atecpool AMHP060 User manual

INVERTER POOL HEAT PUMP

E

USER MANUAL

Table of contents

A. Foreword 1

B. Safety Precautions 2

1. Warning 2

2. Attention 2

3. Safety 2

C. About your heat pump 3

1. Transportation 3

2. Accessories: 3

3. Operating condition and range: 4

4. Introduction of different modes: 4

5. Technical parameter 4

6. Dimension 5

D. Installation guidance 6

1. Installation reminder 6

2. Wiring 10

3. Electric wiring Diagram 10

4. References for protecting devices and cable specification 10

E. Operation guidance 11

1. Key Function 11

2. Operation Instruction 11

F. Testing 13

1. Inspect heat pump before use 13

2. Trial 13

G. Maintenance 14

H. Trouble shooting for common faults 15

I. Electrical wiring schematic (optional) 17

J. Wi-Fi operation 19

1

A. Foreword

Thank you for choosing our inverter pool heat pump, which is designed for more silent and energy saving

user experience. It is an ideal way for green pool heating.

We hope you'll enjoy using our heat pumps.

Thank you!

2

B. Safety Precautions

We have provided important safety messages in this manual and on your heater.

Please always read and obey all safety messages.

1. Warning

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in personal injury or injury to a

third party. These signs are rare, but are extremely important.

2. Attention

a. Set proper temperature in order to get comfortable water temperature to avoid overheating or

overcooling.

b. Please don’t stack substances, which will block air flow near inlet or outlet area, otherwise the

efficiency of the heater will be reduced or even stopped.

c. Don’t use or stock combustible gas or liquid such as thinners, paint and fuel to avoid fire.

d. In order to optimize the heating effect, please install heat preservation insulation on pipes between

swimming pool and the heater, and please use a recommended cover on the swimming pool.

e. Connecting pipes of the swimming pool and the heater should be ≤10m.

3. Safety

a. Please keep the main power supply switch far away from the children.

b. When a power cut happens during operating, and later the power is restored, the heater will start up.

c. Please switch off the main power supply in lightning and storm weather to prevent from machine

damage that caused by lightning.

d. Installation and any repairing should be conducted in the area with good ventilation. The ignition

source is prohibited during the operation.

3

C. About your heat pump

1. Transportation

a. Always keep upright

b. Loose the screws in the bottom,

and use the forklift to transport.

c. Do not lift the water union, otherwise, the titanium heat

exchanger inside the heat pump may be damaged)

2. Accessories:

AMHP060

AMHP090

4

3. Operating condition and range:

To provide you comfort and pleasure, please set swimming pool water temperature efficiently and

economically.

The heat pump can work between air 0°C~55°C, and its ideal operation range is between air 15°C ~

25°C.

4. Introduction of different modes:

a. The heat pump has two modes: Boost and Silence.

b. They have different strengths under different conditions.

5. Technical parameter

Model

AMHP060

AMHP090

PERFORMANCE CONDITION: Air 27°C/ Water 27°C/ Humid. 80%

Heating capacity (kW)

60.2

115.0

Average COP at 50% Speed

10.5

10

PERFORMANCE CONDITION: Air 15°C/ Water 26°C/ Humid. 70%

Heating capacity (kW)

40.1

80.8

Average COP at 50% Speed

7

7

TECHNICAL SPECIFICATIONS

Advised pool volume (m3) *

62~130

125~260

Operating air temperature (℃)

0℃~55℃

Fan direction

Vertical

Power supply

400V/3Ph/50Hz

Rated input power (kW)

2.26~8.90

4.68~17.5

Rated input current (A)

3.27~12.9

6.78~25.3

Sound level at 10m dB(A)

33.0~41.0

35.0~44.0

Advised water flux (m³/h)

20~25

40~50

Water connection (mm)

75

110

Net dimension LxWxH (mm)

1000x1110x1260

2100x1090x1280

Net Weight (kg)

230

448

Mode

Modes

Strength

Boost mode

Heating capacity: 20% to 100% capacity

Intelligent optimization

Fast heating

Silence mode

Heating capacity: 20% to 80% capacity

Sound level: 3dB (A) lower than Boost mode

5

Remarks:

This heat pump is able to perform normal within air temp 0℃~55℃, efficiency will not be guaranteed out of

this range. Please take into consideration that the pool heater performance and parameters are different under

various conditions.

Related parameters are subject to adjustment periodically for technical improvement without further notice.

For details please refer to nameplate.

