ATWELL UMD-SRB02 User manual

www.atwellinternational.com

UMD-SRB02 Control BoxUMD-SRB02 Control Box

Uncontrolled Movement DetectorUncontrolled Movement Detector

Installation ManualInstallation Manual

Version 1.0Version 1.0

2Atwell International Limited

3UMD-SRB02 Version 1

Contents Overview....................................................................................................................4

Safety Notes...............................................................................................................5

Owners Obligations ...................................................................................................6

Specification ..............................................................................................................7

Operation.......................................................................................................7

The System....................................................................................................8

The Movement Detector (UMD-SP01)..........................................................8

The Controller (UMD-SRB02).........................................................................8

Signals............................................................................................................9

Handling, Transport & Storage ...............................................................................10

Components Supplied.............................................................................................10

Installation................................................................................................................11

General Advice ...........................................................................................11

The Control Box (UMD-SRB02)....................................................................11

Wiring .....................................................................................................................12

Mechanical Installation ...........................................................................................18

Normal Operation....................................................................................................19

Resetting the System ..................................................................................19

Bypassing the System.................................................................................20

Test Deployment of Brakes.........................................................................21

Uncontrolled Movement Settings...........................................................................22

Site Testing of Uncontrolled Movement .................................................................22

Instructions for Rescue Operations........................................................................23

Regular Maintenance ..............................................................................................24

Maintenance Instructions .......................................................................................25

Controller.....................................................................................................25

Movement Detector Assembly...................................................................25

Operational Checks.....................................................................................25

Spare Parts...............................................................................................................26

General Information ................................................................................................26

Definitions................................................................................................................27

Very Important.........................................................................................................28

4Atwell International Limited

The movement detection control panel is designed to be installed with new lifts

and retrofitted to existing passenger and goods lifts and used in conjunction with

the bi-directional VG rope brake (VGRB2) and VG safety gears.

It has been designed and constructed to comply with all current UKCA and CE

requirements, i.e. EMC, Low Voltage, RoHS, WEEE and more specifically to meet the

requirements of EN 81-20:2020 (5.6. Precautions against freefall, excessive speed,

unintended car movement and creeping of the car).

The movement detection controls connect to the main lift control panel. From

here it can receive power and signals to tell if the lift doors are open, or that the lift

over speed governor is operating correctly. It also sends signals to the lift to stop

the lift at the next floor when a fault is detected.

The system will always deploy the brakes or safety gear immediately and interrupt

the main lift safety circuit if over-speed is signalled.

The movement detector monitors movement by looking at an idler wheel resting

on one of the main ropes. As the rope moves so does the idler wheel, and as the

idler wheel rotates the movement and direction of movement is detected.

When the doors are open the system is checking for excessive movement. If

excessive movement is detected then the brakes or safety gear, under its control

will be deployed and in addition to this, an emergency stop signal will be sent to

the main lift control panel, by means of interrupting the main safety circuit.

There are other functions included within the system such as an indication of

status to assist fault finding, resetting of the brakes, manual override to test the

deployment of the brakes, ability to bypass the system (allowing car top control,

without deploying the rope brakes) and pit safety to monitor car movement when

engineers are in the lift shaft or pit.

Power loss is catered for by the incorporation of an internal battery backup system

to seamlessly switch from mains power to battery and back again without the

need for manual intervention to reset the brakes or safety gear. But if during the

power loss excessive movement occurs, or the overspeed governor trips, the

brakes or safety gear will be deployed and a full reset will be required.

If during its normal operation, the system develops a fault then an error or alert

signal will be sent requesting the lift stops at the next floor, doors opened, and

stays there until the fault is corrected. During this time whilst the doors are open

the system will continue to monitor excessive movement.

Overview

5UMD-SRB02 Version 1

Both employers and employees have a duty of care in relation to the health and

safety of people or property which may be affected by their actions, or failure to

act. Therefore, building owners or those who have responsibility for controlling

buildings are required under the Management of Health and Safety at Work

Regulations to ensure that their premises are safe and free from risk to health so

far as is practicable. This includes access to the plant equipment and articles or

substances used and in this particular respect will be relevant to the Workplace

(Health, Safety, and Welfare) Regulations.

Installation, commissioning, and maintenance of this system should only be carried

out by authorised persons who have received the necessary instruction because it

is dangerous for any other persons to attempt to do so.

