AU Tool HTS708 User manual

www.autooltech.com

汽车干冰清洗机

使用手册

AUTOOL HTS708

Copyright Information

All rights reserved by AUTOOL TECH. CO., LTD. No part of this publication may

be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without

the prior written permission of AUTOOL. The information contained herein is

designed only for the use of this unit. AUTOOL is not responsible for any use of

this information as applied to other units.

Neither AUTOOL nor its affiliates shall be liable to the purchaser of this unit or

third parties for damages, losses, costs, or expenses incurred by purchaser or

third parties as a result of: accident, misuse, or abuse of this unit, or

unauthorized modifications, repairs, or alterations to this unit, or failure to strictly

comply with AUTOOL operating and maintenance instructions.

AUTOOL shall not be liable for any damages or problems arising from the use of

anyoptions or any consumable products other than those designated as

OriginalAUTOOL Products or AUTOOL Approved Products by AUTOOL.

Other product names used herein are for identification purposes only and may

betrademarks of their respective owners. AUTOOL disclaims any and all rights

in those marks.

Manual are either trademarks, registered trademarks, service marks, domain

names, logos, company names of or are otherwise the property of AUTOOL or

its affiliates. Incountries where any of the AUTOOL trademarks, service marks,

domain names, logos and company names are not registered, AUTOOL claims

other rights associated with unregistered trademarks, service marks, domain

names, logos, and company names. Other products or company names referred

to in this manual maybe trademarks of their respective owners. You may not use

any trademark, service mark, domain name, logo, or company name of

AUTOOL or any third party without permission from the owner of the applicable

trademark, service mark, domain name, logo, or company name. You may

contact AUTOOL by visiting AUTOOL at https://www.autooltech.com, or writing

this manual for purposes or for all other questions relating to this manual.

Precautions

1. Before using the instrument, please read this manual carefully for proper

operation.

2. It is strictly forbidden to touch the dry ice and ice blasting pipe.

3. It must be kept clean when adding dry ice, and no other foreign objects fall

into the equipment.

4. This equipment uses solid CO2 particles, and ventilation must be ensured

when operating dry ice cleaning.

5. Before carrying out the work, it is necessary to wear protective goggles, ear

muffs, work clothes and gloves.

6. Before each work, set the ice supply speed to "0" and test if condensate is

sprayed out of the nozzle.

7. Whenever the operation is not finished and you need to pause in the middle,

please first set the ice speed to "0" and then turn on the blasting gun for 30-50s

to ensure that the leftover ice is blasted out of the ice outlet tube to prevent ice

blockage.

8. In order to ensure sufficient pressure and flow of compressed air from the air

source, please choose the supply pipe of the air source larger than DN20 outside

diameter and the pressure of the air source larger than 6 bar, so as to have a

better cleaning effect.

9. To prevent electric shock, do not touch the working equipment in wet areas or

operate the equipment in the rain.

10. In the middle of ongoing work, if you encounter equipment failure, please

immediately disconnect the power.

Principle Introduction

Dry ice blast cleaning technology is based on the use of ultra-low temperature

dry ice particles, and by compressed airflow, the dry ice particles are hit by the

gas at high speed to be cleaned surface dirt. The sudden drop in temperature of

the dirt on the surface causes the surface to become brittle while causing these

extremely low-temperature dry ice gases to enter inside the cracked

contaminants. When surface dirt is hit, the dry ice particles quickly sublimation to

gas and these cracked contaminants are peeled away from the surface of the

object and removed.

Applicable fields

Dry ice blast cleaners are widely used in fields such as rubber, casting,

automobiles, ships, electric power, chemicals, printing, plastics, food,

pharmaceuticals, and aviation.

Features

Highly effective cleaning equipment can greatly increase productivity

The main function of the dry ice cleaning machine is capable of cleaning various

equipment. With this cleaning technique, on the one hand, it can avoid

production interruptions due to downtime, and on the other hand, disassembly

and damage to the equipment can be reduced, which essentially protects the

equipment and increases productivity.

1. Avoid injury to personnel from hazardous materials

CO2 is a non-toxic substance. By cleaning with dry ice instead of toxic

chemicals, we can prevent harmful substances from adhering to the equipment

for a long time, which can affect the overall operation and cause harm to people.