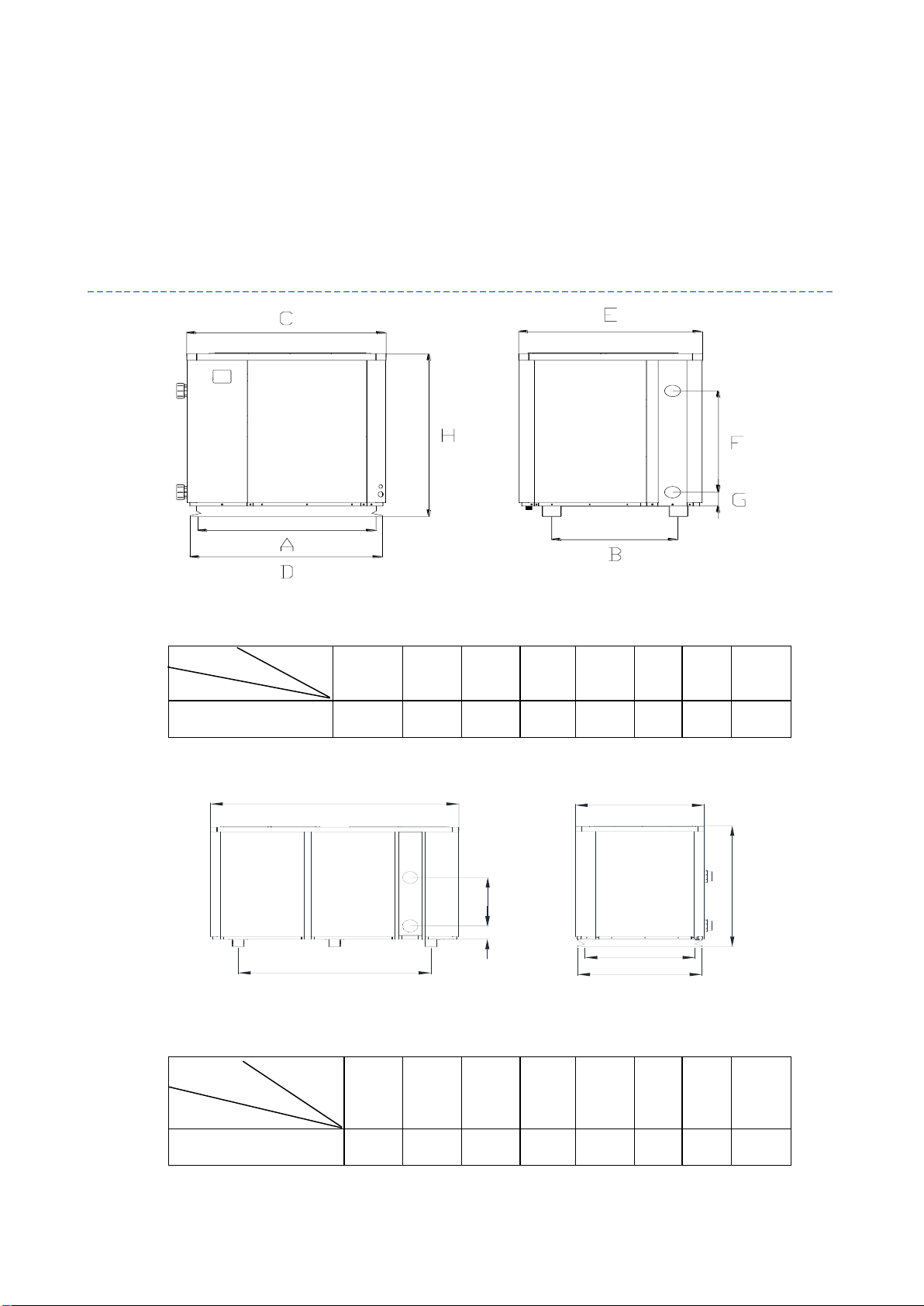

6. Dimension

E

B

F

G

D

A

H

C

A

B

C

D

E

F

G

H

AMHP060

1010

705

1110

1070

1023

780

105

1260

A

B

C

D

E

F

G

H

AMHP090

1010

1630

1090

1050

2100

515

140

1280

Name

Size (mm)

Model

Name

Size (mm)