Any failure to take adequate precautions may render the authorised person guilty

of negligence should an accident occur.

It is essential that a “Competent Person” has installed and commissioned this

system. It is also essential that a “Competent Person” maintain this system in a

safe manner and at regular intervals as described in this manual.

The “Competent Person” must have had adequate training in theory and practice

together with experience of the equipment in question; to enable a true assessment

of its condition for continued safe operation.

No alterations, modifications or repairs to this system or its components should be

undertaken without the written consent and advice or instruction of the supplier

Atwell International. Any advice or instructions from the supplier must be followed;

any deviation may risk the safe operation of the lift. Even if consent is given then all

the risks associated with the work will have to be suitably and sufficiently assessed

by the owner before these alterations are implemented.

No replacement parts other than those specified or supplied by the supplier Atwell

International should be used as incompatible parts may risk the safe operation

of the lift. Genuine spares are available within 24 hours at a reasonable cost. But

if spares are needed quicker then the exact same or equivalent parts may be

sourced locally once the exact specification of those parts has been obtained and

you have suitably assessed the implications of using non-standard parts. If there

is any doubt then you should render the lift out of service and contact Atwell

International or one of its appointed agents for assistance.

Safety Notes

6Atwell International Limited

The Owner of the Lift or any delegated party shall inform the Maintenance

Company immediately:

a) about any detected abnormal functioning of the installation;

b) before any modification work on the installation;

c) about any modification of any equipment or condition related to the

installation which existed at the time of the original installation;

In the case of suspected or actual dangerous situations, the installation

shall be put out of service immediately.

We strongly advise that you should carry out a Risk Assessment to determine, as

completely as possible, the different intervention procedures of the maintenance

operations and to associate appropriate safety measures with each of these

procedures.

This Warning Label is incorporated into the control box lid graphic to warn you of

Live Electrical Parts, DO NOT REMOVE the lid if you are not a competent electrician

capable of safely assessing the potentially dangerous internal connections.

Owners Obligations

Danger

Isolate main

Isolate main

supply

supply

before opening

before opening

7UMD-SRB02 Version 1

Operation

A sensor is fitted to an idler wheel or tension weight pulley or safety gear sensor

acting on a wire rope attached to the lift car. The sensor will detect movement in

either direction.

A controller box will be fitted nearby and connected to the sensor, main lift control

panel, over-speed governor & VG rope brakes or VG safety gear.

Once the system has been installed and set up, the rope brakes or safety gear

must be set.

The controller will receive an external signal to say that the lift doors are open,

which will activate the system to “Monitor for movement”.

If movement is detected above the predetermined limit of 100mm to 900mm,

(actual pre set limit is 150mm but can be modified to suit customer requirements)

the controller will actuate a safety relay causing all safety systems to be deployed.

Once deployed, the controller will deliberately not allow the lift to run or revert to a

normal state until the rope brakes or safety gear have been manually reset.

If no movement was detected and the controller receives a signal to say the doors

are closed it will deactivate and allow the normal operation of the lift and primary

safety circuit.

During its operation, the control box will also continue to monitor the integrity of

the connection to the sensor assembly. It will also monitor the status of the rope

brakes or safety gear.

It will perform a simple self-diagnostic test to ensure all sensors are working, if a

fault develops a fault signal will be sent to the main lift control panel to request it to

bring the lift to halt at the next floor and open the doors (Please note the controller

can only send the signal and not control stopping of the lift). When the lift doors

open the rope brakes or safety gear will be deployed.

If during the monitoring phase, the connection to the sensor is lost, the rope brakes

or safety gear will be deployed.

Due to the battery backup, if mains power fails with the doors open, the system

will continue to operate and safely monitor for movement. If mains power fails

when the doors are closed the system will automatically monitor for movement

but will allow greater movement before applying the brakes.

The system is directly connected to the lift over-speed governor. So if over speed is

signalled the rope brakes or safety gear will be deployed immediately.

Maintenance, other than checking the cleanliness of the idler pulley assembly, is not

required for the actual components of the system, but it is strongly recommended

that the operation is regularly checked and tested by competent persons (lift

engineers) to comply with the regulations.