2. Quickly removes a variety of stubborn dirty deposits.

With the dry ice blast cleaning machine, the adhered dirty deposit can be

thoroughly removed, and also has good protection for the equipment, so as to

avoid affecting the operation and use of the equipment while being cleaned.

Technical parameter

Power supply: AC220V±10% 50Hz

Dry ice capacity: 7.5KG

Compressed air flow: >1~2.03/min

State of dry ice particles: 3mm

Air supply pressure: 0.3~1.0Mpa

Dry ice blasting amount (adjustable): 0~3.2Kg/min

Size: 500mm*450mm*800mm

Net weight: 60KG

Gross weight: 75KG

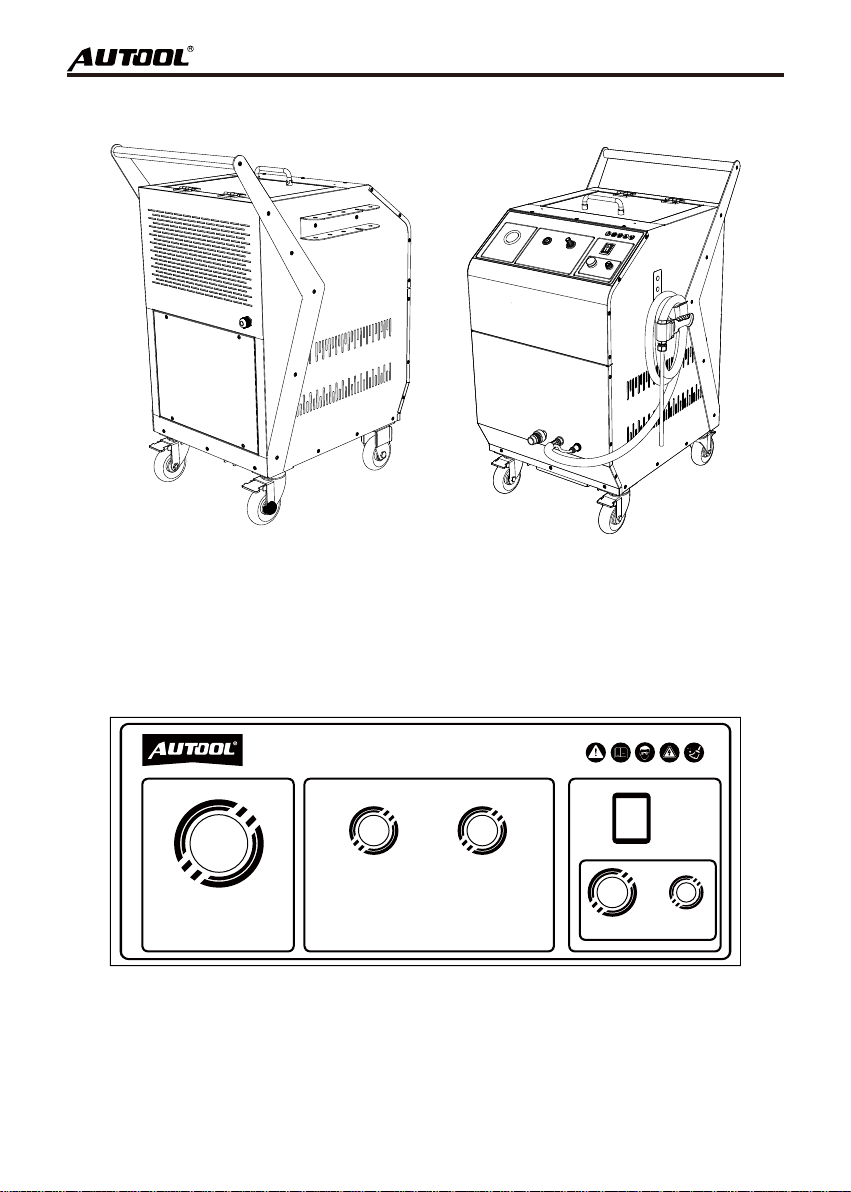

Structure Diagram

1-Power supply;2-Fittings bracket;3-Dry ice tank;4-Control panel;5-Air source

interface; 6-Trolley;7-Dry ice blasting gun;8-Universal wheel

Description of Control panel

1-pressure gauge; 2-start/clean controller; 3-dry ice amount adjustment

controller; 4-power switch; 5-power indicator light; 6-fuse.

