4

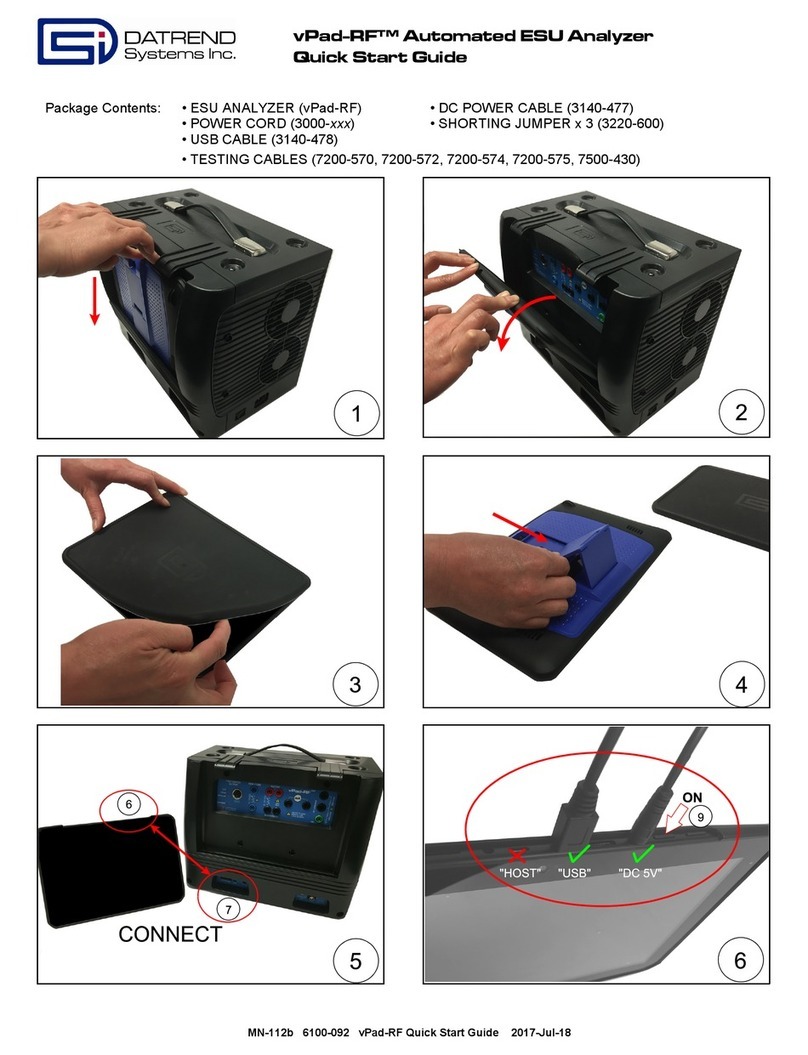

Diagram B– Piggyback example (for CIS)

