ATSG Chrysler 45RFE User manual

INDEX

Copyright © ATSG 1999 September, 1999

CHRYSLER 45RFE

2

AUTOMATIC TRANSMISSION SERVICE GROUP

9200 S. DADELAND BLVD. SUITE 720

MIAMI, FLORIDA 33156

(305) 670-4161

CLUTCH APPLICATIONCHART...................................................................................................................... 4

SOLENOID ON/OFFCHART............................................................................................................................... 5

CASECONNECTORANDTCM PIN CAVITYIDENTIFICATION............................................................... 11

WIRING SCHEMATIC ......................................................................................................................................... 13

CONTROLRELAYANDFUSE LOCATIONS .................................................................................................. 14

TRS/SOLENOIDBODYTESTS.......................................................................................................................... 18

OBDIIDIAGNOSTICTROUBLECODE IDENTIFICATION ........................................................................ 20

OILPASSAGEIDENTIFICATION..................................................................................................................... 22

LINEPRESSURETESTING................................................................................................................................ 30

GENERALOPERATIONINFORMATION........................................................................................................ 31

TRANSMISSIONDISASSEMBLYPROCEDURE............................................................................................. 32

COMPONENTREBUILDPROCESS

TRANSMISSION CASEASSEMBLY.............................................................................................................. 42

LOW/REVERSECLUTCHHOUSINGASSEMBLY..................................................................................... 44

2-4CLUTCHRETAINERASSEMBLY........................................................................................................... 50

GEAR TRAINCOMPONENTS........................................................................................................................ 53

INPUT CLUTCHHOUSINGASSEMBLY...................................................................................................... 54

INPUT CLUTCHHOUSINGSNAPRINGIDENTIFICATION................................................................... 56

OILPUMPASSEMBLYINCLUDING VALVES........................................................................................... 65

VALVEBODY ASSEMBLY .............................................................................................................................. 73

TRANSMISSIONFINALASSEMBLY................................................................................................................ 83

CHECKINGFRONTANDREAR END-PLAY ................................................................................................... 89

AIRPRESSURETESTS......................................................................................................................................... 91

END-PLAYSPECIFICATIONS............................................................................................................................ 96

FLUIDSPECIFICATIONS.................................................................................................................................... 96

TORQUESPECIFICATIONSANDBOLTIDENTIFICATION....................................................................... 97

EXPLODEDILLUSTRATIONSOFINTERNAL PARTS.................................................................................. 98

THRUSTBEARINGCHART............................................................................................................................... 108

SPECIALTOOLS.................................................................................................................................................. 109

IDENTIFICATIONTAG LOCATION................................................................................................................. 112

CAUTION: ATSG service manuals are intended for use by professional,

qualified technicians. Attempting repairs or service without the proper

training, tools and equipment could cause injury to you or others and damage

tothevehiclethat may causeitnottooperateproperly.

GO TO PAGE

PREVIOUS

MENU

AKPPHELP.RU Руководство по ремонту АКПП

INTRODUCTION

AUTOMATIC TRANSMISSION SERVICE GROUP

9200 S. DADELAND BLVD. SUITE 720

MIAMI, FLORIDA 33156

(305) 670-4161

DALE ENGLAND

FIELD SERVICE CONSULTANT

ED KRUSE

TECHNICAL CONSULTANT

WAYNE COLONNA

TECHNICAL SUPERVISOR

ROBERT D. CHERRNAY

TECHNICAL DIRECTOR

PETER LUBAN

TECHNICAL CONSULTANT

JIM DIAL

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

JERRY GOTT

TECHNICAL CONSULTANT

ARSENIO RIVERA

TECHNICAL CONSULTANT

DAVID CHALKER

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

CHRYSLER 45RFE

1

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form

or by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tablesand charts.