Model

6

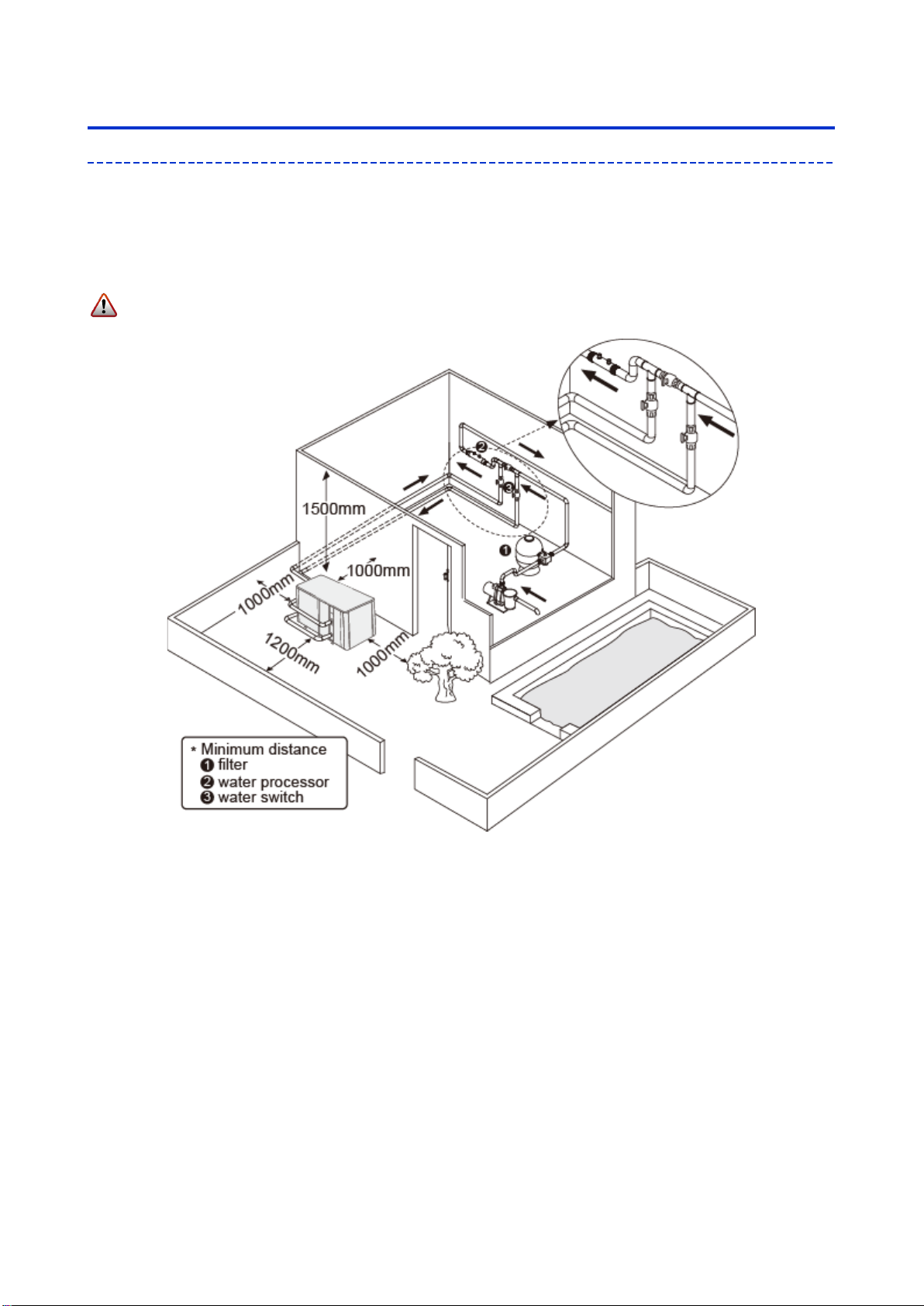

D. Installation guidance

1. Installation reminder

Only a professional staff is allowed to install the heat pump. The users are not qualified to install by

themselves, otherwise the heat pump might be damaged and risky for users’ safety.

a. Location and water pipe connection

The inverter pool heat pump should be installed in a good ventilation place.

1) The frame must be fixed by bolts (M10) to concrete foundation or brackets. The concrete foundation

must be solid and fastened; the bracket must be strong enough and antirust treated;

2) Please don’t stack substances that will block air flow near inlet or outlet area, and there is no barrier

within 50cm behind the main machine, or the efficiency of the heater will be reduced or even

stopped;

3) The machine needs an appended pump (Supplied by the user). The recommended pump

specification-flux: refer to Technical Parameter, Max. lift ≥10m;

4) When the machine is running, there will be condensation water discharged from the bottom, please

pay attention to it. Please hold the drainage nozzle (accessory) into the hole and clip it well, and then

connect a pipe to drain the condensation water out.