1

2

3

4

5

6

7

8

1

2 3

4

6

5

Equipment debugging

1. Connect the air source and power supply. Check whether the data of the air

pressure indicator is displayed normally and the power access is properly.

2. Make preparations for the debugging, including: Completely connect the

machine and the workbench; clean up the debris and dust on the workbench;

check whether the parts are loose, and clean up the objects that are randomly

placed on the machine or workbench.

3. First set to the blowing mode for trial operation from slow to fast debugging,

and then put the dry ice material into the machine for debugging if it is

determined that there is no abnormality.

Adjust the amount of dry ice blasting

1. Add the dry ice into the machine and cover it.

2. According to the degree of cleaning, turn the controller knob to adjust the dry

ice amount to achieve the best effect.

After the cleaning work

1. Turn the controller knob of the dry ice amount to the "0" position and turn on

the blasting gun for 30-50s until no water is blasted out.

2. Turn the knob controller to the cleaning mode, and the equipment will clean

the dry ice residue by itself. Manual cleaning is required if necessary.

3.Disconnect the power switch and air source, and put away the blasting gun

and accessories.

Common failures and troubleshooting methods

Common failures

1.The ice funnel in the dry ice container is blocked

2.The internal of the dry ice tube is blocked.

3.The dry ice tube leaks ice and air.

4.Poor cleaning effect, incomplete cleaning of relatively stubborn carbon

deposits

Troubleshooting methods

1. Stop working, and open the cover to see if the dry ice is overfilled. If it is too

much, take out some of the dry ice and start working again.

2. Check if the vibration pump is working, if not, please contact the manufacturer

for replacement.

3. When dry ice is poured into the funnel, it instantly takes away the air inside the

funnel, thus forming condensate clumps, which need manual assistance to move

up and down a bit.

4. During the working, the residual dry ice inside the dry ice tube and

compressed air will condense into ice because of intermittent use or stopping the

use of the dry ice machine, thus causing the dry ice tube to be blocked with ice.If

it belongs to this kind of operating condition, first adjust the ice output to 0, and

then turn on the gun switch and continue for 3 minutes, and then adjust the ice

output to 20%-30%, and then check the ice effect.

5. Examine the air source to ensure that the compressed air supplied to the dry

ice cleaning machine is free of oil and water.

6. The dry ice pipe has been used overtime, and the dry ice has been rubbing

against the pipe wall for a long time, resulting in thinning inside the pipe, please

contact the manufacturer for replacement.

7. In case the cleaning is not complete, first check whether the air source air

pressure and flow rate are insufficient. The pressure of the air storage tank in the

workshop and the working pressure of the dry ice machine are not less than

6bar, and the ice output is not less than 1.5m3/min. The air supply pipe is too

thin and too long, and the pressure drop of the pipe is too large. In this case, the

main air supply pipe in the workshop is required to be cleaned directly.

Warranty

● Thank you for choosing our products, we will provide you with the following

services and promises.

● The warranty period of this product is 1 year.

● After the warranty period expires, repairs will be charged for replacement

parts.

● After the failure, please contact the manufacturer, we will give you the most

complete service in the

shortest time.

The following items are not covered by the warranty:

● Vulnerable parts are not covered by the warranty, including: glass tube, signal

sire, stickers, connectors pressure gauge, oil outlet pipe.

● When no cleaning agent is added to the ultrasonic tank, turning on the

ultrasonic

cleaning switch will damage the ultrasonic system, which is not covered by the

warranty.

● If the testing agent is not replaced in time after long-term use, the oil pump

filter

screen is blocked and the oil pump is burned out of the warranty.

● The use of fuel injector cleaning agent as fuel injector testing agent will cause

the

fuel pump to burn out, which is not covered by the warranty.

● Man-made faults are not covered by the warranty.

Disclaimer: All information, illustrations, and specifications contained in this

manual, AUTOOL resumes the right of modify this manual and the machine itself

with no prior notice. The physical appearance and color may differ from what is

shown in the manual, please refer to the actual product. Every effort has

been made to make all descriptions in the book accurate, but inevitably there

are still inaccuracies, if in doubt, please contact your dealer or AUTOOL

after-service centre, we are not responsible for any consequences arising from

misunderstandings.