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

Copyright © ATSG 1999

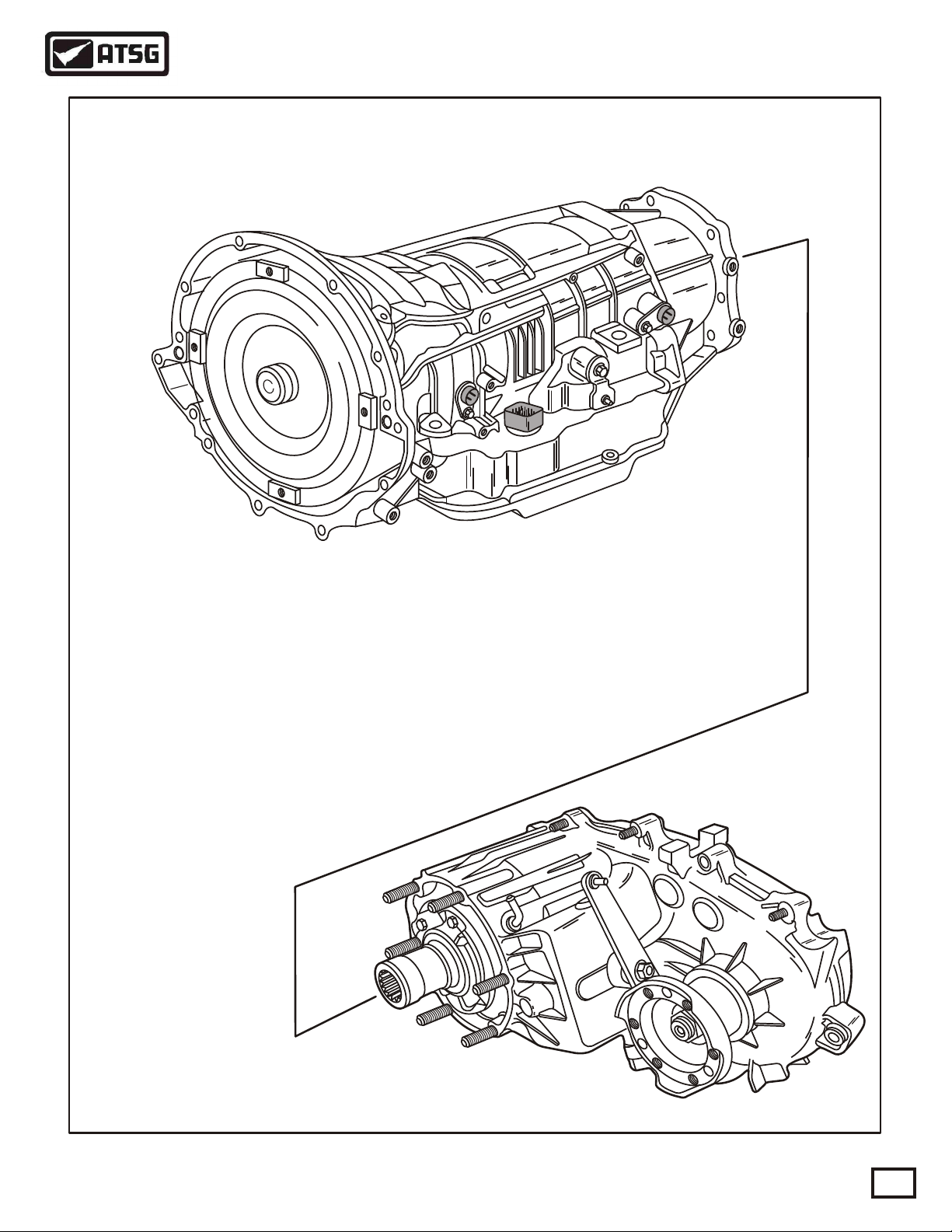

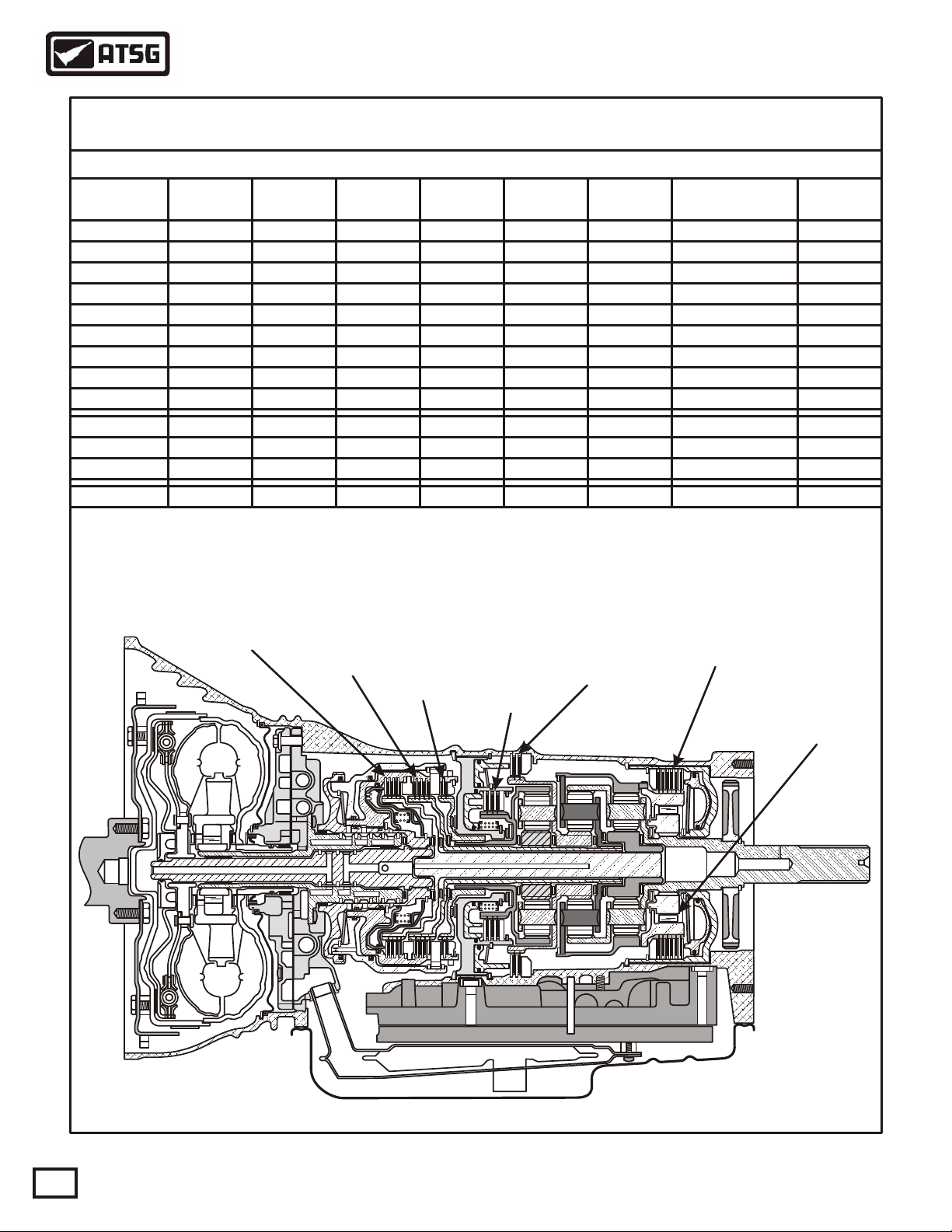

Beginning at the start of production for the 1999 model year Chrysler Corporation has introduced a brand new

rear wheel drive transmission for the 99 Jeep Grand Cherokee with the 4.7L engine, and scheduled for the Ram

Pick-up for the 2000 model year. This is the first completely new rear wheel drive automatic transmission from

Chrysler in more than thirty years. The 45RFE designation tells us that this new unit has 4forward speeds, a

relativetorque ratingof 5,isforReardrivevehiclesandisFullyElectroniccontrolled.RefertoFigure1.

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

3

JEEP GRAND CHEROKEE 45RFE TRANSMISSION

FOUND BEHIND 4.7L ENGINE FOR 1999

Copyright © 1999 ATSG

Figure 1

4= Four Forward Speeds

5= Relative Torque Capacity

R= Rear Wheel Drive

FE = Fully Electronic

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

4

Copyright © 1999 ATSG

CLUTCH APPLICATION CHART

SELECTOR

POSITION LO/REV

CLUTCH UD

CLUTCH SECOND

CLUTCH OD

CLUTCH GEAR

RATIO

LOW OVERRUN

CLUTCH

FOURTH

CLUTCH REVERSE

CLUTCH

PARK ON

ON ON 3.00:1

3.00:1

3.00:1

3.00:1

1.67:1

1.67:1

1.67:1

1.50:1

1.00:1

1.00:1

0.75:1

ON

ON

ON

ON

ON

ON

ON

ON

ON ON

ON ON

ON

ON

ON

ON

ON

ON

HOLD

HOLD

HOLD

REVERSE

NEUTRAL

OD-1ST

(1)-1ST

(2)-1ST

(2)-2ND

OD-2ND

OD-3RD

OD-4TH

OD-LIMP

(2)-LIMP

2ND PRIME

ON*

ON*

ON*

L/R Clutch is on only with the output shaft speed below 150 RPM.

*

Figure 2

Underdrive

Clutch Overdrive

Clutch Reverse

Clutch

Second

Clutch

Fourth

Clutch

Low/Reverse

Clutch

Low Roller

Clutch

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

5

Copyright © 1999 ATSG

The operation of the 45RFE is very similar to the Chrysler 41TE (A604) and 42LE (A606) transaxles that you

are already familar with. The 45RFE has no internal bands, but uses several different clutch assemblies instead.

The Input Clutch Housing retains the underdrive clutch, overdrive clutch and the reverse clutch and is set up

almost identical to the 41TE transaxle, except much larger. The 45RFE also contains seperate holding clutches,

such as the 2nd clutch, 4th clutch and the low/reverse clutch. This unit also uses one overrunning or freewheel

devicecalled thelow overrunclutch.

To achieve its different gear ratios, the 45RFE applies different combinations of two clutch packs at a time, as

shown in Figure 2. In Park and Neutral, only the low/reverse clutch is applied. Notice also that a unique

characteristic of the 45RFE is its alternate 2nd gear ratio, or "2nd prime" as it is known. The 2nd prime is

enabled only during kickdown shifts above certain speeds, that enhances vehicle performance by allowing for a

higher gear ratio passing gear at highway speeds. Refer to the chart in Figure 2 for the clutches that are applied

foreach shiftlever position.

Another feature ofthisunit is thethreeplanetary gearsets,asshown inFigure2, which isonemore than youare

used to seeing in a Chrysler unit. These planetary gear sets provide a deeper 1st and reverse ratio and does not

needa seperateoverdrive unit. AllgearratiosarealsoshowninthechartinFigure2.

MECHANICAL OPERATION

Modulating (EMCC) if the Converter Clutch has been signaled.

