ATETOOL AE988 User manual

AE988/AE988D/AE970/AE970D

User Manual

Soldering Station

AE988/AE988D/AE970/AE970D 电焊台

使用说明书

Packing List

Product Specification

Safety and Precautions

Using Method(AE988D/AE970D)

Main unit: 1pc

Handle: 1pc

Iron stand: 1pc

User manual: 1pc

Brass wool: 1pc

Model No. AE988 AE970 AE970D

AE988D

Total Power

Power consumption

Tip to ground

impedance

Tip to ground voltage

Heating element

Cable length

Weight

70W 70W

80W 80W

Main Unit

Handle

25VAC

79g 79g

65W75W 75W65W

<2Ω

<2mV

1.2m

Note: specifications and appearance are subject to change for product improvement without prior

notice

PTC ceramic

heater Integrated tip PTC ceramic

heater

200-480℃(392-896℉)

±1℃( ±1.8℉){〉200℃(400℉)}

50-500℃

(122-932℉)

150-550℃

(302-1022℉)

Output voltage

Temperature

range

Temperature

stability

Dimension

weight(power cable

excluded)

The precautions in this manual are divided into the following [warning] and [attention].

Please fully understand the content.

Warning: misuse may cause death or serious injury to the user

For your own safety, please strictly abide by the following precautions

Please strictly observe the following precautions, otherwise it may cause injuries or death

!

Note: misuse may cause injury to users or substantial damage to objects involved

!

● Do not touch the soldering iron tip or the metal part around it while using

● Do not use it around combustibles

● Inform the people around of the potential risk caused by high temperature

● Turn the power off when not in use

● Before replacing parts or tip, turn off the power and wait till the iron tip cools down

● Do not use this product if you are inexperienced or have no sufficient necessary knowledge

without the guidance of related qualified personnel

● Please keep it out of reach of children

● If the power cord is damaged, please ask the manufacturer or its service agent or similar qualified

