Take care to observe polarity of battery and connector. Be sure a good

electrical connection has been made. Then replace the battery and the cover.

NOTE

When battery is connected, the counter memory can

come on in any state. Be sure to reset it before use.

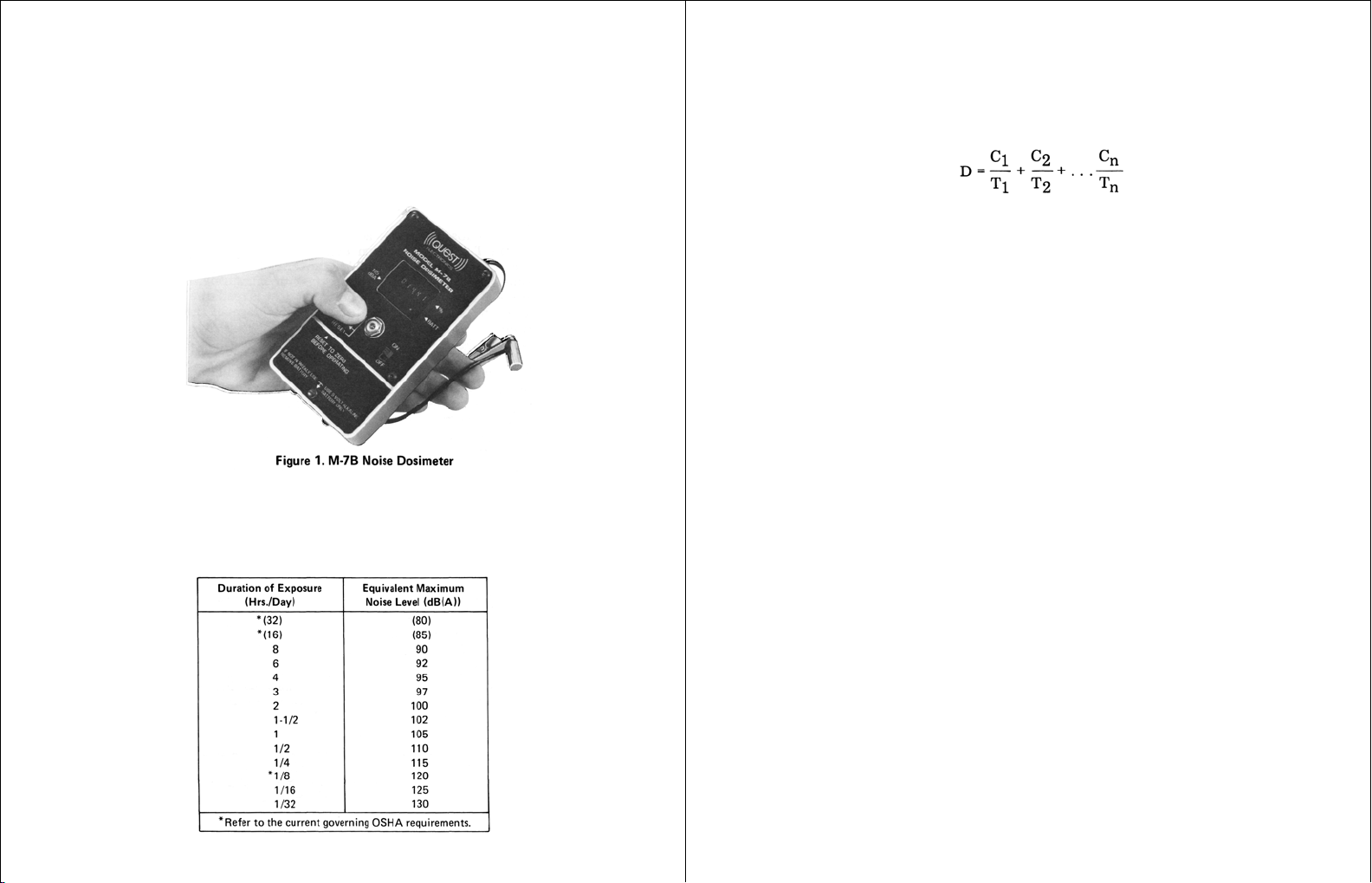

Taking a Measurement

Turn the unit on. Be sure to reset the counter and the 115 dB(A) indicator,

and attach the M-7B to either the belt or the shirt pocket using the spring clip on