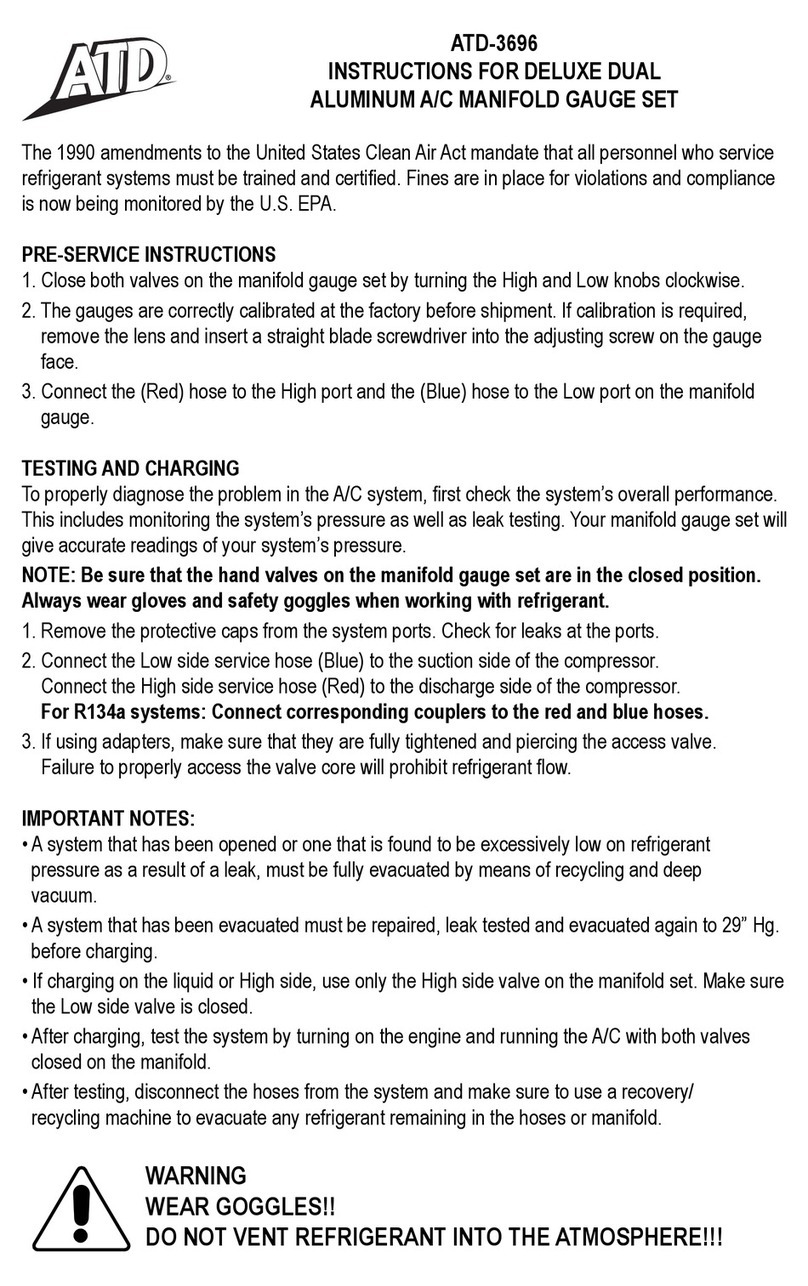

Gauge and hose

assembly

71404

M8–1.00 x M12–1.50

male w/ o-ring

71408

Connecting hose and

valve assembly

60410

M8–1.00 female x M12–1.50 male

14. Deactivate fuel pump and relieve fuel system pressure. With key , put tubing in a fuel can and

press valve. If your tester has no valve assembly, wrap rags around connections and

release slowly. (A assembly can be purchased from your tool distributor.)

15. Remove tester and reconnect all lines.

16. Start engine and check for leaks.

17. Remove fuel from all hoses. Fuel additives and ethanol can damage hoses and seals.If fuel remainsin

gauge hose assembly, connect the smallest banjo bolt adapter into the quick coupler over an approved fuel

container. Hold gauge above hose and depress the valve. Fuel will ow into the fuel container.

CAUTION: If components of this kit are used with a canister cleaner for injector cleaning, they must

be cleaned before storage. Due to the corrosive nature of cleaning , any cleaning

left in hoses and adapters will damage o-rings, hoses and seals. To ensure tool life, the

hose and fuel system test adapter must be with fresh gasoline after each use to

remove the cleaning

Please consult the vehicle service manual, a Mitchell Fuel Injection manual

or Robert Bosch Service Guide regarding pressure test results.

To test:

1. Relieve fuel system pressure.

2. Remove air cleaner assembly.

3. Temporarily plug the Thermac vacuum port on the throttle body.

4. Using the adapters we supply, install the tester in line between the fuel and the throttle body

(Diagram C).If longer pieces of 3/8˝ hose are needed, cut from 3/8˝ fuel line. Use hose clamps on hose.

In some instances, the adapters may have to be piggy-backed in order to get the right combination of

threads to connect. (See Diagram D).

5. If steel tubing is removed, use two wrenches to prevent damage.

6. On some cars, it is easier to put the car on a lift and test from underneath.

7. On some cars with GM TBI systems, it is hard to install adapters. With the

adapters and tubing furnished, many combinations can be made to help you.

8. Reactivate fuel pump, start the engine and check for leaks.

9. When fuel pressure has stabilized after a minute or so, gauge

should read 9–13 PSI (62–90 kPa),(.6–.9 bar), and (.63–.91 Kg/cm2).

10. Deactivate fuel pump, and relieve fuel system pressure. With key , put tubing in a fuel

and press valve. If your tester has no valve assembly, wrap rags around

and release slowly. (A assembly can be purchased from your tool distributor.)

Basic Instructions for Testing GM TBI