atecpool HiHeat ATHP30 Service manual

HIGH TEMPERATURE UNITS

Installation & Instruction Manual

HiHeat Hot Water Heat Pump

ATHP30

CONTENT

1. Preface

2. Overall Information of the Heat Pump

2.1 Device description

2.2 Features of the high temperature heat pump

2.3 Specification data

2.4 Heat pump dimension and view

3. Installation and Maintenance

3.1 Cautions and warning

3.2 Transit

3.3 Installation occasions

3.4 Installation method

3.5 Water loop connection

3.6 Location of the unit

3.7 Power supply connection

3.8 Cable and switch

3.9 Trial running

3.10 Maintenance

5.Troubleshooting and extra information

5.1 Electronic control fault table

5.2 Parameter list

6. The main controller terminals

6.1 Wire control interface diagram and definition

6.2 Controller interface diagram and definition

7. Appendix

7.1

specification

8. Note

Caution & Warning

7.2 Cable

1

2

2

2

3

4

5

5

8

8

8

9

9

10

10

11

12

24

24

25

26

26

26

29

29

30

31

6.3 Interface drawing and definition of the extended module

28

4.Controlling and Operation 13

.......................

..........

13

15

4.1

4.2

4.3

Main interface display and function

Instructions for operation of wire controller

Electronic control failure code and troubleshooting table

..................................................

21

CONTENT

1. Preface

2. Overall Information of the Heat Pump

2.1 Device description

2.2 Features of the high temperature heat pump

2.3 Specification data

2.4 Heat pump dimension and view

3. Installation and Maintenance

3.1 Cautions and warning

3.2 Transit

3.3 Installation occasions

3.4 Installation method

3.5 Water loop connection

3.6 Location of the unit

3.7 Power supply connection

3.8 Cable and switch

3.9 Trial running

3.10 Maintenance

4.Controlling and Operation

4.1

4.2 On and off

4.3 Mode switch

4.4

4.5

4.6

4.7

4.8

5.Troubleshooting and extra information

5.1 Electronic control fault table

5.2 Parameter list

6. The main controller terminals

6.1 Wire control interface diagram and definition

6.2 Controller interface diagram and definition

6.3

7. Appendix

7.1

specification

8. Note

Main interface display and function

Setting of target temperature

Target temp setting

Fast heating

Time heating

Fault interface

4.9 Color Display Calibration

Interface drawing and definition of the extended module

Caution & Warning

7.2 Cable

1

2

2

2

3

4

5

5

8

8

8

9

9

10

10

11

12

13

13

15

15

16

17

18

18

19

20

21

21

22

23

23

23

25

26

26

27

28

1

Preface

Positioning, installation and

commissioning must be

carried out by trained

personnel working in

accordance with these

operating and installation

instructions.

Where children or persons with limited

physical, sensory or mental capabilities

are to be allowed to control this equip-

ment ensure that this will only happen

under supervision or after appropriate

instructions by a person responsible for

their safety. Children should be super-

vised to ensure that they do not play with

the equipment.

Read these operating and installation

instructions carefully and keep them

safe. Should the equipment change

hands, pass these instructions to

the subsequent owner. Pass them to

the trained contractors for servicing

purposes.

Protection

Qualified only

The pictures and drawings in

this manual are for your infor-

mation only.

The manufacturer has the

right to chance or improve

the product when it is needed,

without prior notification to the

users of this device.

For information

Necessary reading

When the product is delivered to the users, please check whether there is

any damage on the unit during transportation; If any please talk with the

forwarder or the contractor.

If the heat pump unit can just be installed a while latter, please keep it free

from damage, rust or abrasion by following methods.

1. all the access like the water connections must be sealed correctly;

2. the unit must be free from sunshine, and placed under 45 ;

3. the unit must be free from heavy dust to avoid dirty on the evaporator;

4. the unit must be placed free from chaos to avoid accident;

5. please check the unit during stock.

Quality check at first receipt of this product

Welcome to air source water heat pump. Your decision to purchase heat pump will

reward you for many years.This is your assurance that you have purchased quality

heat pump system available, one that is manufactured in a state-of-the-art facility

and goes with innovation.

2

Overall Information of the Heat Pump

The air source heat pump extracts heat from ambient air and transfers itto water. By

circulating the water, the energy is used to warm the house efficiently. Through the

usage of floor heating, the heat pump COP can be as high as 4.5.

Compared with oil boiler, gas boiler and electrical heater, heat pump is thebest

solution with high efficiency, safety and environment protect.