personnel to repair it, so as to avoid personal injury or damage to product

● Do not use this product for works other than soldering

● Do not hit the handle hard for removing the tin on the iron tip

● Do not modify this product

● When replace parts, must use original ATETOOL parts

● Do not soak the product in water or use it with wet hands

● Unplug it properly after using

● Smoke will be emitted during soldering, please use it in open space

● Do not engage in other dangerous acts with this product

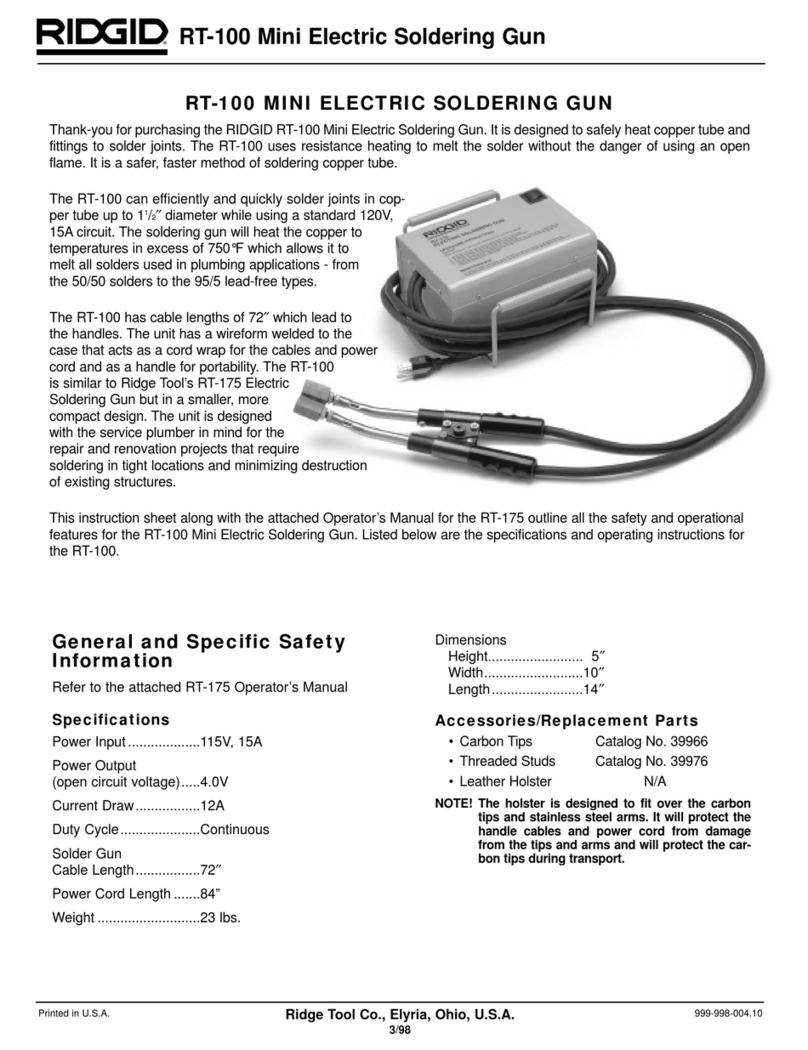

Panel display:

LED segment: digital display

Indicator: indicates the statement of heater (light on/off means power on/off)

Function key: function operation

Knob: to adjust temperature

Calibration hole: for calibrate the temperature

After switching on, indicator lights up and LED segment displays for 1 second, now power is on.

And then it displays the temperature unit or for 1 second, so you know which unit is used

right now. If the standby function is enabled in this soldering station, will be displayed for 1 second

to show standby function is available. Then displays the set temperature for 1.5 seconds, and finally displays

the real time temperature. When the temperature is stable, indicator will flash.

After use, please clean the soldering iron tip and apply new solder on it.

Note: when not in use, please put the soldering iron on the holder. If it won’t be used for a while, please cut off

the power supply.

1.Operation and display instructions

2.Turn on the power switch

3.After use

First press function key, in the meanwhile switch on the power, till LED segment displays , release

the function key, now the temperature unit changes. If it was Fahrenheit, now switch to Celsius, and vice versa.

4.Temperature unit conversion

Temperature range

AE988D:50-500℃(122-932℉)

AE970D:150-550℃(302-1022℉, note: as LED segment shows only 3 digits, 1022 will be displayed as A22,

“A” represents digit “10”)

Temperature adjusted by knob.

5.Temperature adjustment

Temperature locking function on and off:

1)Turning the knob to adjust the temperature to be set.

2)Long press the function key till is displayed.

3)Now LEd segment displays or

4)Turn the knob to set the locking function to be or

5)Press the function key or wait for 10s to automatically save to complete the setting.

6)When the temperature is locked, adjusting the knob does not change the setting temperature, it will display

for 1 second to show that the current temperature is locked.

8.Temperature locking function:

1) Press and hold the function key till the the screen displays , to enter the brightness setting.

2) Show the current digital display brightness level - .

3) Adjust the brightness level through the knob: gear 1-6.

4) Press the function key or wait for 10s to automatically save to complete the setting.

6.Screen brightness setting

Standby function on and off:

1)Press and hold the function key till display on LED segment to enter the standby function on/off setting:

2)Display the current setting or

3)Adjust by knob: or to turn on/off the standby and sleep function.

4)Press the function key or wait for 10s to automatically save to complete the setting.

Standby function

1)When standby function is turned on, the soldering station will enter standby mode after not in use for 10 minutes.

2)In standby mode, LED segment displays and temperature drops to 250 ℃(482 ℉).

3)When any operation is detected, such as using the soldering iron, adjusting knob or pressing the function key,

it will return to the work mode.

4)When in standby mode, if no further operation is detected for 10 minutes, it will enter sleep mode.

Sleep function:

1)That short press the function key or long time in standby mode can make it enter sleep mode:

2)When entering sleep mode, screen displays and heating is turn off.

3)Press the function key to return to normal heating work mode.

7.Standby and sleep functions

!

When power is on, the temperature of the soldering iron tip might reach to

50 ~ 550 ℃(120 ~ 1022℉).