注意事项

● 在使用仪器之前,请仔细阅读本说明书,以便正确操作。

● 严禁触摸干冰及喷冰枪管。

● 倒入干冰时必须要保持干净,无其他异物掉进设备中。

● 本设备所选用的是固态CO2颗粒,操作干冰清洗时必须保证通风。

● 在进行作业前,佩戴好护目镜、耳罩,穿戴好工作服、手套。

● 每次作业前,先将供冰速度设定为“0”,测试看喷嘴中是否有冷凝水喷出。

● 每次作业未结束,中途暂停时,请先将出冰速度调为“0”,然后开启喷枪喷

射30-50s,确保出冰管内残冰喷出,防止堵冰。

● 为保证气源压缩空气压力流量充沛,请选用气源供应管道大于DN20外径,气

源压力大于6bar,这样清洗效果更佳。

● 为了防止受电击,不要在潮湿的部位接触工作的设备或在雨中操作设备。

● 在进行做业中,遇到设备故障,因立即断开电源。

原理简介

干冰清洗技术是利用极低温的干冰颗粒,通过压缩空气的流动,干冰颗粒被气体

高速撞击被清洗的表面污垢,表面污垢突然降温导致表面脆化,同时造成这些温

度极低的干冰气体进入出现裂缝的污染物内,当表面的污垢遭到撞击是,干冰颗

粒迅速升华为气体,这些破裂的污染物从物体的表面被剥离移走。

适用行业领域

干冰清洗机被广泛的应用在橡胶、铸造、汽车、船舶、电力、化工、印刷、塑料

、食品、制药和航空等领域。

功能特点

1.有效清洗设备提高生产率

干冰清洗机的主要功能就是对不同的设备进行清洁,使用这种方式清洁一方面可

以避免停工影响生产,同时还能够减少对设备的拆卸和损坏,在根本上对设备进

行了保护并提高了生产率。

2.避免危险物对人员造成伤害

CO2是一种无毒的物质,用干冰清洗替代有毒化学物质清洗,避免不良物质长期附

着在设备上影响整体的运行以及对人员造成伤害。

3.快速清除各种顽固性污垢

干冰清洗机的使用能够很好的将附着的污垢彻底的清除,同时还能够对设备进行

很好的保护,避免在清洗中影响到设备的运转和使用。

技术参数

● 电源:AC220V±10% 50Hz

● 干冰容量:7.5KG

● 压缩空气流量:>1~2.03/min

● 干冰颗粒状态:3mm

● 供气压力:0.3~1.0Mpa

● 干冰喷射量(可调):0~3.2Kg/min

● 尺寸:500mm*450mm*800mm

● 净重:60KG

● 毛重:75KG

整机结构解析

1-电源;2-喷枪管配件槽;3-干冰槽;4-操作面板;5-气源接口;

6-推手;7-喷冰枪;8-脚轮。

1

2

3

4

5

6

7

8

控制面板说明

1-压力表;2-启动/清洁控制器;3-干冰量调节控制器;4-电源开关;

5-电源指示灯;6-保险丝。

设备调试

● 接好气源、电源。检查气压指示表各数据是否显示正常,电源接入是否正常。

● 做好试机准备工作,包括:将机台完整连接,清理工作台面杂物与灰尘,检查

零件是否有松动,清理乱放在机身上或工作区的物体。

● 先打到吹气模式试运行,由慢速到快速试好后。确定无异常的情况下,再放入

干冰物料试机。

调节干冰喷射量

● 加入干冰,盖好盖板。

● 根据清洗程度,旋钮干冰量调节控制器,达到最佳效果为宜。

结束作业

● 将干冰量调节控制器旋钮至“0”,开启喷枪喷射30-50s,直到没有水分喷出。

● 旋钮控制器至清洁模式,设备自行清洁干冰残留物,必要时需手动清洁。

● 断开电源开关以及气源,收纳好喷枪及配件。

常见问题及分析处理方法

常见故障

● 干冰箱内盛冰漏斗不下冰

● 干冰管出气不出冰(内部堵冰)

