Assembly Instructions / RR.. 1, RR153

1 Introduction / 1.1 Purpose of the assembly instructions

© Copyright 2020 ABB. All rights reserved. HZTL455311P0022_EN Rev.B July 2020

1 Introduction

1.1 Purpose of the assembly instructions

The assembly instructions explain how the ABB turbocharger is fitted to the engine correctly

and without any health and safety risks. This element of the documentation is supplied with

the product, as is required for partly completed machinery in accordance with machinery dir-

ective 2006/42EC.

The assembly instructions are a complement to and expansion of existing national regula-

tions for occupational safety, accident prevention and environmental protection.

1.2 Definition of target group

The assembly instructions are intended for engineers and mechanics responsible for fitting

the turbocharger on the engine. Basic mechanical training is a prerequisite.

All persons who are involved in the transportation and installation of the turbocharger have

read and understood the assembly instructions.

1.3 Symbols and definitions

The following symbols are used in the documents:

wPrerequisite

uWork step

¡Enumeration, first level

- Enumeration, second level

→ Refers to a page number

The trademarks of outside companies are used in this document. These are marked with the

® symbol.

Design variants

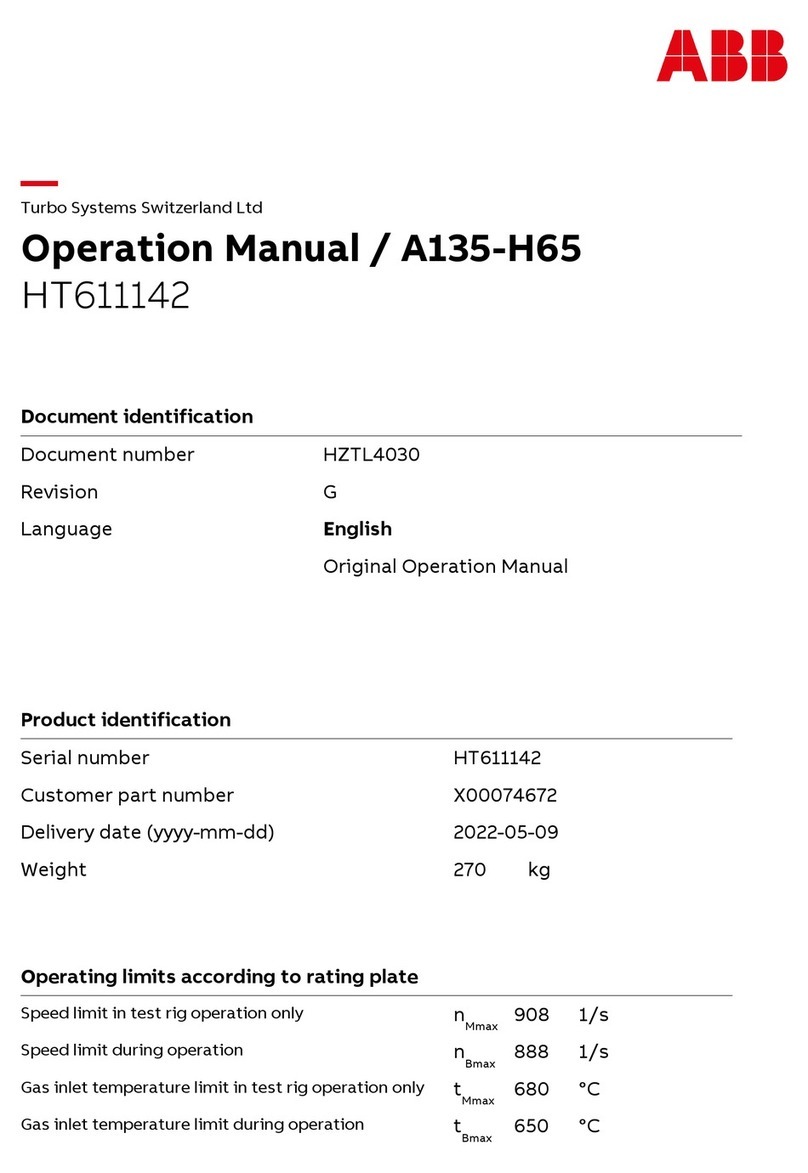

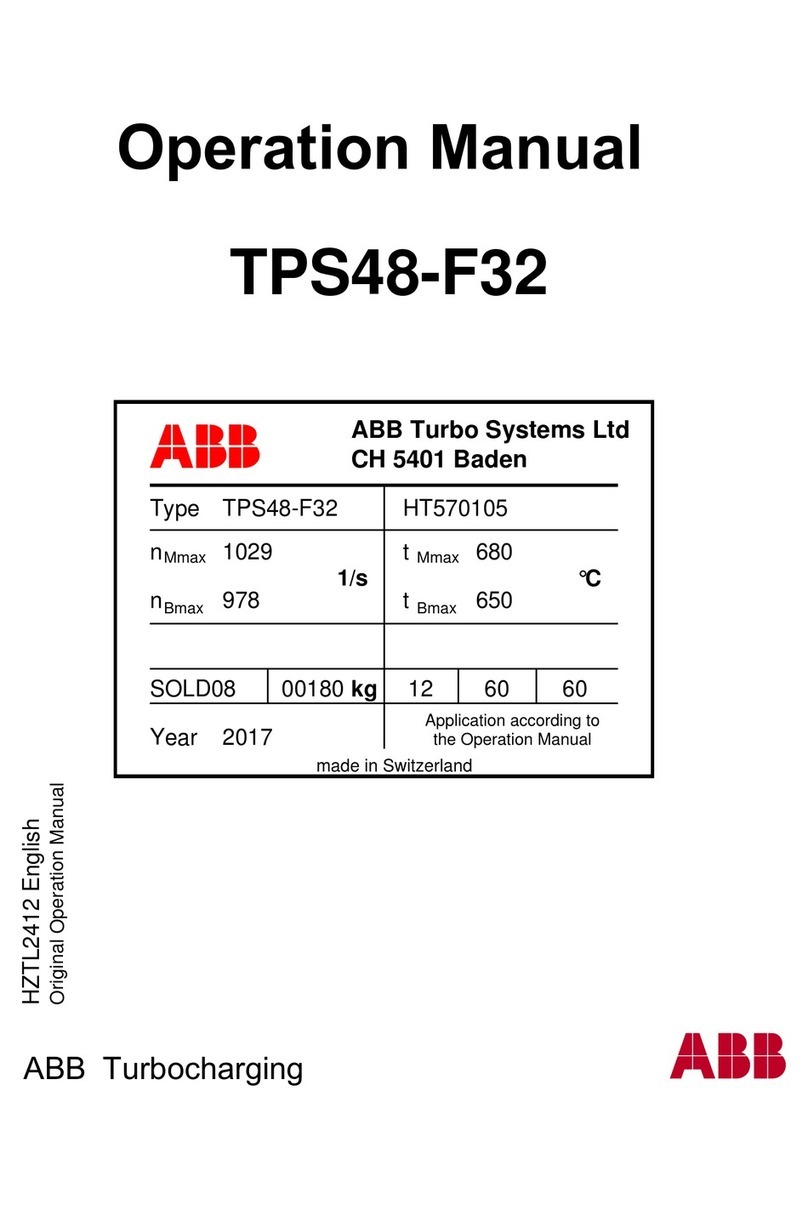

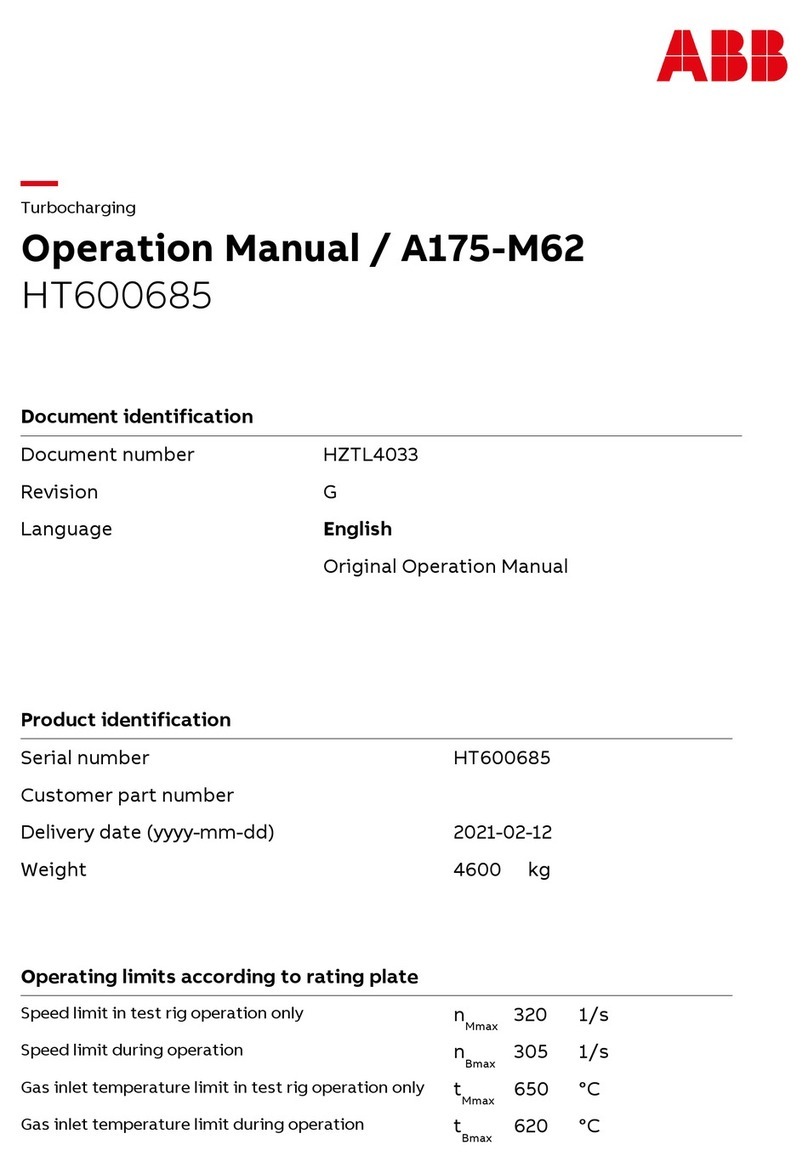

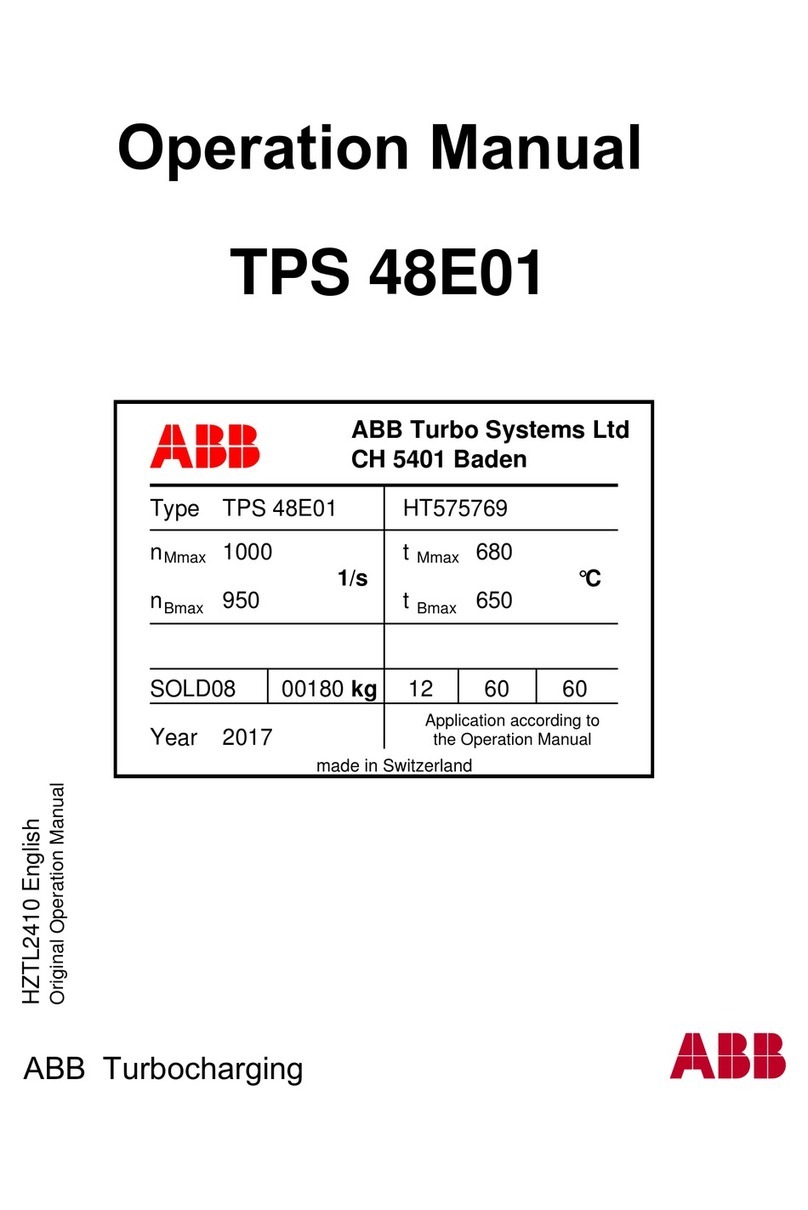

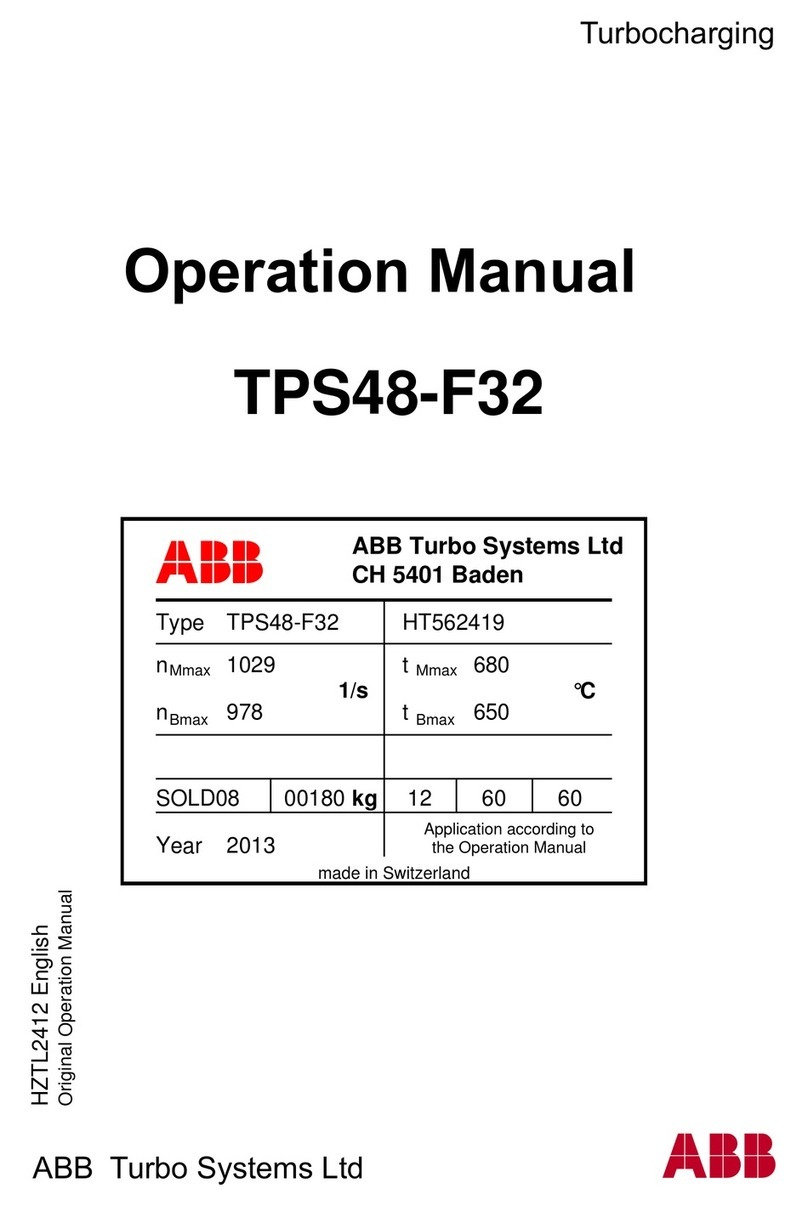

This document is valid for different design variants of turbochargers. There may be sections

and descriptions of components that are not relevant for a specific turbocharger variant.

ABB Turbocharging Service Stations will be happy to provide information on questions re-

garding a design variant (see Contact information at www.abb.com/turbocharging).

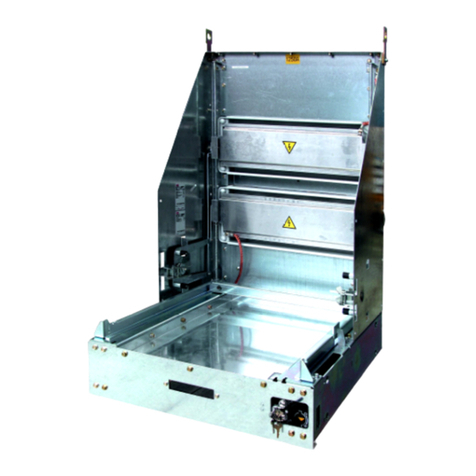

Accuracy of illustrations

The illustrations in this document are general in nature and intended for ease of understand-

ing. Differences in detail are therefore possible.

Page 2 / 17