Misuse may cause burns and fire, please strictly observe the following precautions:

Warning

123

Knob

Indicator

Calibration hole

LED segment

Function key

Socket

Main unit(AE988/AE970) Main unit(AE988D/AE970D)

Iron standHandle Brass wool User manual

Integrated tip

148x120x85mm

1.32kg 1.32kg 1.33kg 1.334kg

68g

68g

.

.

Soldering iron tip maintenance

1. Set the temperature to 250 ℃(480 ℉).

2. After the temperature is stable, clean the soldering iron tip with a brass wool and check its condition.

3. If black oxide is attached to it, please apply new solder (including flux) and wipe it repeatedly with a brass wool

until it’s clean, then apply some new solder.

4. If the soldering iron tip has been deformed, perforated or worn out, please replace it with a new one.

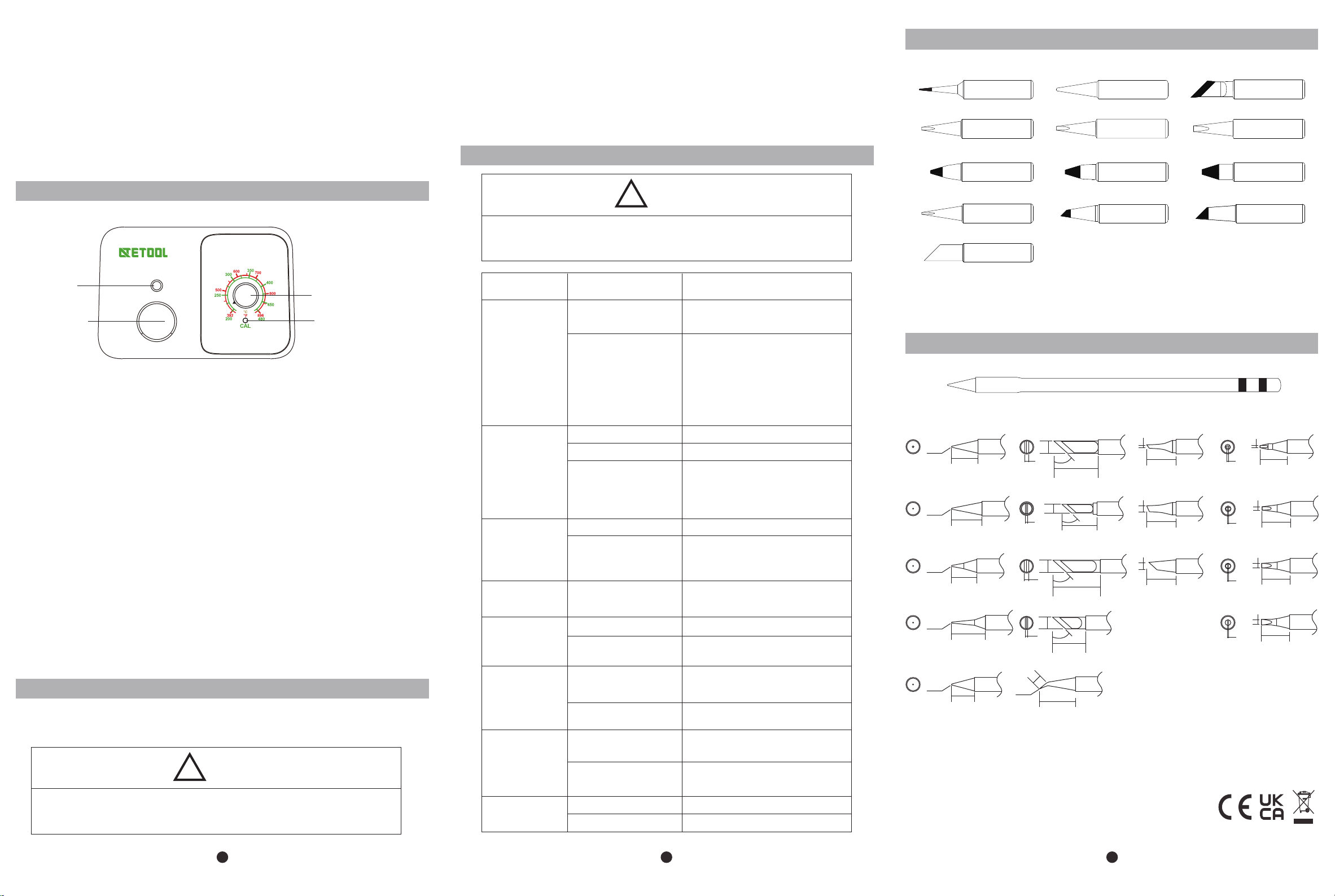

Not working after

power is on

The display shows "S-E"

The display shows "H-E"

Iron tip heating is on

and off

The solder won’t get on

the iron tip

Iron tip temperature is

too low

The iron tip won’t fit

The actual temperature

can’t reach

Check whether the power

cord is good, or plug falls off

Is the fuse OK

Whether the handle cable is well

connected with main unit

Whether the heater is damaged

(the resistance of the blue lead wire

shall be less than 100 Ω at room

temperature).

If damaged, replace the heater

Whether the heater is damaged

(the resistance of the red lead wire

shall be less than 100 Ω at room

temperature)

If damaged, replace the heater

Reconnected

Whether the wire connecting to

handle is broken If so please replace it with a new handle

Whether the wire connecting to

handle is broken If so please replace it with a new handle

Whether the wire connecting to

handle is broken

Check whether the temperature of

the iron tip is too high

Whether the temperature is proper

Is the temperature adjusted correctly