7

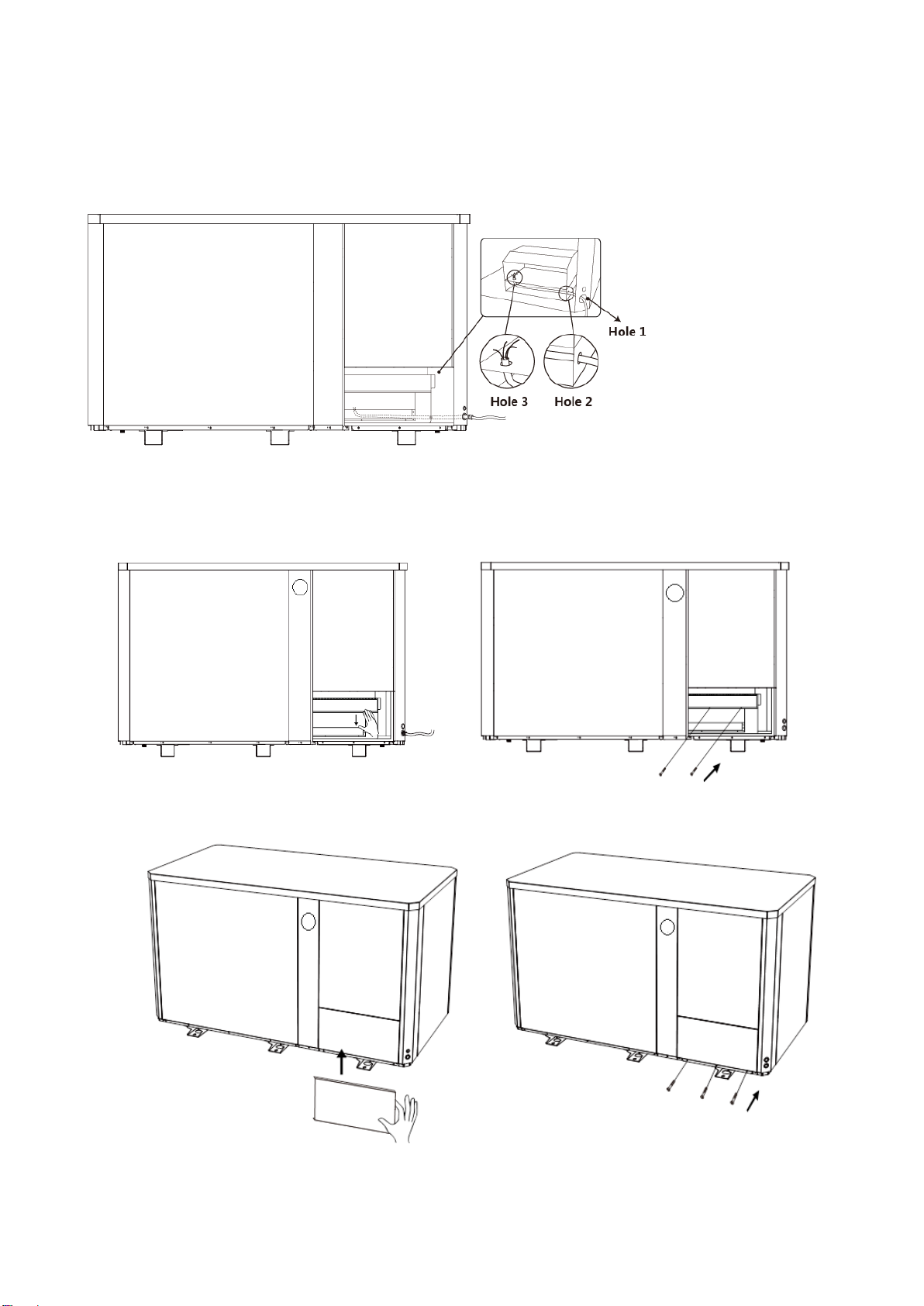

b. The inlet and outlet water unions can’t stand the weight of soft pipes. The heat pump must be

connected with hard pipes!

How to connect to the terminal board of IMC60

Step 1. open the maintenance panel

AMHP060

Remove three screws outside

Open the front right panel and the internal

Connect the wire

Restore the internal panel and the front right panel

8

⑤ Fix by screws

AMHP090

Remove three screws outside

Open the panel

Remove two screws inside

Open the internal

9

Step 2. Power cord must be passed through below 3 holes

Connect the wire through three holes

Restore the internal panel

Fix the internal panel by two screws

Restore the panel

Fix the panel by three screws

10

2. Wiring

a. Connect to appropriate power supply, the voltage should comply with the rated voltage of the

products.

b. Earth the machine well.

c. Wiring must be handled by a professional technician according to the circuit diagram.

d. Set leakage protector according to the local code for wiring (leakage operating current ≤ 30mA).

e. The layout of power cable and signal cable should be orderly and not affecting each other.