*

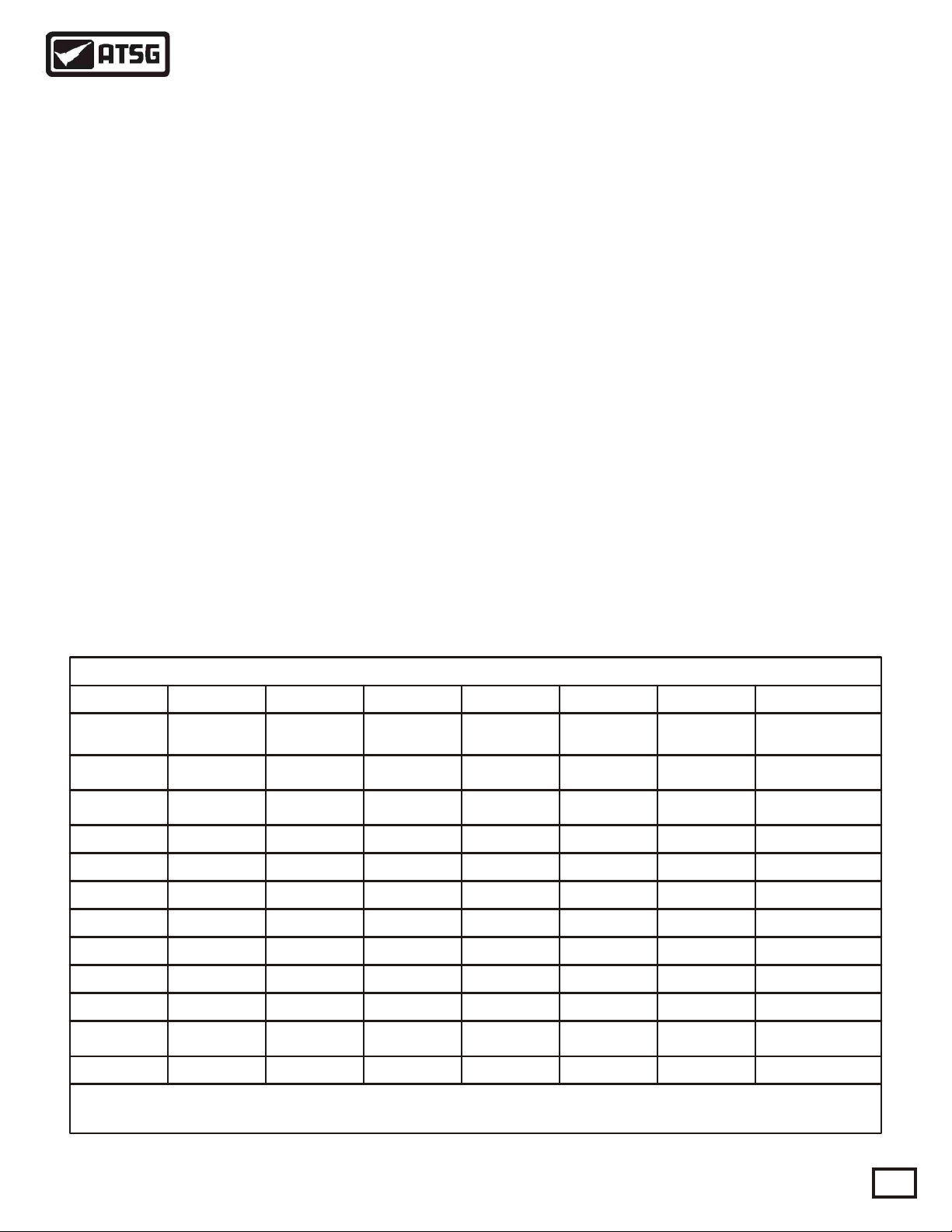

SOLENOID CHART

SELECTOR

POSITION LR/CC

SOLENOID UD

SOLENOID OD

SOLENOID 2nd CLUT

SOLENOID 4th CLUT

SOLENOID Multi-Select

SOLENOID Variable Force

SOLENOID

P/N

Under 8

P/N

Over 8

(1)-1ST Or

Autostick

ON

N.O. N.O. N.O. N.O.N.C. N.C.

ON

ON

OFF OFF OFF OFF OFF OFF OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON ON

ON

ON

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

REVERSE

FAILSAFE

REV-Block

OD-1ST

OD-2ND

OD-3RD

OD-4TH

2ND PRIME

*

*

*

*

Figure 3

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

6

Copyright © 1999 ATSG

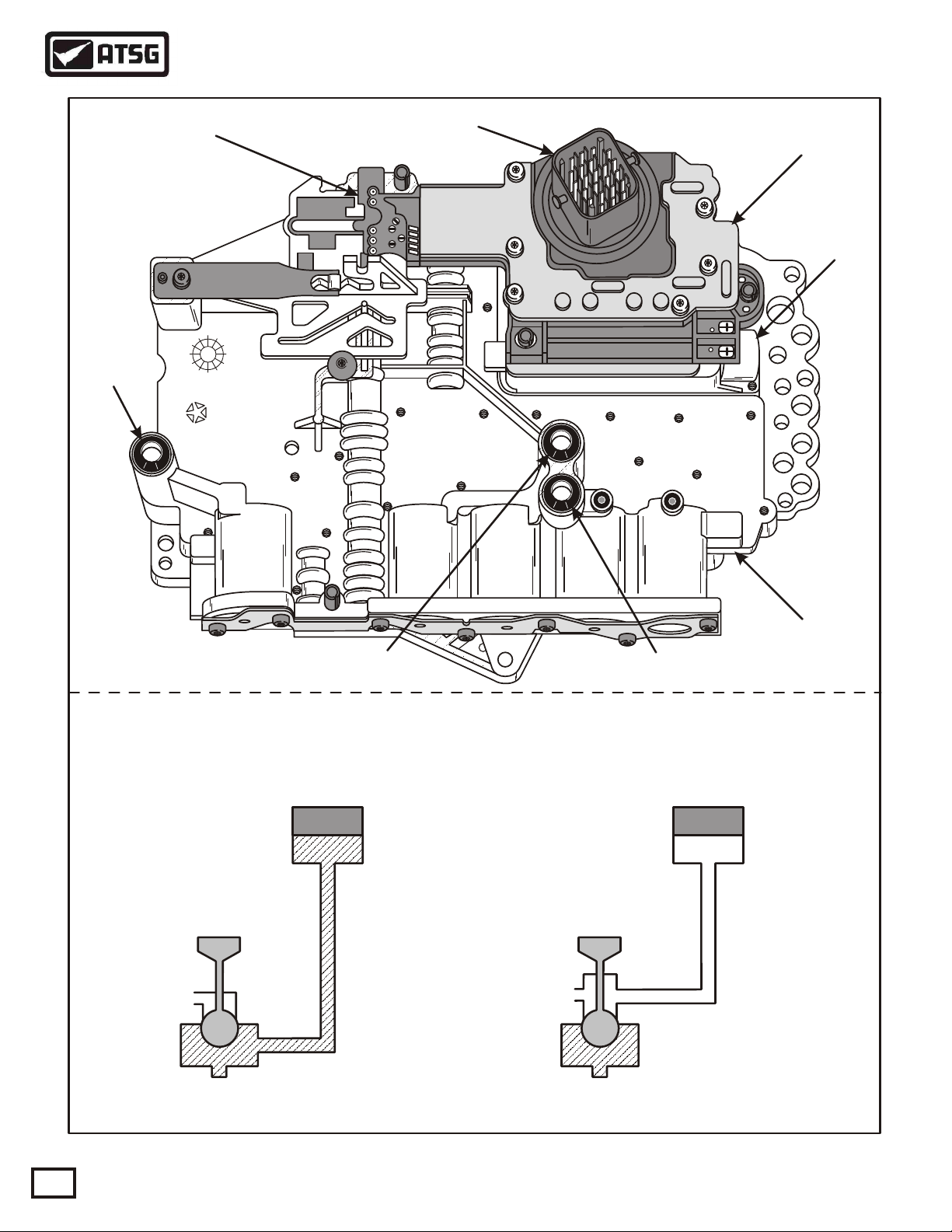

ELECTRICAL OPERATION

TheTransmissionControlModule(TCM)controlsallofthetransmissionfunctionsandis locatedin theengine

compartment, as shown in Figure 5. The Powertrain Control Module (PCM)does not control the transmission.

The electronic components of the 45RFE transmission consist of various sensors and switches as input

information to the TCM, that the TCM uses to determine the appropriate gear ratio and shift schedule points.

There is also the associated wiring, fuses, relays, connectors, splices and grounds for the transmission to

functionas designed. Acomplete transmissionwiringschematichasbeenprovidedforyouinFigure9.

The final output from the TCM is to the six shift solenoids and the line pressure control solenoid located in the

Solenoid Pack/Transmission Range Sensor assembly and bolted on the valve body as shown in Figure 4. The

solenoids in this transmission are unique in that some are normally vented and some are normally applied and is

illustrated in Figure 4. The TCM also communicates with other control modules, such as the PCM, currently

using the two wire CCD Bus for communication. The TCM recieves power from two sources, fused battery