Haven’t done temperature calibration

for a long time

Adjust the set temperature again

Re-calibrate temperature accordingly

Whether there is oxide inside tip, or

soldering iron tip expands

Not original tip or not same type tip

Change the tip and heater

use original factory tip or same type tips

Adjust to the proper temperature

Adjust to the proper temperature

Check whether there is oxide on

the tip

Check whether there is oxide on

the tip

Clean the oxide with a brass wool

Clean the oxide with a brass wool

If so please replace it with a new handle

Connect the power supply well

Figure out the cause of fuse damage:

1. Short circuit inside the station.

2. Inside the handle, the spring might meets the

heating element.

3. Check whether the pin of heating element is

twisted or short circuited.

Even if the cause is unknown, please replace the

fuse. If the fuse get burnt out again, please return

the handle with the main unit for maintenance.

After the power is on, indicator lights up, and the soldering station starts heating up according to the set

temperature. After the temperature is stable, indicator flashes.

Note: when not in use, please put the soldering iron on the holder. If it won’t used for a while, please cut off the

power supply.

1) Adjust the set temperature to 350 ℃(662 ℉) by knob and wait for 2 minutes to stabilize the temperature.

2) Use a thermometer to measure the temperature of the soldering iron tip.

3) Use a cross screwdriver to adjust the calibration hole to make the displayed temperature value equal to the

measured value. For example, if the measured value is 345 ℃, adjust calibration hole to reduce display

temperature 350 to 345, make the display temperature match the measured value.

4) Press the function key to complete calibration.

9.Temperature calibration

Using Method(AE988/AE970)