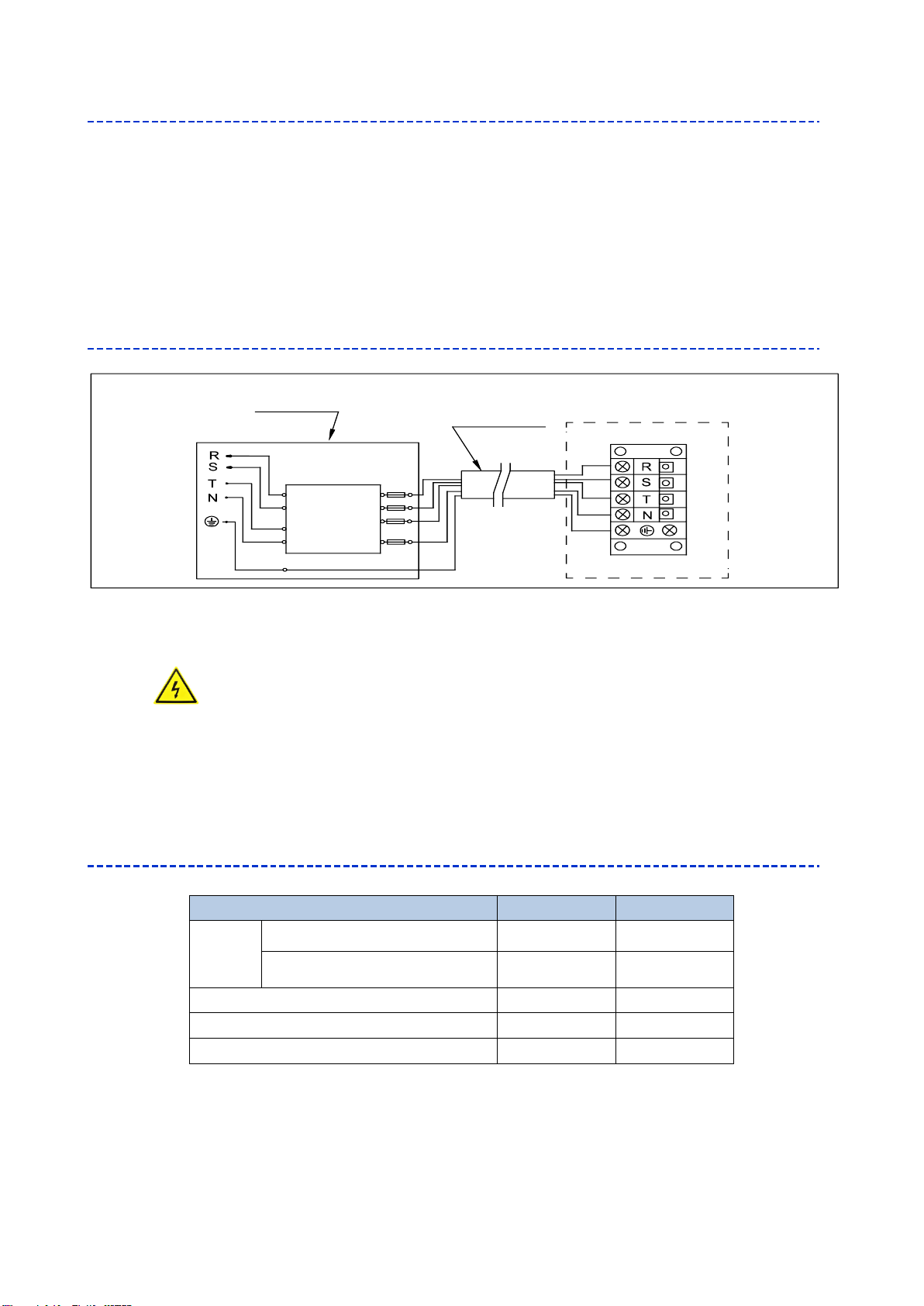

3. Electric wiring Diagram

For power supply: 400V 50Hz

Note: 1) Must be hard wired, plug is not allowed.

2) The swimming pool heat pump must be earthed well.

4. References for protecting devices and cable specification

※ Above data is subject to modification without notice.

Note: The above data is adapted to power cord ≤ 10m. If power cord is>10m, wire diameter must be increased.

The signal cable can be extended to 50m maximumly.

MODEL

AMHP060

AMHP090

Breaker

Maximum Current (A)

23

45

Residual-current circuit breaker

(A)

30

30

Fuse (A)

23

45

Power Cord (mm2)

5x6

5x16

Signal cable (mm2)

3x0.5

3x0.5

Distribution Box(Customer prepare)

Power Cord

Swimming Pool Heat Pump Wiring Board

Power Supply

400V 50Hz

Breaker

Earthing

Fuse

11

E. Operation guidance

1. Key Function

Symbol

Heating & cooling models

i. Power On/Off

ii. Wi-Fi setting

i. Lock/Unlock Screen

ii. Heating mode (18-40°C)

iii. Cooling mode (12-30°C)

iv. Auto mode (12-40°C)

i. Boost

ii. Silence

Temperature Setting

Attention:

i. The controller has power-down memory function.

ii. The buttons will turn dark when it’s locked.

2. Operation Instruction

a. Screen Lock

1) Press for 3 seconds to lock or unlock the screen

2) Automatic Lock Period: 30 seconds if no operation

b. Power On

Press for 3 seconds to unlock screen, Press to power on machine.

12

c. Temperature Setting

Press and to display and adjust set temperature.

d. Mode Selection

1) Heating/Cooling/Auto

Press “ ” to switch among heating ” ”, cooling ” ” and auto mode ” ”.

Heating mode “ ”: Water temperature setting range(18-40°C)

Cooling mode “ ”: Water temperature setting range(12~30°C)

Auto mode “ ”: Water temperature setting range(12~40°C)

* When water inlet temperature is higher than setting point, automatic cooling mode starts.