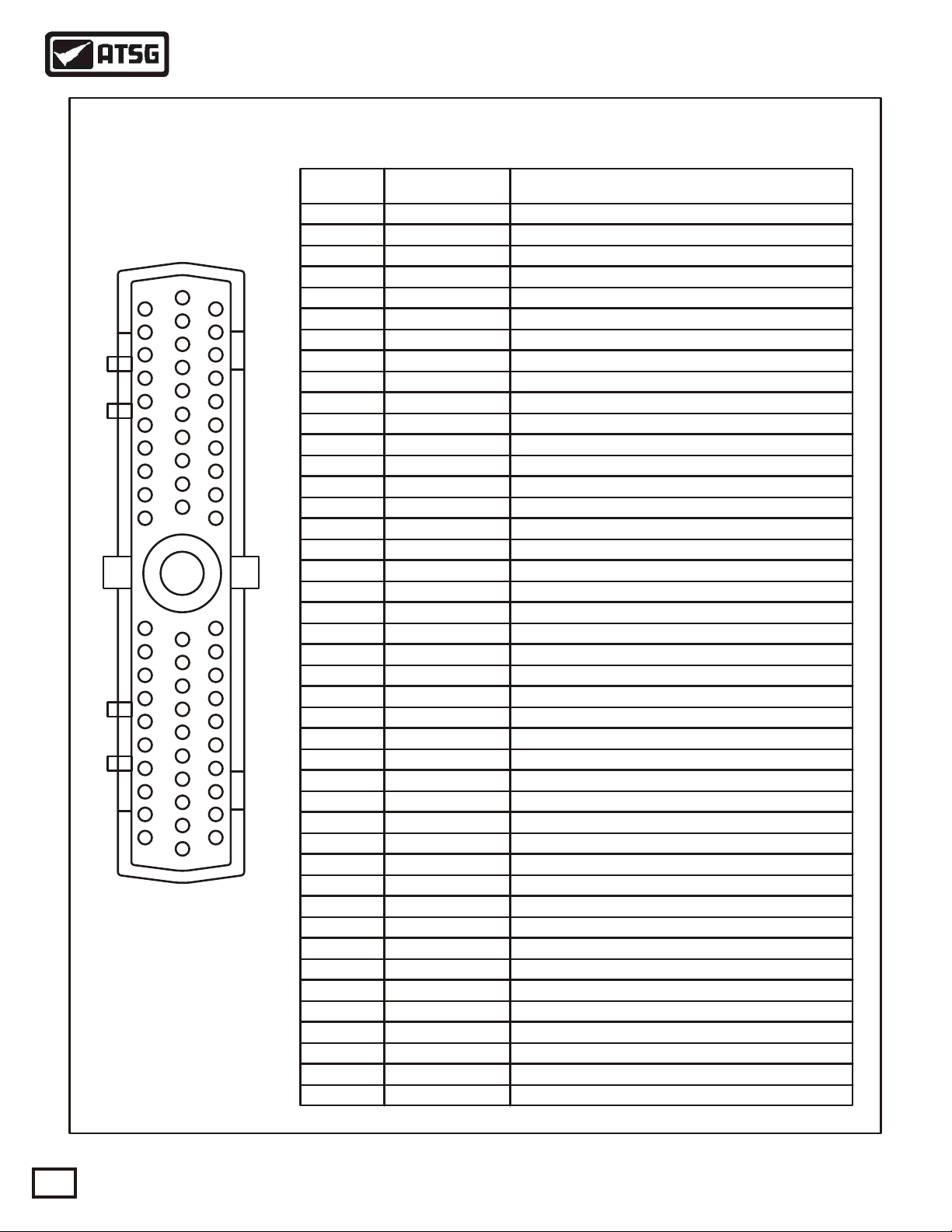

power to pin 56 and fused ignition switch input to pin 11, both at the 60-way connector on the TCM. The TCM

alsohas aground tocompleteitselectricalcircuit.(SeeFigure8).

INPUTS TO THE TCM

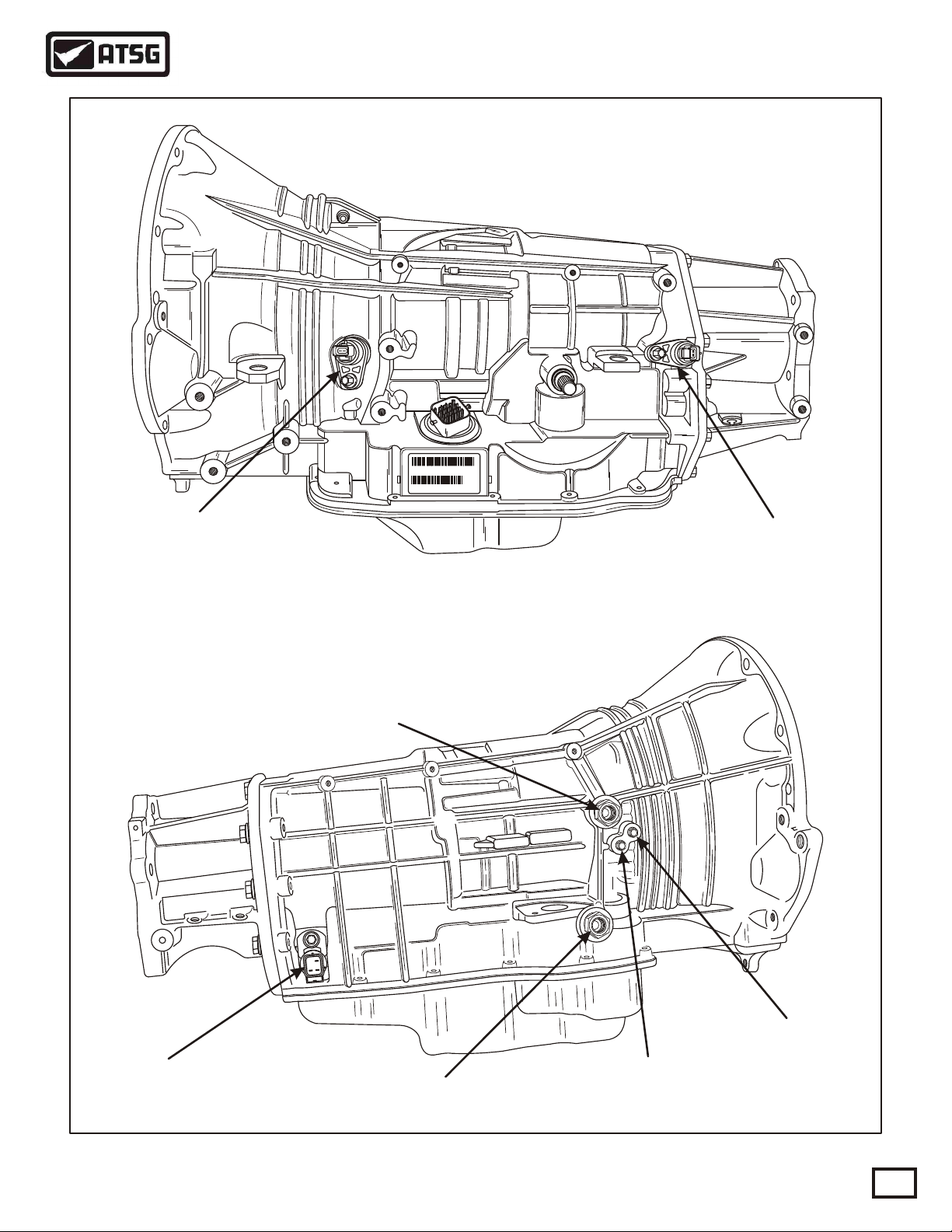

Input and Output Shaft Speed Sensors - are located on the left side of the transmission and are illustrated in

Figure 11. The input shaft speed sensor reads input shaft speed off of a tone wheel. The TCM compares this

reading with that of the output shaft speed sensor, which is also read off of a tone wheel. This comparison

provides the TCM with gear ratio information. The crankshaft position sensor supplies the TCM with engine

RPMdata thatis alsocritical toschedulingshiftpoints.

Line Pressure Sensor - is located on the right rear of the transmission, as illustrated in Figure 11, and supplies

theTCM withline pressureinformation. Thelinepressuresensoroperatesmuchlikeathrottlepositionsensor.

Transmission Fluid Temperature Sensor - is located in the Solenoid Pack/Transmission Range Sensor and is a

thermisterthat theTCMusestomonitertransmissionfluidtemperature.

OverdriveCancel Switch- locatedon theshift leverand cancelsoverdriveoperation.

Solenoid Pack/Transmission Range Sensor- contains several different inputs to the TCM. The TRS contains

five switches that tell the TCM, through different combinations of switch states, what position the manual gear

selectorhas beenplaced. There isalsoaback-uplampswitchincorporatedintheTRS.

In addition to the switches above, there are five pressure switches to moniter pressure in the Low/Rev, Second

Clutch, Fourth Clutch, Underdrive Clutch and Overdrive Clutch hydraulic circuits. The primary function of

these switches is to help the TCM detect when clutch circuit hydraulic failures occur. The TCM continuously

monitorsthe switchesfor thecorrectstates(OpenorClosed)ineachgearasshowninthechartinFigure5.