This high temperature air source heat pump uses advanced heating tech-nology

and intelligent control system to produce hot water at more than65 . So it can

work with the floor heating pipe, the fan coil or the radiator,and replace the boiler

directly.

2.2 Features of the high temperature heat pump

1. Save our planet---earth, by green technology

Heat pump transfers heat from air to the space for heating, so that there is no burning, no

waste, no dirty gas, which maintains good environment for human and saves earth from waste.

2. Serve people by high efficiency and money saving

The heat pump is driven by electricity, and annually average efficiency can be higher than 4.

By timer function, users can make use of the electric power at the low point of a day and save

money for every family.

3. Good for life with safe running

To use heat pump for heating can avoid electrical shot and burning and keep people free

from explosion or poisoning.

4. Easy operation

Heat pump is controlled and protected by micro-computor based contro-ller, the desired

water temperature is set according to real requirement.System protection program will

guarantee the unit to be run at hard environment.

In reverse, cooling is also available when it is needed.

2.1 Device description

In addition, the high temperature heat pump can be used to provide hot water for

sanitary use, like kitchen, shower, etc.

3

Overall information of the Heat Pump

2.3 Specification data

Operating Conditions for Testing: Temperature of external dry/wet bulb: 20 /15 ;

temperature of water inlet: 15 ; temperature of water outlet: 55

Due to product improvement, the machine model designation, parameters or performance may

be subject to changewithout prior notice. The specific configuration shall be based on thename

plate on the product.

Model

kW

L/h

kW

A

pcs

W

RPM

dB(A)

mm

kg

kg

Rated heating capacity

Rated hot water capacity

Rated heating power input

Rated heating current input

COP

Unit

Power supply

Compressor quantity

Compressor type

Fan quantity

Fan power input

Fan rotate speed

Noise

Water pipe outlet/inlet

Unit dimension (L/W/H)

Net Weight

Gross weight

(Subject to data on the nameplate)

(Subject to data on the package)

PASHW060S-XI

19.6

413

4.2

7.2

4.68

380V/3N /50Hz

1

Scroll

2

60 2

840

58

DN25/DN25

1050/455/1242

3

Overall information of the Heat Pump

2.3 Specification data

Operating Conditions for Testing: Temperature of external dry/wet bulb: 20 /15 ;

temperature of water inlet: 15 ; temperature of water outlet: 65

Due to product improvement, the machine model designation, parameters or performance may

be subject to change without prior notice. The specific configuration shall be based on thename

plate on the pro du ct.

Model

kW

L/h

kW

A

pcs

W

RPM

dB(A)

mm

kg

kg

Rated heating capacity

Rated hot water capacity

Rated heating power input

Rated heating current input

COP

Unit

Power supply

Compressor quantity

Compressor type

Fan quantity

Fan power input

Fan rotate speed

Noise

Water pipe outlet/inlet

Unit dimension (L/W/H)

Net Weight

Gross weight see package label

3.58

380-415V/3 N /50H z

1

Scroll

2

200×2

800

58

DN32 /DN32

See the drawing of the units

see nameplate

ATHP30

19

326

5.3

9.2

4

Overall information of the heat pump

2.4 Heat pump dimension and view

High

pressure

gage

Low pressure gage

water outlet

DN32

DN32

water inlet

Unit Models ATHP30

4

Overall information of the heat pump

2.4 Heat pump dimension and view

High pressure gage

DN25

water outlet

DN25

Unit Models PASHW060S-XI

water inlet

5

Installation and Maintenance

3.1 Cautions and Warning

Mark Notes

Mark Meaning

A wrong operation may lead to death or heavy injury on people.

A wrong operation may lead to harm on people or loss of material.

WARNING

ATTENTION

Icon Notes

Icon Meaning

Prohibition. What is prohibited will be nearby this icon

Compulsory implement. The listed action need to be taken.

ATTENTION (include WARNING)

Please pay attention to what is indicated.

To prevent the users and others from the harm of this unit, and avoid damage on the unit or

other property, and use the heat pump properly, please read this manual carefully and

understand the following information correctly.

The piping connection and wiring should be installed according to the local legal laws and

regulations as well as the profession standard.

Low pressure gage

6

The heat pump must be installed by qualified personals,

to avoid improper installation which can lead to water

leakage, electrical shock or fire.

Please make sure that the unit and power connection

have good earthing, otherwise may cause electrical

shock.

Installation

Professional installer

is required.