● 干冰管漏冰、漏气

● 清洗效果不佳,积碳等较顽固污渍清洗不彻底

1

2 3 4

5

6

分析及处理方法

● 停止作业,打开盖板,看是否是干冰装填过多,如果过多就将干冰取出一部分

出来,而后作业。

● 查看震动泵是否工作,如不工作,联系厂商更换。

● 干冰在漏斗填入时,瞬间带走漏斗内部的空气行程冷凝水结块,认为主动的在

漏斗正中心拿钢条 手动辅助上下活动一下。

● 干冰管堵冰是由于间歇性使用间歇性停机,而后立即停机,导致出冰管管内残

留干冰与压缩空气 导致结冰,如确实是这种作业工况1.先将出冰量调节为0, 然后

开启喷枪开关持续开机持续3 分钟,然后将出冰量调节为20%-30% ,而后在看出冰

效果。

● 排查气源,确保供入干冰清洗机的压缩空气无油、无水。

● 干冰管使用时间过长,干冰长时间与管壁摩擦,内部变薄导致,联系厂商进行

更换。

● 清洗不彻底,先排查气源空气压力、流量是否不足,工作室,干冰机工作压力

不低于6bar,量不低于1.5m3/min2.供气管太细、太长,管道压降太大,这种情况

就考虑清洗机直接作业车间主气源管道,进行作业。

售后保修

AUTOOL 整机自客户签收日起享有3年保修期,附件1年保修期。

保修方式:

1. 根据具体的故障情况对设备进行修理或更换;

2. 我方保证所有更换的部件、附件或设备都是全新;

3.在客户收到产品90天内出现故障同时提供视频和图片,我方承担运费并免费提供

相应配件给客户更换。收到产品超过90天,客户承担相应的费用,我方免费提供

配件给客户更换。

以下情况不再免费保修范围:

1.非正规渠道购买AUTOOL的产品;

