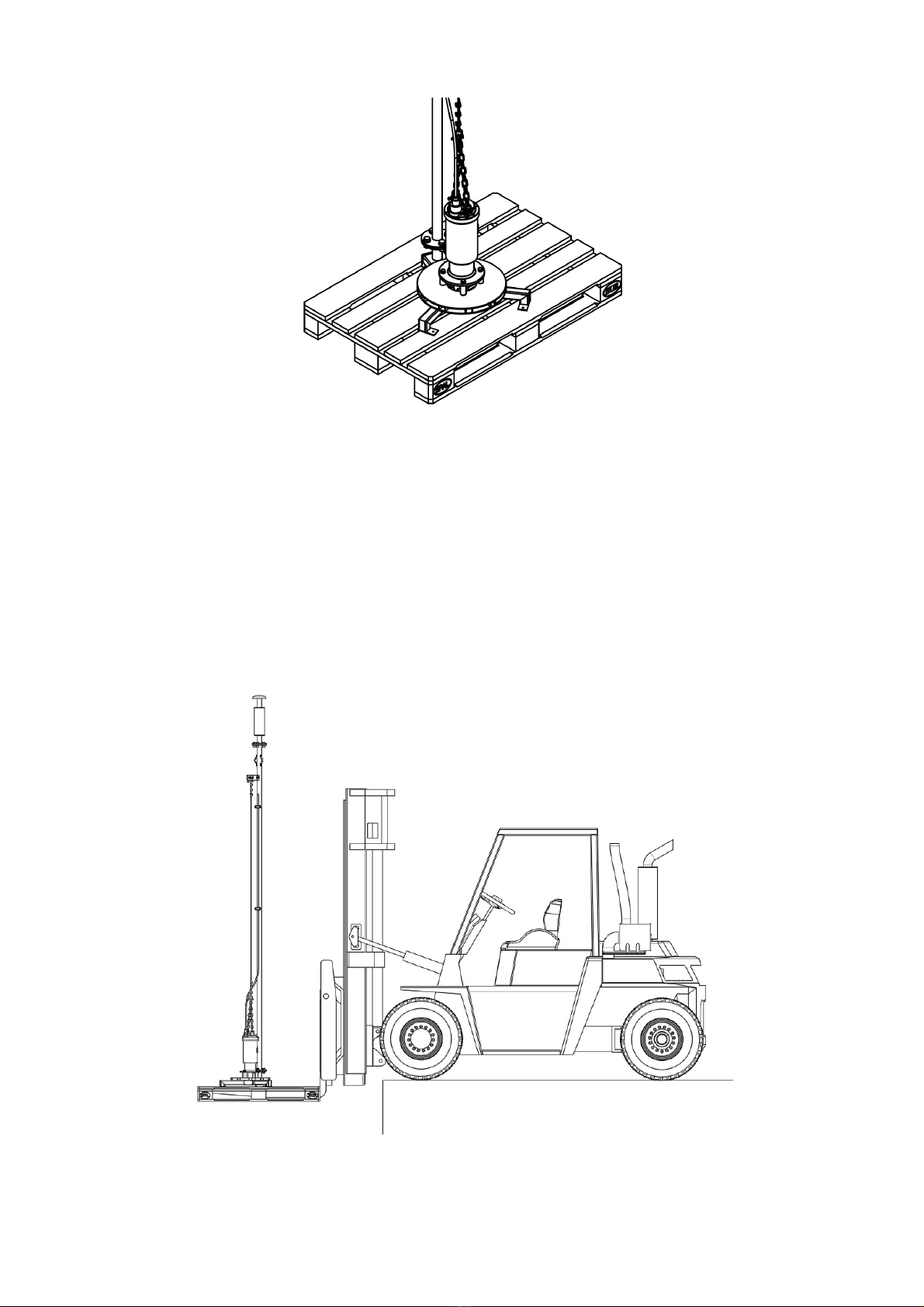

3.2. Handling (loading/unloading).................................................................................................. 7

4. Assembly........................................................................................................................................ 10

4.1. Preliminary work / instructions / installation of the aerator .....................................................10

4.2. Assembly and installation......................................................................................................11