Earthing is required

Warning

Meaning

Operation Meaning

PROHIBITION

Shut off the power

DO NOT put fingers or others into the fans and evaporator

of the unit, otherwise harm may be occurred.

When there is something wrong or strange smell, the power

supply need to be shut off to stop the unit. Continue to run

may cause electrical short or fire.

Move and repair

Entrust

Prohibit

Entrust

When the heat pump need to be moved or installed again,

please entrust dealer or qualified person to carry it out.

Improper installation will lead to water leakage, electrical

shock, injury or fire.

It is prohibited to repair the unit by the user himself,

otherwise

electrical shock or fire may be occur.

When the heat pump need to be repaired, please entrust

dealer or qualified person to carry it out. Improper movement

or repair on the unit will lead to water leakage, electrical

shock, injury or fire.

Meaning

Installation and Maintenance

7

Meaning

Meaning

Switch off

the power

Prohibition

Please switch off the power for clean or maintenance.

It is prohibited to use copper or iron as fuse. The right fuse

must be fixed by electrician for the heat pump.

It is prohibited to spray the flammable gas to the heat pump,

as it may cause fire.

Installation

Operation

Prohibition

Attention

Check the

installation basement

Please check the installation basement in a period (one month),

to avoid any decline or damage on the basement, which may

hurt people or damage the unit

Fix the unit

Installation Place

Need

circuit breaker

The unit CANNOT be installed near the flammable gas.

Once there is any leakage of the gas, fire can be occur.

Make sure that the basement of the heat pump is strong

enough, to avoid any decline or fall down of the unit

Make sure that there is circuit breaker for the unit, lack of

circuit breaker can lead to electrical shock or fire.

Installation and Maintenance

6

The heat pump must be installed by qualified personals,

to avoid improper installation which can lead to water

leakage, electrical shock or fire.

Please make sure that the unit and power connection

have good earthing, otherwise may cause electrical

shock.

Installation

Professional installer

is required.

Earthing is required

Warning

Meaning

Operation Meaning

PROHIBITION

Shut off the power

DO NOT put fingers or others into the fans and evaporator

of the unit, otherwise harm may be occurred.

When there is something wrong or strange smell, the power

supply need to be shut off to stop the unit. Continue to run

may cause electrical short or fire.

Move and repair

Entrust

Prohibit

Entrust

When the heat pump need to be moved or installed again,

please entrust dealer or qualified person to carry it out.

Improper installation will lead to water leakage, electrical

shock, injury or fire.

It is prohibited to repair the unit by the user himself,

otherwise

electrical shock or fire may be occur.

When the heat pump need to be repaired, please entrust

dealer or qualified person to carry it out. Improper movement

or repair on the unit will lead to water leakage, electrical

shock, injury or fire.

Meaning

Installation and Maintenance

7

Meaning

Meaning

Switch off

the power

Prohibition

Please switch off the power for clean or maintenance.

It is prohibited to use copper or iron as fuse. The right fuse

must be fixed by electrician for the heat pump.

It is prohibited to spray the flammable gas to the heat pump,

as it may cause fire.

Installation

Operation

Prohibition

Attention

Check the

installation basement

Please check the installation basement in a period (one month),

to avoid any decline or damage on the basement, which may

hurt people or damage the unit

Fix the unit

Installation Place

Need

circuit breaker

The unit CANNOT be installed near the flammable gas.

Once there is any leakage of the gas, fire can be occur.

Make sure that the basement of the heat pump is strong

enough, to avoid any decline or fall down of the unit

Make sure that there is circuit breaker for the unit, lack of

circuit breaker can lead to electrical shock or fire.

Installation and Maintenance

8

3.2 Transit

When the unit need to be hung up during installation, a 8

meters cable is needed, and there must be soft material

between the cable and the unit to prevent damage to the heat

pump cabinet. (See picture 1)

WARNING

DO NOT touch the heat exchanger of the heat

pump with fingers or other objects

Picture 1

When the heat pump is transported please keep

the unit stand up. The unit cannot be laid down,

otherwise the inner parts of the device may be

damaged.

There must be enough space around the unit for maintenance.

The place is free from heat radiation and other fire flame.

There must be not obstacles near the air inlet and outlet of the heat pump.

A place which is free from strong air blowing.

There must be water channel around the heat pump to drain the condensing water .

The location must have good ventilation.

3.3 Installation occasions

3.4 Installation method

The heat pump can be installed onto the concrete basement by expansion screws, or onto a

steel frame with rubber feet which can be placed on the ground or housetop. Make sure that

the unit is placed horizontally.