Troubleshooting Guide

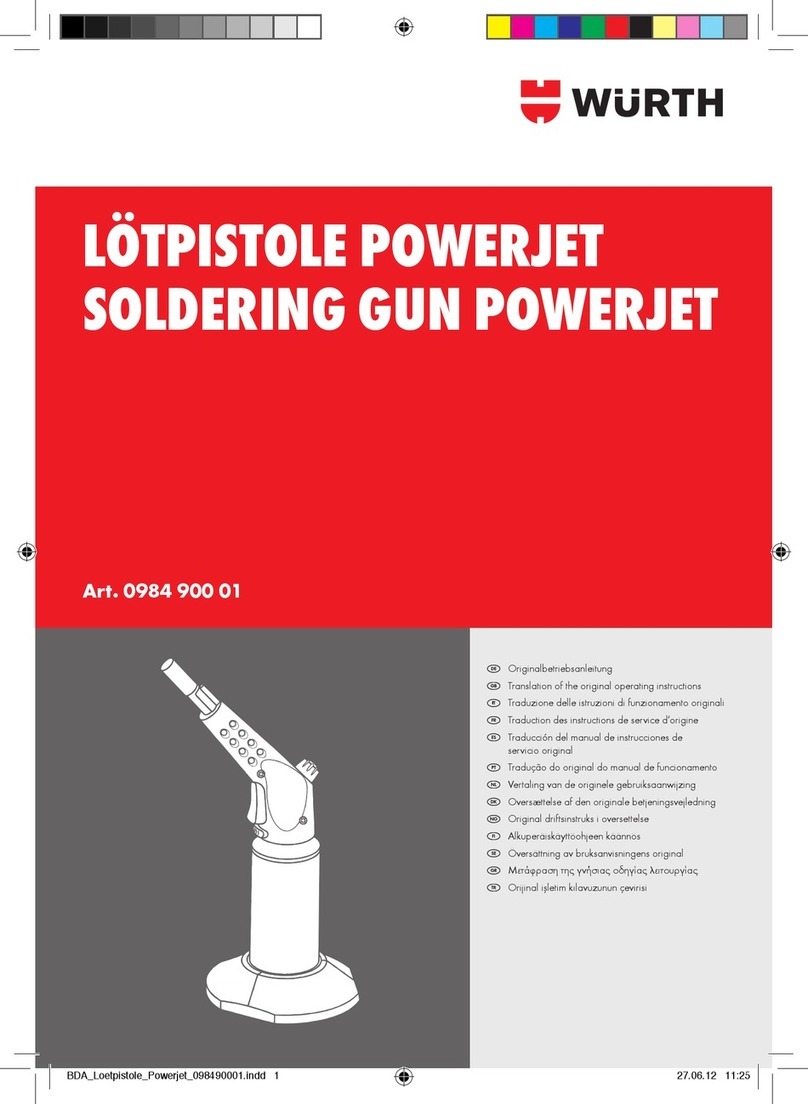

T900M series soldering tips(AE988/AE988D)