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

7

Copyright © 1999 ATSG

OUTPUTS FROM THE TCM

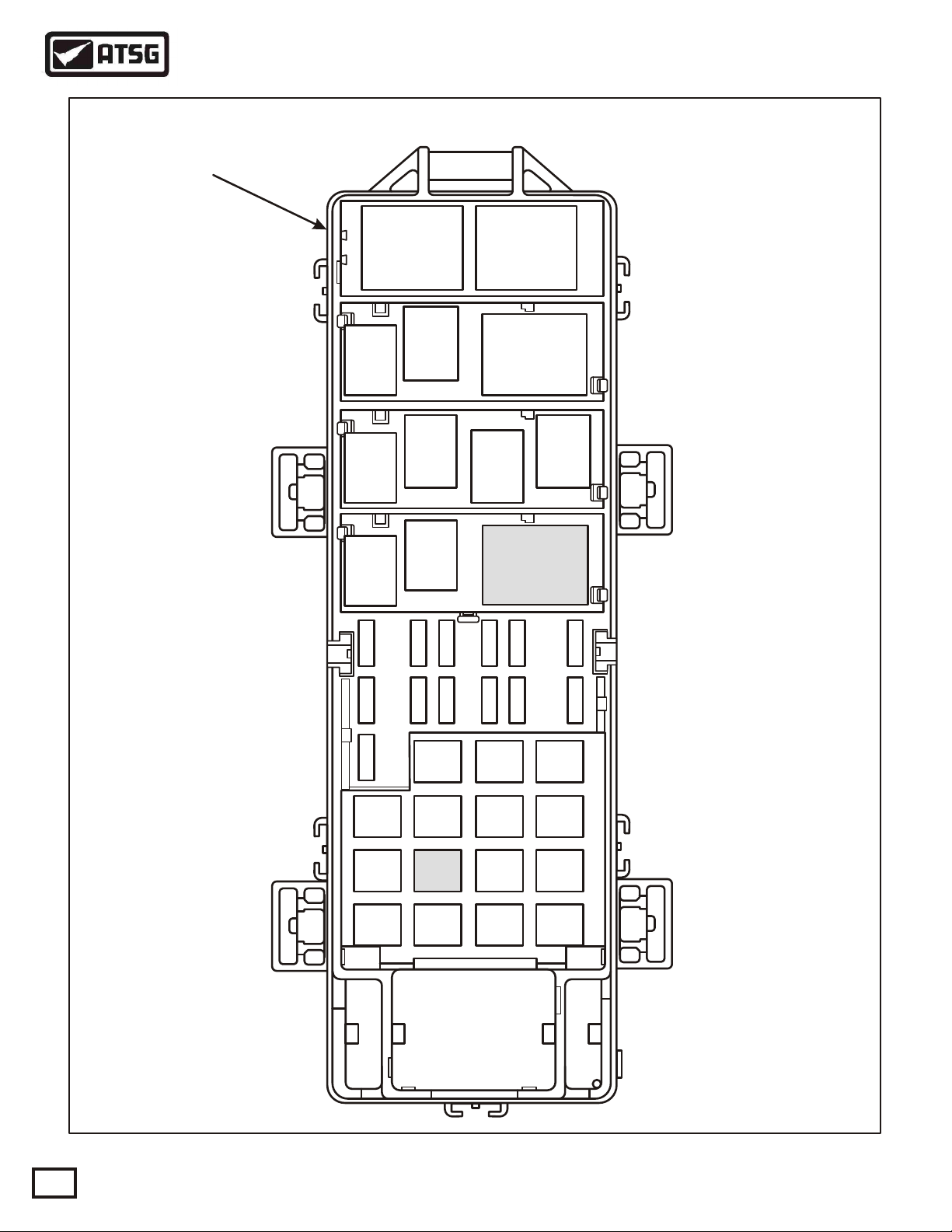

Transmission Control Relay - located in the Power Distribution Center (PDC), as shown in Figure 10, and

recieves a ground signal from terminal 15 at the TCM to close the relay. Refer to the wiring schematic in Figure

9.

UnderdriveSolenoid withPressureSwitch- Thissolenoid isnormally appliedand controlsoil tothe UDclutch

inall 1st,2nd,2ndPrimeand3rdgearsofthetransmission.

OverdriveSolenoidwithPressureSwitch-Thissolenoidisnormallyventedandcontrolsoilto theOD clutchin

3rdand 4thgears inthetransmission.

Fourth Clutch Solenoid with Pressure Switch - This solenoid is normally vented and controls oil to the 4th

clutchin all4th and2ndPrimegearsinthetransmission.

Second Clutch Solenoid with Pressure Switch - This solenoid is normally vented and controls oil to the 2nd

clutchin all2nd gearsinthetransmission.

Low/Reverse Solenoid with Pressure Switch - This solenoid is normally vented and is used to apply the L/R

clutchin 1stfromneutral,orcoastdownto1st,andtocontroloilforconverterclutchengagement.

Multi-Select Solenoid - The Multi-Select Solenoid is normally applied and controls the OD clutch in 3rd gear

Limp-in,2nd clutchinManual2,2ndLimp-inandtheLow/Reverseclutchinreverse.

LIMP-IN MODE OPERATION

DIAGNOSIS AND SERVICE INFORMATION

The TCM has the ability to monitor all transmission related electrical components and if it detects a problem,

takes appropriate action, and most of the time results in the TCM setting a Diagnostic Trouble Code (DTC).

Whetherthis resultsinMILillumination,orLimp-inModeoperation,dependsonthetypeofDTCthatwasset.

IftheTCMdeterminesthat transmission damage may resultfromtheDTC type that was set,theTCMwillshut

off the ground signal to the transmission control relay which will shut off all power to the transmission and the

vehiclewill bein Limp-inModeOperation.

When in Limp-in Mode Operation, with the shift lever in the "Drive" position the transmission will be in 3rd

gear,andif theshift leverismoved to"2"or "L"positionthetransmissionwill bein2nd gear. Thiswillallow the

driverto manuallyshiftthetransmissiontoLimphome.

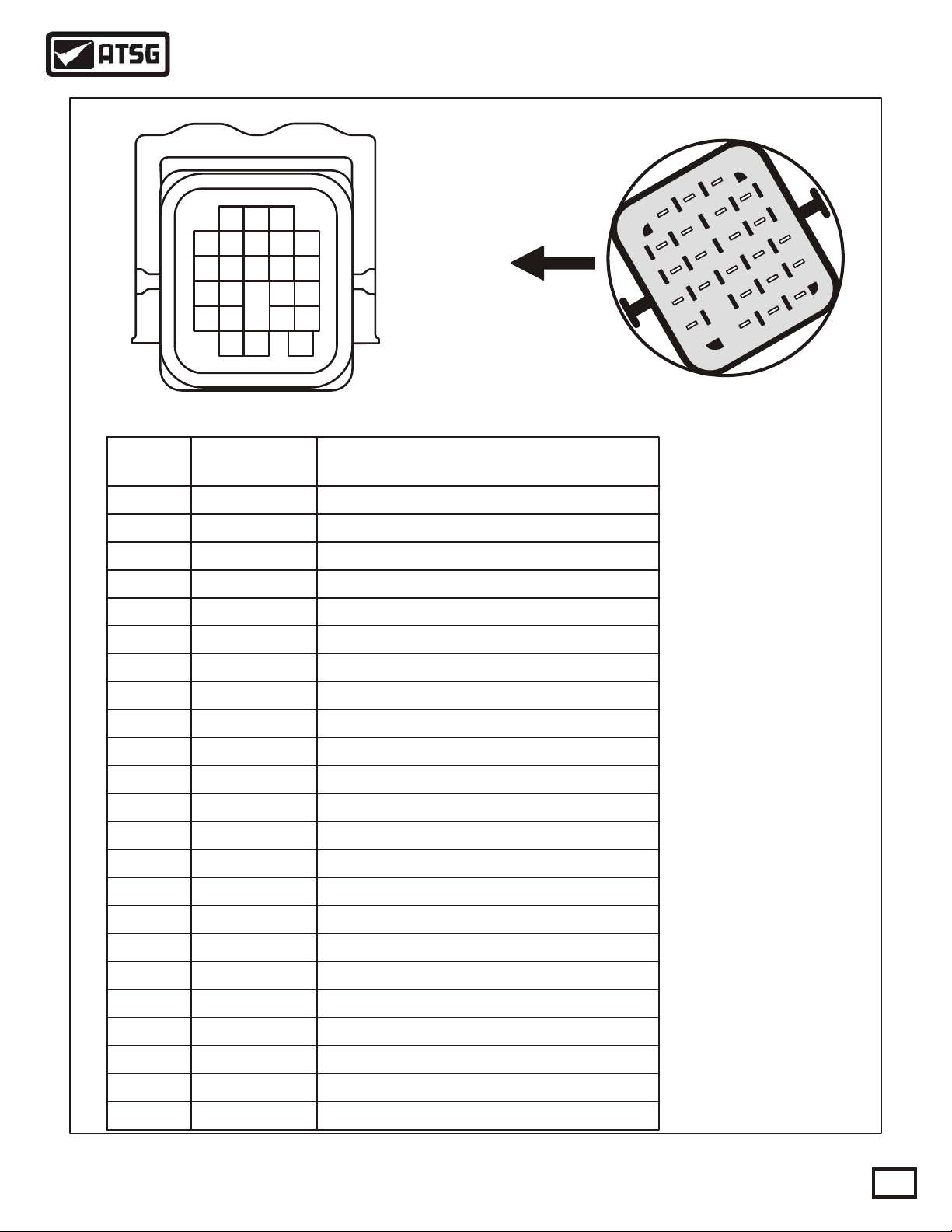

You have been provided with the 23-way case connector pin cavity identification and pin function in Figure 7,

and 60-way TCM connector pin cavity identification and pin function in Figure 8. A complete transmission

wiringschematicisprovidedinFigure9, andtransmission controlrelaylocationinthepowerdistribution center

isshown inFigure 10.