Or please use forklift, since there is wood chassis as package.

Installation and Maintenance

The unit can be installed on any place outdoor which can carry heavy machine such as

terrace, house top, ground and so on.

Picture 1

8

3.2 Transit

When the unit need to be hung up during installation, a 8

meters cable is needed, and there must be soft material

between the cable and the unit to prevent damage to the heat

pump cabinet. (See picture 1)

WARNING

DO NOT touch the heat exchanger of the heat

pump with fingers or other objects

Picture 1

When the heat pump is transported please keep

the unit stand up. The unit cannot be laid down,

otherwise the inner parts of the device may be

damaged.

There must be enough space around the unit for maintenance.

The place is free from heat radiation and other fire flame.

There must be not obstacles near the air inlet and outlet of the heat pump.

A place which is free from strong air blowing.

There must be water channel around the heat pump to drain the condensing water .

The location must have good ventilation.

3.3 Installation occasions

3.4 Installation method

The heat pump can be installed onto the concrete basement by expansion screws, or onto a

steel frame with rubber feet which can be placed on the ground or housetop. Make sure that

the unit is placed horizontally.

Or please use forklift, since there is wood chassis as package.

Installation and Maintenance

The unit can be installed on any place outdoor which can carry heavy machine such as

terrace, house top, ground and so on.

Picture 1

9

Installation and Maintenance

3.5 Water loop connection

Please pay attention to below matters when the water pipe is connected:

Try to reduce the resistance to the water from the piping.

The piping must be clear and free from dirty and blocks. Water leakage test must be

carried out to ensure there is no water leaking. And then the insulation can be made.

Attention that the pipe must be tested by pressure separately. DO NOT test it together

with the heat pump.

The flow switch is installed inside of the heat pump, check to ensure that the wiring and

action of the switch is normal and controlled by the controller.

Try to avoid air stayed inside of the water pipe, and there must be air vent on the top

point of the water loop.

There must be thermometer and pressure meter at the water inlet and outlet, for easy

inspection during running.

There must be expansion tank on the top point of the water loop, and the water level in

the tank must be at least 0.5 meter higher than the top point of the water loop.

The connection between the heat pump and the construction is better to be flexible type, to

avoid vibration transfer. The support to the water pipe must be separate, but not rely on the

heat pump unit .

There must be drainage on the low points of the water system, and there is already

drainage on the chassis of the heat pump. The water in the system must be drain out during

winter if the heat pump is not running. And there must be air vent on the high point of the

water system to drive air of the water. Drainage and air vent need not to be insulated, in

order to maintain.

3.6 Location of the unit

800mm 800mm 500mm

1000mm

The unit

Nut

Spacer

Rubber cushion

Expansion bolt

Concrete

Single unit Picture 1

10

Installation and Maintenance

500mm

800mm 1000mm 1000mm 800mm

Multi-units Picture 2

3.7 Power supply connection

Open the front panel, and open the power supply access.

If the outside water pump is needed, please insert the power supply wire into the wire access also and connect to the

water pump terminals.

The power supply must go through the wire access and be connected to the power supply terminals in the controlling

box. Then connect the 3-signal wire plugs of the wire controller and main controller.

If an additional auxiliary heater is need to be controlled by the heat pump controller, the relay (or power) of the

aux-heater must be connected to the relevant output of the controller.

3.8 Cable and switch

Attention:

The unit should use independent power supply, Wiring required by T abl e 6.1, Power supply vol tag e mus t in line wi th

rated voltage.

Power supply circuit must be equipped with an All-pole disconnect device have at least 3mm contact opening

distance.

Power supply circuit must have earth wire, the earth wire of power should be connected with external earth wire

safely. And the external earth wire must be in order.

The wiring must be completed by professional technicians in accordance with circuit diagram.

The creepage protection device must be settled in accordance with the relevant national technical standards for

electronic equipment.

The power wire and signal wire should be neatly arranged. High voltage wire and low voltage wire must be

separated and free from any interference, and they must be free from any pipe and valves of the unit.

When all the wiring is completed, the power can only be connected after a double check.

Power Specifications

Unit ModelItemsPower

SupplyCableCreepage

Protector

30mA Less

Than 0.1

SET

2

3*2.5mm2

2*2.5mm

380-415V/3N~/50Hz

ATHP30

10

Installation and Maintenance

3.7 Power supply connection

Open the front panel, and open the power supply access.

If the outside water pump is needed, please insert the power supply wire into the wire access also and connect to the

water pump terminals.