* When water inlet temperature is lower than setting point, automatic heating mode starts.

2) Silence/Boost mode selection

Press “ ” to switch between boost mode , silence mode

Default mode: boost

Please choose boost mode for initial heating

e. WIFI

When the screen is on, press “ ”for 3 seconds, after “ ” flashing, enter Wi-Fi connection.

Connect Wi-Fi on mobile phone and input password, and then control equipment by Wi-Fi. When

APP connects Wi-Fi successfully,“ ” lights on.

f. Defrosting

1) Automatic defrosting: When machine is auto defrosting, will flash, and return to previous

working mode when it finishes.

2) Manual Defrosting: To enter forced defrosting mode, the compressor must be working more than 10

minutes. in heating mode, press “ ” and “ ” on touch controller simultaneously for 5 seconds

to start forced defrosting, ” ” is flashing and defrost starts, “ ” stop flashing and defrosting stops.

(Remarks: the interval between manual defrosting should be more than 30 minutes.)

13

F. Testing

1. Inspect heat pump before use

a. The ventilating device and outlets are operating adequately and are not obstructed.

b. It’s prohibited to install refrigeration pipe or components in corrosive environment.

c. Inspect the electric wiring on basis of the electric wiring diagram and earthing connection.

d. Double confirm the main machine power switch should be off.

e. Inspect the air inlet and outlet.

2. Trial

a. The user must “Start the Pump before the Machine, and Turn off the Machine before the Pump”, or

the machine will be damaged.

b. Before start the heat pump, please check for any leakage of water.

c. In order to protect the swimming pool heat pump, the machine is equipped with a time lag starting

function, the fan will run 1 minute earlier than the compressor when starting the machine, and it will

stop running 1 minute later than the compressor when power off the machine.

d. After the swimming pool heat pump start up, please kindly checking for any abnormal noise from the

machine.

14

G. Maintenance

1. In winter season when you don’t swim:

a. Cut off power supply to prevent any machine damage.

b. Drain water clear of the machine.

c. Cover the machine body when not in use.

2. Please clean this machine with household detergents or clean water, NEVER use gasoline, thinners

or any similar fuel.