Special tools that might be needed are illustrated in Figure 12, along with the identification of the pressure taps

that are available on the main valve body. Air pressure test passage identification is provided for you in Figure

13.

ADAPTIVE LEARNING

The 45RFE transmission uses an "Adaptive Learning" feature which allows the TCM to modify the clutch

applyratetomaintainconsistantshiftquality. Thisisdone basedon theamountofwearonthefriction elements.

The TCM then adjusts the duty cycle of the shift solenoids to achieve the smoothest possible upshifts and

downshifts. The TCM adjusts the "Clutch Volume Index" when a shift change takes place to optimize clutch to

clutch timing. Clutch Volume Index is described in Figure 6, along with proper clutch volumes and clutch

clearancesfor the45RFE transmission.

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

8

Copyright © 1999 ATSG

Figure 4

"Solenoid Off"

"Normally Applied" "Solenoid Off"

"Normally Vented"

Underdrive Solenoid

Multi-Select Solenoid

Overdrive Solenoid

4th Clutch Solenoid

2nd Clutch Solenoid

Low/Reverse Solenoid

TWO DIFFERENT TYPES OF SHIFT SOLENOIDS

4799591

97

VALVE BODY

PRESSURE

CONTROL

SOLENOID

SOLENOID

PACK

23-WAY

CONNECTOR

TRANSMISSION

RANGE SENSOR

4th Clutch

Seal

2nd Clutch

Seal

L/R Clutch

Seal

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

9

Copyright © 1999 ATSG

SWITCH CHART

2nd Clut 4th Clut Underdrive Overdrive

Reverse

First

Second

2nd Prime

Third

Fourth

Park/Neut

Low/Rev

Closed

Closed

Closed

Closed

Closed

Closed Closed

Closed

Closed

Closed

Closed*

Open Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

* L/R is closed if output speed is below 150 RPM in Drive and Manual 2.

L/R is open in Manual 1.

PRESSURE SWITCHES

The pressure switches are located inside the solenoid and pressure switch assembly and are only serviced by

replacingthe completeassembly.

The Transmission Control Module (TCM) is located as shown below and relies on five pressure switches to

monitor pressure in the Low/Rev, 2nd Clutch, 4th Clutch, Underdrive, and Overdrive hydraulic circuits. The

primary function of these switches is to help the TCM detect when the clutch circuit hydraulic failures occur.

The switches close at 23 psi and open at 11 psi, and indicate whether or not pressure exists. The switches are

continuously monitored by the TCM for the correct states (Open or Closed) in each gear as shown in the chart

below.

TRANSMISSION

CONTROL MODULE

60 WAY

CONNECTOR

FRONT

Figure 5

AKPPHELP.RU Руководство по ремонту АКПП

10

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

CLUTCH VOLUMES AND CLEARANCES

CLUTCH WHEN UPDATED PROPER VOLUME CLUTCH CLEARANCE

Low/Reverse

Reverse

2-1 or 3-1 Downshift 82 to 134 1.14-1.91mm (.045"-.075")

0.53-1.27mm (.021"-.050")

0.81-1.35mm (.032"-.053")

0.81-1.24mm (.032"-.049")

1.01-1.65mm (.040"-.065")

0.76-1.60mm (.030"-.063")

25 to 64

30 to 64

30 to 64

44 to 92

3-2 Kickdown shift

4-3 Kickdown shift

Not Monitored Not Monitored

2-3 Upshift

3-4 Upshift

2nd Clutch

Overdrive

4th Clutch

Underdrive

CLUTCH VOLUME INDEXES

An important function of the TCM is to monitor Clutch Volume Indexes (CVI). CVIs represent the volume of

fluidneeded tocompress aclutchpackproperly.

The TCM monitors gear ratio changes by monitoring the Input and Output Speed Sensors. The Input Speed

Sensor sends an AC voltage signal to the TCM that represents input shaft rpm. The Output Speed Sensor

providesthe TCMwith outputshaftspeedinformation.

By comparing these two inputs, the TCM can determine actual gear ratio. This is important to the CVI

calculationbecause theTCM determinesCVIsbymonitoringhowlongittakesforagearchangetooccur.

Gear ratios can be determined by using the DRB Scan Tool and reading the Input/Output Speed Sensor values in

the "Monitors" display. Gear ratio can be obtained by dividing the Input Speed Sensor value by the Output

SpeedSensor value.

For example, if the input shaft is turning at 1000 rpm and the output shaft is turning at 500 rpm, the TCM can

determine that the gear ratio is 2:1. In 3rd gear the gear ratio changes to 1:1. The gear ratio changes as clutches

are applied and released. By monitoring the length of time it takes for a gear ratio to change following a shift

request,the TCMcan determinethevolumeoffluidusedtoapplyorreleaseafrictionelement.

The volume of transmission fluid needed to apply the friction elements are continuously updated for the

adaptivecontrols. As frictionmaterial wears,the volumeof fluidneeded toapplythefrictionelementincreases.

Certain mechanical problems within the transmission assembly such as broken return springs, out of position

snap rings, excessive clutch pack clearance, or improper assembly can cause inadequate or out-of-range CVI

readings. Also defective Input/Output Speed Sensors, wiring and poor connections may cause these same

conditions. The following chart identifies the proper CVIs, when they are monitored and updated and the

properclutch packclearances.

Copyright © 1999 ATSG

Figure 6

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

11

123

4

89101112

13

17181920

212223

141516

567

PIN

CAVITY WIRE

COLOR FUNCTION

White/Tan

White

Violet/White

Violet/Black

Tan/Black

Orange/Black

Violet

Violet/Lt. Green

Violet

Red

Pink

Gray

Dk. Green/White

Dk. Blue

Dk. Blue/Black

Yellow/Dk. Blue

White/Dk. Blue

Brown/Yellow

Brown

Brown/Lt. Blue

Lt. Blue

Lt. Green

Lt. Green/Black

Fused Ignition Switch Battery Voltage

LR/TC Clutch Solenoid Control

Overdrive Clutch Solenoid Control

Line Pressure Control Solenoid Control

Underdrive Clutch Solenoid Control

4th Clutch Solenoid Control

2nd Clutch Solenoid Control

Multi-Select Solenoid Control

Speed Sensor Ground

Transmission Oil Temperature Sensor Signal

Transmission Control Relay Output

4th Clutch Pressure Switch Signal

2nd Clutch Pressure Switch Signal

Low/Reverse Clutch Pressure Switch Signal

Overdrive Clutch Pressure Switch Signal

Underdrive Clutch Pressure Switch Signal

Park/Neutral Position Switch Signal

Transmission Range Sensor (T41) Signal

Transmission Range Sensor (T42) Signal

Back-Up Lamp Feed

Transmission Range Sensor (T3) Signal

Transmission Range Sensor (T1) Signal

Transmission Range Sensor (T2) Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

23-WAY CASE CONNECTOR PIN CAVITY IDENTIFICATION AND FUNCTION

Figure 7

1

4

8

5

9

6

10

11

12

13

17

14

18

15

19

16

20

212223

7

2

3

Vehicle Harness Connector Transmission

Case Connector

"Front"

Copyright © 1999 ATSG

AKPPHELP.RU Руководство по ремонту АКПП

12

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

Copyright © 1999 ATSG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PIN

CAVITY WIRE

COLOR FUNCTION

Lt. Green/Black

Lt. Green/White

Tan/Black

Violet

Pink

Pink/Yellow

Gray/Black

Orange/Black

Yellow/Dk.Green

Red/White

Brown

Violet/Lt. Green

Violet/White

Lt. Green

Violet/Tan

Violet/White

Yellow/Violet

White

Violet

Red

Red

Red

Red

Pink

Gray

Gray/Lt. Blue

Dk. Green/White

Dk. Blue

Dk. Blue/Black

Yellow/Dk. Blue

Orange/Dk. Blue

White/Dk. Blue

Brown

Brown/Lt. Blue

Black/Lt. Blue

Red/Black

Black/Yellow

Black/Yellow

Black/Yellow

Black/Red

Lt. Blue

Lt. Green

White/Orange

Transmission Range Sensor T1 Signal

Transmission Range Sensor T3 Signal

Crankshaft Position Sensor Signal

Back-up Lamp Relay Control

Overdrive Clutch Solenoid Control

Line Pressure Control Solenoid Control

Underdrive Clutch Solenoid Control

4th Clutch Solenoid Control

Overdrive Clutch Solenoid Control

2nd Clutch Solenoid Control

L/R-TCC Clutch Solenoid Control

Multi-Select Solenoid Control

Speed Sensor Ground

Output Speed Sensor Signal

Vehicle Speed Sensor Signal

Transmission Oil Temperature Sensor Signal

Transmission Control Relay Output

Transmission Control Relay Control

Transmission Control Relay Output

Transmission Control Relay Output

Ground

Ground

Ground

Ground

PCI Bus

SCI Recieve

5 Volt Supply

4th Clutch Pressure Switch Signal

Overdrive Off Switch Signal

2nd Clutch Pressure Switch Signal

Low/Reverse Clutch Pressure Switch Signal

Sensor Ground

Input Speed Sensor Signal

Overdrive Clutch Pressure Switch Signal

Torque Management Request

Underdrive Clutch Pressure Switch Signal

Line Pressure Sensor Signal

Transmission Range Sensor (T42) Signal

Transmission Range Sensor (T41) Signal

SCI Transmit

Fused Ignition Switch Output (Start)