The power supply must go through the wire access and be connected to the power supply terminals in the controlling

box. Then connect the 3-signal wire plugs of the wire controller and main controller.

If an additional auxiliary heater is need to be controlled by the heat pump controller, the relay (or power) of the

aux-heater must be connected to the relevant output of the controller.

Power Specifications

3.8 Cable and switch

Attention:

The unit should use independent power supply, Wiring required by Table 6.1, Power supply voltage must in line with

rated voltage.

Power supply circuit must be equipped with an All-pole disconnect device have at least 3mm contact opening

distance.

Power supply circuit must have earth wire, the earth wire of power should be connected with external earth wire

safely. And the external earth wire must be in order.

The wiring must be completed by professional technicians in accordance with circuit diagram.

The creepage protection device must be settled in accordance with the relevant national technical standards for

electronic equipment.

The power wire and signal wire should be neatly arranged. High voltage wire and low voltage wire must be

separated and free from any interference, and they must be free from any pipe and valves of the unit.

When all the wiring is completed, the power can only be connected after a double check.

Unit Model Items

PASHW060S-XI

Power

Supply Cable Creepage

Protector

30mA Less

Than 0.1

SET

380V/3N~/50Hz 2

3*6mm 2

2*10mm

500mm

800mm 1000mm 1000mm 800mm

Multi-units Picture 2

11

3.9 Trial running

Inspection before trial running

Check the indoor unit, and make sure that the pipe connection is right and the relevant

valves are open .

Check the heat pump unit including all of the screws and parts of the heat pump to see if

they are in good order. When power on, review the indicator on the controller to see if

there is any failure indication. The gas gauge can be connected to the check valve to

see the high pressure(or low pressure) of the system during trial running.

Check the water loop, to ensure that the water inside of the expansion tank is enough, the

water supply is good, the water loop is full of water and without any air. Also make sure

there is good insulation for the water pipe.

Check the electrical wiring. Make sure that the power voltage is normal, the screws are

fastened, the wiring is made in line with the diagram, and the earthing is connected.

When the water pump runs for 1 minutes, the compressor will start. Hear whether there is

strange sound from the compressor. If abnormal sound occurs please stop the unit and

check the compressor. If the compressor runs well please look for the pressure meter

of the refrigerant.

Then check whether the power input and running current is in line with the manual. If not

please stop and check.

Review whether the outlet water temperature is stable.

The parameters of the controller are set by the factory, it is not allowed to change then

by user himself.

Adjust the valves on the water loop, to make sure that the hot(cool) water supply to each

door is good and meet the requirement of heating(or cooling).

Start the heat pump . Check whether the water pump is running, if it runs normally there

will be 0.2 MPa on the water pressure meter.

Installation and Maintenance

Installation and Maintenance

3.10 Maintenance

Check the water supply and air vent frequently, to avoid lack of water or air in the water loop.

Clean the water filter in a certain period to keep good water quality. Lack of water and dirty

water can damage the unit. The heat pump will start the water pump per 72 hours when it is

not running, to avoid freezing.

Keep the unit in a place which is dry and clean, and has good ventilation. Clean the heat

exchanger in 1 or 2 month and keep good heat exchange rate and save energy.

Check each part of the unit and the pressure of the system. Replace the failure part if there is

any, and recharge the refrigerant if it is needed.

If the heat pump is not used for a long time, please drain out all the water in the unit and seal

the unit to keep it good. Please drain the water from the lowest point of the heat exchanger

to avoid freezing in winter. Water recharge and full inspection on the heat pump is needed

before it is restarted.

Check the power supply and the electrical system, make sure the electrical components are

good, the wiring is well. If there is any part failed with wrong action or smell, please replace in

time.

The water loop of the heat pump MUST be protected from freezing in winter time. Please

pay attention to below suggestions. Nonobservance on below suggestion will invalid the

warranty for the heat pump.

Please do not shut off the power supply to the heat pump in winter. When the air temperature

is below 0 , if the inlet water temperature is above 2 and below 4 ,the water pump will

start for freezing protect, if the inlet water is lower than 2 , the heat pump will run for

heating.

Please drain out the water in the super heater of the heat pump unit in winter, when the super

heater is not used, in case it is heat pump with super heater.

12

¢Ù ¢Ú ¢Û ¢Ü ¢Þ¢Ý

Controlling and Operation

4.1Main interface display and function

(1) Power on interface

(2) Starting up interface

13

Remark: the wire controller can display the temperature unit as " " or " " according to

the unit model you bought.

