9

TROUBLESHOOTINGGUIDE

●Theunitdoesnotoperatewhenthe

powerswitchisturnedon.

●Thesolderingirontipdoesnotheat

up.Sensorerrordisplayed.

●Solderdoesnotwetthetip.

●Thetiptemperatureistoohigh.

●Thetiptemperaturetoolow

●The smoke absorber is not

functioning effectively.

CHECK: Is the power cord and/or the

connectionplugdisconnected?

ACTION:Connectit.

CHECK:Isthefuseblown?

ACTION: Investigate why the fuse blew

andthenreplacethefuse.Ifthecausecan

notbedetermined,replacethefuse.Ifthe

fuseblowsagain,sendtheunitforrepair.

CHECK: Is the power cord and/or the

connectionplugconnected?

ACTION:Connectit.

CHECK: Isthetipinsertedproperly?

ACTION:Insertthetipcompletely.

CHECK: Istheconnectioncordand/orthe

heater/sensorbroken?

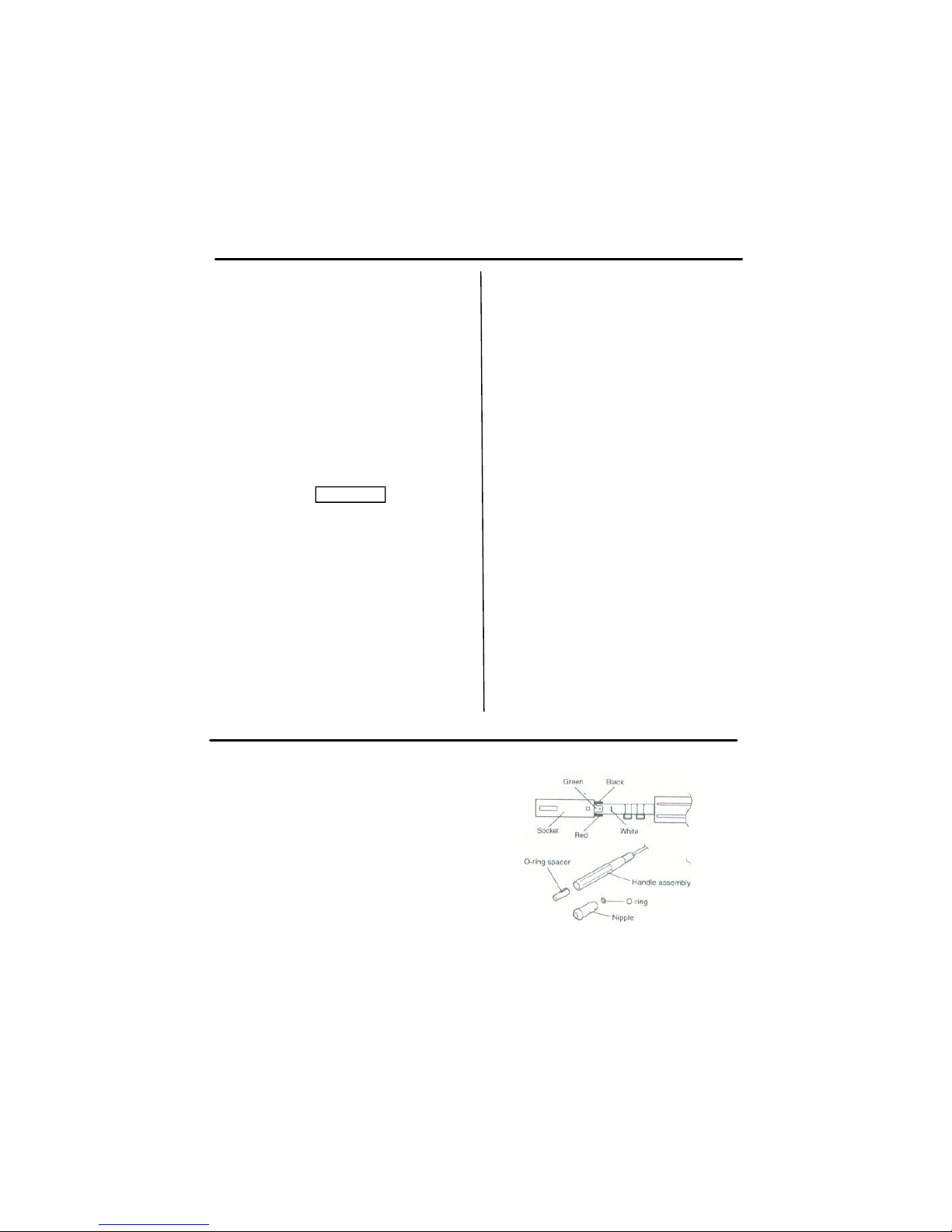

ACTION: Check the connectioncord and/

ortheheater/sensorforbreakage.(p.10)

CHECK:Isthetiptemperaturetoohigh?

ACTION:Setappropriatetemperature.

CHECK:Isthetipcontaminatedw/oxide?

ACTION:Removetheoxide

CHECK: Istheconnectioncordbroken?

ACTION: Check the connection cord for

breakage.(p.10)

CHECK: Isthetipcontaminatedw/oxide?

ACTION:Removetheoxide.

CHECK:Isthesmokeabsorberpipeorhot

airgunpipetangled?

ACTION: Free up the pipe from any

tangles.

CHECK: Is the smoke absorber opening

strandedorthefilterclutteredwithdirt?

ACTION: Free up the stranded part or

replacethefilterpadwithanewone.

Beforecheckingtheinsidepartofthestationorreplacingparts,besureto

disconnectthepowerplug.Failuretodosomayresultinelectricshock.