2

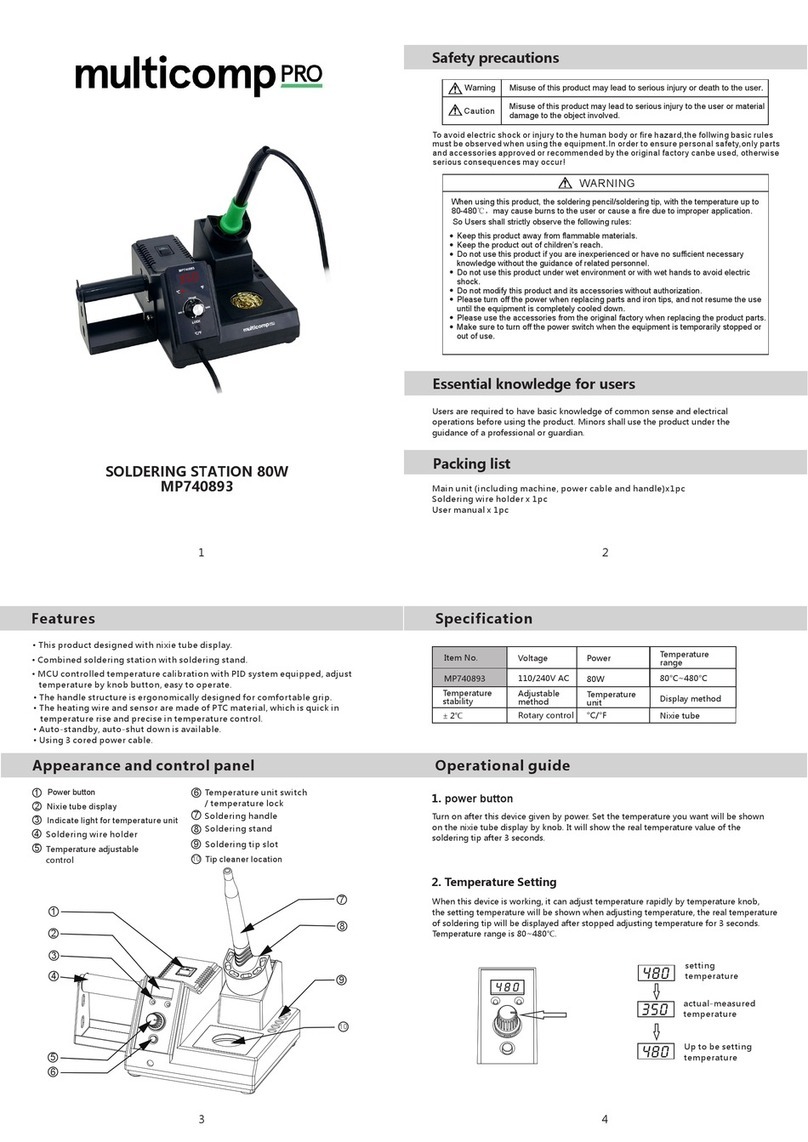

Structure of Advanced soldering stations

system

The Advanced series has basic modules giving

you full flexibility for choosing what you need for

the work in hand, the modules being supplied

separately.

Dual control unit

-AD 4200 USA Ref.4200100

Model AD 4200 can be used with two tools

simultaneous, either handpieces or hot tweezers.

Can be used with either combination of 2210 and

2245 handpieces and the hot tweezers PA 1200 and

PA 4200.

Handpieces

-2210 Ref.2210000

Power: 20W. For high precision work, SMD, etc.

-2245 Ref.2245000

Power: 50W. For general soldering work.

Hottweezers

-PA 1200 Ref.1200000

For general precision desoldering with SMD

components.

Power:40W.

Effective power per cartridge fitted: 20W.

-PA 4200 Ref.4200000

For general desoldering and soldering work in

professional electronics.

Power:100W.

Effective power per cartridge fitted: 50W.