3. Check bolts, cables and connections regularly.

4. If repair or scrap is required, please contact authorized service center nearby.

5. Do not attempt to work on the equipment by yourself. Improper operation may cause danger.

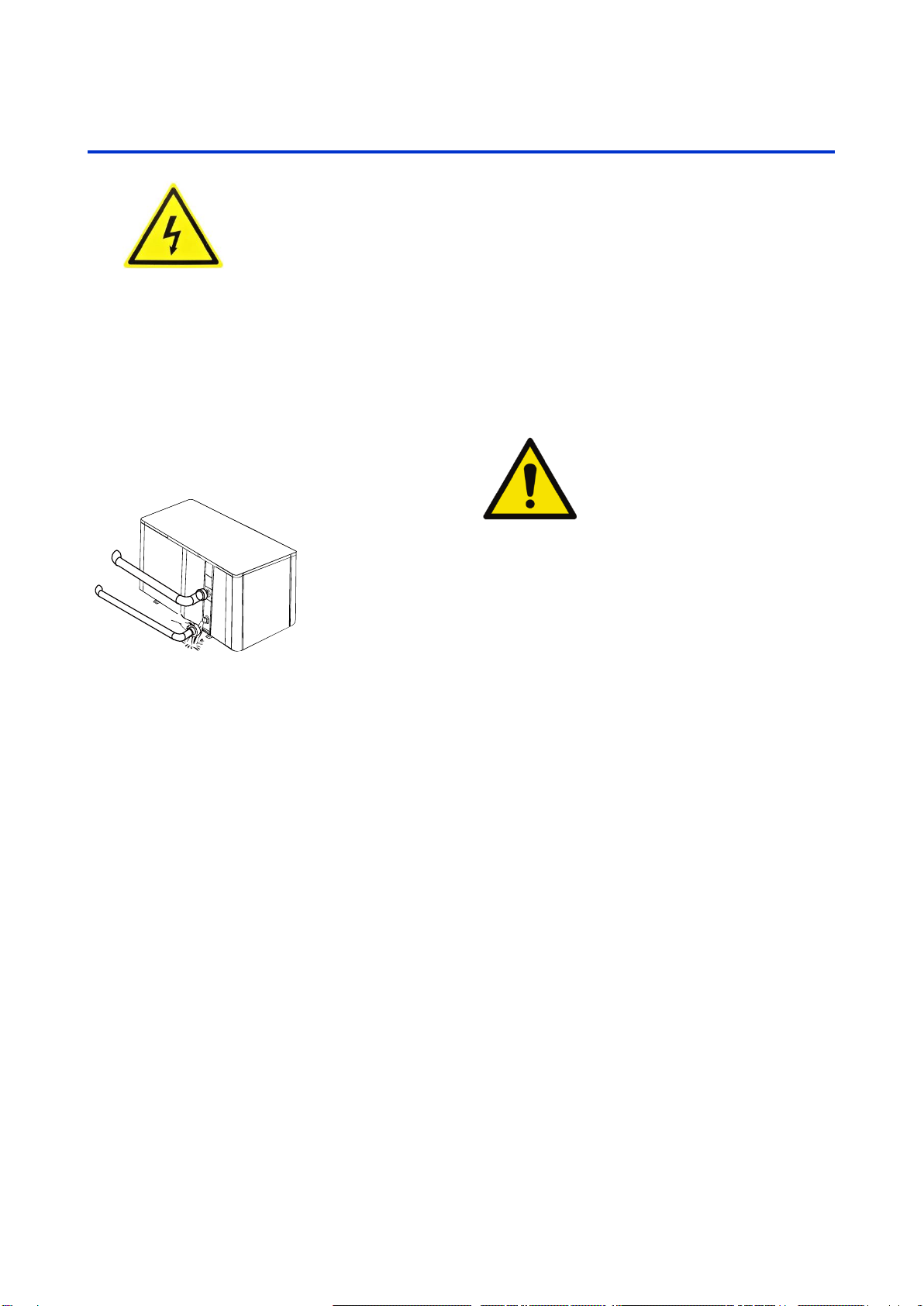

!!Important:

Unscrew the water nozzle of inlet pipe

to let the water flow out.

When the water in machine freezes in winter

season, the titanium heat exchanger may be

damaged.

“CUT OFF” power supply of the heater

before cleaning, examination and repairing

15

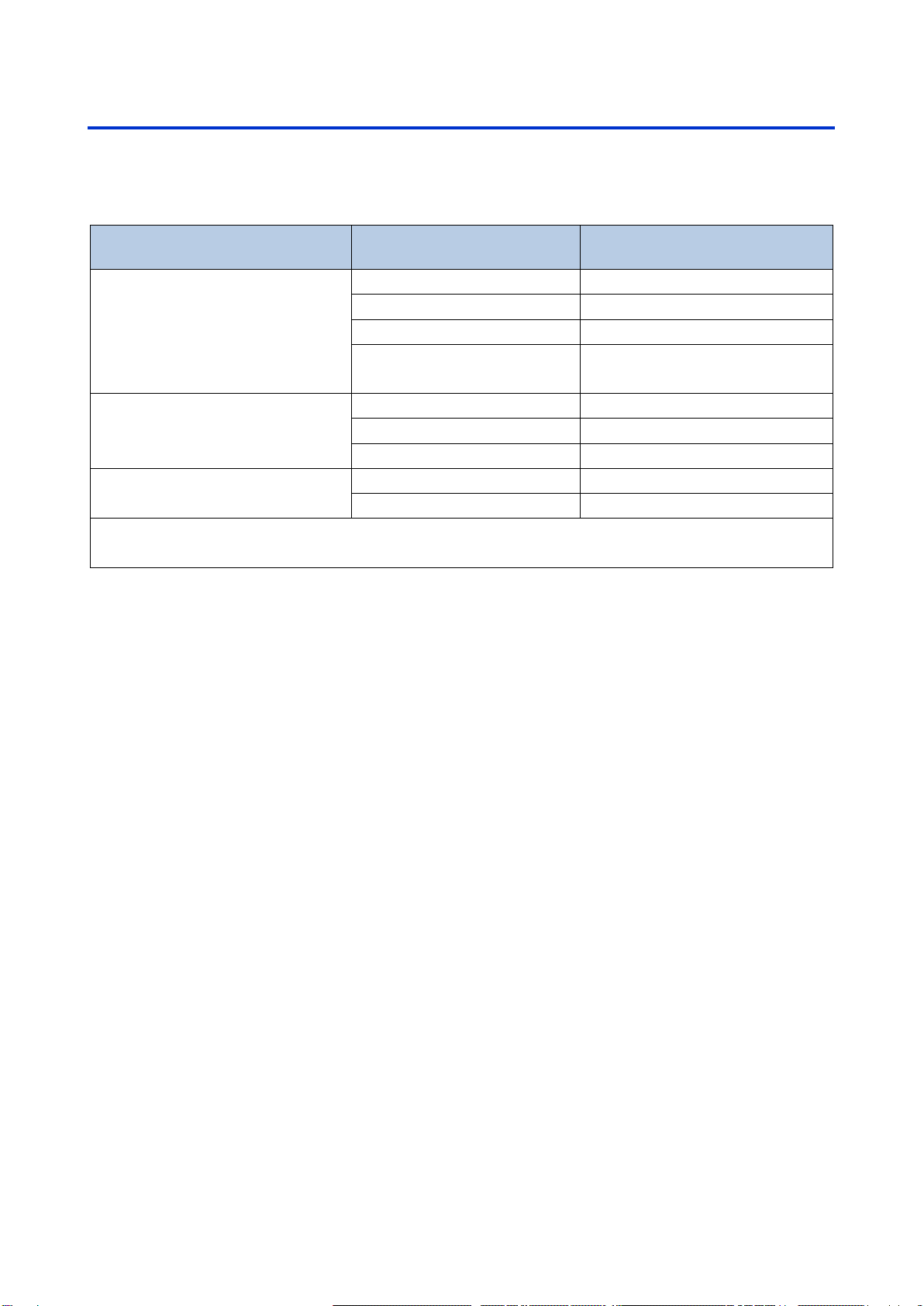

H. Trouble shooting for common faults

1. Failure solution and code

----------------------------------------------------------------------------------------------------------------------------------------

