lNTRODUCrI'lON

SECTION

I

1-1

GENERAL

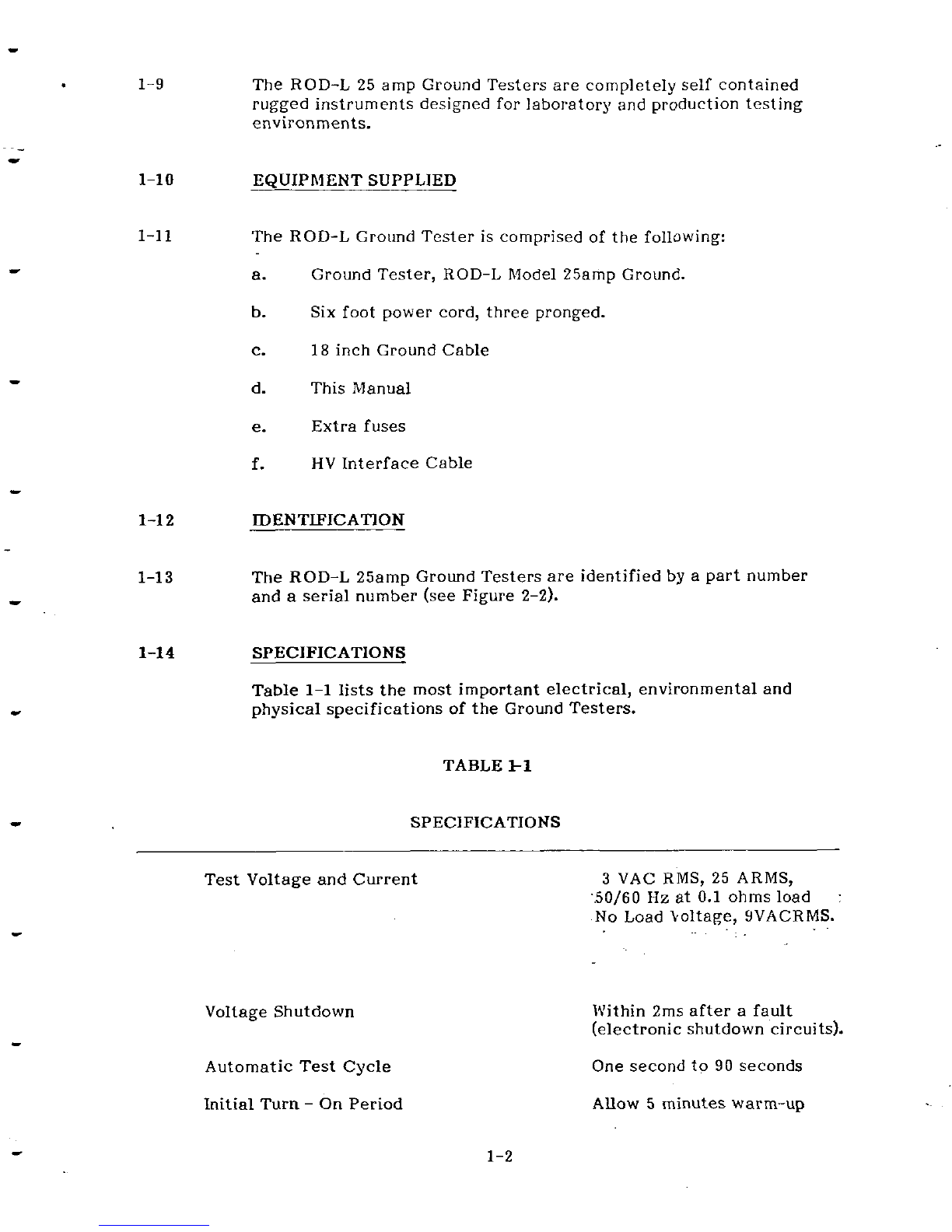

1-2 This publication, which provides operating and servicinginstructions for

the ROD-L Electronics 25 amp Ground Testers is divided into five sections.

sections I describes the Instrument and list its specifications. Section

II

contains Installation Instructions and Operating Procedures. Section 111

contains Theory of Operation. Section IV contains Service and Calibration

Instructions. Section

V

contains Replacement Parts Information, Parts

Location Diagrams and Schematics.

1-3 25amp Ground Testers are Low Voltage testers with ground continuity

test capability for performance of ground tests in accordance with

applicable B.S.I., V.D.E. and I.E.C. standards.

1-4 The 25 amp ground test is one of many tests required by certification

agencies

as

proof of an instrument's ability to withstand power line

spikes without becoming a hazard to itself or the user. For example,

lighting, drastic load changes or power line outages can place short

duration spikes on power lines of many times nominal line voltage. The

gnd should be able todivert any leakage to the chassis without getting

damaged.

1-5 GENERAL DESCRIPTION

1-6 The ROD-L Model 25amp Ground Testers apply low voltage tothe device

under

test

for a duration of time preset from one second to

90

seconds.

The device under test is plugged into the front panel receptacle (or special

rear panel connector on some models). Test limits for total resistance

are preset by the user via a rear panel control. When the device under

test is defective, automatic circuitry turns off the low voltage and meter,

lights the FAIL lamp and activates an audible alarm. These audible and

visual alarms must be manually reset atfront panel or can be reset by

remote control (see options).

1-7 All Models incorporate a rapid, automatic electronic shutdown circuit to

turn off the low voltage within two milliseconds after a fault.

1-8 For operator use, the test cycle is fully automatic; accidental test

initiation is prevented by use of a recessed start switch. If ground fails

during the test, the Tester automatically activates failure operation, i.e.,

voltage is shut down and there is a visual and audible alarm.