14

Operation and Use

¢Ù

¢Ú ¢Û ¢Ü ¢Þ¢Ý

Operation and Use

13

Key number Key name Key function

On and off

Mode key

Temperature

setting

Fast heating

Timer setting

Setup key

Fault icon

Click this key to switch ON or OFF

Red represents ON, while grey represents OFF

Click this key to set the target temperature

Click this key to start the rapid heating

This key will be displayed during heating

Click this key to set the timer White represents not

enabled, while green represents enabled

Note:

is defrosting icon, the machine is in defrosting mode when this icon is shown;

is hot water mode icon, this machine is in hot water mode when this icon is shown;

is heating mode icon, this machine is in heating mode when this icon is shown.

Key function

Click this key to check the unit status, time,factory

parameter, temperature curve, timer setting and

Mute setting

Hot water mode, heating mode, cooling mode,

hot water+heating mode or hot water+cooling mode

can be selected by pressing this key.

This Icon will flash when there is an error shown up,

then the display will enter Failure record interface

after tapping this icon

4.1.Main interface display and function

(1) Electricity Interface

(2) Main interface of power-off interface

Fig.1 Electricity interface

Fig.2 Power-off interface

14

Operation and Use

¢Ù

¢Ú ¢Û ¢Ü ¢Þ¢Ý

Operation and Use

4.1Main interface display and function

13

¢ß

¢à

(1) Power on interface

(2) Starting up interface

①

②

③

④

⑤

⑥

Button function

No. Name Function

Power

Setpoint

Unit

Lock

Timer

Setting

Press to switch Control 4 units with communication

to fully open and close

Press to set the target temperature

Press to Enter the unit state of 4 circulating machines

Press to lock or unlock screen

Press to Enter the timing setting interface ( Power Timer,

Return Water Valve Timer,Temp Timer)

Press to enter function setting interface (Parameter,Failure,

Status Time,Electric Heating,Temp Curve)

(3) Main interface of power-on

①

②

③

④

⑤

⑥

⑦⑨

⑩

11 12 13 14 15

⑧

Fig.3 Power-on interace

16

Operation and Use

15

Operation and Use

(1) tapping hot water mode icon , then the display will change to this mode interface;

(2) tapping heating mode icon , then the display will enter this mode interface;

(3) tapping cooling mode icon ,then the display will switch to this mode interface;

Note: If what you have purchased is a cooling-only or heating-only model,

the mode switch will be invalid.

(4) tapping hot water+heating mode icon , then the display will go into

hot water+heating mode interface;

(5) tapping hot water+cooling mode icon , then the display will come to

hot water+cooling mode interface;

In the main interface, there are five modes can be selected after tapping the mode key.

Take hot water + cooling mode for example

Tapping , the wire controller back to main interface;

Tapping , the target temp of hot water can be set by pop-up keyboard;

Tapping , the target temp of cooling mode can be set by pop-up keyboard.

;

3. Setting of target temperature

In the main interface, press “Lock” button to activate the lock screen function,

sstatus icon 14

tatus icon will light; press “Lock” button again and enter

unlock the screen and the status icon will not be displayed.

(4) Lock screen function

⑦

⑧

⑩

11

12

13

14

15

⑨

No. Icon Description

Indicating the operating status:

red-heating mode; grey-power-off mode.

Set target water tank temperature

Set target return water temperature

Indicating the date and time

Indicating the Temp Timer function is activated

Indicating that the electric auxiliary heating mode is activated

Indicating that the power timer mode is activated

Indicating the lock screen status

Failure alarm icon. Indicating that while the failure occurs, the

icon blinks; after the failure is removed, the icon is no longer

displayed

Display circle

4.2 Instructions for operation of wire controller

(1) Power on/ off

In the main interface, press “Power” button ① to power on/ off the unit.

(2) Target temperature setting

To adjust the target temperature value, press the "set point" button ② to enter the

corresponding target temperature setting interface, click different buttons to set

different temperatures respectively, and then input the required parameters

according to the effective range displayed at the bottom of the screen.

Running status icons description

(3) Unit selection

In the main interface, press “Unit ” button ③ Enter the unit status check of 4

circulating machines.

the password 22 to

16

Operation and Use

15

Operation and Use

2. Mode switch

1. On and off

1.In shutting down interface (on/off key is in gray status),

press on/off key can start up the machine.

2 Note: In starting up interface (on/off key is in red status),

press on/off key can shut down the machine.