Fused Ignition Switch Output (Start-Run)

Fused Battery Voltage

1

2

3

6

7

9

8

10

11

12

13

14

15

16

17

18

19

20

36

37

38

39

40

41

42

43

46

47

48

49

50

51

52

53

54

55

56

57

59

60

29

30

28

60-WAY CONNECTOR PIN CAVITY IDENTIFICATION AND FUNCTION

Figure 8

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

13

L/R

Pressure

Switch

2nd Clut

Pressure

Switch

OD

Pressure

Switch

4th Clut

Pressure

Switch

UD

Pressure

Switch

TRS

T42

Signal

Back-Up

Lamp

Switch

TRS

T41

Signal

TRS

T3

Signal

TRS

T2

Signal

TRS

T1

Signal

Line

Pressure

Sensor

Signal

5 Volt

Supply

Ground

Pressure Sensor

Multi-Select

Solenoid

Underdrive

Solenoid

Overdrive

Solenoid

2nd Clutch

Solenoid

4th Clutch

Solenoid

LR/TCC

Solenoid

Pressure

Control

Solenoid

Starter

Relay Ignition

Switch

12V

Output

Speed

Sensor

Input

Speed

Sensor

POWER DISTRIBUTION CENTER

TRANSMISSION

CONTROL RELAY

FUSE 5

30A

10 1217 721 23 2220 19 18 16 15 14 138 9 4 3 5 1 6112

TRANSMISSION CONTROL MODULE

16 15 53 38 301736

40 55 60 19 59 20 53

18 3929 3748 5747 50 3 2 1 41 42 549

52 13 14

TFT

Sensor

Copyright © 1999 ATSG

Back-up

Lamps

Figure 9

AKPPHELP.RU Руководство по ремонту АКПП

14

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

Copyright © 1999 ATSG

Spare

Relay Spare

Relay

Horn

Relay

AC

Clutch

Relay

Wiper

On/Off

Relay

Wiper

Hi/Lo

Relay

Heater

Relay

Down-

Stream

Heater

Relay

Up-

Stream

Starter

Relay

Fuel

Pump

Relay

Automatic

Shutdown

Relay

Transmission

Control

Relay

Fuse 5

(30A)

TRANSMISSION CONTROL RELAY AND FUSE LOCATIONS

POWER DISTRIBUTION CENTER

Figure 10

AKPPHELP.RU Руководство по ремонту АКПП

243810187P52119099AA

TITTJ243810187

P52119099AA 45RF AA

099

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

15

INPUT SPEED

SENSOR

LINE PRESSURE

SENSOR FROM COOLER LOCK-UP "ON"

PRESSURE

LOCK-UP "OFF"

PRESSURE

OUTPUT SPEED

SENSOR

Figure 11

TO COOLER

Copyright © 1999 ATSG

AKPPHELP.RU Руководство по ремонту АКПП

16

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

Copyright © 1999 ATSG

VALVE BODY

MANDATORY TOOLS NEEDED FOR CHECKING PRESSURES ON 45RFE

Pressure Tap Adapter Tool No. 8258, to check oil

pressuresthroughthevalve bodytaps.

Line Pressure Adapter Tool No. 8259, to install into the

line pressure sensor circuit, and then reinstall the

sensorandpressuregage.