the case. If desired, the detachable security cover may be used to prevent

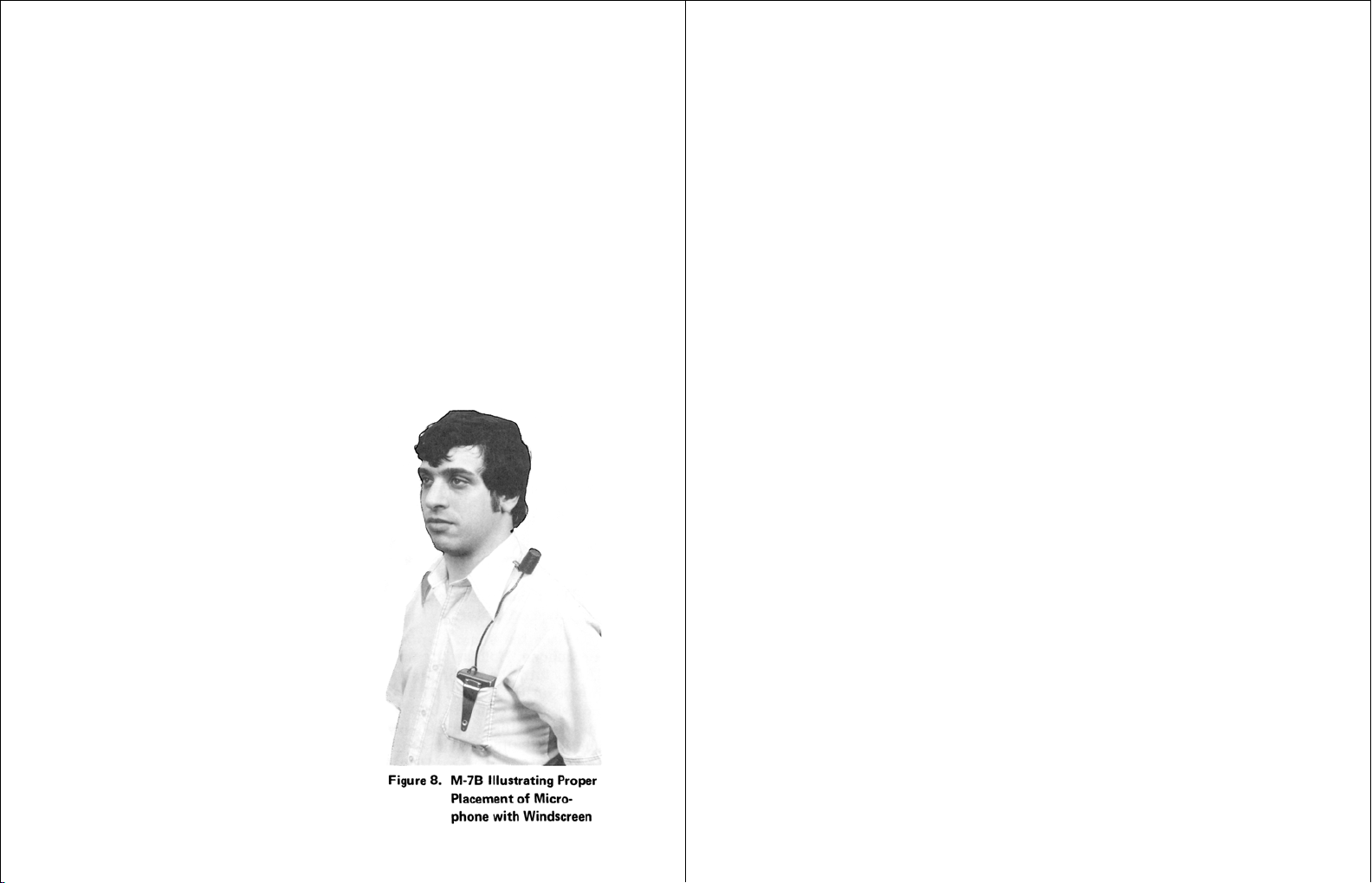

tampering with the dosimeter. Clip the microphone to the shirt or jacket collar

high on the shoulder. (Refer to "Effects of Operator's Presence", page 10).

