Miller Weldmaster SeamVision User manual

Instruction Manual

Page 1

330-833-6739

service@weldmaster.com

www.weldmaster.com

This instruction manual is intended to be a guide when operating the SeamVision.

To ensure optimal performance from your welder, please follow the recommenda-

tions and specifications precisely.

You can also subscribe to Miller Weldmaster Insiders to stay updated on tech tips,

machine maintenance updates, and more at www.weldmaster.com/insiders.

Instruction Manual

Page 2TABLE OF CONTENTS

Chapter 1: Intended Use

Chapter 2: Principles of Heat Sealing

Chapter 3: Definition of Controls

Chapter 4: Machine Flow Chart

Chapter 5: Maintenance

Chapter 6: Transportation Specs and Storage

Page 3

Page 4

Pages 5-6

Page 6

Page 7

Pages 8-9

Page 9

Table of Contents

Instruction Manual

Page 3

1.0 Intended Use

CHAPTER 1 INTENDED USE

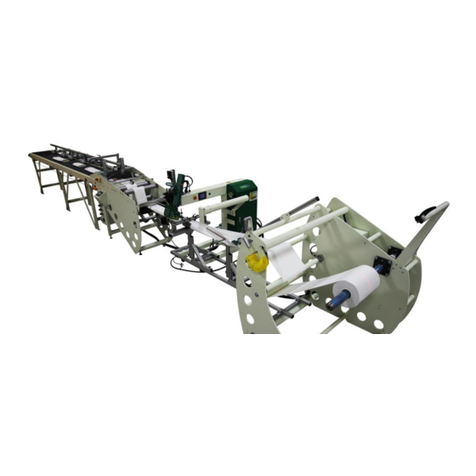

The Seam Vision system is an affordable and accurate solution for conventional and automation

systems that require non-contact temperature measurements. It is a real time monitoring system that

immediately identifies thermal problems that would otherwise go undetected. Its built-in logic makes

it ideal for product and process monitoring in quality and reliability assurance programs.

The Seamvision technology is used in the automotive, semiconductor/electronics, and food and

pharmaceutical industries for inspection and has been adapted and developed by Miller Weldmaster

for the industrial fabrics and technical textile industries. The Seamvision System works by precisely

measuring the intensity of the flow of photons from the fabric through the atmosphere to the optics

of the detector to actively monitor a welded seam in real-time as the process occurs. The Seam

Vision system then provides real time data back to the operator for the refinement to maintain

consistent seams. The Seamvision System will provide alarm information for post production testing.

The manufacturer does not approve of:

• Any other uses for these machines.

• Unauthorized modification of the machines.

Only a properly-trained technician may operate and/or perform any routine

maintenance or repairs to the machines.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring

from any inappropriate use of this machine.

Instruction Manual

Page 4CHAPTER 2 PRINCIPALS OF HEAT SEALING

2.0 Principals of Heat Sealing

Heating System

The Heat required for the welding operation is created electrically by hot air or hot wedge. Both methods

apply heat to the material to be welded.

Speed

The Speed of the Weld Rollers determines the amount of time the heat is applied to the material being

welded. The slower the speed setting, the more the material will be heated. The faster the speed setting,

the less the material will be heated. To achieve the best weld, a minimal amount of heat should be ap-

plied to the material while still achieving a full weld. Too much heat will cause distortion of the material;

while not enough heat will prevent the material from welding.

Pressure

The pressure of the weld roller is the final step when creating a weld. The pressure of the weld roller

compresses the heated material together completing the welding process.

Summary

When heat sealing, the correct combination of heat, speed, and pressure will allow you to achieve a

properly welded seam.

ALWAYS PERFORM A TEST WELD!

Instruction Manual

Page 5 CHAPTER 4 DEFINITION OF CONTROLS

Setup

Seam Temp Average: This shows the average temperature that the Seam

Vision is capturing.

