ATLAS COPCO - INDUSTRIAL AIR DIVISION

P.O. Box 103, B-2610 WILRIJK - BELGIUM

Instruction manual

for compressed air filters

DD - DDp - PD - QD filters

Instruction manual..................................................................................................3

Bedieningshandleiding...........................................................................................9

Manuel d’instructions............................................................................................15

Bedienungsanleitung............................................................................................21

Libro de Instrucciones..........................................................................................27

Instruktionsbok.....................................................................................................33

Manuale di istruzioni.............................................................................................39

Instruksjonsmanual ..............................................................................................45

Instruktionsbog.....................................................................................................51

ΕΓΧΕΙΡΙ∆ΙΟ ΧΡΗΣΗΣ ..........................................................................................57

Manual de instruções...........................................................................................63

Ohjekirja...............................................................................................................69

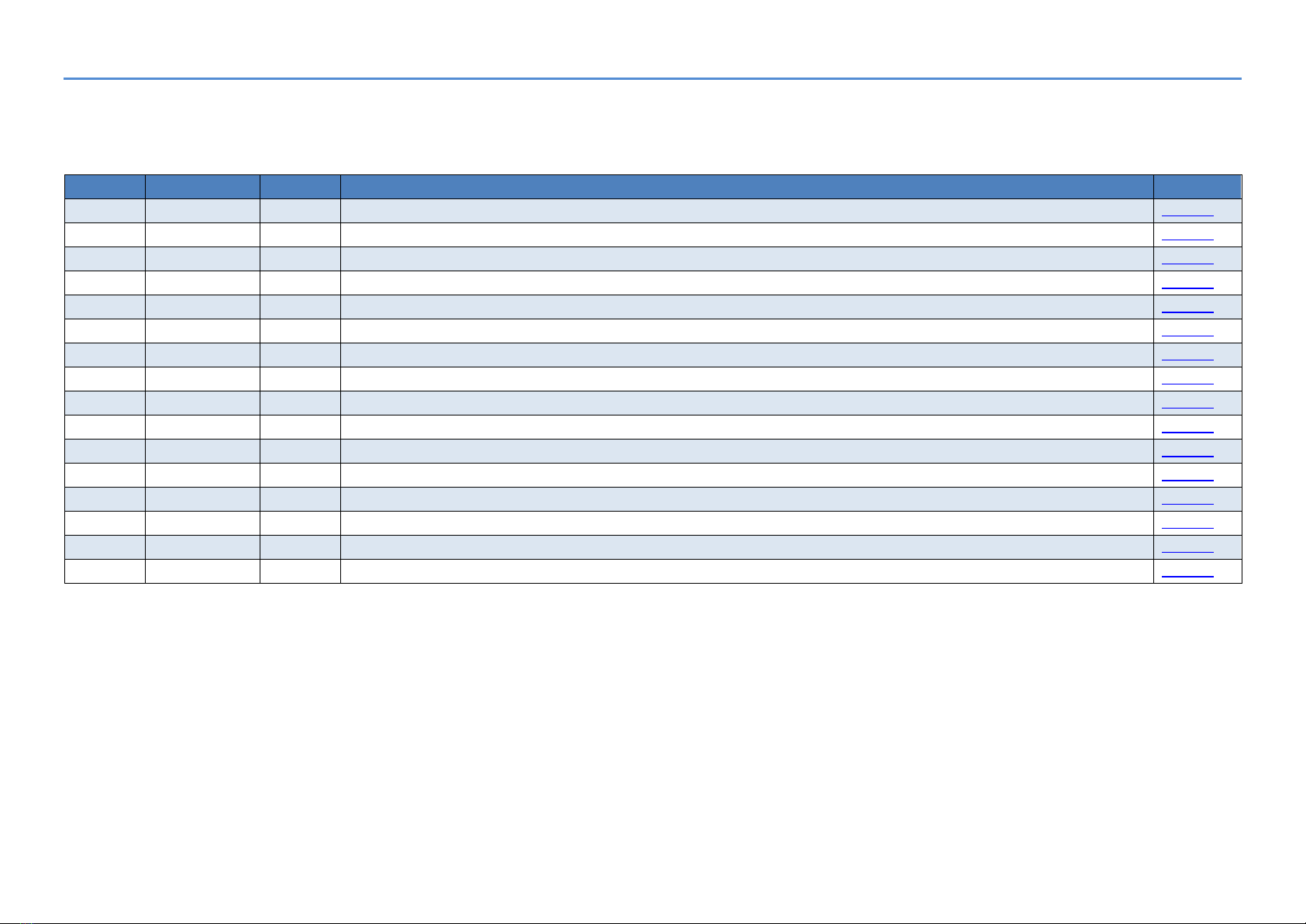

Spare parts catalogue...........................................................................................75

Onderdelenlijst – Liste de pièces – Ersatzteilliste – Lista de las partes –

Reservdelsförteckning – Listino parti di ricambio – Deleliste –

Reservedelsliste – KατάλoγoςEξαρτηµάτων – Lista de peças – Osaluettelo

Glossary...............................................................................................................82

Woordenlijst – Glossaire – Glossar – Glosario – Ordlista – Glossario –

Ordliste – Ordliste – Γλωσσαριo – Glossário – Sanasto

REGISTRATION CODE

Collecton:

Ancillaries

Tab:

38

Sequence:

-

Printed Matter Number

2904 0108 04

2003-07

Vendor Manual Atlas Copco A090-070423-004 PD & DD Filters Instruction Manual