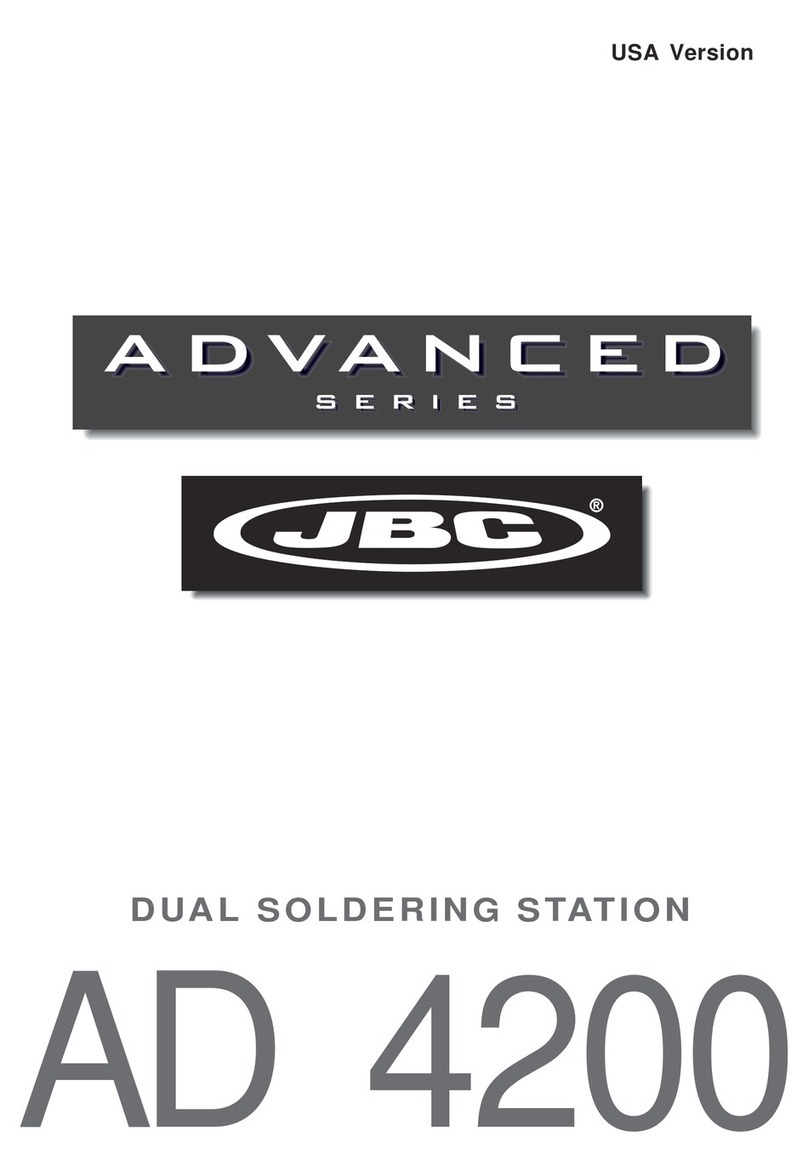

T80 series soldering tips(AE970/AE970D)

Maintenance

Warning

Please pay close attention when the soldering station is in use at high temperature, cut off the power

and unplug the power cord after use.

!

Indicator: indicate the power state(light on/off means power on/off)

Knob: adjust the temperature

Calibration hole: for calibrate the temperature

1.Operation and display instructions

2.Switch on the power

Temperature range: AE988/AE970:200-480℃(392-896℉).

Temperature adjusted by knob.

3.Temperature adjustment

1) Adjust the set temperature to 350 ℃(662 ℉) by knob and wait for 2 minutes to stabilize the temperature.

2) Use a thermometer to measure the temperature of the soldering iron tip.

3) Use a cross screwdriver to adjust calibration hole to make the measured value equal to set temperaure.

For example, if measured value is 345℃, adjust calibration hole to increase it to 350, make the measured

value match set temperature.

4) Temperature calibration completed.

4.Temperature calibration

In order to make this product durable, please maintain it regularly. The lifespan of this product depends on the

used temperature, quality of solder wire and soldering paste, frequency of use etc. Please repair and maintain

it according to specific use conditions.

Knob

Calibration hole

Indicator

socket

Warning

Failure

phenomenon Examination Dealing method

● When checking or replacing parts, be sure to pull out the power plug to prevent electric shock

● If the power cable is damage, it must be sent to the manufacturer, agency store or maintenance

personnel with the same qualification for repair to avoid accidents

!

4 5 6

T80-B2

900M-T-I 900M-T-B 900M-T-K

900M-T-1.2D 900M-T-1.6D 900M-T-2.4D

900M-T-3.2D 900M-T-4.6D 900M-T-6.5D

900M-T-0.8C

900M-T-6.4C

900M-T-3C 900M-T-5C

R0.5

10

T80-B2

R0.2

12

R0.2

7.5

T80-BL

R0.2

9.5

T80-I

T80-ILS

T80-B

R0.15

13.5

2

4.7

15

45°

T80-K

2.4

4.7

17

45°

T80-KF

1.5

4.7

11

45°

T80-KL

T80-KU

1.2

3

11

45°

R0.2

T80-J02

12

3.5

T80-BC1

11.5

1

T80-BC2

11.5

2

T80-BC3

10

3

T80-D08

9.5

0.8

0.5

T80-D12

10

1.2

0.5

T80-D16

10

1.6

0.5

T80-D24

10

2.4

0.5

Shenzhen ATETOOL Co., Ltd.

Address:F5, 1-2 #, Tongfuyu, Aiqun Road, Shiyan Street, Bao'an District, Shenzhen,

518132,P.R.China

Tel: (0755) 23408674 - 802

Support:(0755) 23408704 - 818

URL: www.atten.com.cn( in Chinese )

www.atten.com(in English)

(More soldering tips information please contact us)

(More soldering tips information please contact us)

CBN300123(A)

MADE IN CHINA

This manual suits for next models

3