Specification

8Atwell International Limited

The System

The system is contained within a robust plastic enclosure. Fail Safe Design, easy

site wiring especially with plug and socket options, where the sensors, brakes and

controller will be connected via a plug and socket arrangement to assist on site

wiring.

Power feed and lift panel connections will be the responsibility of the end customer.

Set of parts to be supplied in the full system include;

• Control Box (UMD-SRB02).

• Sensor Box (UMD-SP01).

• Sensor Mounting Bracket and fixings.

• Set of 3 interconnecting cables.

• Set of documentation (in English).

The Movement Detector (UMD-SP01)

The movement detector will be a fixed non-contact non-adjustable type.

The actual motion sensors are enclosed in a sealed enclosure to protect from

moisture, vibration and tampering. This is a non-serviceable component, any doubt

then it should be replaced by contacting Atwell International.

The movement detector is sprung mounted to a bracket. The bracket is directly

mounted to the rope brake assembly. Alignment and tension on the rope can be

adjusted during installation and to account for wear..

The Detector is constantly monitored, so if there is a fault with it or the connection

to it then an ALERT signal will be sent to the main lift panel. This is to request the lift

to stop at the next level, open the doors then render itself out of service. If the fault

is detected whilst the doors are open then the brakes will be deployed, because

this is the worst-case scenario and the system or safety gear must be fail safe.

The Controller (UMD-SRB02)

The controller will be enclosed in a Polycarbonate/ABS. IP40 rated enclosure

suitable for the lift control room. It is approximately 290mm long x 260mm tall x

120mm deep.

With the exception of replacing the battery every 3 years it does not require any

maintenance, other than periodical testing and inspection in accordance with your

site risk assessment and the lift regulations.

It contains a programmable safety device, visual display screen, battery power

supply and fuses.

With a simple modification to the door wiring connections now also complies with

the latest EN81-20:2020.

9UMD-SRB02 Version 1

Indication of the system status will be provided by messages displayed in the

controller window

In addition to this a small visual display shows a text interface explaining the status

and warnings.

Signals

Controller input power supply will be 230V or 110V AC 50/60Hz, it has an internal

12v DC control voltage, power supply and battery backup.

The system requires the following signals and connections to the external contacts

to enable it to operate.

1. A car Door Open / Closed Input signal.

2. A landing Door Open / Closed Input signal.

These inputs should be a connected to a Dry / volt free, normally open, pair of relay

contacts wired parallel. It only requires a maximum switching current of 0.25A 12V

DC.

3. An over speed OK signal, normally closed when no over speed, opens when

lift is over speeding.

Please note if the lift loses mains power the above door signals will open, therefore

the third signal we need must be connected directly to the over speed governor

switch, as if this signal opens the brakes will be immediately deployed.

Output signals from the controller will be volt free relay contacts. The contacts are

rated for up to 2 Amp Max at 250VAC. These are:-

4. Main Lift Safety Circuit Output Signal.

5. Main Lift Alert Output Signal

If replacing the safety circuit fuse it must be a slow blow 2 Amp fuse (Part No. little

fuse 0215002 MXEP)

10 Atwell International Limited

The components of this system have been carefully packaged for shipping,

including strapping and strong tape. If you use a knife to cut open the boxes,

please be very careful to ensure that you only cut through the tape and straps and

not through the cardboard potentially damaging the components inside.

Please inspect the components of this system thoroughly prior to attempting to

install it. If the brakes, cables, controller or sensor has been or suspected to have

been damaged or exposed to moisture, they should not be used. Please return

them to Atwell International for examination and re-test.

The brakes, control boxes or sensors should never be lifted or carried by their

cables. They should never be allowed to get wet or exposed to moisture.

WARNING: the lid should never be hung by the ribbon cable!!

Handling, Transport &

Storage

Please check that the following parts have been supplied and received in good

order prior to attempting to install the system.

• Movement Detector (UMD-SP01).

• Movement Detector Bracket and fasteners.

• Control box (VG UMD-SRB02).

• Spare fuses. (2 types 2 of each).

• Green Mating Plugs.

• Manual & Documentation pack.

• 3 Prewired cables for simplified installation.

• 1 x Power lead.

Components Supplied

11UMD-SRB02 Version 1

General Advice

The area for which this unit is intended should comply with the lift room regulations

so that its installation, operation and maintenance is carried out in a risk free

environment.