Sensor Delay: Once the nozzle or wedge swings into position, the Sensor

Delay will delay the Seam Temp Average reading until set point is reached.

Sensor Delay will be adjusted by operator to desired setting.

Seam Temp High Alarm: This will allow you to create a window that if the

Seam Temp Average rises above desired setting will trigger the Light Stack

signal and/or Bell Alarm. The High Alarm will be adjusted by operator to

desired setting.

Seam Temp Low Alarm: This will allow you to create a window that if the

Seam Temp Average falls below desired setting will trigger the Light Stack

signal and/or Bell Alarm. The Low Alarm will be adjusted by operator to

desired setting.

Data Log: This, when activated, will allow you to save any Seam Temp

data.

Transfer Data: This will allow you to move any Seam Temp data collected

to a thumb drive.

Bell Alarm: This will sound when Seam Temp Average falls below or rises

above the desired alarm settings window.

Delete Data: This will allow you to get rid of any Seam Temp data

collected on a thumb drive.

3.0 Definition of Controls

Setup

Recipe

Recipe

Recipe Data Load: When using different material this will allow you to

load different Seam Temp High/Low Alarm settings previously saved.

Recipe Data Edit: This will allow you to edit previously saved Seam Temp

High/Low Alarm settings.

Recipe Data Save: This will allow you to save the current Seam Temp

High/Low Alarm settings for different materials. You can save up to 10

products.

Instruction Manual

Page 6CHAPTER 4 DEFINITION OF CONTROLS

3.0 Definition of Controls

Operator Control

This is the home screen and will show your live temperature along

with the Average Seam Temp, the Seam Temp High/Low Alarm set-

tings, and the current Recipe Data selected. You can access the Setup

screen as well using the orange icon in the bottom right corner.

Operator Control

This screen, when selected through the Sensor Delay, Seam Temp

High Alarm, Seam Temp Low Alarm and the Sample Rate icons, will

allow you to edit the desired settings for each feature.

Seam Temperature

The Seam Temperature line graph will show the Average Seam Temp

in relation to how long the Sample Rate is set.

Sample Rate: This is used to increase or decrease the time for re-

cording the Average Seam Temp.

Seam Temperature

Instruction Manual

Page 7 CHAPTER 5 MACHINE FLOW CHART

4.0 Machine Flow Chart

Instruction Manual

Page 8CHAPTER 6 MAINTENANCE

5.0 Maintenance

Sensor & Laser Positioning

The sensor measures the average temperature of a circular area within the two lasers. The slot on

the provided mounting bracket will allow for adjustment of the size of the area to be measured. The

lasers will rotate and their distance from one another will change as the sensor is moved closer

and farther away from the surface to be measured, however the sensing area always remains a

complete circle.

Instruction Manual

Page 9 CHAPTER 6 MAINTENANCE

5.0 Maintenance

Electrical Circuits

1. When replacing parts and components, you must use the part or components

of the same type as the original or equivalent to the original type. Original equipment

replacement parts should be purchased through Miller Weldmaster and or a Miller

Weldmaster authorize distributor.

2. To avoid damaging the control module, Display and Operating Panel, never plug or

unplug the cables connecting the PLC, Display and Operating Panel while the power

is on.

3. If there is any fault that cannot be removed, please immediately contact the service

department at Miller Weldmaster.

NOTICE: By not properly maintaining the machine, the performance may be effected. Please

contact Miller Weldmaster with any questions.

6.0 Transportation Specs and Storage

Storage

The manufacturer recommends that any time the machine is not in use, it must be protected from

excess dust and moisture. The operator should familiarize themselves with the warning symbols on

the machine to be alert to the potentially hazardous areas on the machine.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any

inappropriate use of this machine.