On and off .As the main interface shows

¢Ù

¢Ú

¢Ü

¢Û

¢Ý

5.2 Usage of wire controller (5) Timer setting

Button function

No. Name Function

Power Timer

Temp Timer

Press to jump to the timing switch setting interface

Press to jump to the return valve timing setting interface

Press to jump to the time-sharing temperature control setting

interface

Return Water

Valve Timer

16 17 18

19

20

Fig. 4 Timer interface

Fig. 5 Power timer interface

21

22

Power Timer

16

18

17

18

Operation and Use

17

Operation and Use

5. Fast heating

6. Timer setting

Click the timer setting key to enter the timer setting and

the interface display is as follows:

¢Ù

¢Ú

¢Û

Under the heating mode, click the fast heating key the above interface will appear.

Click to start the fast heating and click to close it.

Power Timer function allows you to set the opening time of the unit for each day of

the week, while this function is enable, the main interface displays “ ”.

Temp Timer function means time-sharing temperature control, which is two

segments of staggered peak temperature control, and the target temperature of

two segments of different time periods can be set according to different modes.

When the system time enters the staggered peak time and the time-sharing

temperature control function is enabled, the main interface displays “ ”.

Fig. 6 Temp timer interface

23 24

Temp Timer

Return Water Valve Timer

Note: green: enable; grey: not enable.

setting.

Note: green: enable; grey: not enable.

The timing interface of return valve is similar to that of time switch machine.

To enalbe Power Timer function, firstly press Timer button ⑤ in the main

interface, secondly press Power Timer button (Fig.4), it jumps to Power timer

21

22

16

20

PM, then press to select the time,

an

and lastly press to enable or turn off the

interface (Fig.5), press

interface (Fig.5), press

interface (Fig.5), press to select

19

to select

th

the day of the wee

e day of the week, press to select AM or

To enalbe Temp Timer function, firstly press Timer button ⑤ in the main inter-

face(Fig.4), secondly press Temp Timer button

18 it jumps to Temp timer

interface (Fig.6), then enter the starting, ending time and target temperature

setpoint value setpoint value ,

23

and lastly press

24 to enable or turn off the setting.

18

Operation and Use

17

Operation and Use

4. When the target temp is being set, pop-up keyboard is shown as following:

Key name

Key number Key function

Tapping this key can back to

the main interface.

Return key

Enter key

Delete key Tapping this key to undo

the last action.

Note: means the new target temp under current setting

Tapping this key can save you

action and back to the main

interface.