2.未按产品说明书要求使用和维护造成的损坏。

声明:偶然公司保留更改产品设计与规格的权利,届时恕不另行通知。实物外观

与颜色可能与说明书中显示的有差别,请以实物为准。我们已尽最大努力力求使

书中所有描述准确,但仍难免有不妥之处,如有疑问,请联系经销商或偶然售后

服务中心,本公司不承担任何因误解而产生的后果。

深圳市偶然科技有限公司

广东省深圳市宝安区北八路航城锦驰产业园

Shenhua Innovation Park, Baoan, Shenzhen, China

www.autooltech.com

+86-400 032 0988 / +86-755-27807580

Table of contents

Other AU Tool Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Lechler

Lechler IntenseClean Hygienic 5TA Series Maintenance instructions

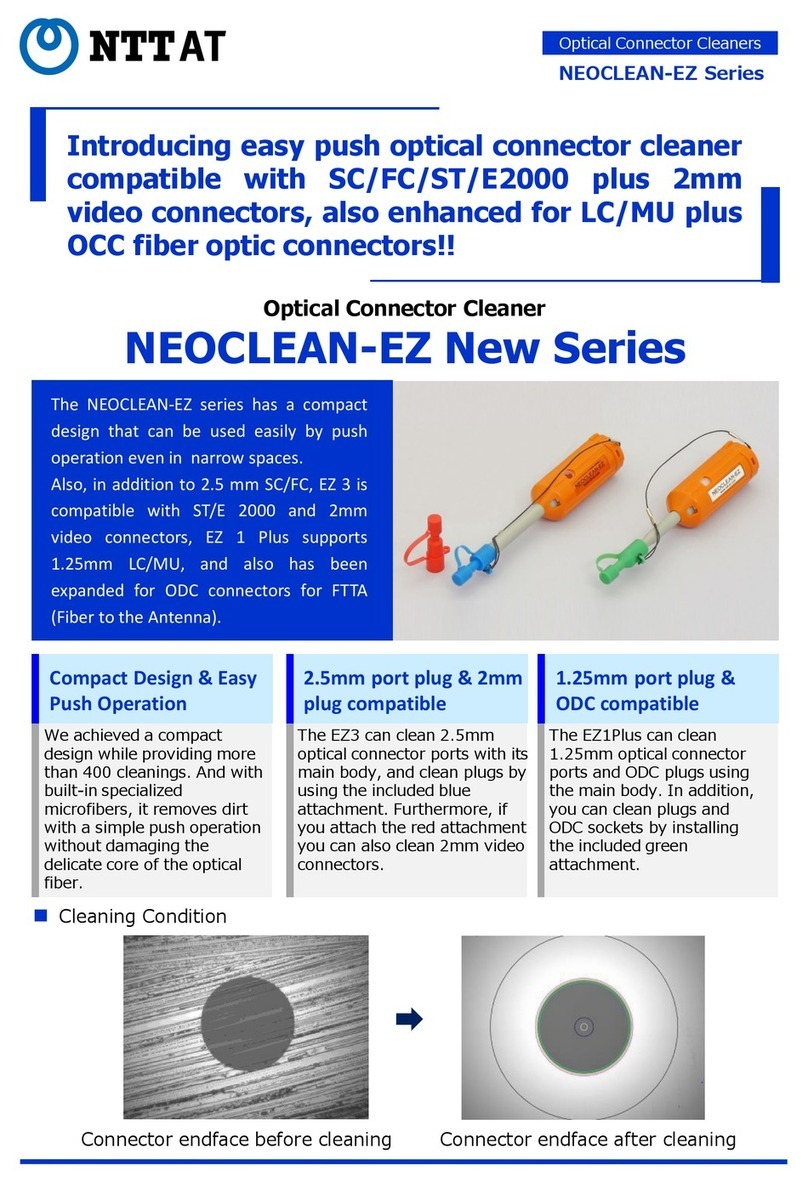

ntt

ntt NEOCLEAN-EZ New Series quick start guide

General Pipe Cleaners

General Pipe Cleaners TheMetro operating instructions

Westfalia

Westfalia 96 07 38 Original instructions

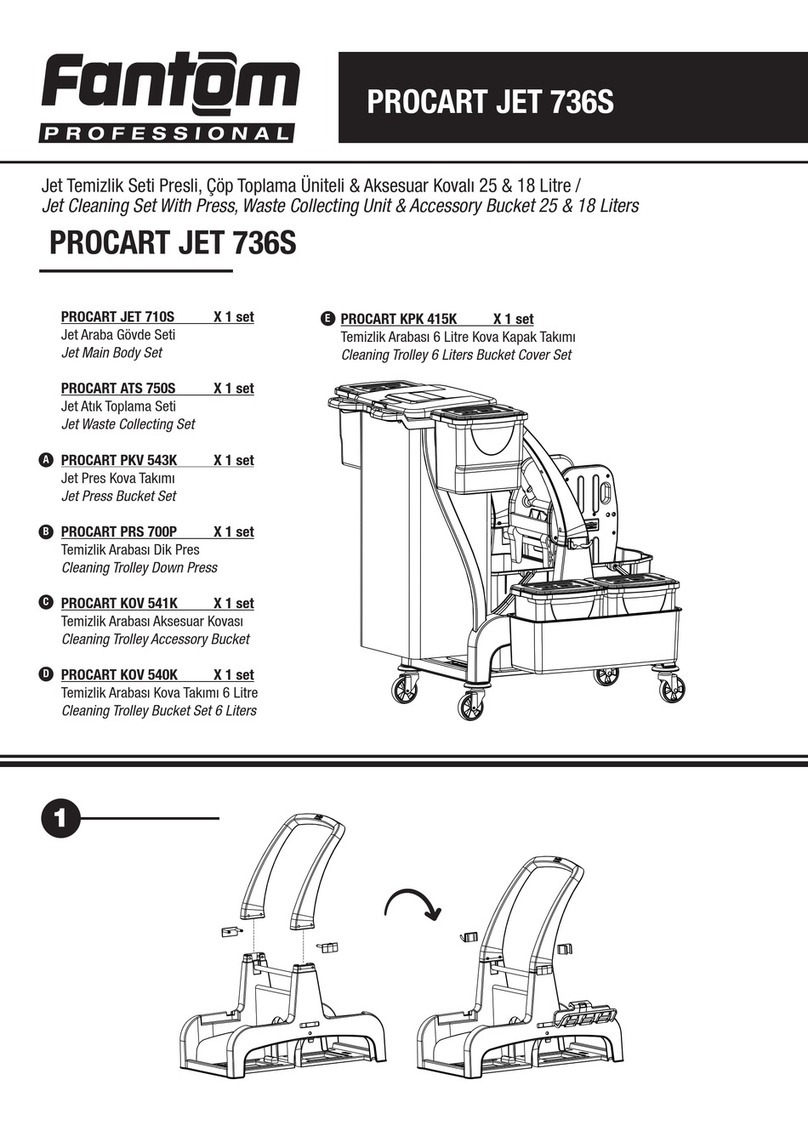

Fantom Professional

Fantom Professional PROCART JET 736S quick start guide

Berkshire

Berkshire Cleanroom Mop Cart with Buckets Installation instruction