EU Declaration of Conformity.......................................................................................... 3

Annex 1 to EU Declaration of Conformity............................................................................4

Nameplate................................................................................................................5

Safety Instructions....................................................................................................... 7

Obligations................................................................................................................7

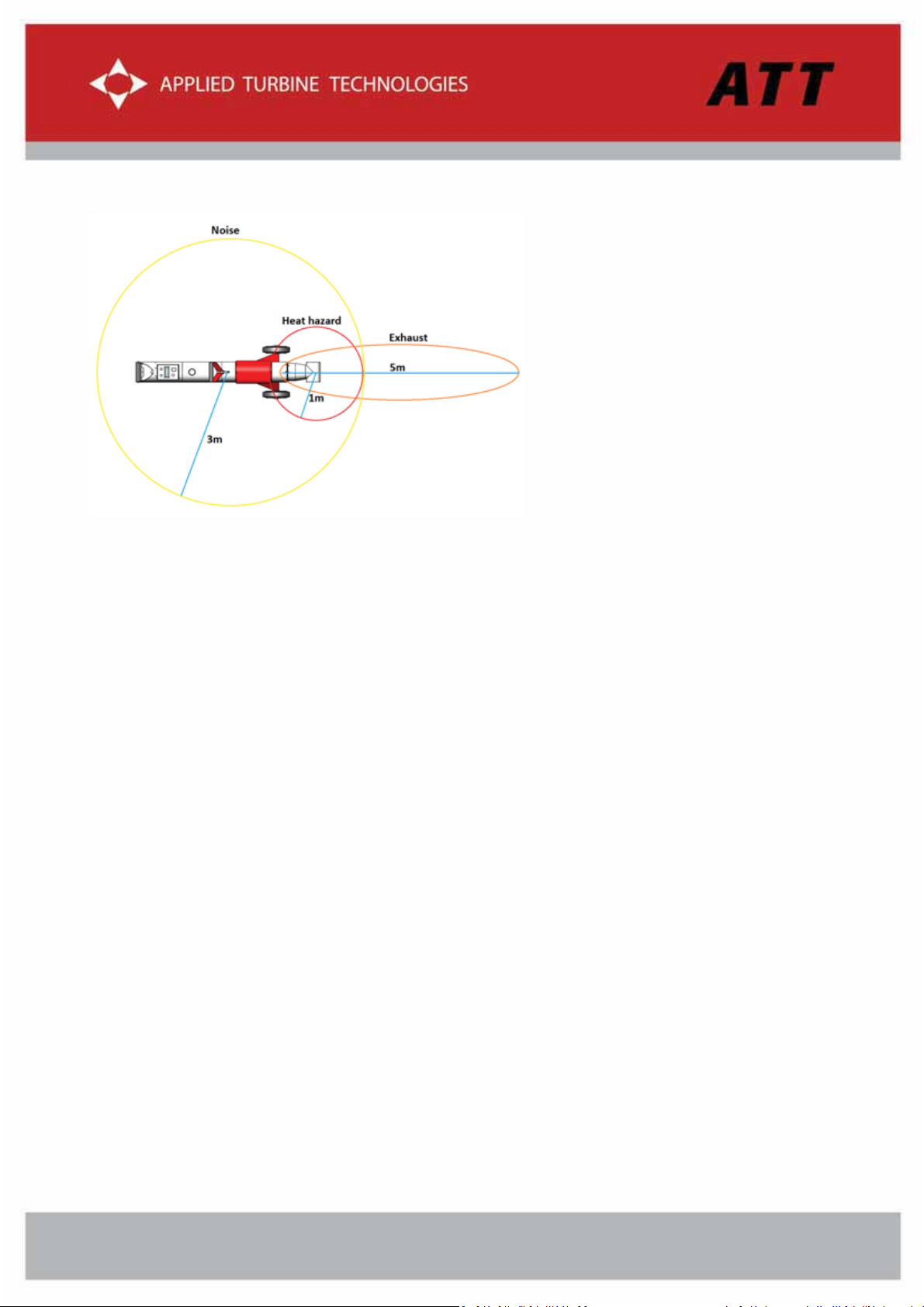

Hazard and danger zones...............................................................................................8

Intended use .............................................................................................................8

Misuse .....................................................................................................................9

Disclaimer ................................................................................................................10

Introduction..............................................................................................................10

Hammer Jet Dryer & Cleaner........................................................................................ 10

Product Overview.......................................................................................................11

Display “Operation Hours & Time to Service”..................................................................... 12

Display “Ready to Start”.............................................................................................. 12

Display “Idle” – Ready to use ........................................................................................ 13

Display “Low Power Setting” ........................................................................................ 13

Recommended elevation for optimal drying speed............................................................... 14

Display “High Power Setting”........................................................................................ 14

Accessories and Spares ............................................................................................... 15

Operation.................................................................................................................16

Safety Instructions..................................................................................................... 16

Before start-up......................................................................................................... 17

Safety Stop............................................................................................................. 18

Power-up and start-up................................................................................................ 19

Shut down and Cooling................................................................................................ 22

Parking, transport and storage ...................................................................................... 22

Dismantling the turbine module from the chassis ................................................................ 23

Installing the turbine module........................................................................................ 25

Charging the Hammer Jet ............................................................................................ 28

Filter Removal ......................................................................................................... 29

Cleaning the turbine compartment ................................................................................. 31

Display shut down ..................................................................................................... 32

Re-fuelling.............................................................................................................. 32

Filter inspection and change......................................................................................... 33

Technical Data...........................................................................................................34

Dimensions.............................................................................................................. 34

Warning Signs .......................................................................................................... 36

Troubleshooting.........................................................................................................37

Off conditions.......................................................................................................... 37

Maintenance and Service..............................................................................................38

Turbine module compartment....................................................................................... 38

Filter cover............................................................................................................. 38

Overview of recommended maintenance and service............................................................ 39

Wheel inspection and replacement ................................................................................. 39

Storage & Transportation..............................................................................................40

Wastedisposal............................................................................................................40