Instruction Manual

Page 10

CHAPTER 8 MACHINE SPECIFICATIONS

NOTES:_________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Instruction Manual

Page 11 CHAPTER 9 MAINTENANCE

NOTES:_________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Instruction Manual

Page 12CHAPTER 9 MAINTENANCE

NOTES:_________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Instruction Manual

Page 13 CHAPTER 9 MAINTENANCE

NOTES:_________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Table of contents

Other Miller Weldmaster Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

3M

3M 3M-Matic 8000af Instructions and parts list

Conductix-Wampfler

Conductix-Wampfler 0832 operating instructions

ABB

ABB HT588474 Operation manual

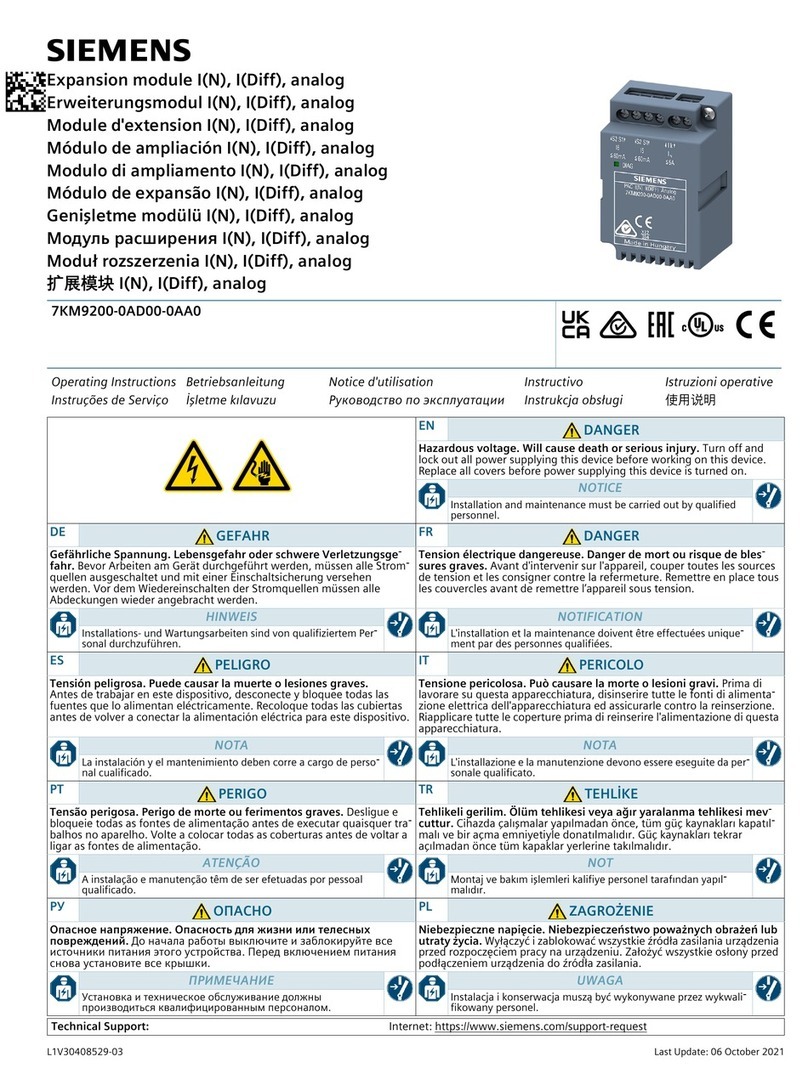

Siemens

Siemens 7KM9200-0AD00-0AA0 operating instructions

Greenheck

Greenheck ESD-202 Installation, operation and maintenance manual

Beckhoff

Beckhoff AG2250 operating instructions

ABB

ABB HT612854 Operation manual

Vantage Hearth

Vantage Hearth Hollister-Whitney GLV-40D2 instruction manual

Hofmann

Hofmann geodyna 6300 instructions

Habasit

Habasit Rossi MR V Series operating instructions

Lutz-Jesco

Lutz-Jesco EASYPRO COMPACT operating instructions

CAB

CAB 4214 Series Assembly instructions