Specific hazards arise for inadequate lighting, untidy work area, trip hazards and

poor access.

The Control Box (UMD-SRB02)

It is recommended that the Control box is ideally mounted at approximately 1.5

metres high on to a solid wall adjacent to the main lift control panel and close to

the rope brake and monitoring pulley position. Consideration should be given to

access for operation and maintenance of the control box as well as ease of cable

runs.

Installation

12 Atwell International Limited

Once the control box is in place, cable runs can commence. See Drg. page 16

CONNECTION OVERVIEW DIAGRAM for help to plan the cable runs.

There are Plug and Socket connectors supplied, cable support precautions should

be used to to prevent strain and damage to the individual cores.

We would strongly suggest that the power is fed from the main lift panel protected

by a circuit breaker Type D rated at 3 Amps. This must be a permanent supply and

not routinely isolated or disconnected as the battery back up in the UMD will be

operated beyond its intended use. The back up is designed for very infrequent

and intermittent use. The brakes are designed to be permanently energised and

only deployed in the event of an emergency or routine monthly inspection. Any

installed cables and connections must also comply with local regulations.

The battery backup will maintain the brakes whilst the lift is stopping, and for a

short period of 10 - 20 minutes. After this time the brakes will be deployed and the

system will require a full reset once mains power has been restored.

The external plug connections are fitted so as to prevent the need for access

inside of the control box.

During wiring great care must be taken to ensure that there is no risk of short

circuits from stray strands, cross connection, loose terminals or strain on cable

joins. All terminations should be made using boot lace ferrules or similar and each

wire appropriately identified with its corresponding wire number at each end of

the cable. Wiring of power and internal main lift connections must be carried out

by a competent electrician, and checked prior to applying power.

Wiring

230V

Danger

Isolate main

Isolate main

supply

supply

before opening

before opening

13UMD-SRB02 Version 1

Wiring (continued)

Note: Fuses are all now fitted at the factory prior to dispatch. The control box is

shipped with one battery lead disconnected. This needs to be connected before

the system is put into service.

Fitting of fuses & battery connection

SAFETY NOTE: Once connected to the main lift control panel there will be

potentially live connections within the VG UMD-SRB02 enclosure and the terminal

housing even when the fuses for the enclosure have been withdrawn.

14 Atwell International Limited

Make sure power is disconnected prior to attempting to check or replace fuses. As

there are live terminals connected through to the end of the fuse so if you touch

the fuse it could be Live!

Please check rating against labels of each fuse.

F1 = Internal Power Supply 500mA if 240v supply 800maA for 110v Supply

F2 = Control voltage 2.0Amps (12V DC)

The Fuses we use are Manufactured by SIBA and they are:

5mm diameter x 20mm long glass fuses

Connections to the Main Lift Control Panel must be carried out carefully to ensure

that the correct function of the signals is produced.

The control box input signals are 12V DC 100 mA they require a dry / volt free relay

contact normally open and energised when the Car and Landing doors are closed.

In addition, a connection directly to the normally closed (when not in over speed

condition) over speed governor switch is required.

The operation of these switches is essential to enable the VG UMD-SRB02 to

operate safely, i.e. If a cable is broken or the lift over speeds the UMD-SRB02 will

be FAIL SAFE. i.e. any problems, the rope brakes or safety gear will be deployed.

The connection from the Main Lift Panel such as Alert signal and emergency

stop must be 230 Volts maximum and must not exceed 2 amps. The control box

provides dry / volt free relay contacts for your signals.