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Figure 12

4799655

05111

AK

1

98

Overdrive Clutch

Pressure

Low/Reverse

Clutch Pressure

Line Pressure

4th Clutch

Pressure 2nd Clutch

Pressure

Underdrive Clutch

Pressure

Reverse Clutch

Pressure

AKPPHELP.RU Руководство по ремонту АКПП

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

17

Copyright © 1999 ATSG

Low/Reverse

Clutch

2nd Clutch 4th Clutch

COOLER FILTER

COOLER FILTER

BYPASS VALVE

Overdrive

Clutch

Underdrive

Clutch

Reverse

Clutch

Figure 13

243810187P52119099AA

TITTJ243810187

P52119099AA 45RF AA

099

AIR PRESSURE TESTS

AKPPHELP.RU Руководство по ремонту АКПП

Figure 14

3000 5%

3000 5%

3000 5%

3000 5%

T2

T1

T3

T42

T41

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

18

Copyright © 1999 ATSG

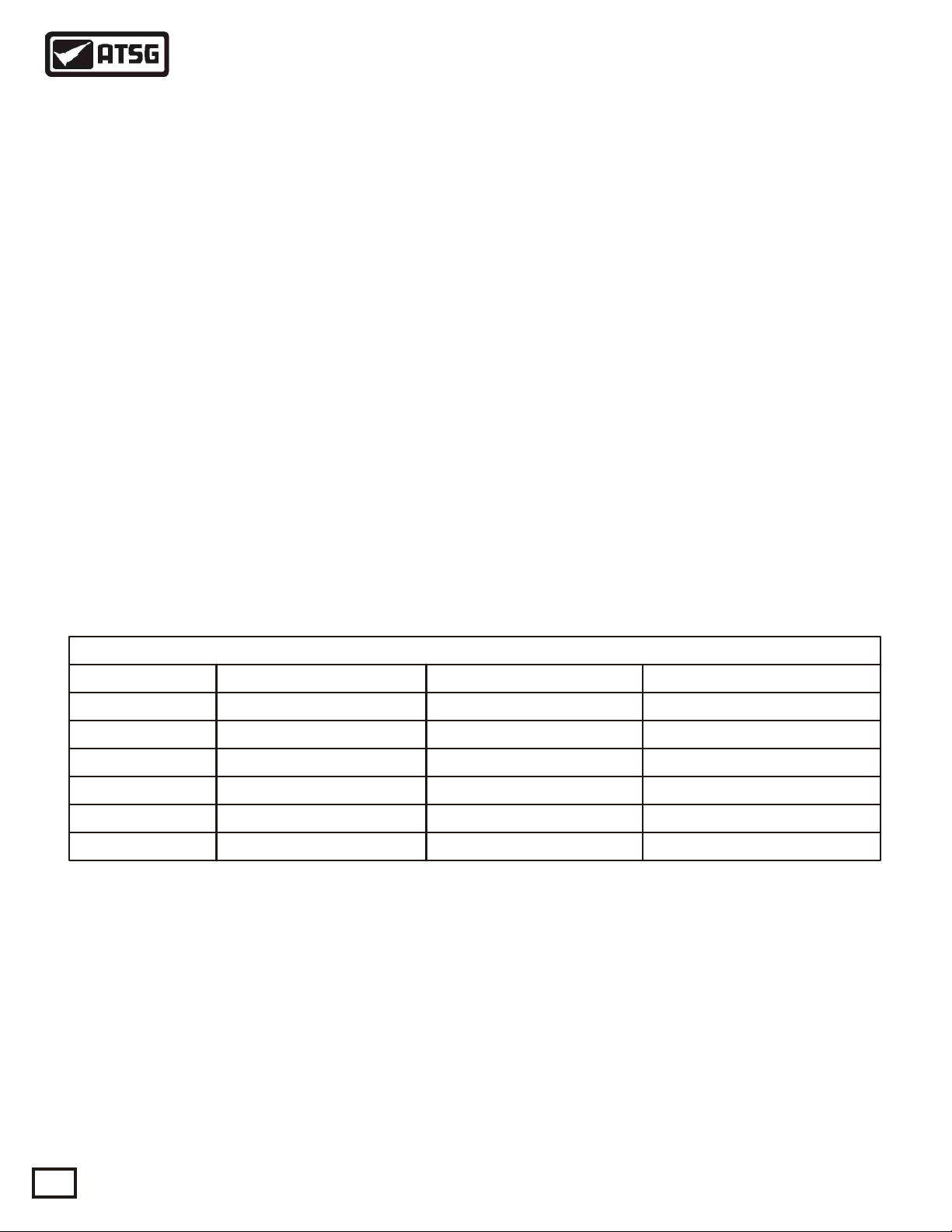

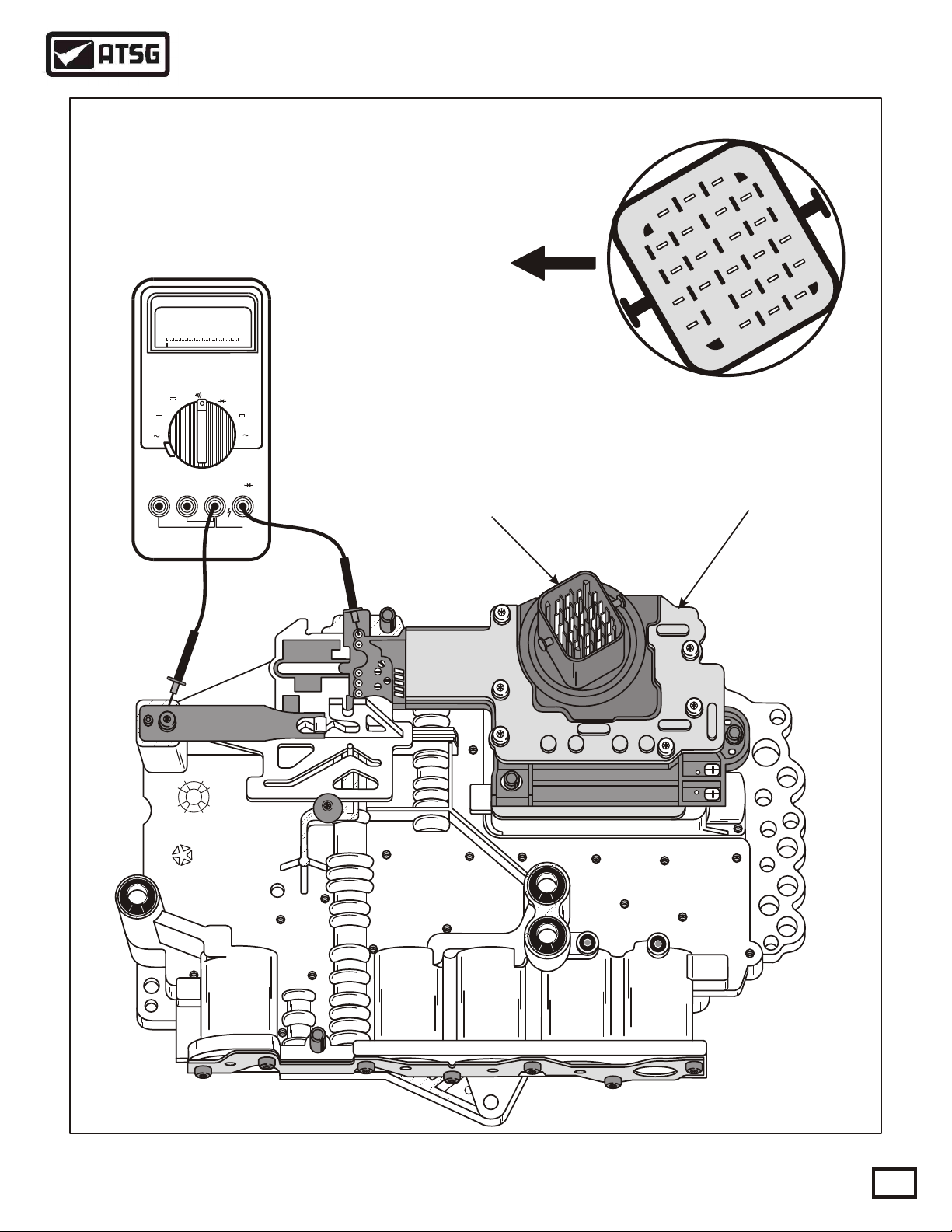

TRS/SOLENOID BODY TESTS

TRANSMISSION RANGE SENSOR CHART

CIRCUIT METER P R N OD 2 1

C

C

C

C = Closed O = Open

C C

C C

C

C

C

C

C

CO O

O

O O

OOO

O O

O O

O

O

O

O OT41

T42

T3

T1

T2

T41 & GRD OR CONNECTOR PIN 4 & GRD

T42 & GRD OR CONNECTOR PIN 5 & GRD

T3 & GRD OR CONNECTOR PIN 8 & GRD

T1 & GRD OR CONNECTOR PIN 9 & GRD

T2 & GRD OR CONNECTOR PIN 13 & GRD

SOLENOID RESISTANCE CHART

RESISTANCESOLENOID

LR/TCC 10 AND 2

10 AND 7

10 AND 17

10 AND 20

10 AND 19

10 AND 21

10 AND 12

22 AND 23

OVERDRIVE

UNDERDRIVE

2ND CLUTCH

4TH CLUTCH

MULTI-SELECT

LINE PRESSURE

TOT SENSOR

CONNECTOR PINS

1.9 W@ 72°F

1.9 W@ 72°F

1.9 W@ 72°F

1.9 W@ 72°F

1.9 W@ 72°F

1.9 W@ 72°F

4.3 W@ 72°F

9.37k W@ 72°F

AKPPHELP.RU Руководство по ремонту АКПП

Figure 15

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

19

Copyright © 1999 ATSG

4799591

97

23-WAY

CONNECTOR

TRANSMISSION RANGE SENSOR

AND SOLENOID BODY ASSEMBLY

1

4

8

5

9

6

10

11

12

13

17

14

18

15

19

16

20

2122

23

7

2

3

Transmission

Case Connector

"Front"

WW

0.1

OFF

RPM

RPMCOMmAA

V

V

mV WW

WW

VmA

A

mA

A

Meter shown checking T41 Circuit

and should correspond with chart

in Figure 14. Solenoid tests must

be made thru case connector pins.

AKPPHELP.RU Руководство по ремонту АКПП

45RFE OBDII DIAGNOSTIC TROUBLE CODE LIST

Description

Check Shifter Signal (28)

Bus Communication (19)

Internal TCM (11, 13)

Internal TCM (17)

Internal TCM (16)

Input Speed Sensor Error (56)

Output Speed Sensor Error (57)

Engine Speed Sensor Circuit Error (18)

Gear Ratio Error In 1st Gear (51)

Gear Ratio Error In 2nd Gear (52)

Gear Ratio Error In 3rd Gear (53)

Gear Ratio Error In 4th Gear (54)

Gear Ratio Error In Reverse (50)

Torque Converter Clutch Control Circuit (38)

Low/Reverse Solenoid Circuit Error (C1)

2nd Clutch Solenoid Circuit Error (C2)

Overdrive Solenoid Circuit Error (C3)

4th Clutch Solenoid Circuit Error (C4)

Line Pressure Out Of Range (C8)

Restricted Port In T3 Range (65)

Line Pressure Low (C9)

Line Pressure High (CB)

Underdrive Hydraulic Pressure Test Failure (BO)

Underdrive Pressure Switch Sense Circuit (90)

4th Clutch Pressure Switch Sense Circuit (88)

2nd Clutch Pressure Switch Sense Circuit (82)

4th Clutch Hydraulic Pressure Test Failure (A8)

2nd Clutch Hydraulic Pressure Test Failure (A2)

Line Pressure Sensor Voltage Out Of Range (CA)

Underdrive Solenoid Circuit Error (C5)

Speed Ratio Error 2nd Prime (55)

Inadequate Element Volume 4th Clutch (64)

P0120

P0600

P0705

P0700

P0604

P0605

P1715

P1735

P0715

P0720

P0725

P0731

P0732

P0733

P0734

P0736

P0740

P0750

P0755

P0760

P0765

P0770

P1720

P1721

P1722

P1724

P1726

P1727

P1728

P1732

P1733

P1734

P1736

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES*

YES*

YES

YES**

YES**

YES**

YES**

YES**

YES**

YES**

YES**

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES**

NO

NO

NO

NO

NO

NO

NO

Throttle Position Signal Out Of Range (29)

Limp-in MIL Illumination

OBDII

Codes

Figure 16

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

20

Copyright © 1999 ATSG

Multi-Select Solenoid Circuit Error (C6)P1737 YES YES

AKPPHELP.RU Руководство по ремонту АКПП

Table of contents

Other ATSG Microphone System manuals