4.2.1. Mounting the extension channels (HBA-C only) ..............................................................11

4.2.2. Mounting the intake pipe and the silencer (optional)........................................................11

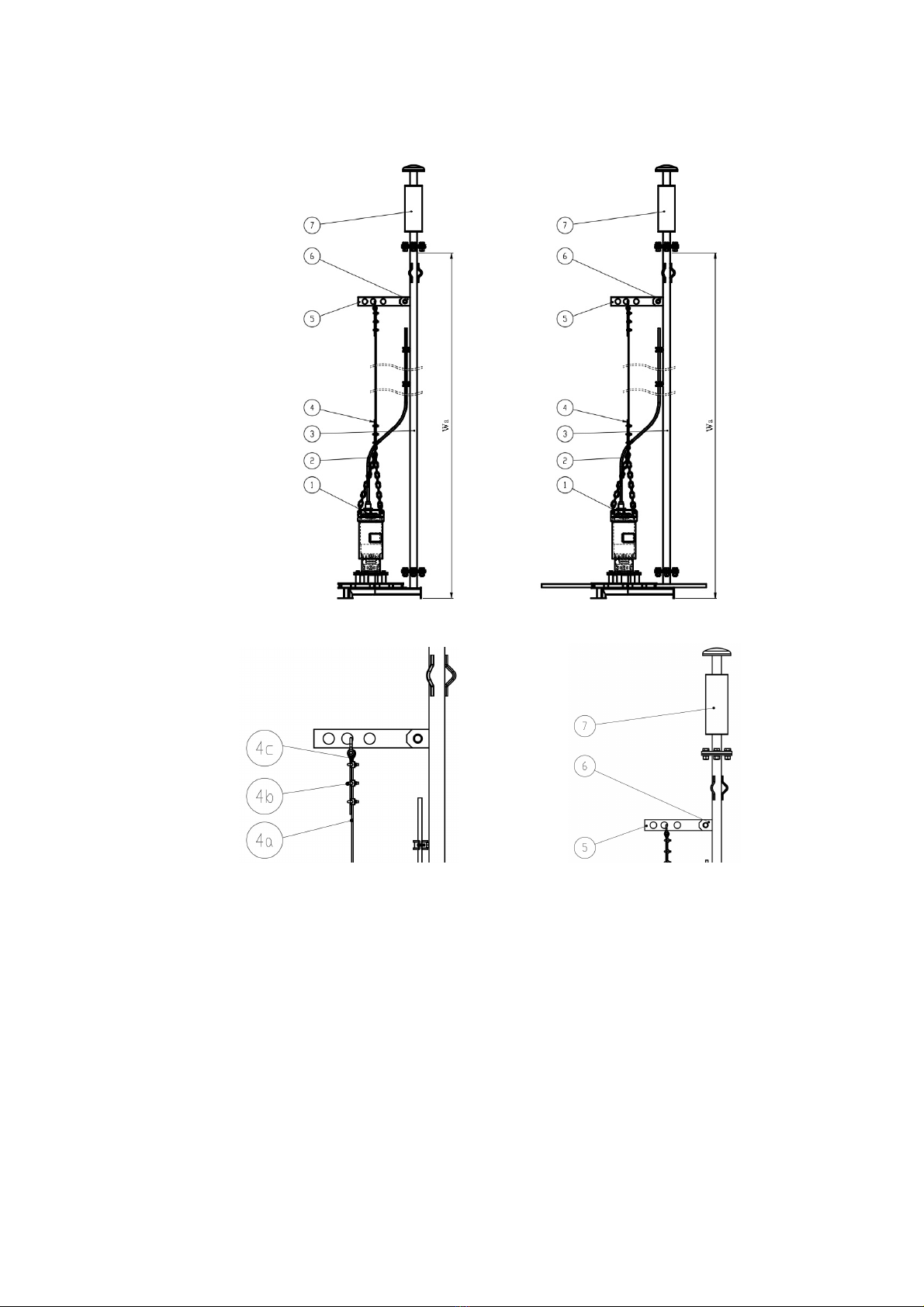

4.2.3. Assembly of the lifting device supplied by ATB (optional)................................................11

4.2.4. Installation of the power cable .........................................................................................13

4.2.5. Installation of the aerator in the tank................................................................................13

4.3. Instructions for electrical connection......................................................................................14

4.3.1. General instructions ........................................................................................................14

4.3.2. Control panel...................................................................................................................15

4.3.3. Direction of rotation .........................................................................................................16

4.3.4. Delta connection..............................................................................................................17

4.3.5. Star connection ...............................................................................................................17

4.4. Start-up .................................................................................................................................18

5. Operation and maintenance.......................................................................................................... 19

5.1. Operation ..............................................................................................................................19

5.2. Maintenance .........................................................................................................................19

5.2.1. Leakage test....................................................................................................................20

5.2.2. Oil check ........................................................................................................................21

5.2.3. General overhaul.............................................................................................................22

5.2.4. Checking the insulation of the motor................................................................................22

5.2.5. Lubrication.......................................................................................................................23

5.2.6. Checking the impeller......................................................................................................23

5.2.7. Checking the air intake....................................................................................................23

ENCLOSURE I: General data ............................................................................................................ 27

ENCLOSURE II: Declaration of conformity...................................................................................... 28

ENCLOSURE III: Maintenance sheet ................................................................................................ 29

ENCLOSURE IV: O&M manual of the motor.................................................................................... 30