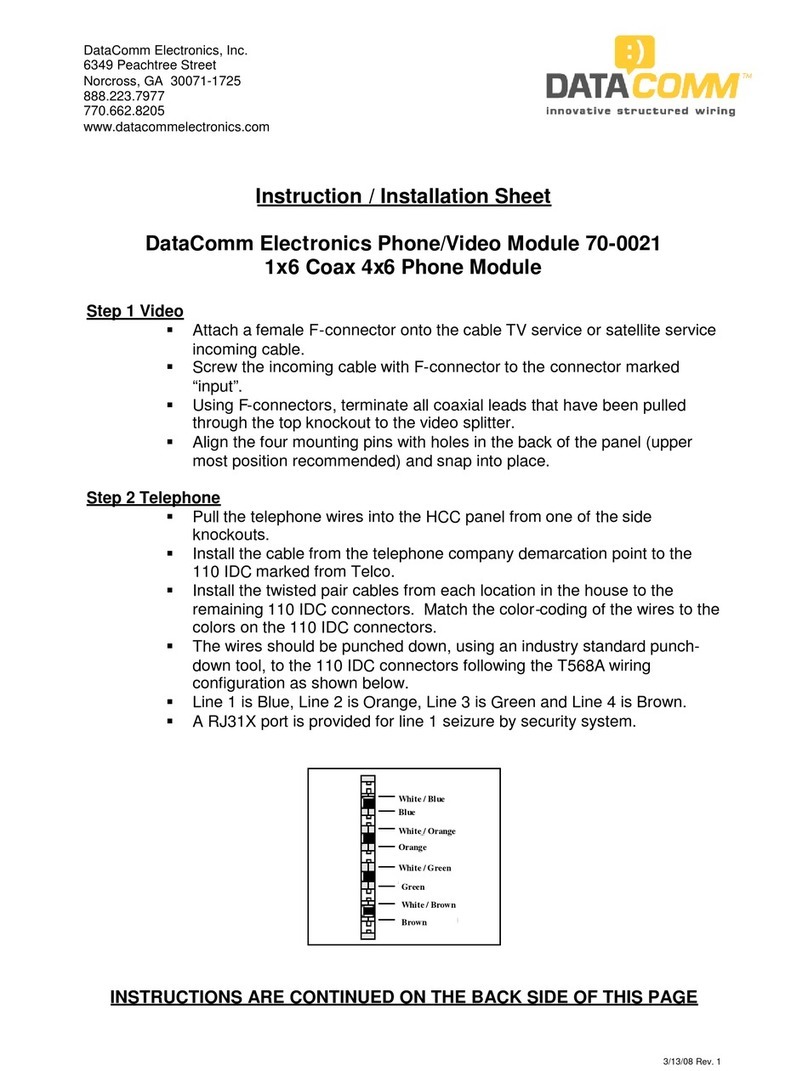

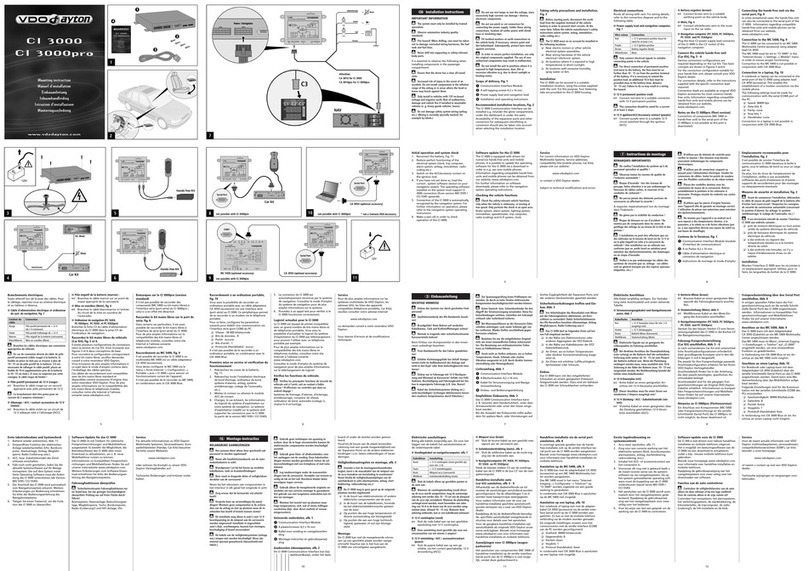

On page 16 / 17 there is a list of all the electrical connections to the multipole plug

and their functions.

Wiring (continued)

15UMD-SRB02 Version 1

DO NOT TAMPER WITH THE CONTROL BOX

If it does not allow the brakes to reset then

there is still a problem with the lift!

Rectify the problem and the controller will allow a reset.

SAFETY NOTE:

Do not leave the lift to run in “engineer mode”, this is purely a function to allow you

to carry out maintenance on the lift without triggering uncontrolled movement.

You will have circumvented the part of the safety circuit.

Wiring (continued)

16 Atwell International Limited

Wiring (continued)

L

N

Connection is vai the supplied plug in IEC Lead, reccomendations is to use a local switched fused spur.