(6) Setting function

2827

26

Fig. 7-1 Setting interface

29

Fig. 7-2 Setting interface

25

Page left

Page

right

Table of contents

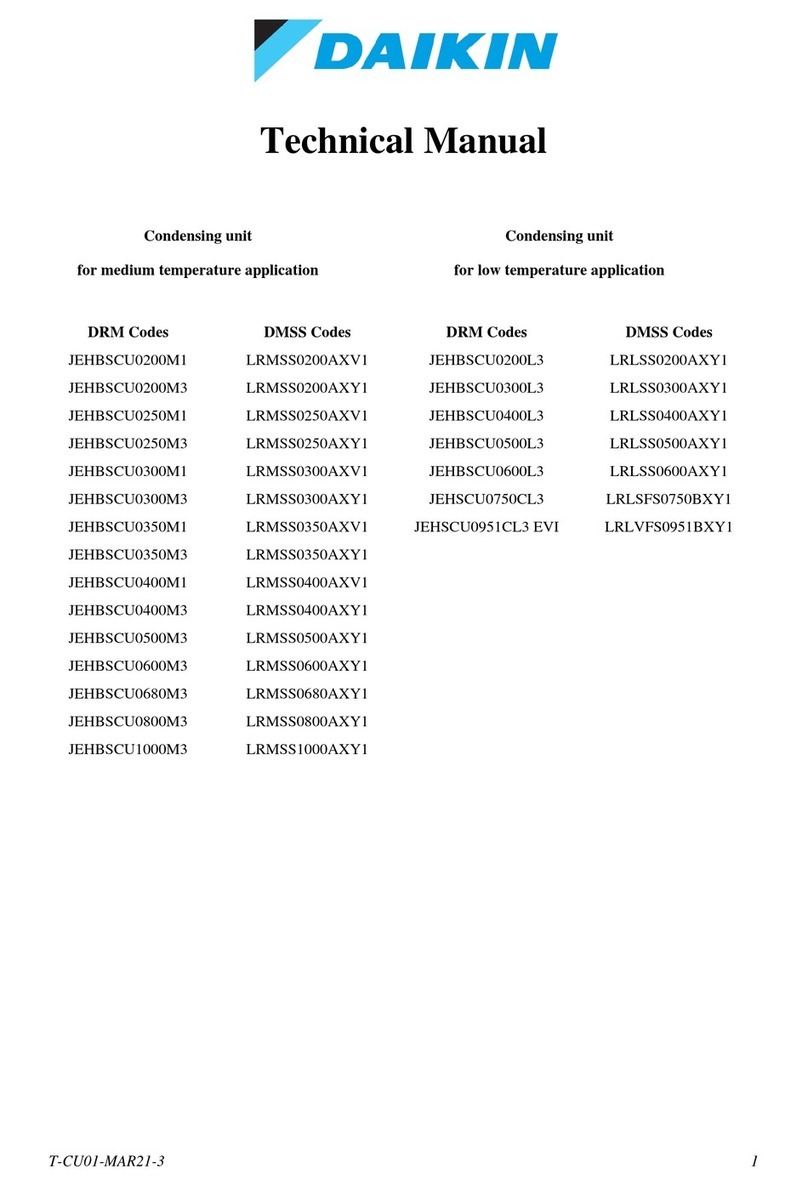

Other atecpool Heat Pump manuals

Popular Heat Pump manuals by other brands

Bosch

Bosch CS 3000 AWP Installation and operating instructions

AERMEC

AERMEC AN R407C Technical and Installation Booklet

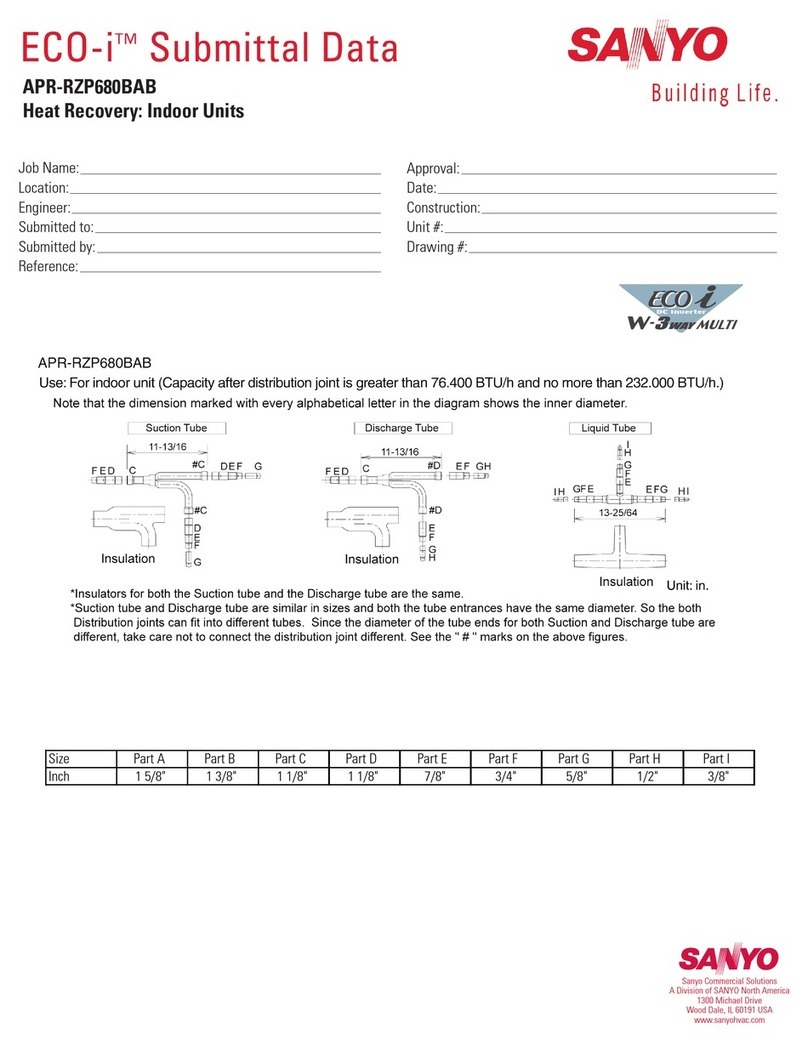

Gree

Gree VIREO GEN3 3VIR09HP115V1A Service manual

LG

LG Multi V III Solo ARUN LM3 Series Service manual

Palm

Palm H Series Installation and operation manual

Zehnder Rittling

Zehnder Rittling ComfoClime 24 Installer manual