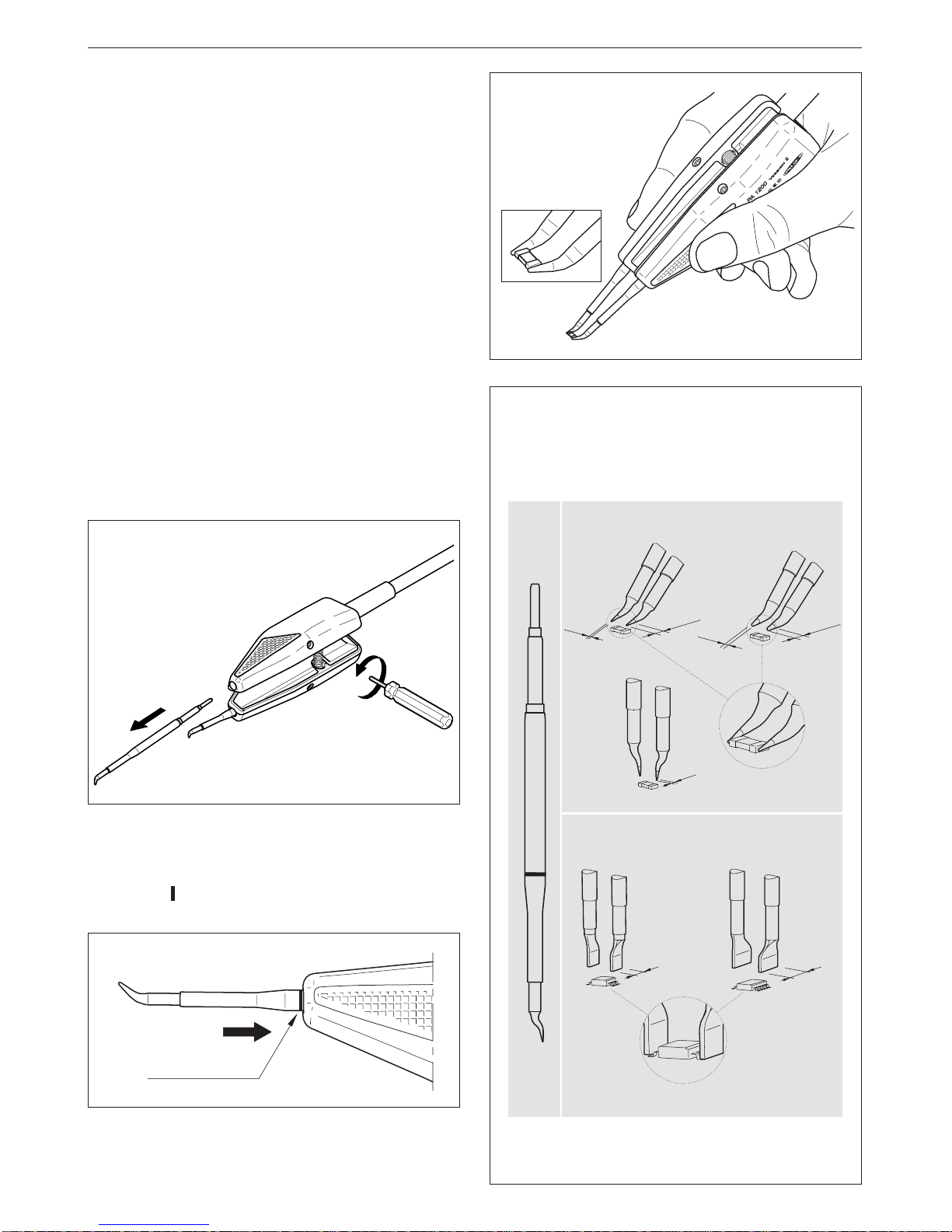

Cartridges

-Rangeofcartridges2210 (forthe2210 handpiece).

-Rangeofcartridges2245 (forthe2245 handpiece).

-Range of cartridges for micro hot tweezers PA

1200.

-Range of cartridges for hot tweezers PA 4200.