PE

COM Used By Atwell for external reset

N/0 Used By Atwell For future upgraded models - No connection required

+V Used By Atwell for external load monitoring

S1 For future upgraded models - No connection required

S2 For future upgraded models - No connection required

RED

BLACK

BLUE

GREEN

BROWN

YELLOW

WHITE

V OUT

Motor Connection, The UMD needs a Volt Free / Dry contact

V IN

that opens when the motor is off, the contact should close when the motor is running.

V OUT

Landing & Car Door Contact, The UMD needs a Volt Free / Dry contact

V IN

that opens when the car door is open, the contact should close when the doors are closed.

ES1

External Emergency Stop, The UMD needs a Volt Free / Dry contact

ES2

that opens when the brakes needs to be deployed the contact should be linked across if not required

EXT1

External Overspeed Govenor, The UMD needs a Volt Free / Dry contact

EXT2

that opens when the brakes needs to be deployed the contact should be linked across if not required

RED

BLUE

YELLOW

GREEN

RED

BLUE

YELLOW

GREEN

COM

Main Lift Safety Circuit, It should be wired in series with all other limit switches

N/0 The UMD provides a Volt Free / Dry contact, it will open when the brakes are deployed or lift is at electrical tripping speed.

COM

Alert /Warning signal, a request to stop the lift at the next floor and take the lift out of service as a fault has been detected.

N/0 The UMD provides a Volt Free / Dry contact, it will open when there is a fault detected and closes whel all is OK.

Main Fuse

500mA

ALERT

SC

BRAKE B

BRAKE A

EXT

ESTOP

DOOR

MOTOR

ENCODER

LOAD

CELLS

RELAY

Circuit Breaker / Fuse Lift Panel Isolator Switch

SENSOR PACK

Fitted to ROPE BRAKE

or IDLER PULLEY

or OVER SPEED GOVENOR

Connect cable braid to the Black wire or any Ground connection

Cable

Cable

Rope Brake A

Connect cable braid to the Green wire or any Ground connection

Cable

Rope Brake B

Connect cable braid to the Green wire or any Ground connection

17UMD-SRB02 Version 1

L

N Connection is vai the supplied plug in IEC Lead, reccomendations is to use a local switched fused spur.

PE

COM Used By Atwell for external reset

N/0 Used By Atwell For future upgraded models - No connection required

+V Used By Atwell for external load monitoring

S1 For future upgraded models - No connection required

S2 For future upgraded models - No connection required

RED

BLACK

BLUE

GREEN

BROWN

YELLOW

WHITE

V OUT Motor Connection, The UMD needs a Volt Free / Dry contact

V IN that opens when the motor is off, the contact should close when the motor is running.

V OUT Landing & Car Door Contact, The UMD needs a Volt Free / Dry contact

V IN that opens when the car door is open, the contact should close when the doors are closed.

ES1 External Emergency Stop, The UMD needs a Volt Free / Dry contact

ES2 that opens when the brakes needs to be deployed the contact should be linked across if not required

EXT1 External Overspeed Govenor, The UMD needs a Volt Free / Dry contact

EXT2 that opens when the brakes needs to be deployed the contact should be linked across if not required

RED

BLUE

YELLOW

GREEN

RED

BLUE

YELLOW

GREEN

COM Main Lift Safety Circuit, It should be wired in series with all other limit switches

N/0 The UMD provides a Volt Free / Dry contact, it will open when the brakes are deployed or lift is at electrical tripping speed.

COM Alert /Warning signal, a request to stop the lift at the next floor and take the lift out of service as a fault has been detected.

N/0 The UMD provides a Volt Free / Dry contact, it will open when there is a fault detected and closes whel all is OK.

Main Fuse

500mA

ALERT

SC

BRAKE B

BRAKE A

EXT

ESTOP

DOOR

MOTOR

ENCODER

LOAD

CELLS

RELAY

Circuit Breaker / Fuse

Lift Panel Isolator Switch

SENSOR PACK

Fitted to ROPE BRAKE

or IDLER PULLEY

or OVER SPEED GOVENOR

Connect cable braid to the Black wire or any Ground connection

Cable

Cable

Rope Brake A

Connect cable braid to the Green wire or any Ground connection

Cable

Rope Brake B

Connect cable braid to the Green wire or any Ground connection

18 Atwell International Limited

Mechanical Installation For information on mechanically installing the VG rope brakes or VG safety gear

please see the specific documentation for the individual items as supplied.