Place the cable in the best position available, possibly under the shirt, to

prevent it from being entangled with other objects.

NOTE

If area noise rather than personal noise is to be monitored,

reset the counter and 115 dB(A) indicator and attach the M-7B

to a tripod using the 1/4-20 threaded insert on the spring clip.

Suspend the microphone away from solid surfaces, and at an

angle equivalent to random incidence (approximately 70° to

the direction of the sound source). With the unit turned ON, the

M-7B is now measuring and integrating noise levels between

the lower threshold limit and 140 dB(A) maximum.

Take the exposure measurement, either a short term sample or an all day

monitor, as needed. If noise levels vary considerably, monitor the noise for the

full work day.

At the end of the exposure period, depress the READ button. The noise

dose for the duration of the measurement period is displayed along with the

115 dB(A) indication (if 115 dB(A) was exceeded). Also, the BATT indicator

should light for a minimum of one second, indicating that the battery power was

sufficient during the measurement period.

After the data has been read, the unit can be turned off. This does not

destroy the count in the memory but does reset the 115 dB(A) latch. If the M-7B

will not be used again for a week or more, it is best to remove the battery to

prevent further drain.

Noise Exposure Conversion Chart

When the M-7B is used to take a measurement for the full work day, the

dosage for that day appears directly in the display. For example, if the reading

for 8 hours was 200.00 (200% of allowable

exposure), it would mean that the wearer had received twice the maximum

dosage for the day. If the measurement is taken for 4 hours of an 8 hour work

day, the counter should read less than 050.00 (50% of the allowable exposure)

to be within the specified limits. Regardless of the length of the work day, the

M-7B indicates the percentage of allowable noise that has been received up to

that time.

After taking a measurement for some determined time period, the readout

exposure can be converted to the equivalent dB(A) level for the entire time

period, and can also be used to determine the allowable exposure time per day

by using the Conversion Chart in Figure 6. This chart is also provided as a

handy separate slide rule "Noise Exposure Calculator" with each M-7B.

The Chart in Figure 6 is used to convert the dosimeter reading to both

Equivalent OSHA Exposure in dB(A) and to the Allowable Exposure Time per

Day in Hours. The chart is based on an allowable exposure of 90 dB(A) for 8

hours — which is indicated by a dosimeter reading of 100.00. In the example

above the dosimeter reading of 200.00 is converted by referring to the diagonal

line representing a measurement period of 8 hours. Find the intersection of this

line with the line representing a counter reading of 200.00. The vertical line

through this intersection indicates that the equivalent OSHA exposure, shown

at the top of the Chart, is 95 dB(A) and that the allowable exposure time per

day, shown at the bottom of the chart, is 4 hours.

Conversions for other counter readings and measurement periods are made

in a similar manner by using the appropriate counter reading and diagonal

measurement period line.

SHORT DURATION MEASUREMENTS can be taken if the noise level for

the period under measurement is representative of the entire day. Also, a

period of measurement should be long enough to accumulate a reading of at

least 000.50 to insure accuracy.

As another example, a measurement is taken for 5 minutes and the total

count accumulation is 005.60. Find the 5 minute period of measurement line on

the Conversion Chart. Next, locate the intersection of this diagonal line and the

005.60 counter reading at the left. The top of the Chart indicates the equivalent

dB(A) level is 102 dB(A), and the bottom of the Chart shows 1.5 hours is the

allowable exposure time per day.

Effects of Operator's Presence

Any object or surface can act as a reflector of sound. An operator or person

wearing the dosimeter is also a reflector and affects the microphone

performance. The M-7B is calibrated to read correctly with the microphone in a

random incidence sound field without the