1

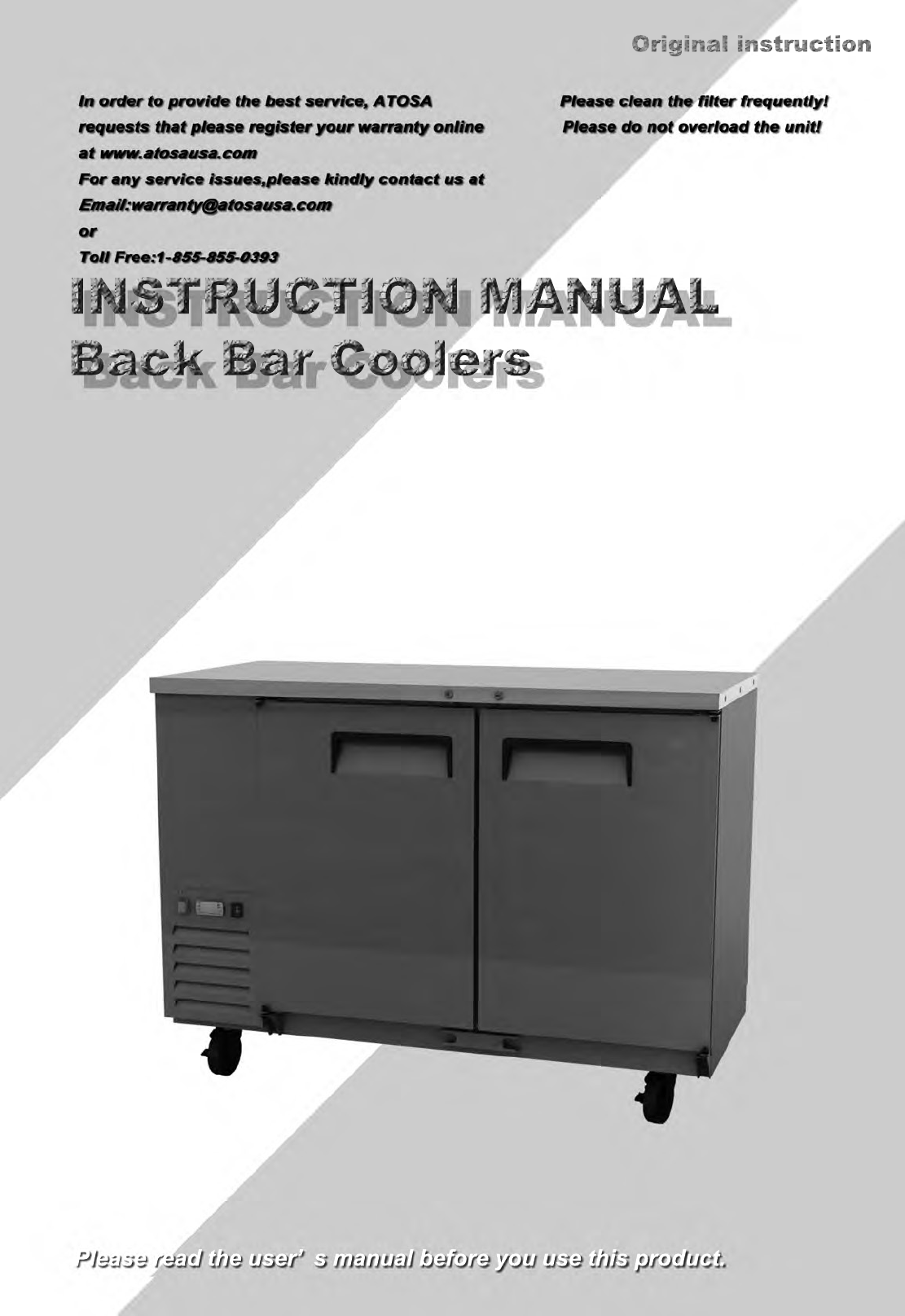

Back Bar Coolers

Installation, use and maintenance instructions

INDEX

1 Terms and conditions.........................................................................

........

2

2 Introduction............................................................................

.....................

6

3 The manufacturer cannot be held liable in the following cases

..................

8

4 Transportation and storage

........................................................................

9

5 Commissioning...............................................................

............................

9

5.1 Positioning................................................................

...........................

9

5.2 Initial cleaning....................................................................................10

5.2 Initial cleaning....................................................................................10

5.3 Connection to electrical supply..........................................................10

5.4 Connection to drains.........................................................

.................

11

6 Technical characteristics

.........................................................................12

6.1 Noise and vibration............................................................................12

6.2 Possible applications

...............................................

.........................

12

7 Usage............................................................................

7 Usage............................................................................

...........................

12

7.1 Activation...........................................................................................12

7.1.1 Switching on/off

.......................................................................

12

7.1.2 Visualisation of cell temperature

..............................................

13

7.1.3 Setting the cell temperature

..............................

......................

.

13

7.1.4 Visualisation of alarm codes.....................................................13

7.2 Storage of food-stuffs...........................................

7.2 Storage of food-stuffs...........................................

.............................

14

7.3 Defrosting.............................................................

.............................

14

7.3.1 Defrost timer................................................

.............................

14

7.3.2 Manual defrosting........................................

............................

.15

8 Maintenance................................................................

...........................

..15

8.1 Periodic cleaning.....................................................

........................

..15

8.2 Cleaning of condenser.................................

8.2 Cleaning of condenser.................................

....................................

.15

8.3 Period of inactivity of cabinet..................

..........................................

16

9 Trouble shooting and remedies................................................................16

9.1 If the cabinet does not operate..........................................................16

9.2 If the required temperature is not achieved.......................................16

9.3 If the cabinet leaks water...................................................................17

9.4 If the cabinet is unacceptably noisy...................................................17

9.5 Improbable risks.......................................

9.5 Improbable risks.......................................

.........................................

17

10 Substitution of spares................................................

.............................

17

11 Dismantling.............................................................................................18

Official approval and rules...........................................................................19

Technical Parameters..................................................................................20

Correct disposal of this product....................................................................21