Please note this device is a precision encoder device and is not capable of

withstanding a drop or severe mechanical shock, so never use a hammer to adjust

it.

It is also sealed, there are no user adjustable or repairable parts inside it, all

warranties will be void and the product will be destroyed if you open it. If you

suspect it is faulty then replace it, return to Atwell International who will inspect

it and will supply a replacement unit if it was found to have failed under warranty.

Securely bolt the brackets supplied to the tapped holes provided in the rope brake

side bars, adjust backward or forward for slight tension against the rope.

It may be necessary to adjust the alignment of the wheel to the rope. This is done

by carefully unscrewing the M4 cap head retaining screw on the wheel, and then

sliding the wheel so the rope is centred on the wheel. Re-tighten the M4 cap

headscrew onto the shaft.

Check for smooth operation and no excessive play or run out.

Connect the other end of this sensor cable to the UMD-SRB02 panel via the

connecting plugs, if you have not done so yet.

Slight pressure only.

Allow further movement

on springs. Do not adjust

it so that the springs are

coil bound.

Connect sensor cable

to the sensor box.

M4 Screw

19UMD-SRB02 Version 1

Resetting the System

To “SET” the system for the very first time is the same procedure as each time you

need to “RESET” the system, and that is as follows.

• Check that all faults are cleared and that there is no reason why the lift cannot

be put back into service. i.e. reason for brakes to be deployed has been rectified.

(If there are faults rectify them first.)

• 1. Check the visual display on the UMD-SRB02 control panel for the reason of

engagement.

• 2. Carry out a visual inspection of the VG Rope Brake/s Checking which brake

has fully engaged.

• 3. Investigate the reason for the engagement and carry out the appropriate

action.

• 4. Read Local Hand Winding Instructions.

• 5. To reset the brake(s) Press the GREEN reset button.

• 6. Select Confirm to enter Reset Mode (relay should sound).

• 7. Perform a manual reset on the Brake/s and press the GREEN reset button on

the panel. The Screen will then return home. Download the VG Robe Brake Manual

for guidance.

• 8. On the deployed but not fully engaged rope brake, using the Rope Brake

handle to re-engage the drop jaw with the electro-magnet. Check the Rope Brake

set is lit on the control panel.

• 9. Hand wind the machine in the opposite direction of the engagement for

approximately 25mm. This will free the drop jaw from the ropes.

• 10. On the deployed and engaged rope brake, using the Rope Brake handle re-

engage the drop jaw with the electromagnet. Check the Rope Brake set is also lit

on the control panel.

• 11. Continue to follow the local hand-winding instructions for the geared

machine.

• NOTE: If there is no power and the battery backup has failed after 30minutes

release the drop jaw and insert the plastic mechanical stops at the back of the

drop jaw to prevent the jaw from re-engaging.

Normal Operation

20 Atwell International Limited

TO RE-INSTALL LIFT SERVICE FOLLOWING HAND WINDING

1. Ensure both rope brakes are reset and the corresponding green lights are lit on

the control panel.

2. Ensure the reason for the engagement has been fully investigated and resolved.

3. Check the lift is operating correctly.

WARNING - If the safety devices controlled by this controller are bypassed

it will revert to normal running in one hour.

4. The rope brakes will require lifting into position, and then they will hold there.

5. The System is now SET.

IF THE ROPE BRAKES ARE NOT RESETTING

• Check wiring and connections.

• Check the wiring of the switch and magnet.

• Check the connection of the 8 pin plug.

• Check for overspeed circuit fault.

Normal Operation

(continued)

Bypassing the System (Engineer Maintenance Control)

To “BYPASS” the system you will disable the movement detection function, but if

the lift over speeds or free falls then the brakes or safety gear will still be deployed.

This function is purely for testing and maintaining the lift. If you are sure you need

to bypass the movement detection then this is how it should be done.

• Select Menu.

• Mode Select.

• Select By-Pass.

• Select confirm.

• The controller will then remain in By-Pass for 1 hour only and then return

to normal running.

To get back to normal running mode.

• Select Menu.