Failure

Reason

Solution

Heat pump doesn’t run

No power

Wait until the power recovers

Power switch is off

Switch on the power

Fuse burned

Check and change the fuse

The breaker is off

Check and turn on the

breaker

Fan running but with

insufficient heating

evaporator blocked

Remove the obstacles

Air outlet blocked

Remove the obstacles

3 minutes start delay

Wait patiently

Display normal, but no

heating

Set temp. too low

Set proper heating temp.

3 minutes start delay

Wait patiently

If above solutions don’t work, please contact your installer with detailed information and

your model number. Don’t try to repair it yourself.

Note: If the following conditions happen, please stop the machine immediately, and cut off

the power supply immediately, then contact your dealer:

1.Inaccurate switch action.

2.The fuse is frequently broken or leakage circuit breaker jumped.

16

Protection & Failure code

NO.

Display

Protection code description

1

E3

No water protection

2

E5

Power supply excesses operation range

3

E6

Excessive temp difference between inlet and outlet water(Insufficient

water flow protection)

4

Eb

Ambient temperature too high or too low protection

5

Ed

Anti-freezing reminder

NO.

Display

Failure code description

1

E1

High pressure protection

2

E2

Low pressure protection

3

E4

3 phase sequence protection (three phase only)

4

E7

Water outlet temp too high or too low protection

5

E8

High exhaust temp protection

6

EA

Evaporator overheat protection (only at cooling mode)

7

EC

System communication failure

8

P0

Controller communication failure

9

P1

Water inlet temp sensor failure

10

P2

Water outlet temp sensor failure

11

P3

Gas exhaust temp sensor failure

12

P4

Evaporator coil pipe temp sensor failure

13

P5

Gas return temp sensor failure

14

P6

Cooling coil pipe temp sensor failure

15

P7

Ambient temp sensor failure

16

P8

Cooling plate sensor failure

17

P9

Current sensor failure

18

PA

Restart memory failure

19

F1

Compressor drive module failure

20

F2

PFC module failure

21

F3

Compressor start failure

22

F4

Compressor running failure

23

F5

Inverter board over current protection

24

F6

Inverter board overheat protection

25

F7

Current protection

26

F8

Cooling plate overheat protection

27

F9

Fan motor failure

28

Fb

Power filter plate No-power protection

28

FA

PFC module over current protection

29

FA

PFC module over current protection

30

FC

AC fan motor overcurrent protection

31

Fd

AC fan motor overheat protection

32

FE

AC fan motor phase protection

Notice!

System 1 failure 1 or no display after the error code

System 2 failure 2 is displayed after the error code

17

I. Electrical wiring schematic (optional)

Breaker/fuse

(Customer prepare)

Power Supply

400V~/50Hz

Water pump: 400V voltage

Water Pump

Water Pump

Breaker/fuse

(Customer prepare)

Power Supply

400V~/50Hz

Earthing

Power Cord

coil voltage:400V

Customer remote

control switch

connector

Earthing

Contactor

18

Water pump control and timer connection

1: Water pump timer

2: Water pump wiring of Heat Pump

Note: The installer should connect 1 parallel with 2 (as above picture). To start the water pump, condition

1 or 2 is connected. To stop the water pump, both 1 and 2 should be disconnected.

This manual suits for next models

1

Table of contents

Other atecpool Heat Pump manuals

Popular Heat Pump manuals by other brands

Astral Pool

Astral Pool APH3 INVERBOOST User and service manual

Water Furnace

Water Furnace Envision NRAC026 installation manual

HydroPro

HydroPro 5 User and service manual

Astral Pool

Astral Pool ALASKA Series TECHNICAL MANUAL. START-UP AND OPERATION

alphainnoTec

alphainnoTec SWC - Series operating manual

Mark

Mark HKEU 353 Technical manual

Glowworm

Glowworm Envirosorb 5 Installation and servicing

kensol

kensol HYDROBOX KTH1 Installation and operating instructions

RV Products

RV Products 8535 SERIES Service manual

Daikin

Daikin RXZ25NV1B Service manual

Mareli Systems

Mareli Systems FGS10MB installation manual

Enviritech

Enviritech Heat Pump user manual