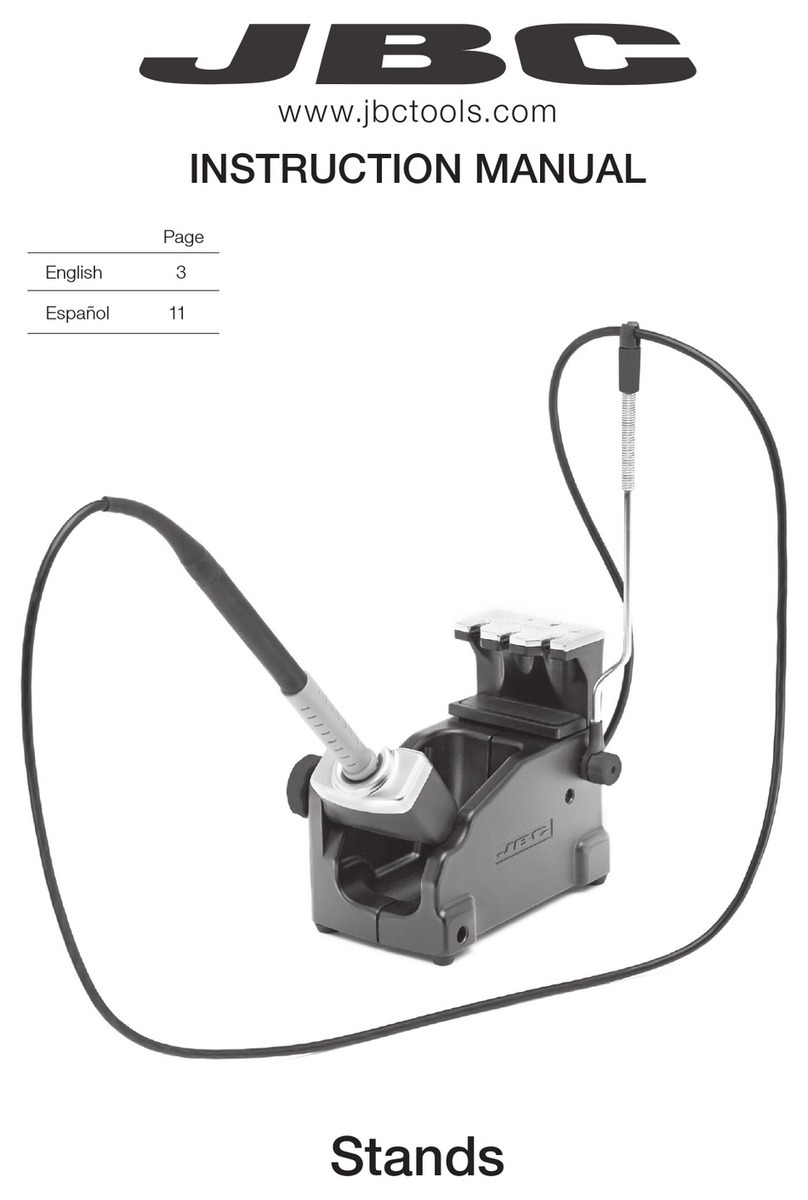

Stands

-Soldering iron stand AD 8200 Ref.0268200

-PA 8420 Ref.0748420

Stand for the hot tweezers PA 4200.

-PA 8100 Ref.0748100

Stand for the hot tweezers PA 1200 and PA 4200.

For a dual soldering station work properly is

necessary: the dual control unit, a handpiece or the

hot tweezers, and the corresponding stand and

cartridge.

Dual control unit AD 4200

The station is supplied with:

-Control unit.

-Connection cable to mains.

-Instructions manual.

-Transport packaging.

Technical specifications

-Temperature selection from 200 to 700°F (±5%).

-Power: 135W.

-Safety transformer, mains separator and double

isolation, with integrated fuse of temperature

protection.

-Input: 120V 60Hz. Output: 24V.

-Electrical protection Class I.

-Total weight of unit: 12.5 lbs.

-ESD protected housing.

Typical surface resistance: 105-1011Ohms/

square.

-Equipotential connector is earth connected to the

plug feed of the station.

listed.

RECOMMENDATIONS FOR USE

For soldering and desoldering

-Clean the contacts and the printed circuit to

be desoldered of dust or dirt.

-Preferably select a temperature below 662°F.

Excess temperature may cause the printed

circuit tracks to break loose.

-The tip must be well tinned for good heat

conduction. If it has been inoperative for any

length of time, it should be retinned.