• Mode Select.

• Run.

Table of contents

Popular Control Unit manuals by other brands

DataComm Electronics

DataComm Electronics 70-0021 Instruction/installation sheet

IFM Electronic

IFM Electronic Ecomat100 CR1083 PDM360 NG installation instructions

VDO

VDO CI 3000 - COMPATIBILITY LIST Mounting instruction

Avalue Technology

Avalue Technology ESM-EHLC user manual

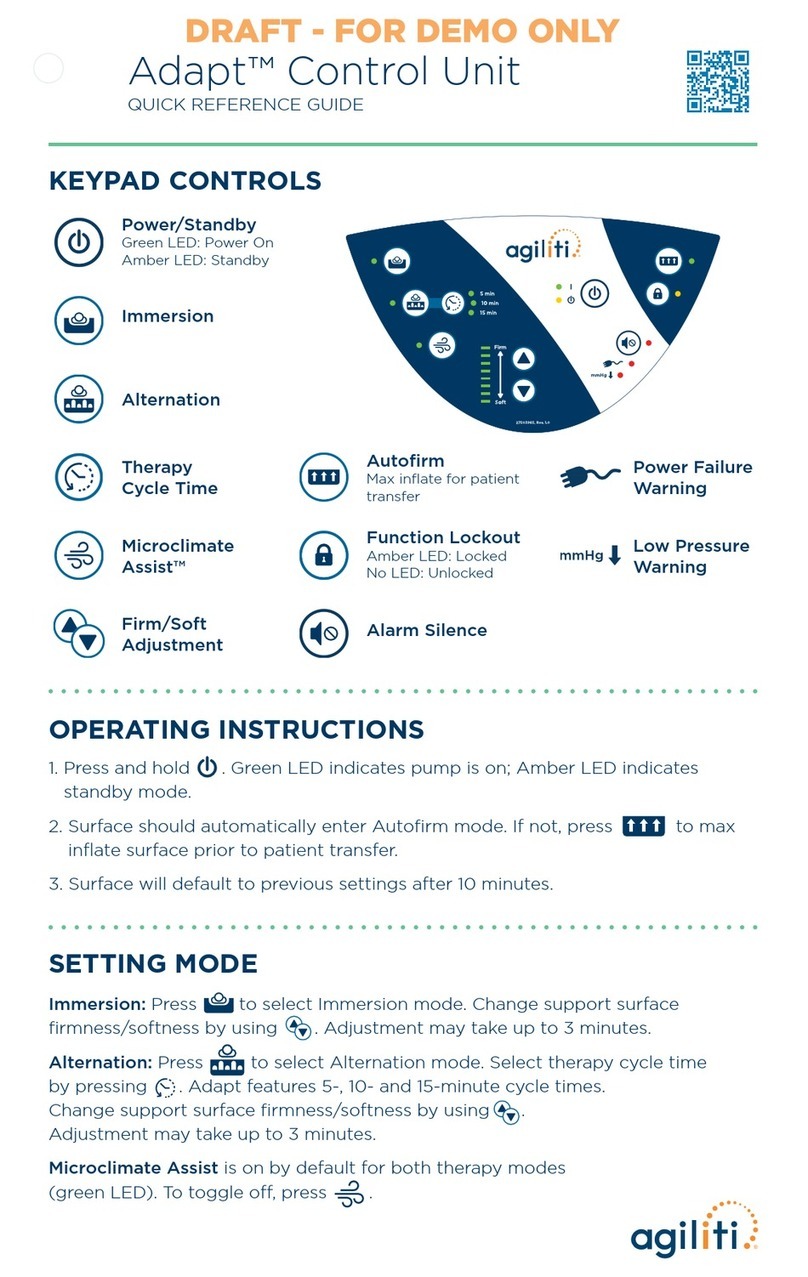

agiliti

agiliti Adapt Quick reference guide

Valcom

Valcom V-2003A-E user guide

Bosch

Bosch Rexroth ctrlX CORE manual

Bürkert

Bürkert Type 2000 operating instructions

National Instruments

National Instruments PXIe-4322 installation guide

Iron Age Audioworks

Iron Age Audioworks 500 Series user manual

Phoenix

Phoenix VP1-250-eSSD user manual

Grundfos

Grundfos CIM 150 Functional profile and user manual